Method for preparing high-performance lithium iron phosphate cathode material by using compound type reducing agent

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of large difference in iron concentration between the surface and the interior of the sample, insufficient discharge capacity of the material, and large particle size of the material, etc., to achieve Good cycle performance, uniform crystal structure and composition, and high purity

Inactive Publication Date: 2011-06-15

HEFEI GUOXUAN HIGH TECH POWER ENERGY

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the classic synthetic route in the liquid phase method is to use ferrous salt, phosphoric acid and lithium hydroxide as raw materials. In this reaction process, the loss of lithium salt is large, and the utilization rate is only about 33.3% (taking ferrous sulfate as an example). Lithium is left in the solution after the reaction, the waste of lithium is serious, and the waste liquid is also very serious to environmental pollution

Compared with the commonly used divalent iron source route, the main problem of ferric iron is that the reduction is relatively difficult, especially in the process of using iron oxide as the iron source. Due to the stable iron oxide lattice and the large mass of iron ions, the diffusion is difficult. , which will cause a large difference in the concentration of iron between the surface and the interior of the sample. At the same time, the decomposition temperature of a single organic carbon source such as sucrose is relatively low. It is difficult to completely reduce ferric iron to ferrous iron under high temperature reaction conditions. The common solutions are: Two, one is to increase the amount used; the other is to prolong the sintering time

The former method will cause the carbon content of the finished product to be too high, the volumetric energy density will decrease, and the processing performance will deteriorate; although the latter method is conducive to ion diffusion and crystal growth, the obtained material has good crystallinity and complete crystal form, but the material The size of the particles will grow, and the agglomeration phenomenon will be aggravated, which will affect the electrochemical performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

