Silicon-oxygen composite negative electrode material and manufacturing method thereof

A negative electrode material, silicon oxide technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problem of low first effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described below with reference to the accompanying drawings in the embodiments of the present invention.

[0027] The embodiments of the present invention mainly relate to a new silicon-oxygen composite negative electrode material, which is used to make negative electrodes of lithium batteries. The lithium battery is mainly used in terminal consumer products, such as various mobile phones, tablet computers, notebook computers and other wearable or mobile electronic devices.

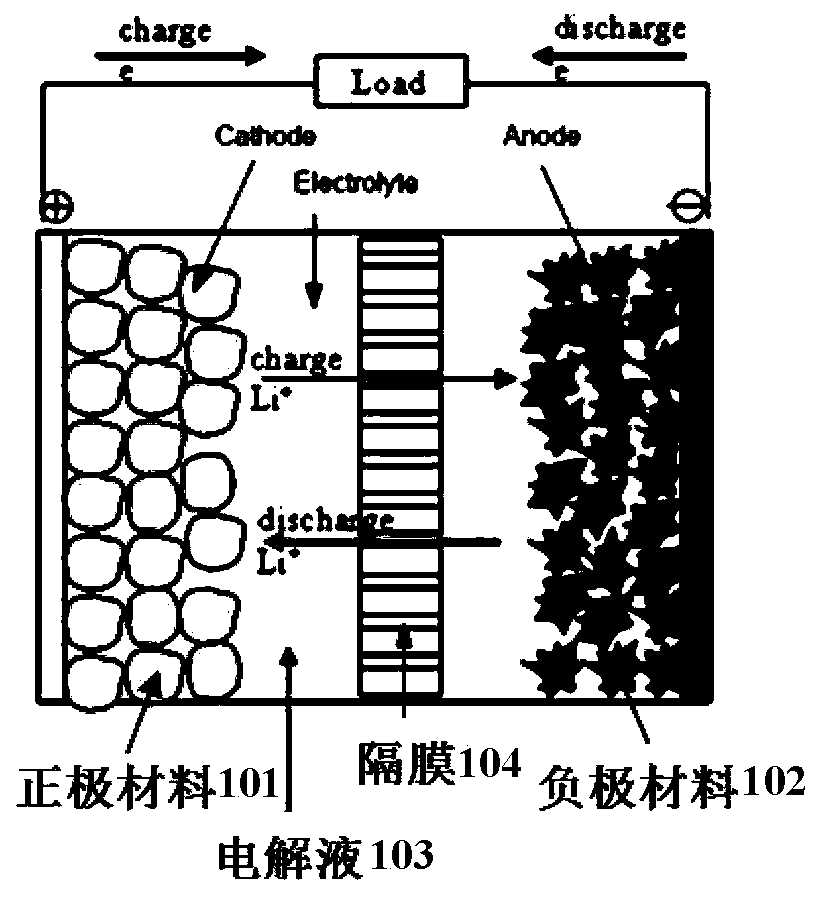

[0028] like figure 1 As shown, the core components of the lithium battery include a positive electrode material 101, a negative electrode material 102, an electrolyte 103, a separator 104, and corresponding communication accessories and circuits. The positive and negative electrode materials can deintercalate lithium ions to realize energy storage and release, the electrolyte is the carrier for lithium ions to be transported between the positive and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com