Positive electrode active material and preparation method thereof, positive electrode and lithium ion secondary battery

A technology of positive active material and modified material, applied in secondary batteries, active material electrodes, positive electrodes, etc., can solve problems such as easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Embodiments of the present invention also provide a method for preparing the positive electrode active material, comprising the following steps:

[0062] a. Provide the lithium nickel manganese oxide modified material;

[0063] b. mixing an inorganic compound or an inorganic compound precursor with the lithium nickel manganese oxide modified material to obtain a coating mixture, and the inorganic compound precursor is sintered to form the inorganic compound; and

[0064] c. Sintering the coating mixture in a non-oxidizing atmosphere at 250° C. to 550° C. for 0.5 hours to 20 hours.

[0065] In some embodiments, the step of providing the lithium nickel manganese oxide modified material includes:

[0066] a1. Mixing a phosphorus source, a rock-salt-like phase inducer, and the lithium nickel manganese oxide spinel structure material to obtain a doping mixture; and

[0067] a2. Sintering the doped mixture at 600° C. to 1200° C. for 0.5 hours to 20 hours.

[0068] The lith...

Embodiment 1

[0097] 18g of LiNi 0.5 mn 1.5 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54g CuO and 0.267g (NH 4 ) 2 HPO 4 Mix evenly, and calcinate the obtained mixture in oxygen at 600°C for 5 hours, with a heating rate of 3°C / min and a cooling rate of 5°C / min, to obtain a phosphorus-doped lithium nickel manganese oxide modified material. Take 10g of the modified material, 0.05g of boron oxide and 0.1g of alumina for uniform solid phase mixing, and then sinter in air at 450°C for 10h, and finally obtain boron oxide and alumina co-coated, surface gradient P-doped nickel manganese acid Lithium cathode active material.

