Carbon-containing sulfide solid electrolyte for solid-state lithium battery and preparation method of carbon-containing sulfide solid electrolyte

A technology of solid electrolytes and sulfides, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve problems such as disappearance, achieve the effects of improving electronic conductance, reducing interface resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

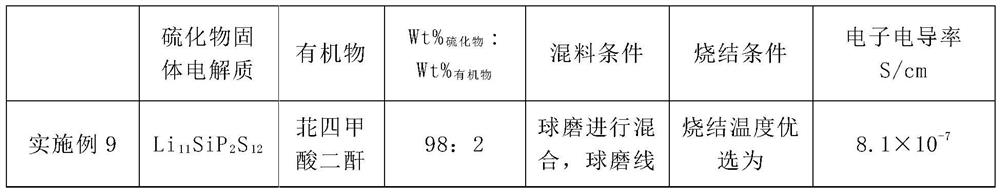

[0024] A method for preparing a carbon-containing sulfide solid electrolyte for a solid-state lithium battery, comprising the following steps: first, fully mixing the sulfide solid electrolyte and organic matter according to the mass ratio to obtain a mixture, and the mass ratio of the organic matter is 0.01%-20%. Among them, the sulfide solid electrolyte includes Li 7 P 2 S 8 I. Li 10 GeP 2 S 12 , Li 3.25 Ge 0.25 P 0.75 S 4 , Li 7 GePS 8 , Li 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 , Li 5.4 P.S. 4.4 Cl 1.6 , Li 6 P.S. 5 Cl, Li 2 S·P 2 S 5 · LiCl, Li 6 P.S. 5 Br, Li 2 S·P 2 S 5 ·LiBr、Li 6 P.S. 5 I. Li 2 S·P 2 S 5 · LiI, Li 4 SnS 4 , Li 2 SnS 3 , Li 3 P.S. 4 , Li 7 P 3 S 11 , Li 2 S GeS 2 , Li 2 S·P 2 S 5 , Li 2 S·As 2 S 5 ·SnS 2 , Li 4 P.S. 4 I. Li 7 P 2.9 S 10.85 Mo 0.01 , Li 2 S·P 2 S 5 .P 2 o 5 , Li 9.6 P 3 S 12 , Li 7 P 2.9 mn 0.01 S 10.7 I 0.3 , Li 10 SnP 2 S 12 , Li 10 SiP 2 S 12 , Li 10.35 sn 0.27 Si...

