Patents

Literature

44results about How to "Improved lattice structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

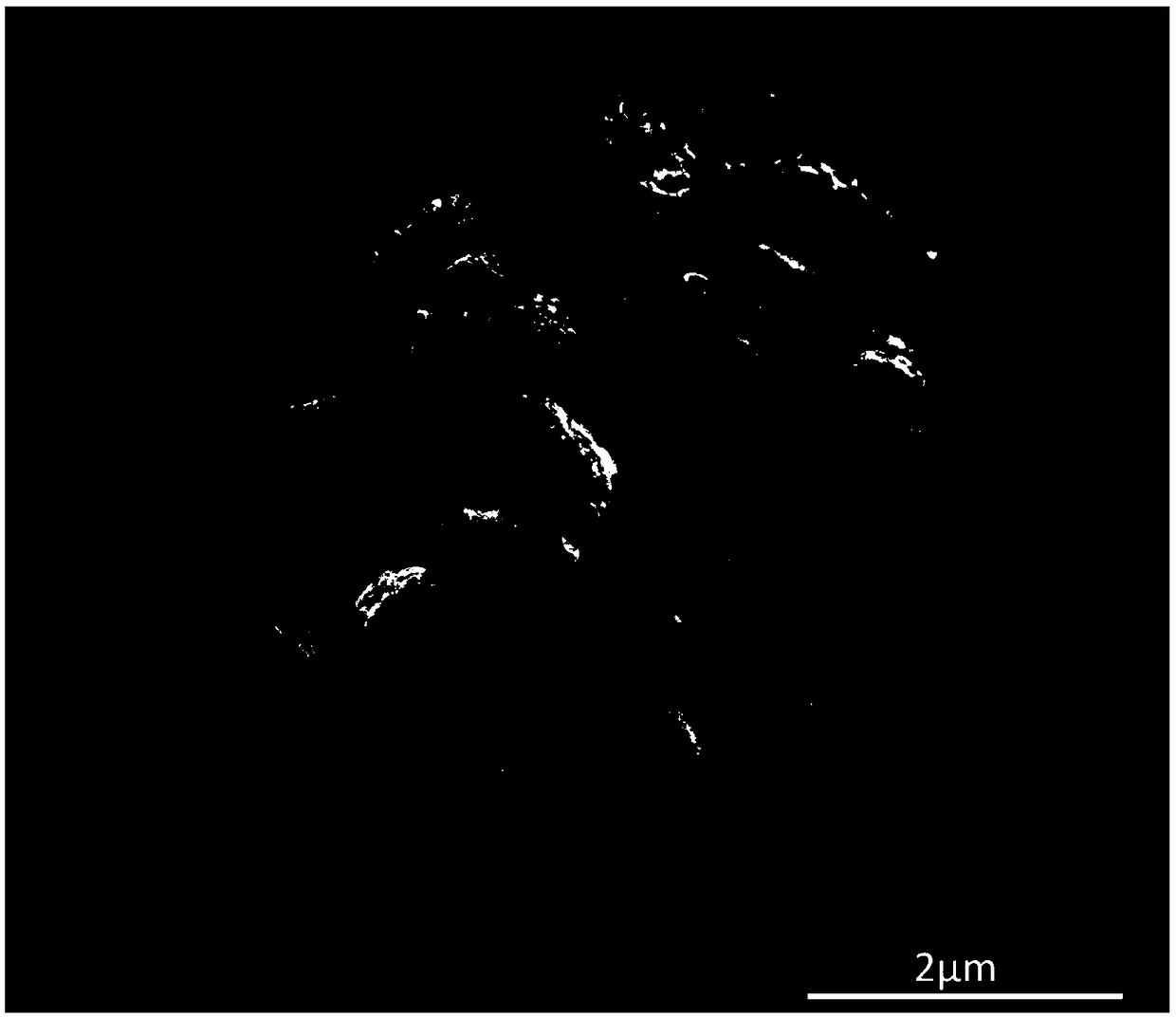

Multi-element mixed doping coating modified ternary positive electrode material and preparation method thereof

InactiveCN109192972AReduce cationic shufflingReduce polarizationSecondary cellsPositive electrodesRADIUSLithium

The invention discloses a multi-element mixed doping and coating modified ternary positive electrode material and a preparation method thereof. According to the lattice structure characteristics of ternary positive electrode materials, two kinds of metal ions with different ionic radii are doped selectively by multi-element mixed doping method. One kind of metal ions with lithium ion radius equalto or close to lithium ion radius can reduce the cation mixing and discharging. The other kind of metal ions with the same or close radius as transition metal ions (Mn4 +, Co3 +) can reduce the polarization and enhance the electrochemical performance. At that same time, a protective layer is coated on the surface of the ternary positive electrode material by a secondary sinter process to prevent the dissolution of transition metal ions on the surface of the ternary positive electrode material, thereby the ternary positive electrode material with excellent rate performance and cycling performance is prepare. The method is simple in process, convenient in operation and good in reproducibility, and is suitable for large-scale industrial production.

