Preparation method of silicon-graphene compound conductive paste

A graphene composite, conductive paste technology, applied in the field of electrodes, can solve the problems of large volume expansion and contraction, deterioration of electrode cycle performance, active material shedding, etc., and achieve the effects of improving electronic conductivity, high production efficiency, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

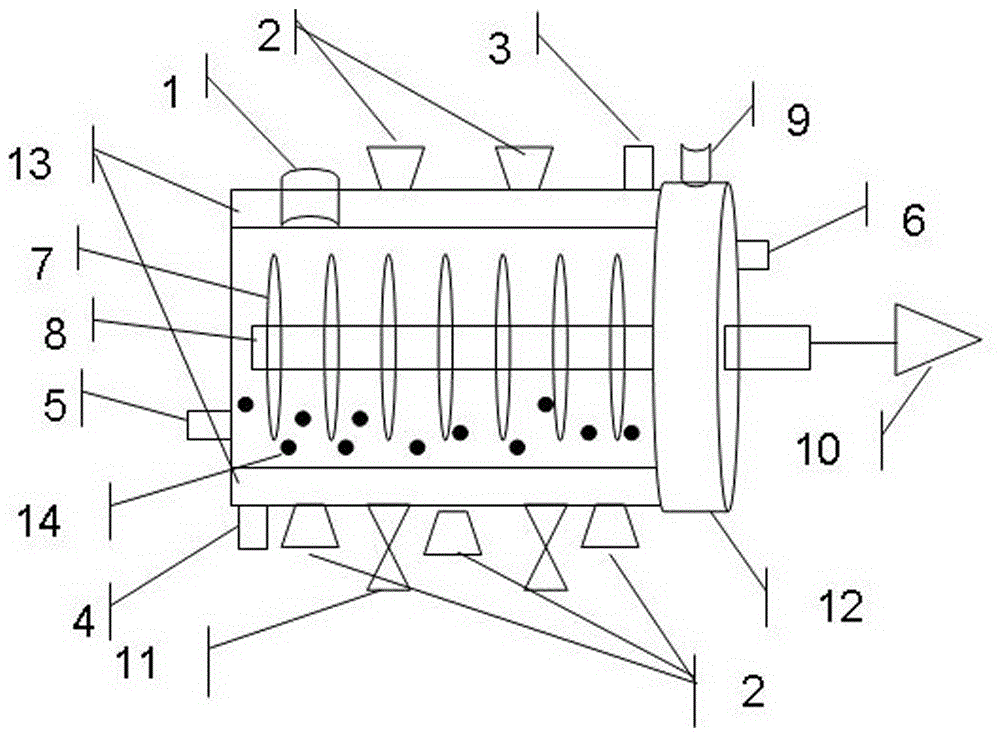

Image

Examples

Embodiment 1

[0022] A preparation method of silicon-graphene composite conductive paste, comprising the following steps,

[0023] 1) Pretreatment of graphite:

[0024] Put graphite in a mixed solution composed of oxidant and intercalation agent, and ultrasonically stir at 60°C for 0.5h. The obtained product is washed, filtered, and dried, and then placed in a muffle furnace. Treat at high temperature for 0.1 h to obtain the expanded graphite product, which is dissolved in water or an organic solvent, the organic solvent being N-methylpyrrolidone (NMP); ultrasonication for 2 h to obtain a graphene dispersion for use.

[0025] 2) Preparation of silicon-graphene composite conductive paste:

[0026] Put micron-sized high-purity silicon powder (99.99%) and grinding balls in the grinding tank at a mass ratio of 1:1; use a vacuum pump to evacuate the system and then introduce a protective atmosphere (argon or nitrogen), and repeat the operation Three times; turn on the motor to start stirring t...

Embodiment 2

[0028] A preparation method of silicon-graphene composite conductive paste, comprising the following steps,

[0029] 1) Pretreatment of graphite:

[0030] Graphite is placed in a mixed solution composed of oxidant and intercalation agent, and treated with ultrasonic stirring at 20°C for 5h. The obtained product is washed, filtered, and dried, then placed in a muffle furnace, and heated in a nitrogen atmosphere at a high temperature of 600°C. Under treatment for 6 hours, the obtained expanded graphite product is dissolved in water or an organic solvent, the organic solvent being ethylene glycol (EG); ultrasonication for 0.5 hours to obtain a graphene dispersion for use.

[0031] 2) Preparation of silicon-graphene composite conductive paste:

[0032] Put micron-sized high-purity silicon powder (99.99%) and grinding balls in the grinding tank at a mass ratio of 50:1; vacuumize the system with a vacuum pump and then introduce a protective atmosphere (argon or nitrogen), and repea...

Embodiment 3

[0034] A preparation method of silicon-graphene composite conductive paste, comprising the following steps,

[0035] 1) Pretreatment of graphite:

[0036] Graphite is placed in a mixed solution composed of oxidant and intercalation agent, and treated with ultrasonic stirring at 30°C for 3h. The obtained product is washed, filtered, and dried, and then placed in a muffle furnace. Under treatment for 3 hours, the obtained expanded graphite product is dissolved in water or an organic solvent, the organic solvent is a mixture of n-butanol and terpineol at a volume ratio of 1:2; ultrasonication for 1.5 hours to obtain a graphene dispersion for use.

[0037] 2) Preparation of silicon-graphene composite conductive paste:

[0038] Put micron-sized high-purity silicon powder (99.99%) and grinding balls in the grinding tank at a mass ratio of 20:1; vacuumize the system with a vacuum pump and then introduce a protective atmosphere (argon or nitrogen), and repeat the operation Three tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com