Auxiliary electrode film of lithium air battery as well as preparation and application method thereof

A lithium-air battery and auxiliary electrode technology, applied in battery electrodes, fuel cell-type half-cells, primary battery-type half-cells, fuel cells, etc., can solve the problems that the cycle life of lithium-air batteries needs to be improved, and achieve excellent viscosity Junction, high stability, and the effect of improving electronic conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Stir 9.80 mg of carbon nanotubes and 0.98 mg of polyvinyl formal in 176.4 mg of N-methylpyrrolidone for 9 hours, sonicate for 2.5 hours, add 0.9500 g of pure water, and stir for 10 hours to obtain a slurry. Wherein, the structural unit of polyvinyl formal is:

[0030]

[0031] (where R3=R4=H)

[0032] The polyvinyl formal (PVFM) based polymer film has a thickness of 85 μm and a porosity of 62.3%. Cut the polymer film into an area of 3×3cm 2 of squares. The above-mentioned slurry was scraped and coated on the film with a doctor blade, and the coating thickness was 100 microns. Blast heating at 80°C for 8 hours to obtain an auxiliary electrode film with a carbon loading of 1.05 mg / cm 2 .

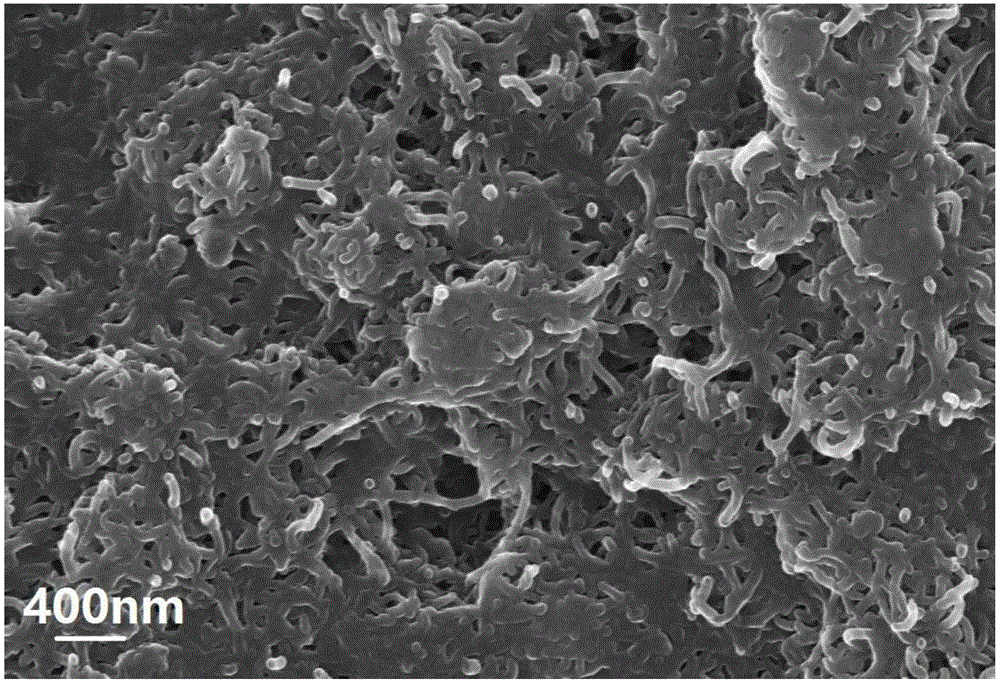

[0033] figure 1 The scanning electron microscope image of the composite layer side of the auxiliary electrode film prepared for Example 1, the linear structure in the figure is the positive electrode material carbon nanotube, as can be seen from the SEM image, the carbon mate...

Embodiment 2

[0035] Stir 5.40 mg of conductive carbon black and 0.65 mg of polyvinyl formal in 97.2 mg of N-methylpyrrolidone for 6 h, sonicate for 1.5 h, add 1.2650 g of pure water, and stir for 12 h to obtain a slurry. Wherein, the structural unit of polyvinyl formal is:

[0036]

[0037] (where R3=R4=H)

[0038] The polyvinyl formal (PVFM) based polymer film has a thickness of 105 μm and a porosity of 73.2%. Cut the polymer film into an area of 3×3cm 2 The polymer film is fixed with a template, the slurry is poured on the film, the template is vibrated to spread the slurry on the whole film, and the mass of the added positive electrode coating is 0.7450g. Heated by blowing air at 100°C for 10 hours to obtain a membrane electrode substrate with a carbon load of 0.33 mg / cm 2 .