Owner:圣戈莱(北京)科技有限公司

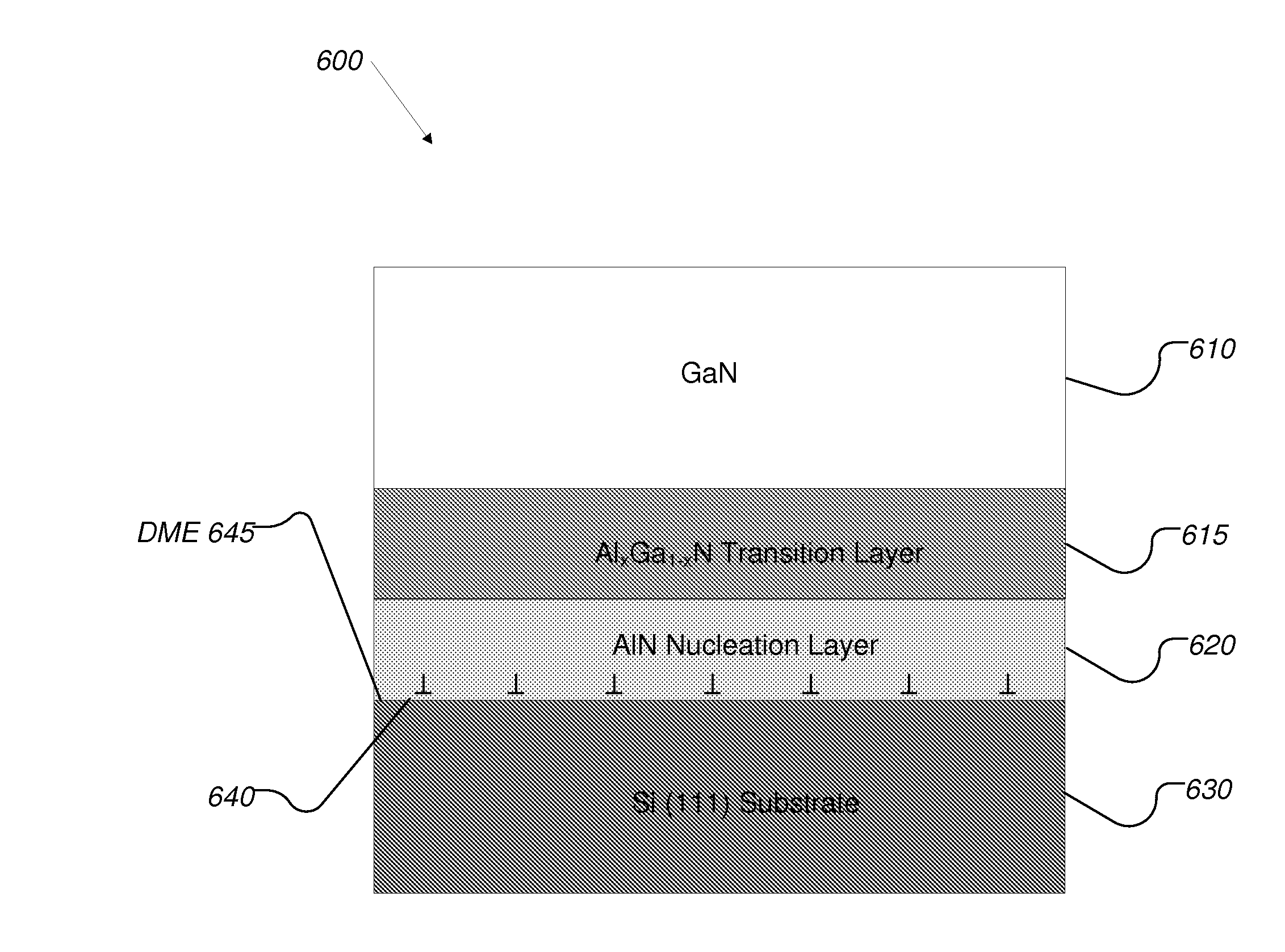

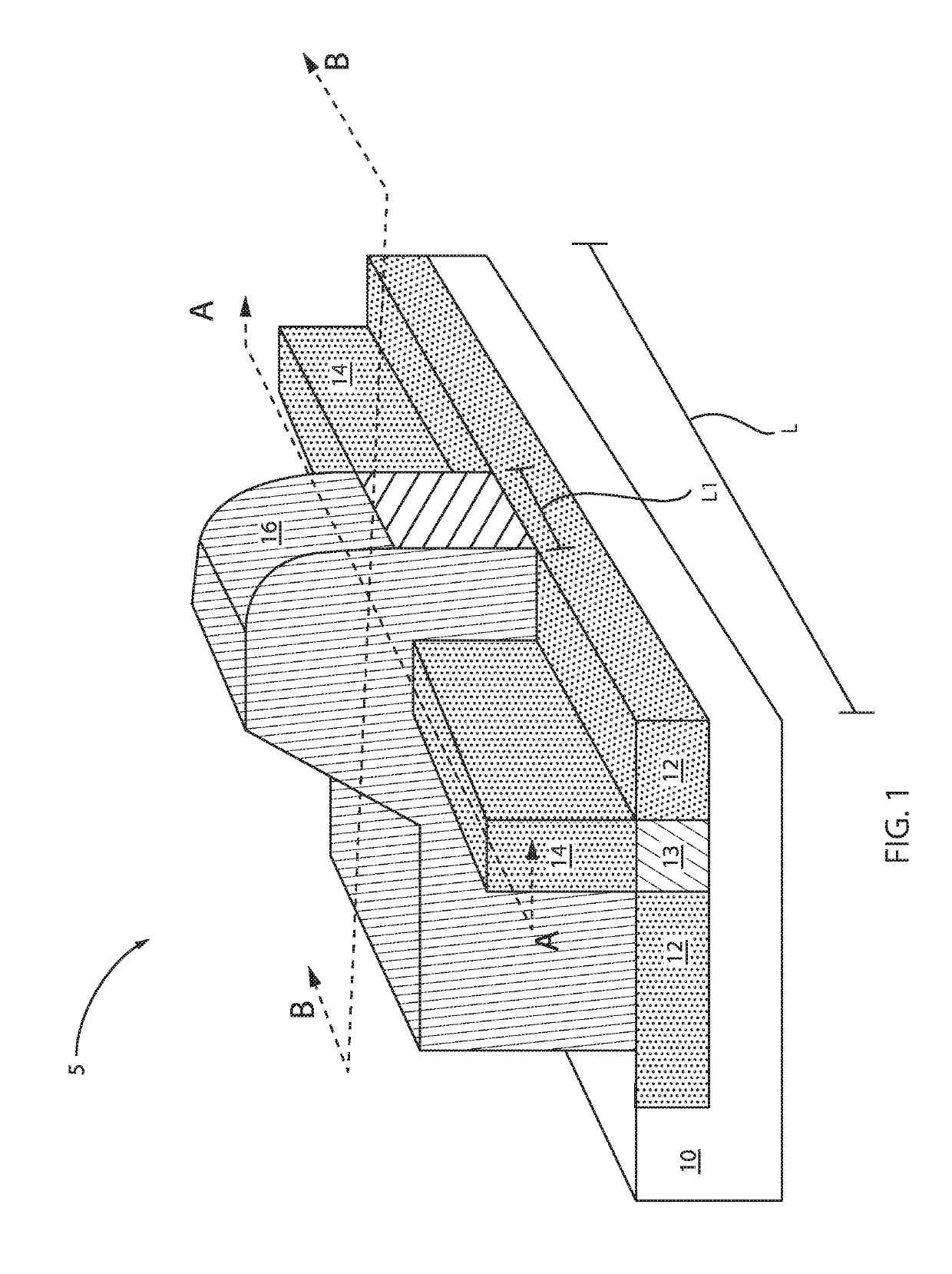