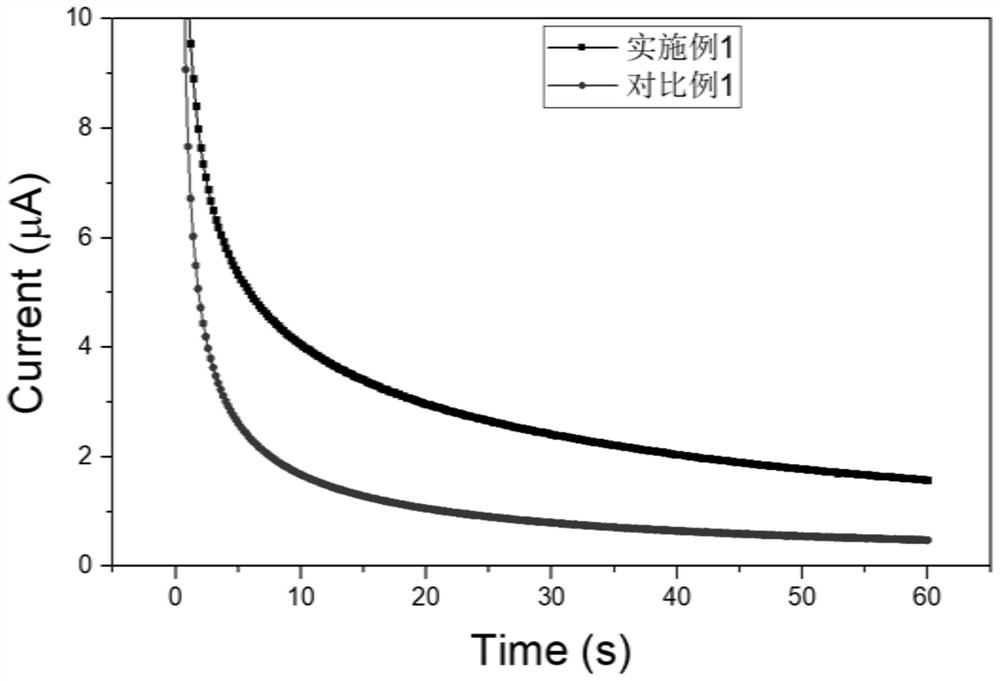

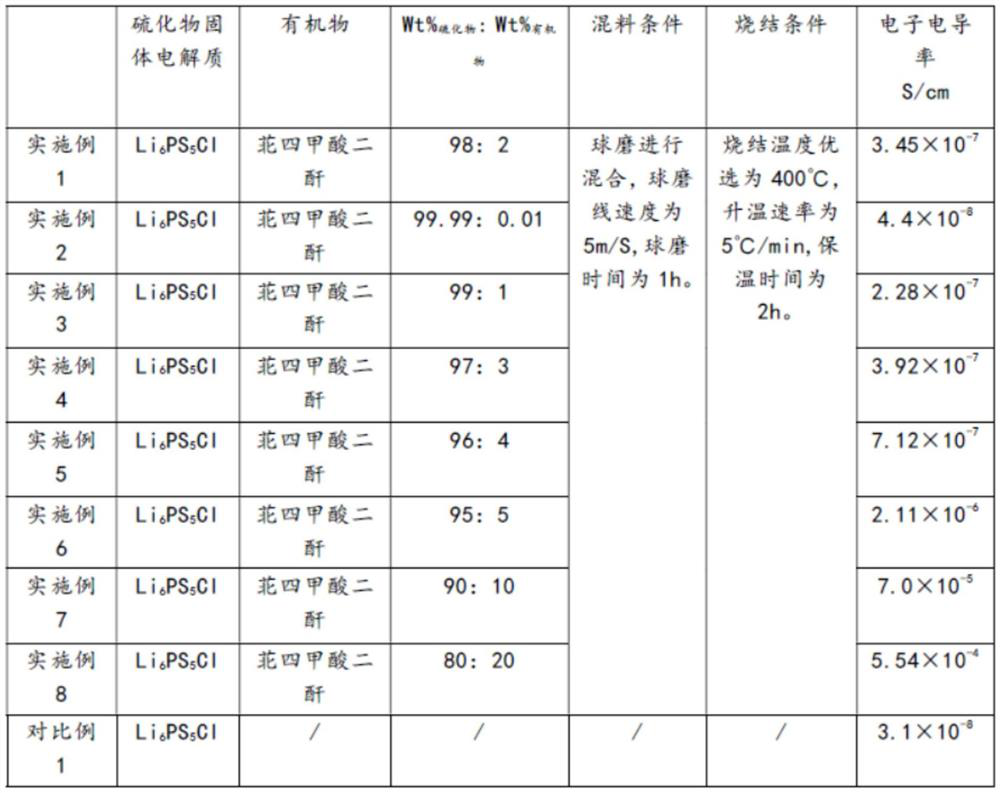

Embodiment 1

[0028] The preparation method of carbon-containing sulfide solid electrolyte, selects sulfide solid electrolyte Li in the present embodiment 6 P.S. 5 Cl and polycyclic aromatic hydrocarbon organic matter perylenetetracarboxylic dianhydride are weighed at a mass ratio of 98:2, and mixed by ball milling. The ball milling line speed is 5m / s, and the ball milling time is 1h. After the mixing is completed, the materials are placed in a sintering furnace for sintering , the sintering temperature is preferably 400°C, the heating rate is 5°C / min, the holding time is 2h, after the holding is completed, it is cooled to room temperature, and the solid electrolyte containing carbon sulfide is obtained after crushing.

Embodiment 2-8

[0033]

[0034] As shown in the table above, changing the sulfide solid electrolyte Li 6 P.S. 5 The mass ratio of Cl and polycyclic aromatic hydrocarbon organic matter perylenetetracarboxylic dianhydride is mixed by ball milling, the ball milling line speed is 5m / s, and the ball milling time is 1h. After the mixing is completed, the material is placed in a sintering furnace for sintering. The sintering temperature is preferably 400°C, the heating rate is 5°C / min, and the holding time is 2h. After the holding is completed, it is cooled to room temperature and crushed to obtain a carbon-sulfide solid electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com