Electrical machine having a cooling device, and method for producing said electrical machine

A cooling device and cooling medium technology, applied in cooling/ventilation devices, electromechanical devices, manufacturing stator/rotor bodies, etc., can solve the problems of increased heat transfer resistance, cooling jacket manufacturing and assembly costs, etc. Improved cooling efficiency, the effect of simple design solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

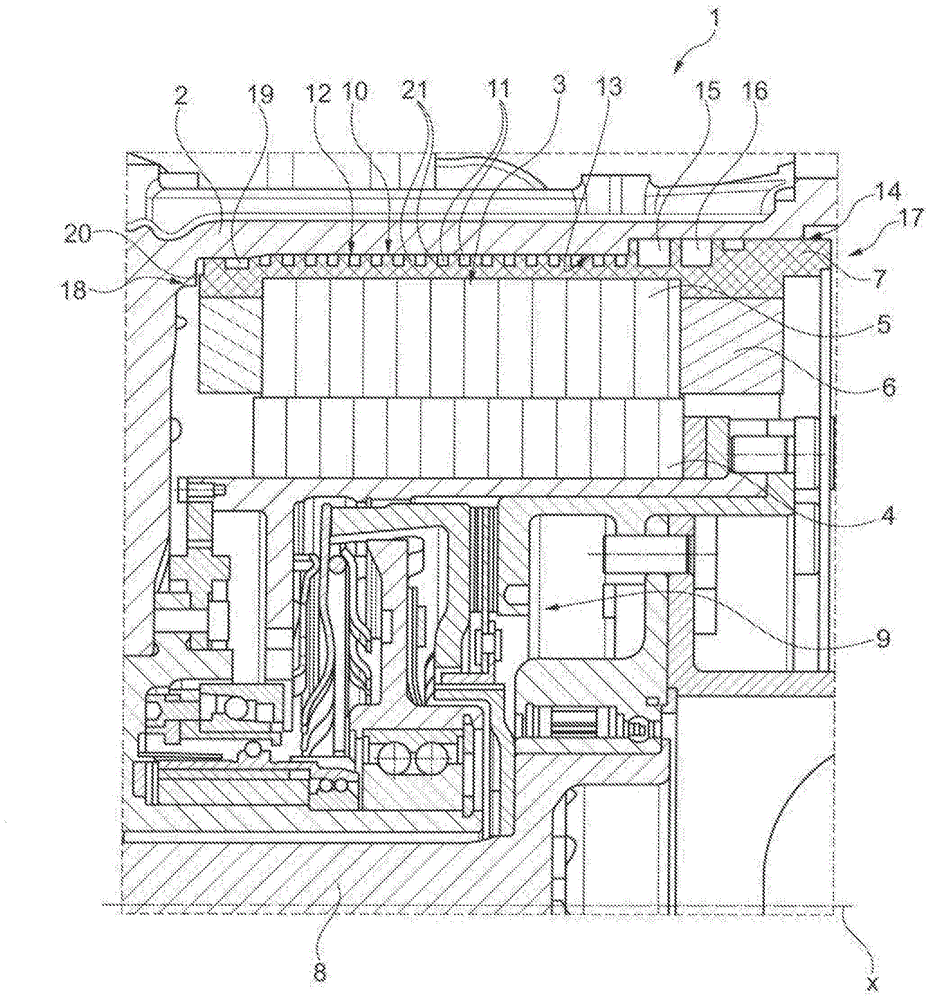

[0028] The single FIGURE shows, in partial section, an electric machine 1 with a housing 2 , a stator 3 fixedly accommodated therein, and a rotor 4 rotatable about an axis of rotation x. The stator is formed from a soft magnetic core 5 and a winding accommodated therein, which winding has winding ends 6 . The plastic body 7 seals the stator 3 in the direction of the housing 2 . A friction clutch 9 is arranged between the drive shaft 8 and the rotor 4 , which is arranged radially and axially inside the rotor 4 .

[0029] A cooling device 10 is arranged between the housing 2 and the stator 3 . It is formed by cooling channels 12 introduced as recesses 11 into the plastic body. A cooling medium, which dissipates the heat loss heat of the stator, is conducted into the cooling channel. The recess 11 is arranged helically on the outer periphery of the plastic body 7 along the axis of rotation x and covers substantially the entire axial width of the stator 3 . In order to produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com