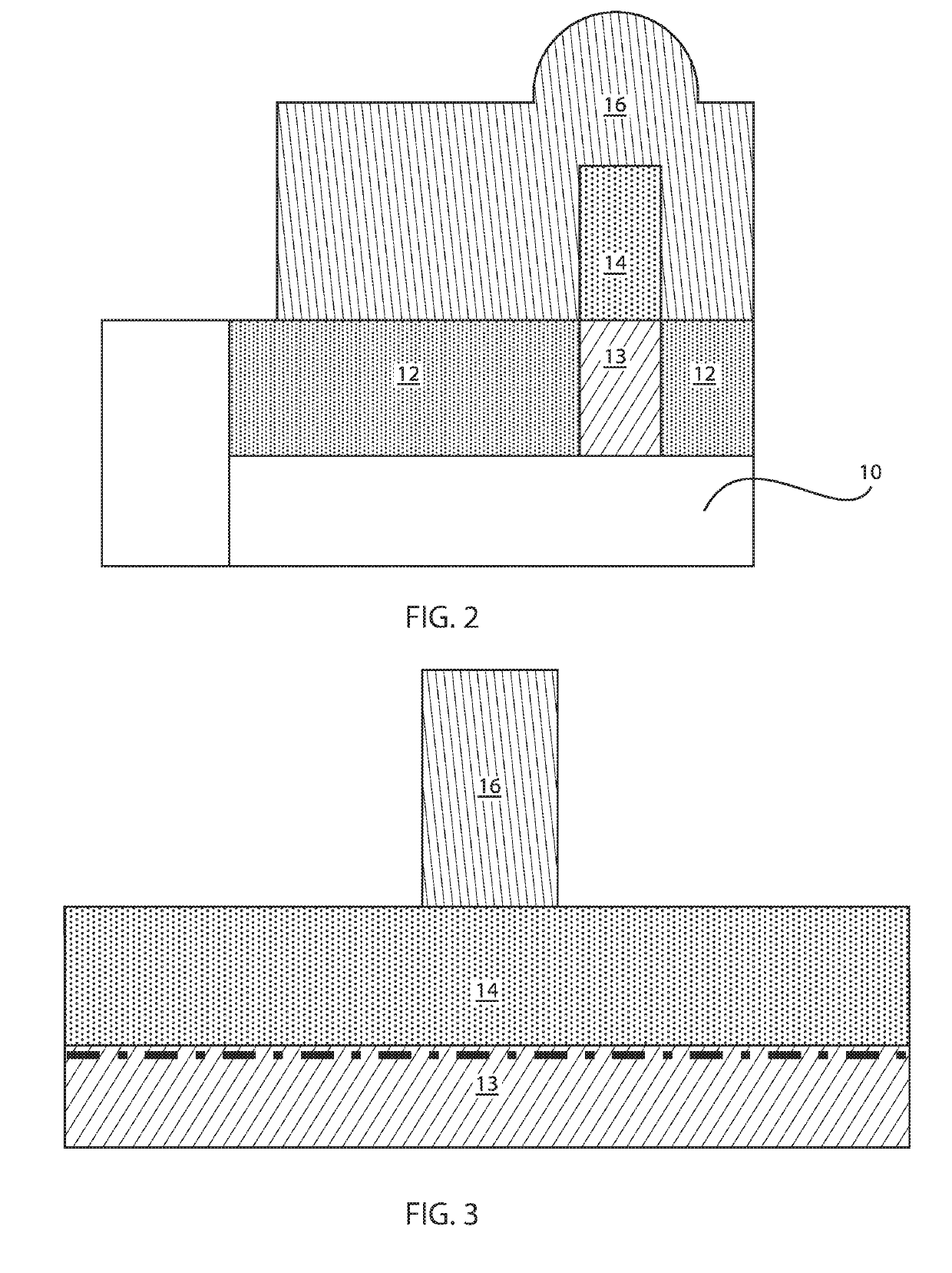

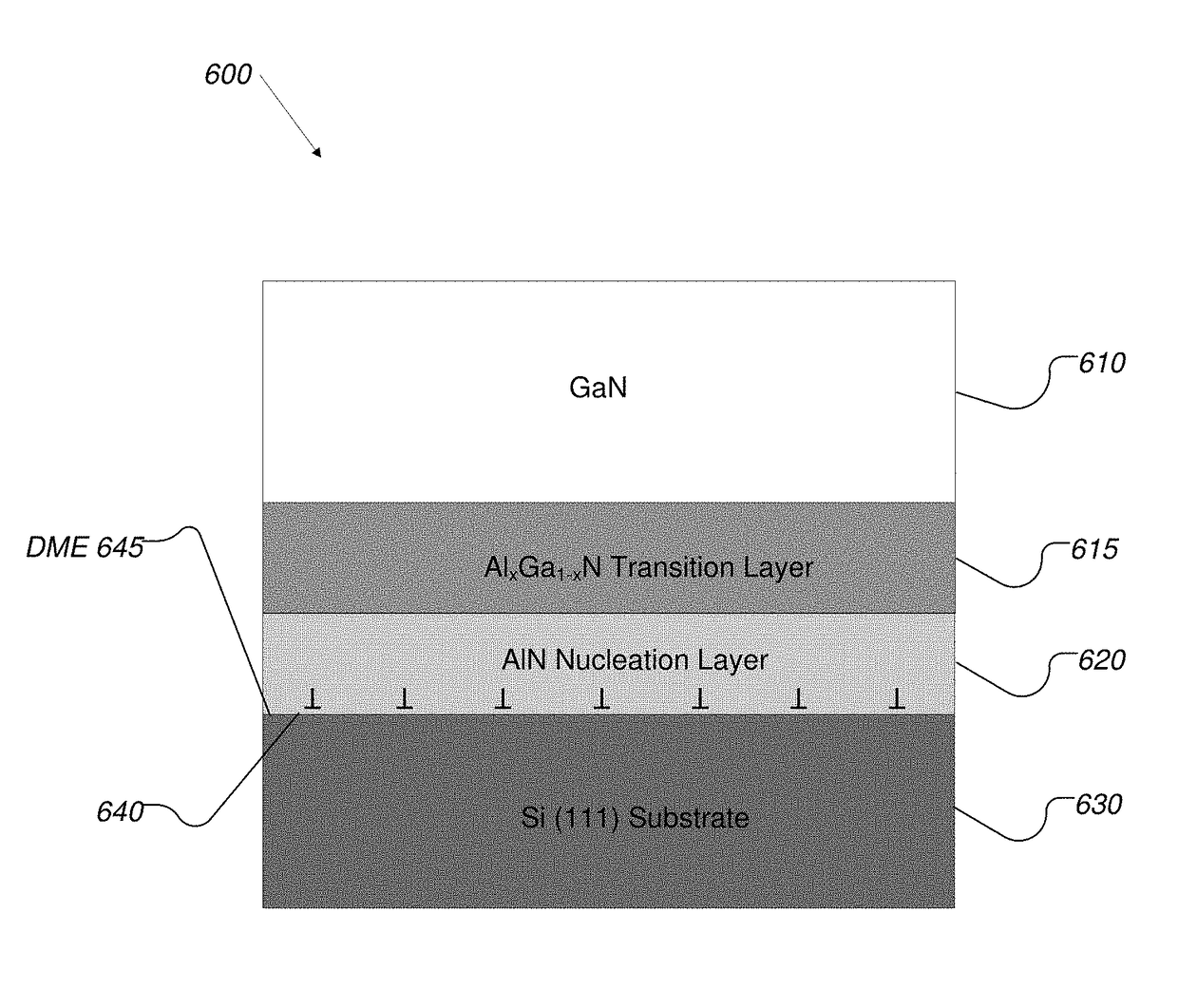

