K ion-doped and high-voltage spinel/carbon double-layer coated lithium-rich anode material and preparation method thereof

A lithium-rich positive electrode material, ion doping technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high sintering temperature, limited conductivity of pyrolytic carbon, difficult to control the degree of carbonization of dopamine, etc., to increase electron- Effects of lithium ion conductance, improved electrochemical performance, and fast three-dimensional lithium ion conduction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

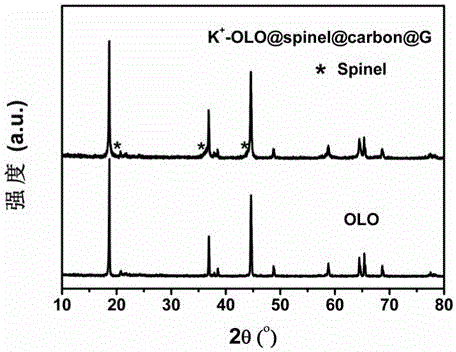

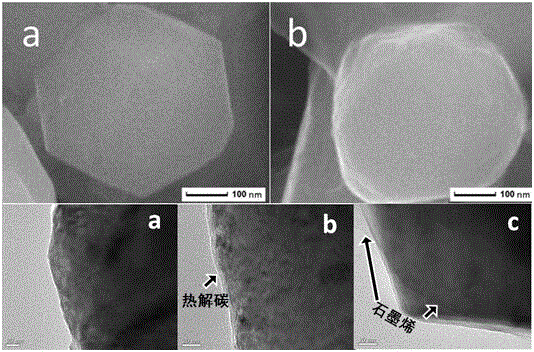

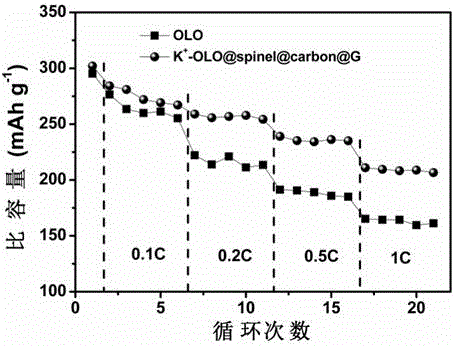

[0035] K + Doping and synergistic coating composite modification of dopamine polymer and graphene applied to lithium-rich manganese-based ternary cathode material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , prepared by the following steps:

[0036] (1) Take K + The number of moles is about Li + Add 1% nitrate by mole to the above-mentioned stoichiometric lithium, nickel, cobalt and manganese nitrate solution, add an appropriate amount of citric acid as a complexing agent, and spray dry it after it is dissolved and stirred evenly to obtain a precursor powder ;

[0037] (2) Sinter the above precursor powder at 950 °C for 10 h to obtain K + Doped modified lithium-rich ternary cathode material powder as the nucleus;

[0038] (3) Take 1g of the above K + The doped modified lithium-rich cathode material powder was added to 100ml of 10mmol / LTris-HCL buffer solution (PH=8.5) and ultrasonically stirred for 1h. Then add 0.3 g of dopamine hydrochloride and continue stirring for 6 hou...

Embodiment 2

[0043] K + Doping and synergistic coating composite modification of dopamine polymer and graphene applied to lithium-rich manganese-based cathode materials Li 1.2 mn 0.6 Ni 0.2 o 2 , prepared by the following steps:

[0044] (1) Take K + The number of moles is about Li + Add 0.5% nitrate by mole to the above-mentioned stoichiometric lithium, nickel, cobalt and manganese nitrate solution, add an appropriate amount of citric acid as a complexing agent, and spray dry it after it is dissolved and stirred evenly to obtain a precursor powder ;

[0045] (2) Sinter the above precursor powder at 950 °C for 10 h to obtain K + Doped modified lithium-rich cathode materials;

[0046] (3) Take 1g of the above K + The doped modified lithium-rich cathode material powder was added to 100ml of 10mmol / LTris-HCL buffer solution (PH=8.0) and ultrasonically stirred for 1h. Then add 0.3 g of dopamine hydrochloride and continue stirring for 10 h, filter and dry to obtain a lithium-rich posi...

Embodiment 3

[0050] K + Doping and synergistic coating composite modification of dopamine polymer and graphene applied to lithium-rich manganese-based cathode materials Li 1.2 mn 1.5 Ni 0.5 o 2 , prepared by the following steps:

[0051] (1) Take K + The number of moles is about Li + Add 0.8% nitrate by mole to the above-mentioned stoichiometric lithium, nickel, cobalt and manganese nitrate solution, add an appropriate amount of citric acid as a complexing agent, and spray dry it after it is dissolved and stirred evenly to obtain a precursor powder ;

[0052] (2) Sinter the above precursor powder at 950 °C for 10 h to obtain K + Doped modified lithium-rich ternary cathode material;

[0053] (3) Take 1g of the above K + The doped modified lithium-rich cathode material powder was added to 100ml of 10mmol / LTris-HCL buffer solution (PH=8.3) and ultrasonically stirred for 1h. Then add 0.3 g of dopamine hydrochloride and continue stirring for 8 hours, filter and dry to obtain a lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com