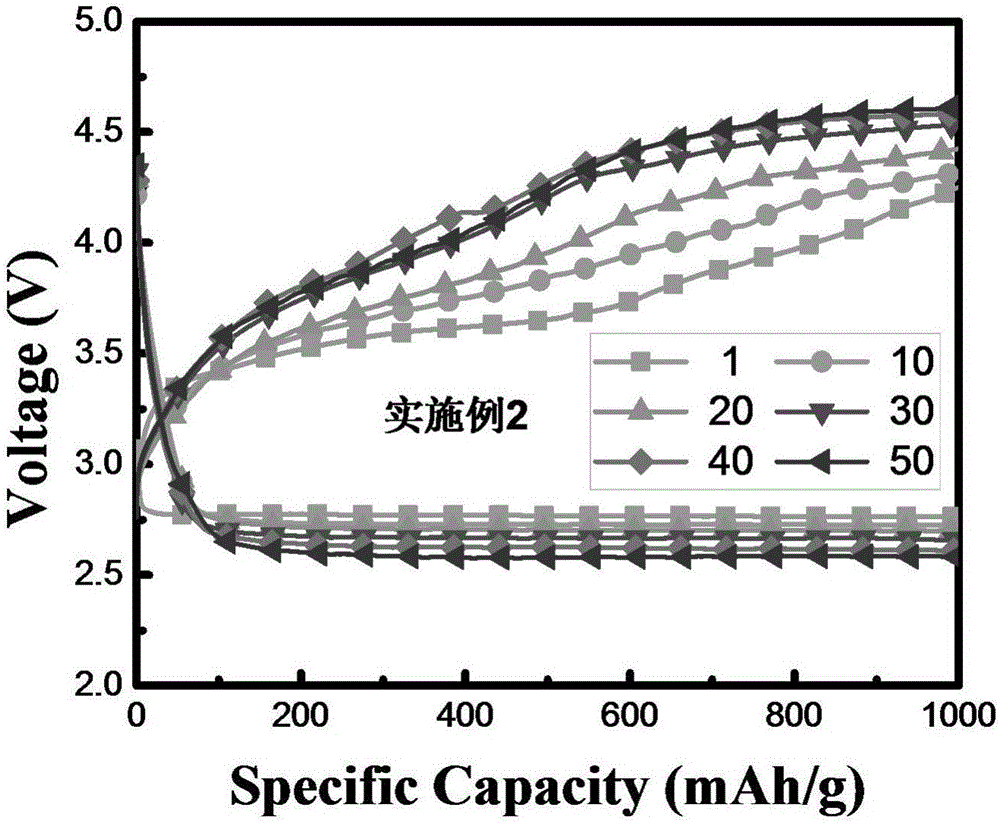

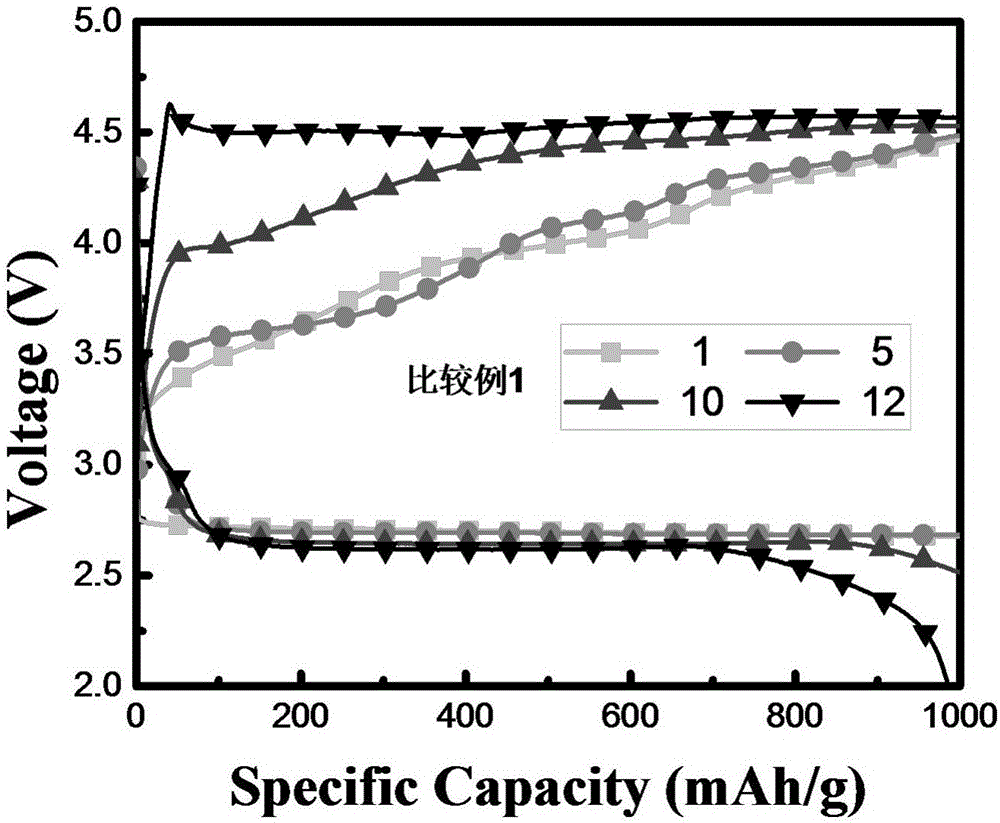

[0039] figure 2 The auxiliary electrode film prepared for Example 2 was cut into Φ=12mm discs, and the charge-discharge cycle test results of assembling a CR2032 button lithium-air battery. Among them,...

Embodiment 3

[0049] Stir 8.54 mg of graphene and 1.20 mg of polyvinyl butyral in 135.00 mg of N-methylpyrrolidone for 10 h, sonicate for 3 h, add 1.2000 g of pure water, and stir for 16 h to obtain a slurry. Wherein, the structural unit of polyvinyl butyral is:

[0050]

[0051] (where R3=R4=CH 2 CH 2 CH 3 )

[0052] The polyvinyl butyral (PVB)-based polymer film had a thickness of 150 μm and a porosity of 84.3%. Cut the polymer film into an area of 3×3cm 2 The polymer film was fixed, and the slurry was evenly sprayed on the surface of the polymer film with an airbrush. Each time it was sprayed, it was air-dried at 90°C for 45 minutes, and sprayed 8 times in total. Heated with air blast at 100°C for 12 hours to obtain an auxiliary electrode film with a carbon loading of 0.18 mg / cm 2 .

[0053] Figure 4 The capacity retention rate of the auxiliary electrode film-assembled lithium-air battery prepared in Example 3 in charge-discharge cycle tests at different rates. The auxilia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com