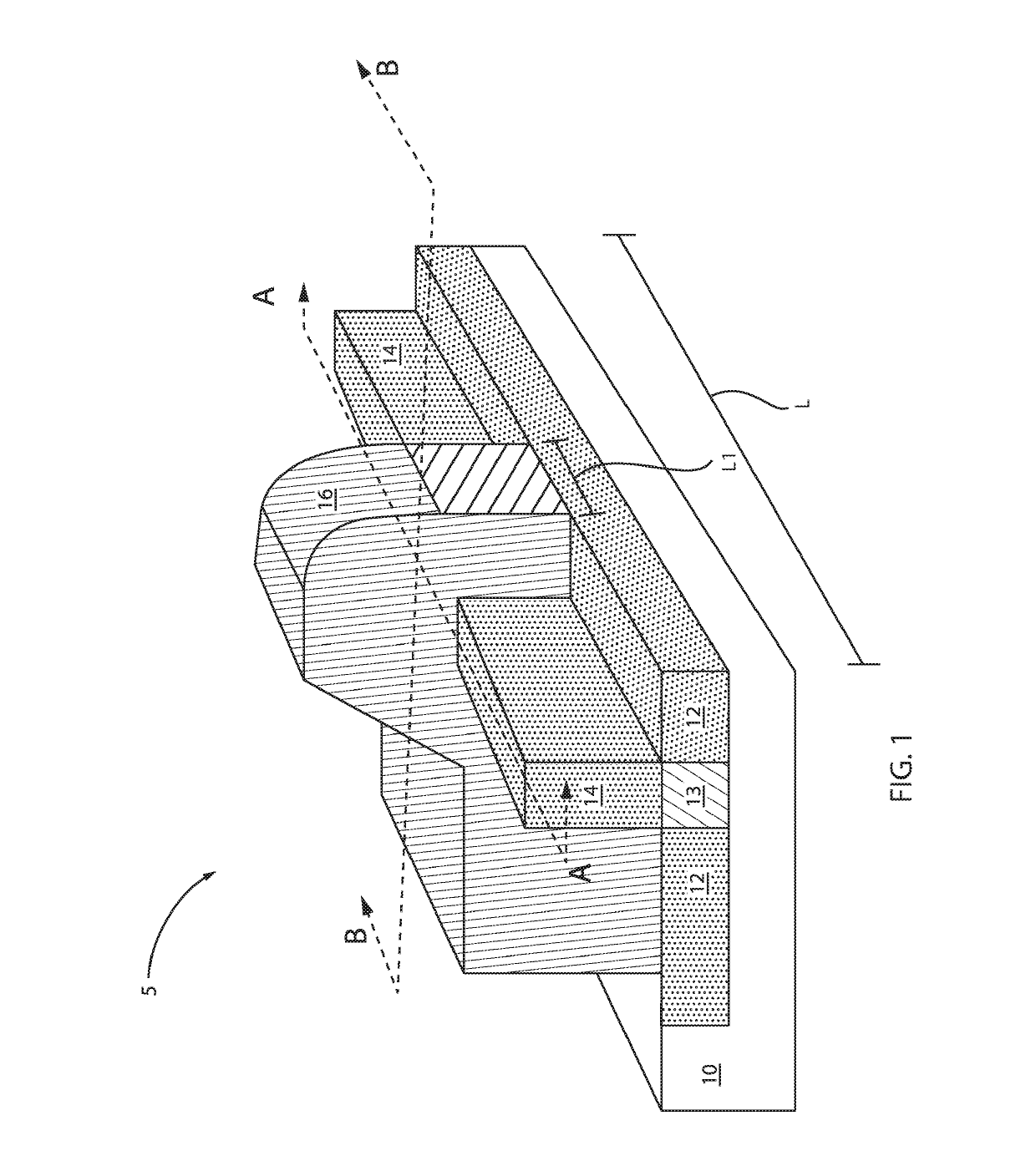

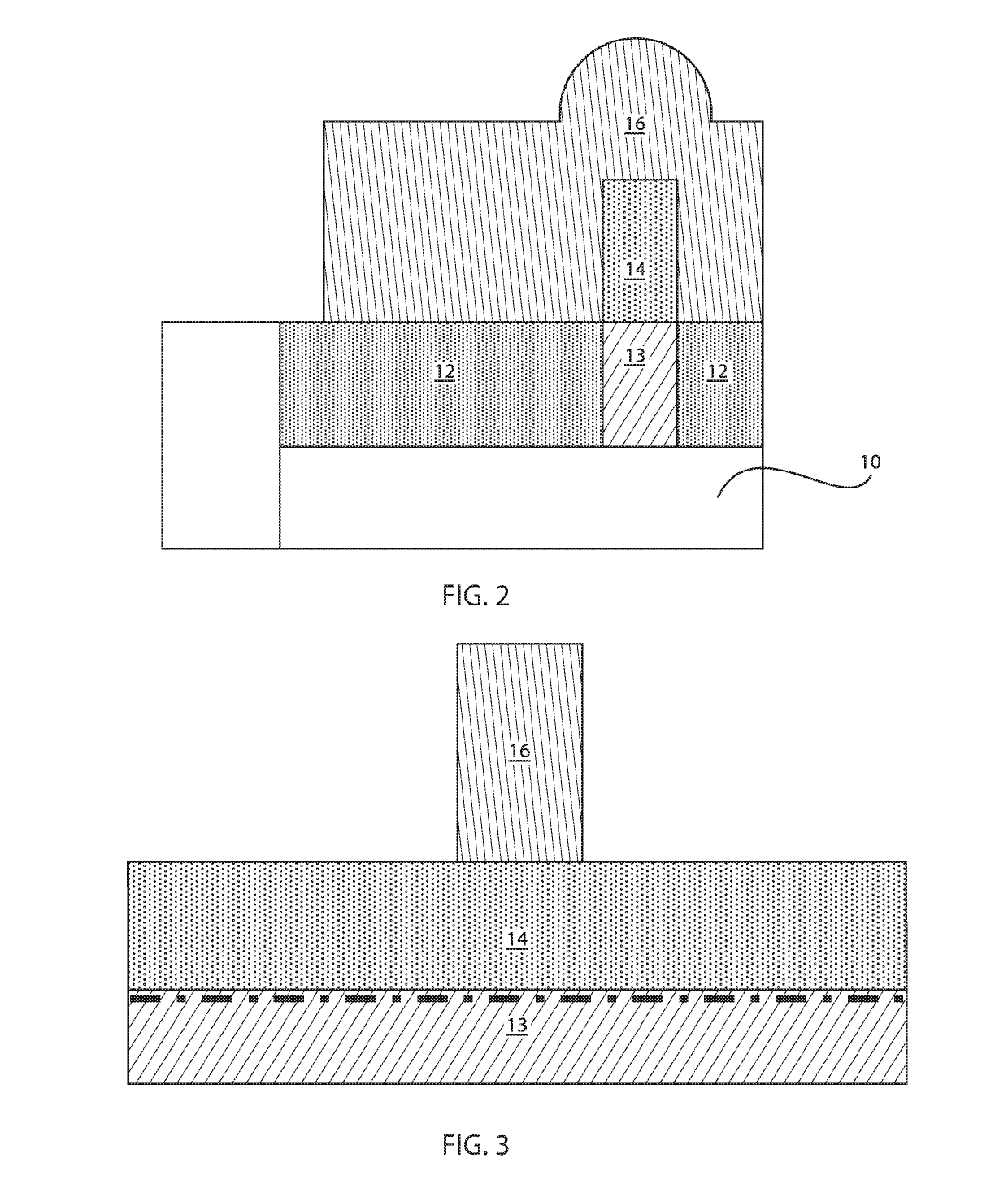

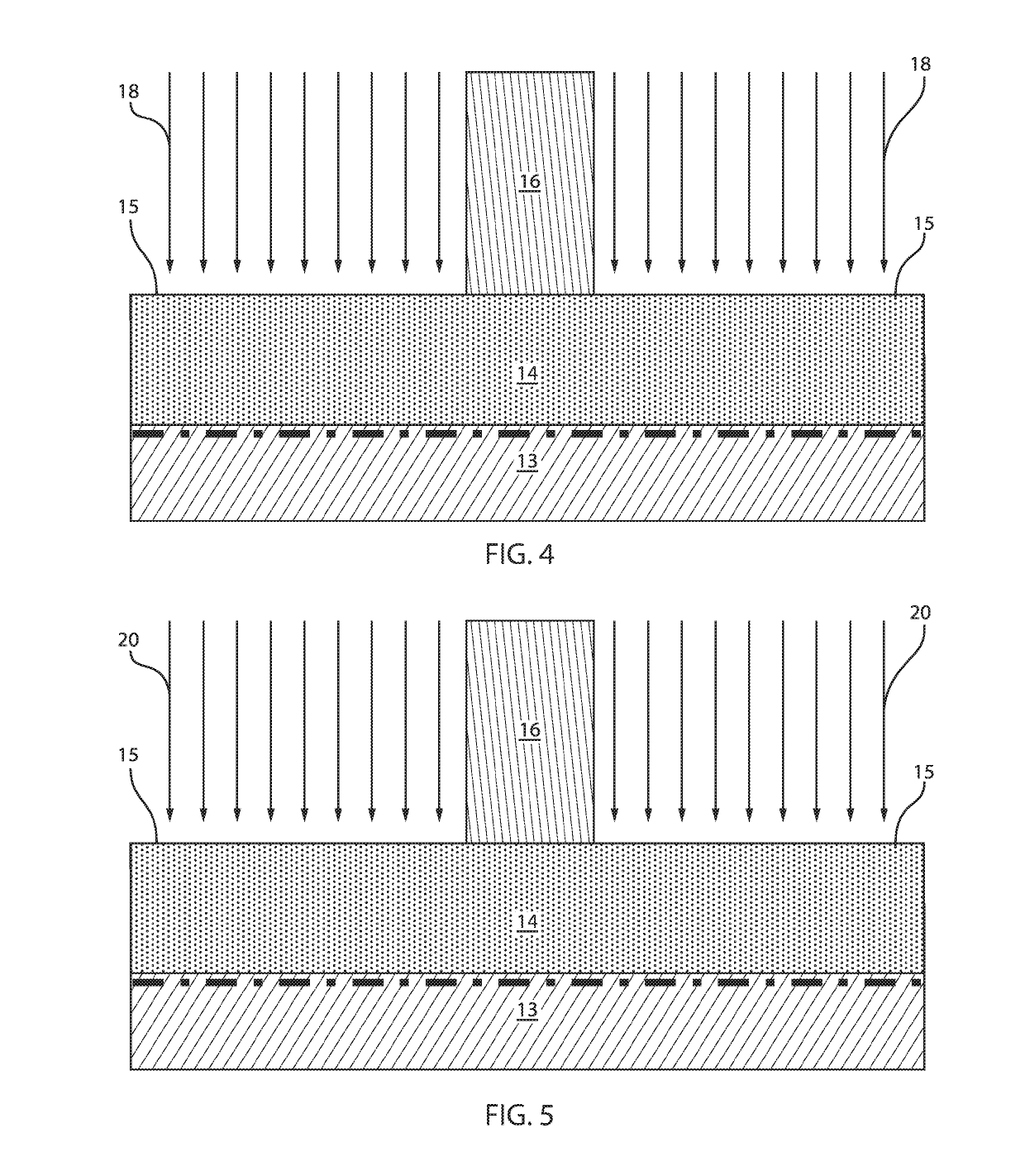

Method and apparatus for forming device quality gallium nitride layers on silicon substrates