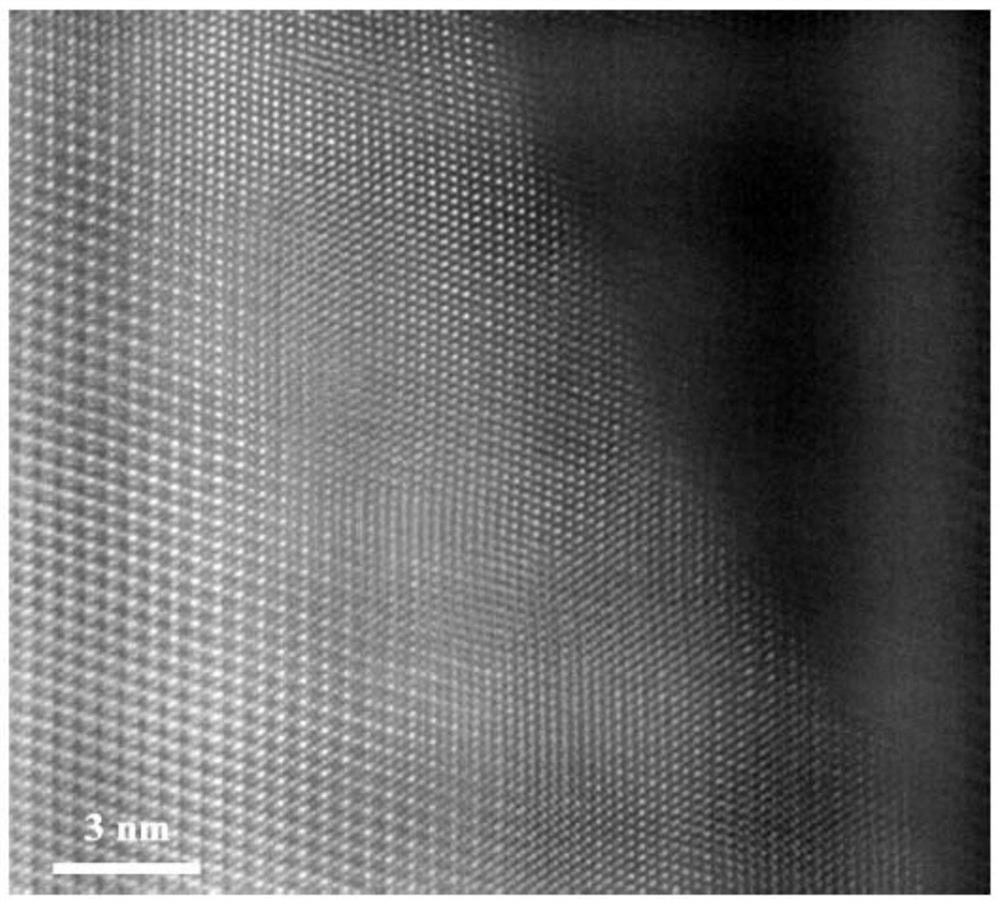

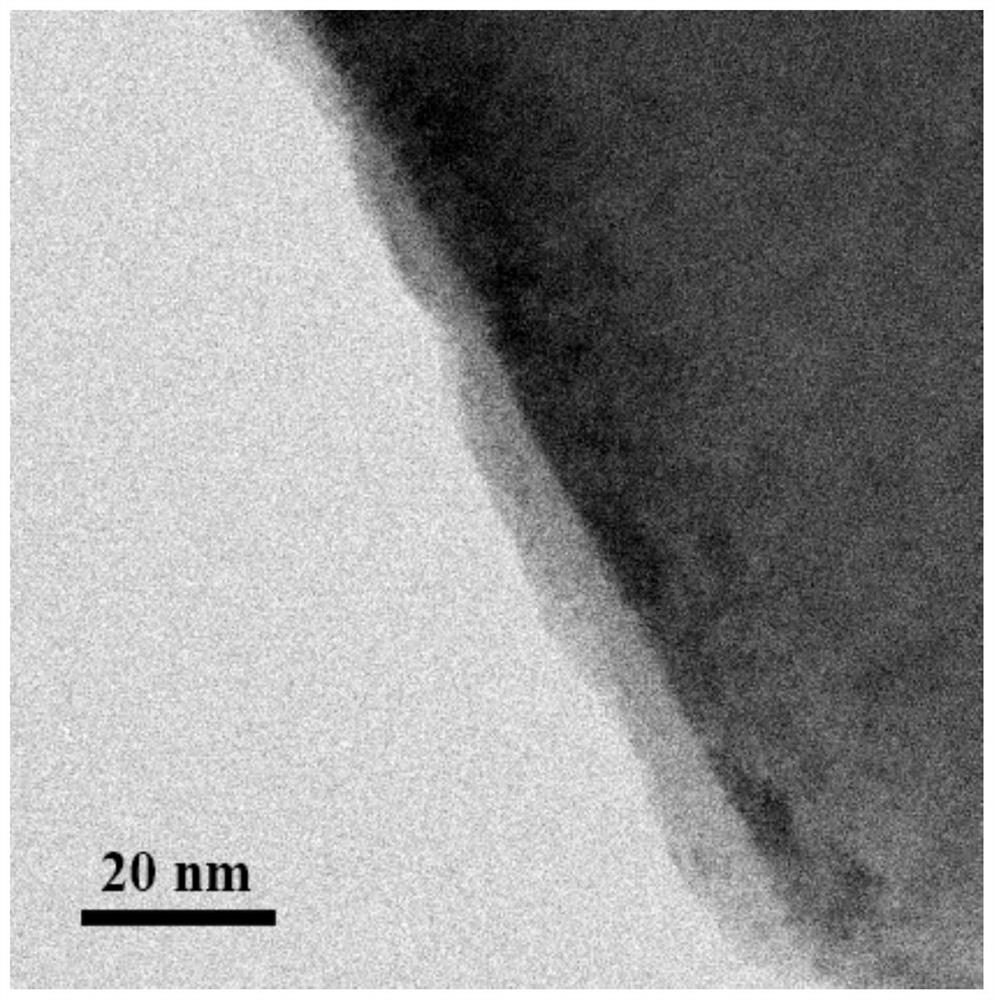

[0098] figure 1 The STEM image of the phosphorous element gradient-doped lithium nickel manganese oxide modified material prepared in Example 1 is shown. From figure 1 It can be seen that the surface of the material has a rock-salt-like phase generated by the occupation of 16c atoms of spinel octahedron, and the thickness of the rock-salt-like phase ...

Embodiment 2

[0102] 18g of LiNi 0.4 mn 1.6 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54gH 3 PO 4 Uniformly mixed with 1g of oxalic acid and calcined the resulting mixture in oxygen at 600°C for 5h, with a heating rate of 3°C / min and a cooling rate of 5°C / min, to obtain a phosphorus-gradient-doped lithium nickel manganese oxide modified material. Take 10g of the modified material and 0.1g of polyvinylidene fluoride for uniform solid-state mixing, and then sinter in vacuum at 250°C for 15h, and finally obtain a fluoride-coated, surface gradient P-doped lithium nickel manganese oxide positive electrode active material.

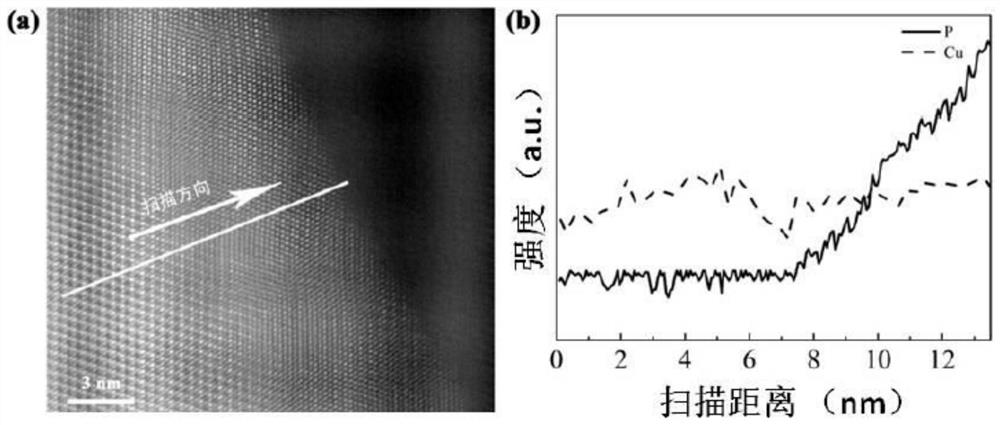

[0103] Figure 4 Shown are the STEM images of the phosphorous element gradient-doped lithium nickel manganese oxide modified material prepared in Example 2, wherein (a) and (b) are images at different magnifications, respectively. from Figure 4 It can be seen that there is a rock-salt phase formed by the occupation of spinel octahedron 8a atoms on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com