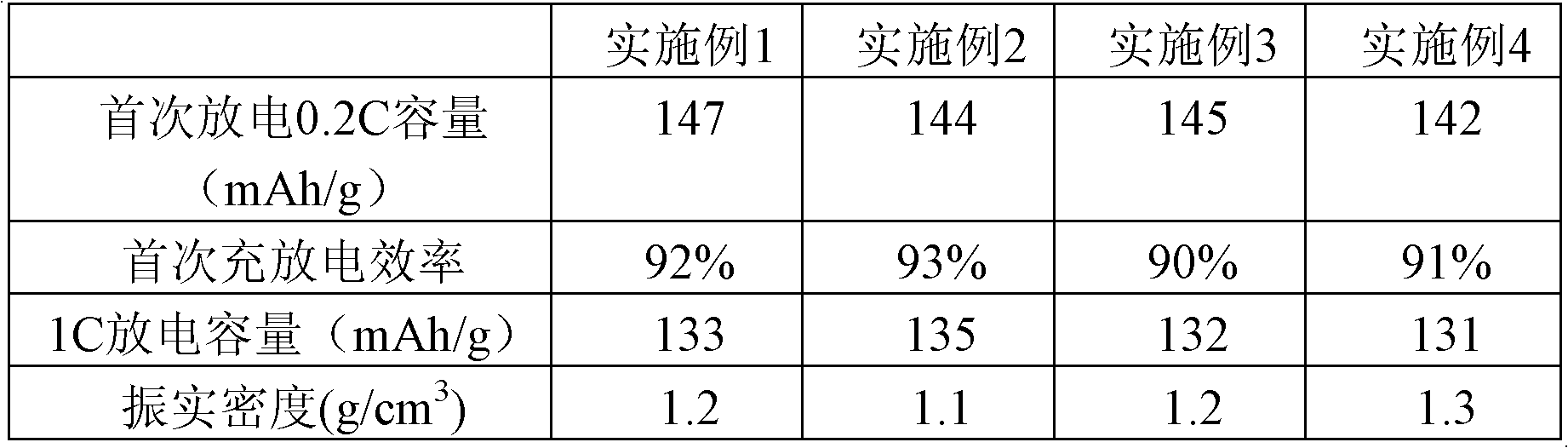

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

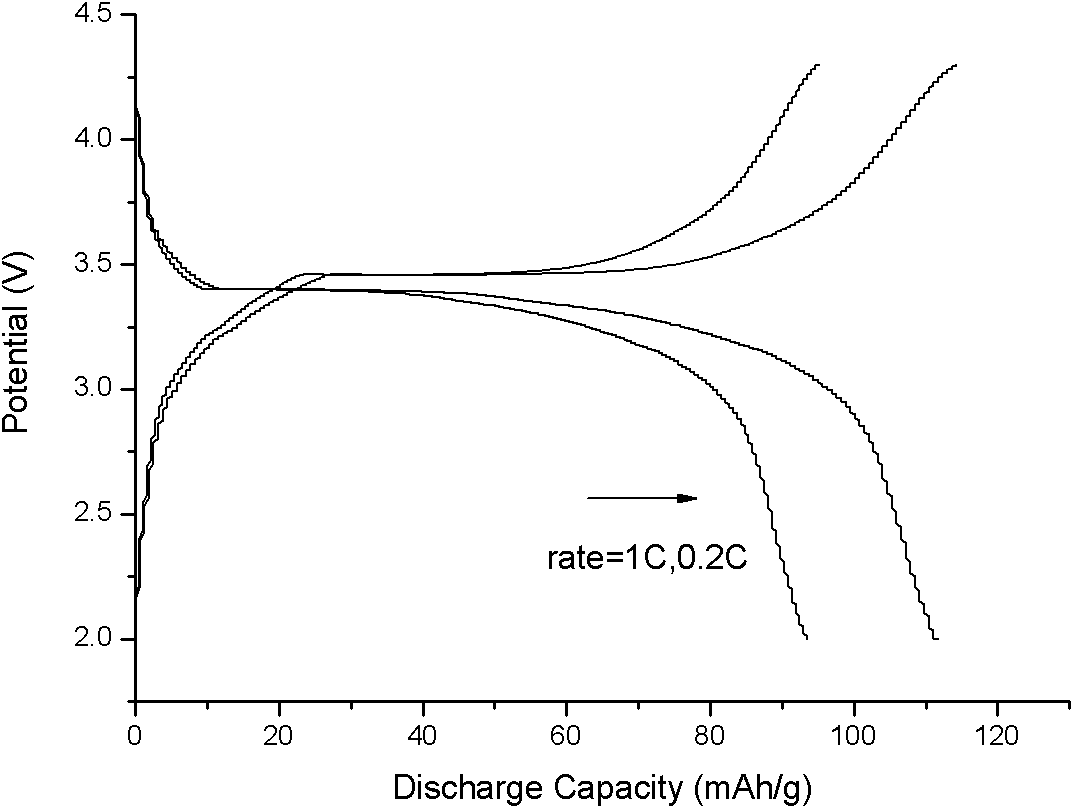

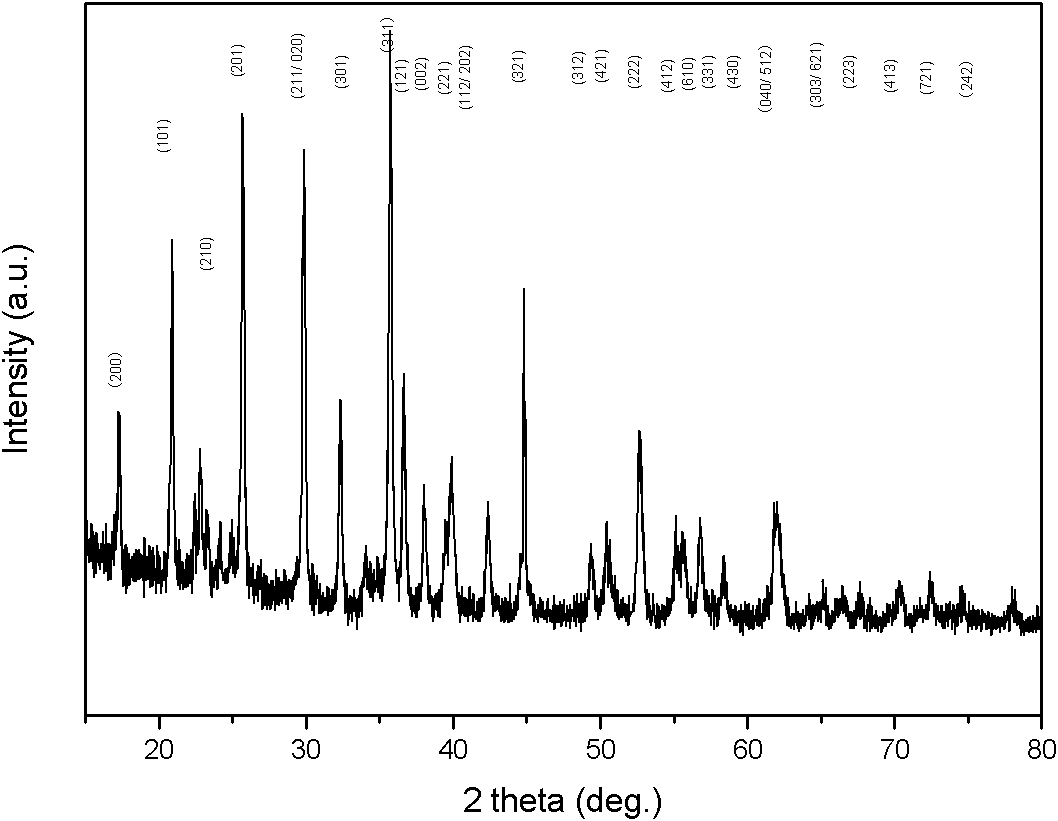

The invention relates to a method for preparing high-performance lithium iron phosphate cathode material by using compound type reducing agent, belonging to the technical field of preparation of a lithium ion battery cathode material. The invention has the technical point that the method comprises the following steps: carrying out uniform compound ball-milling on an iron source, a lithium source, a phosphorous source and a compound carbon source for 1-3 hours, wherein the stoichiometric ratio of the lithium source to the iron source to the phosphorous is (1-1.1): 1: 1, and the compound carbon source accounts for 6-10% of the total mass of the materials; drying size obtained by the compound ball-milling at the temperature of 100-120 DEG C and smashing the dried size; heating the smashed size to 650-800 DEG C in nitrogen atmosphere at the heating rate of 2-5 DEG C / min, insulating for 3-15 hours, and cooling to room temperature to obtain lithium iron phosphate powder. A method combining compound carbon thermal reduction and mechanical activation is adopted, cheap iron oxide is taken as the iron source, the doped compound carbon source is taken as reducing agent and conductive agent, and lithium iron phosphate cathode material with stable structure and high electrochemical activity is synthesized by one-step reaction.

Description

Method for preparing high-performance lithium iron phosphate cathode material with composite reducing agent technical field The invention relates to a method for preparing a high-performance lithium iron phosphate positive electrode material with a composite reducing agent, and belongs to the technical field of lithium ion battery positive electrode material preparation. Background technique The long cycle life and good safety performance of lithium-ion batteries make them have broad application prospects in portable electronic devices, electric vehicles, space technology, defense industry, etc. Electric bicycles, hybrid vehicles, etc. are the first choice for providing low-cost clean energy, which requires this lithium-ion battery not only to have high capacity, but also to have high power. Judging from the current usage situation, although LiXC6 / Li1-XCoO2 lithium-ion batteries can meet the requirements of most mobile electronic products and the existing improvement of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/1397

CPCY02E60/122Y02E60/12Y02E60/10

Inventor 蔡若愚刘大军

Owner HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com