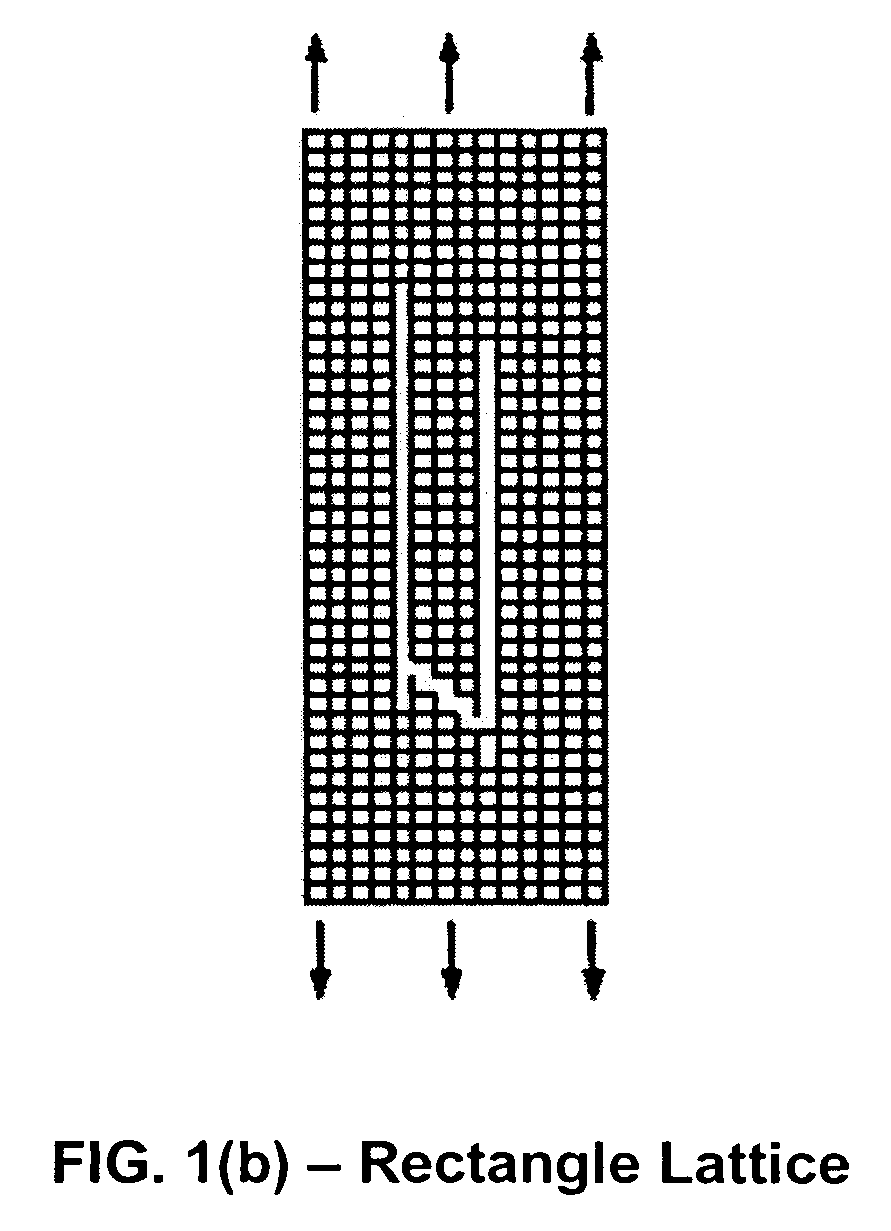

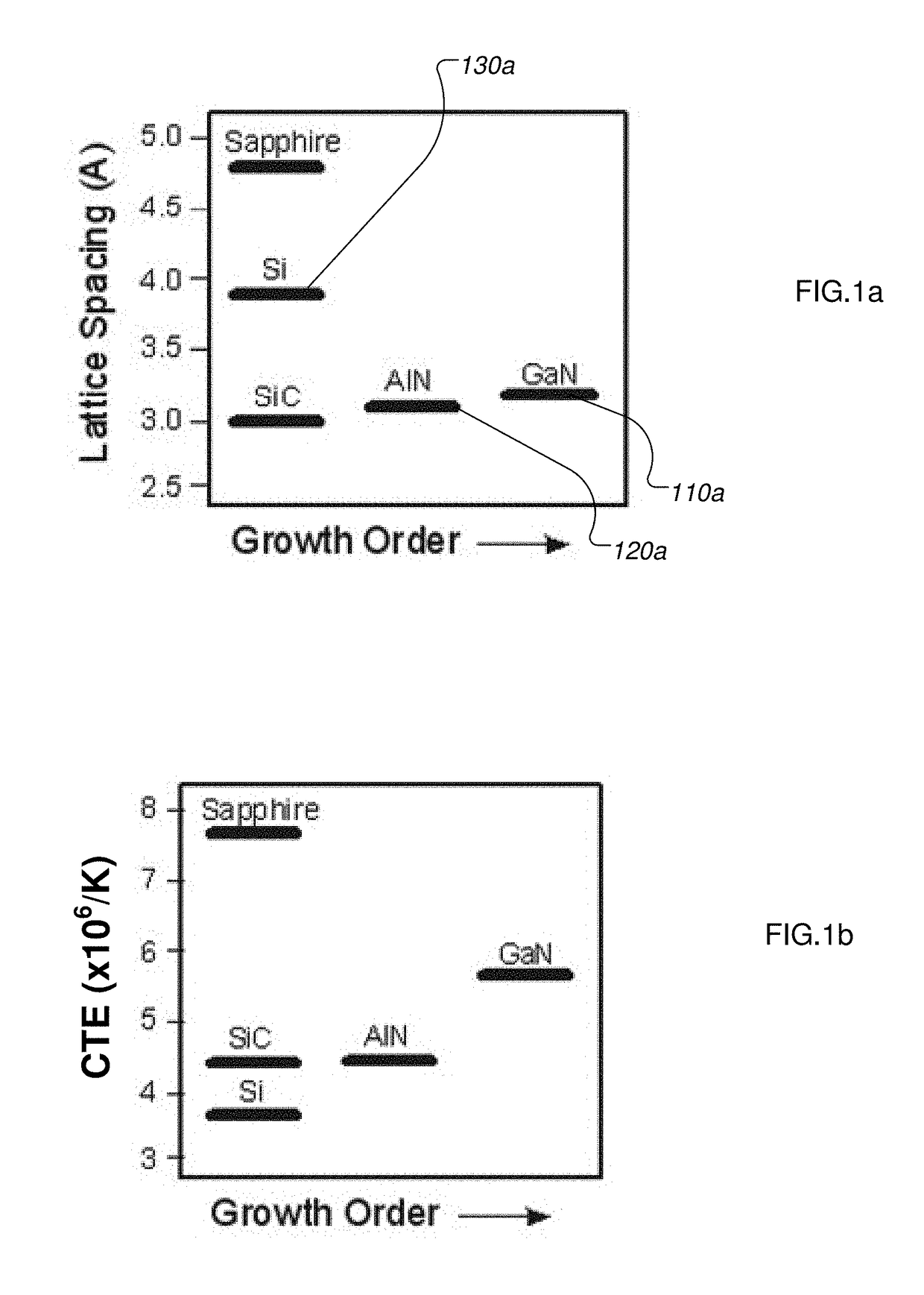

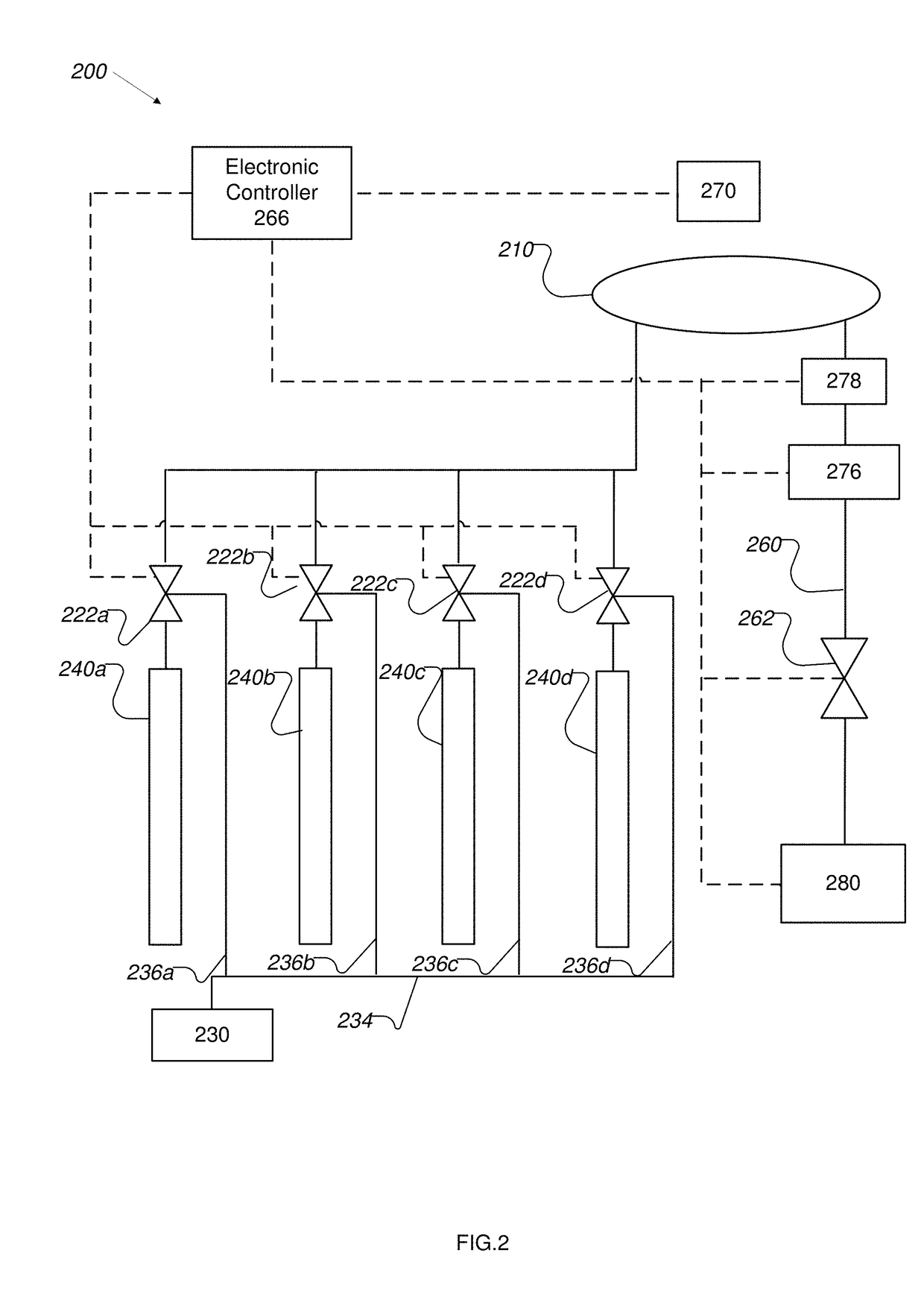

InactiveUS20160203972A1Improved lattice structureReduce spacingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction temperatureNucleation

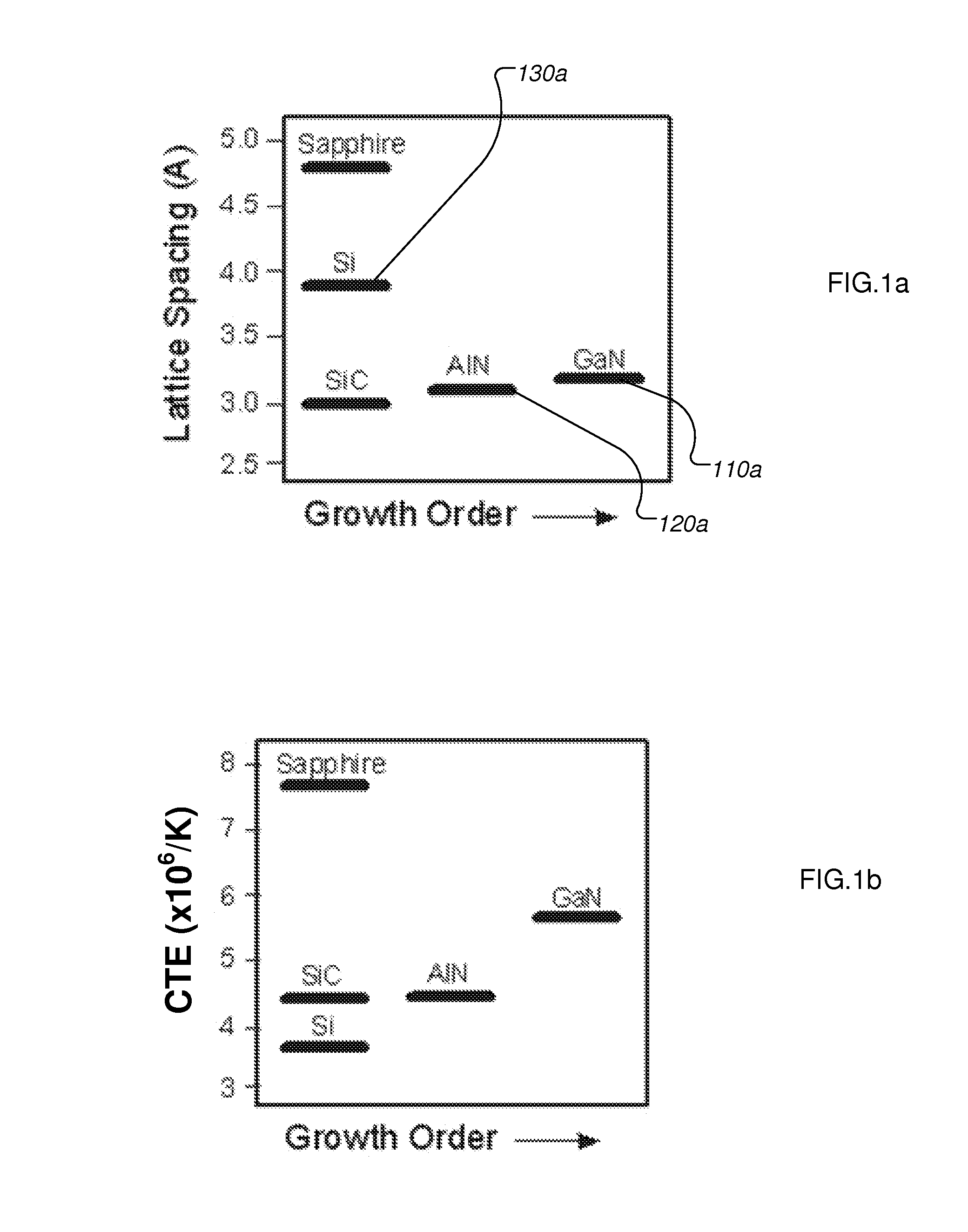

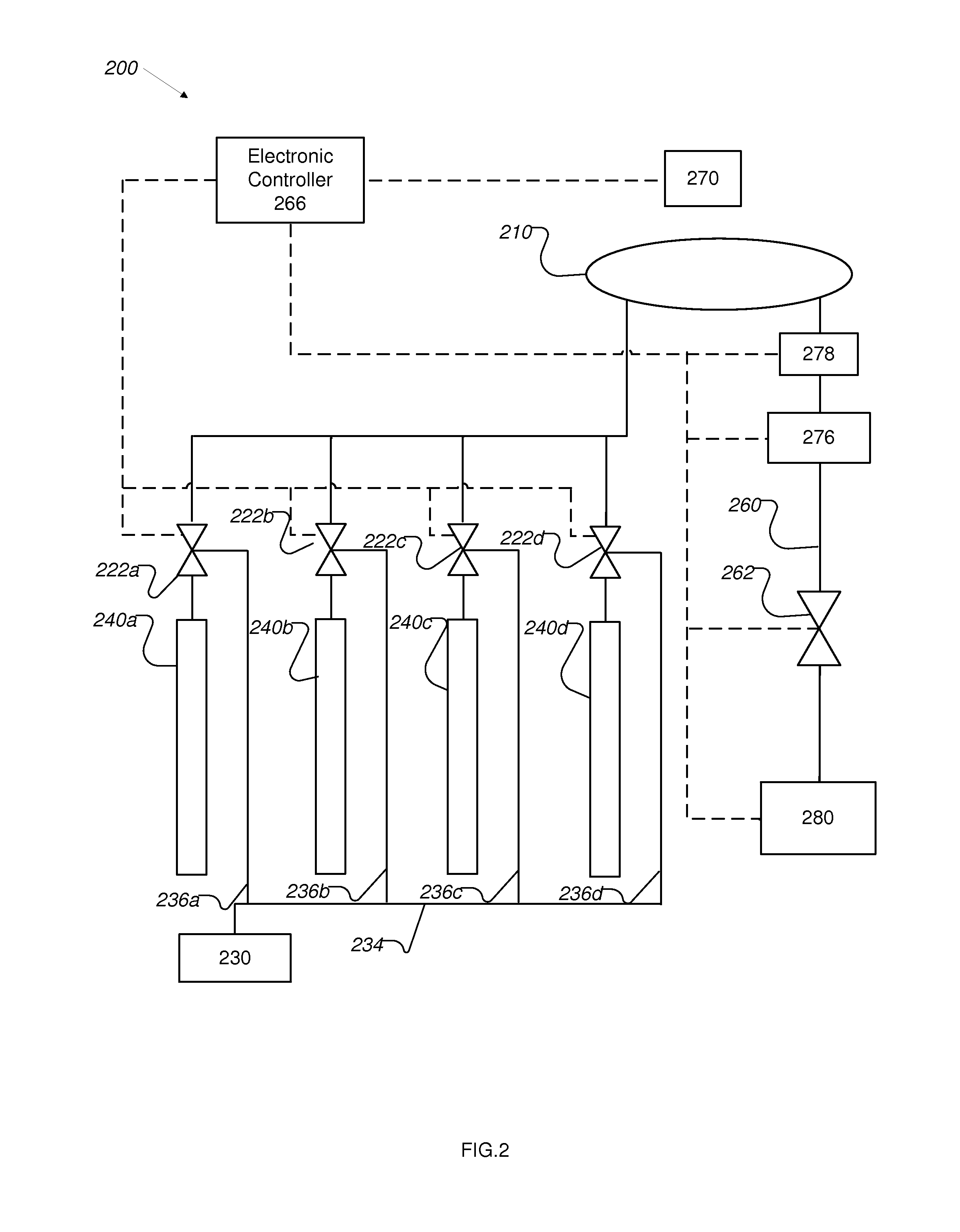

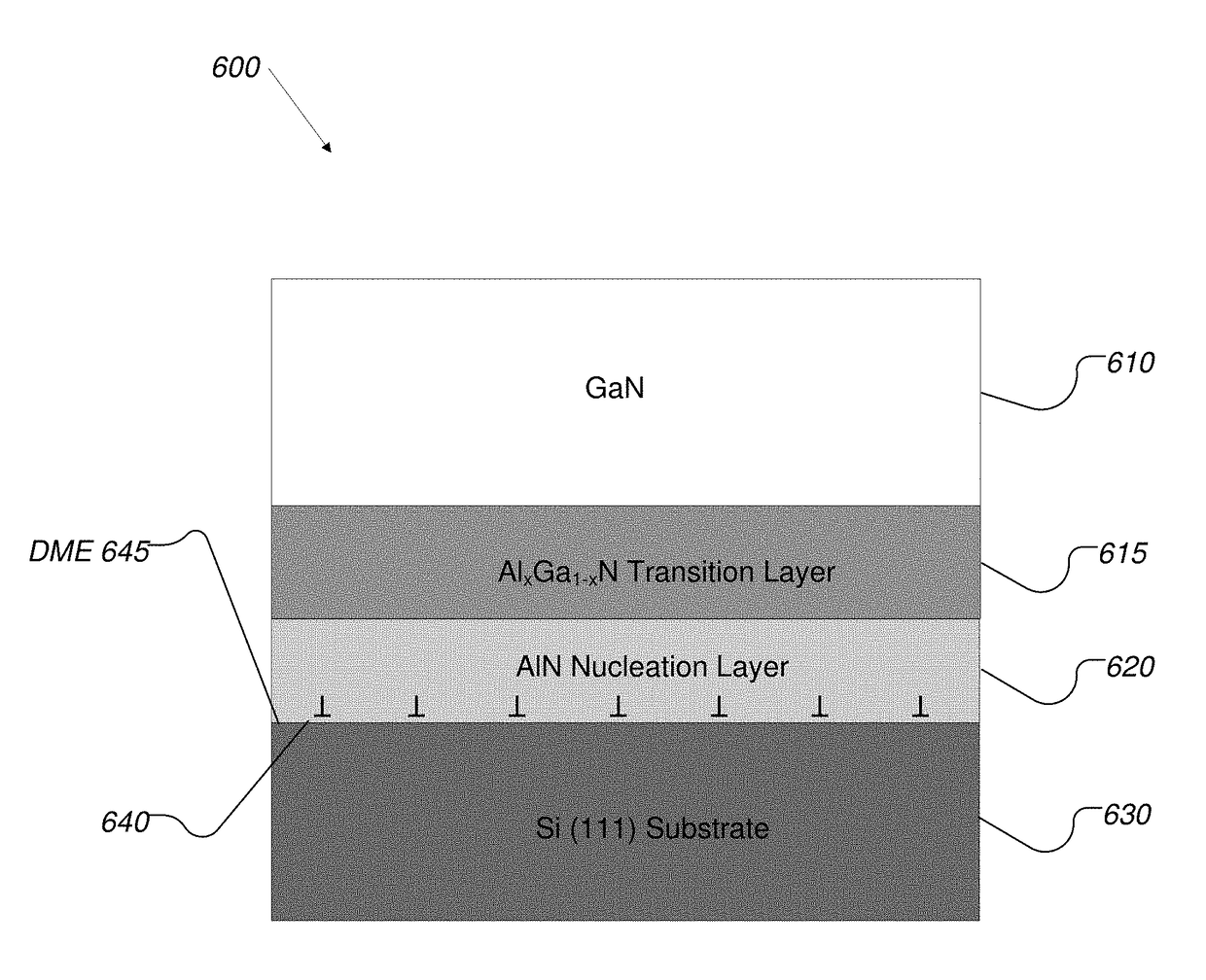

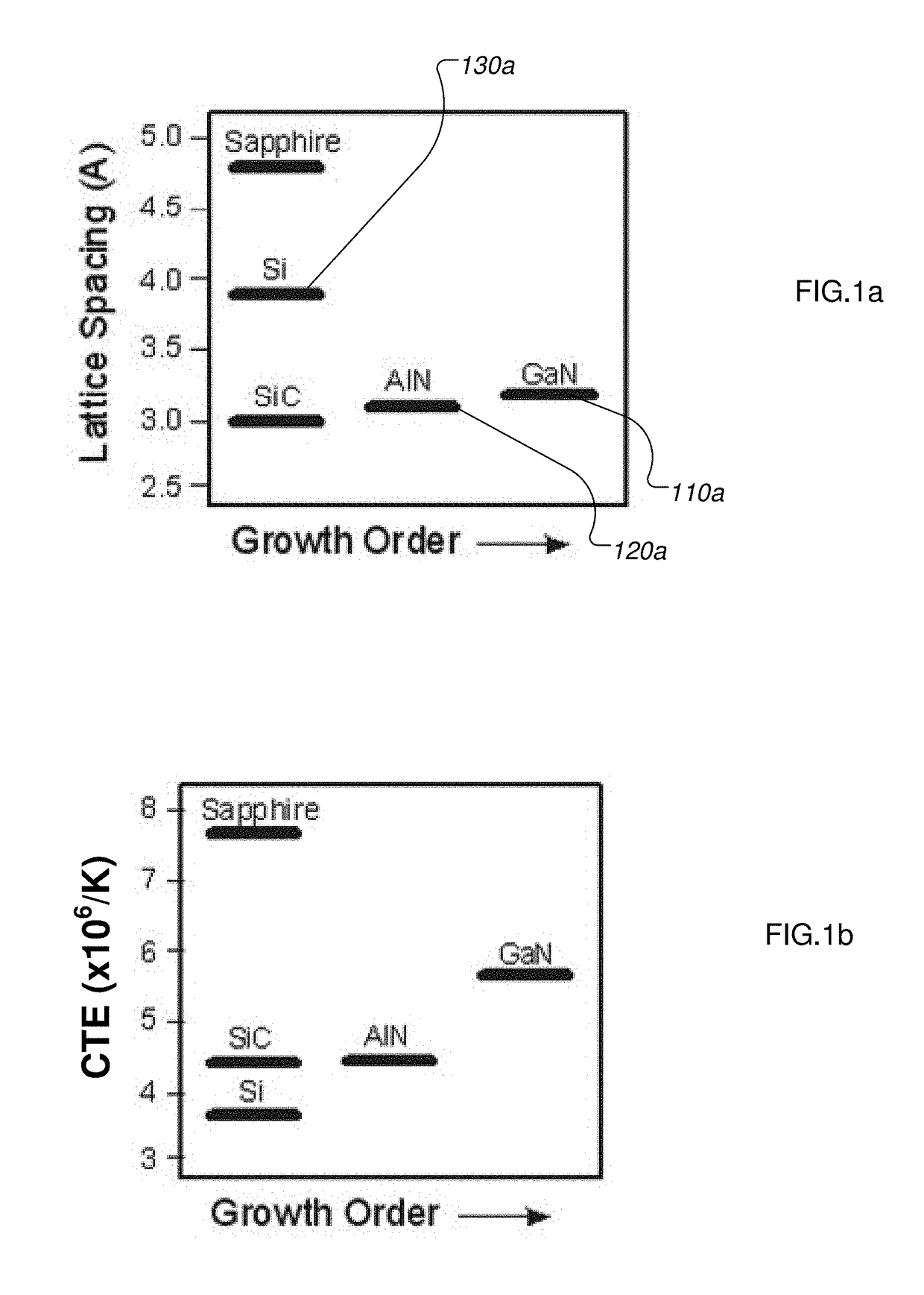

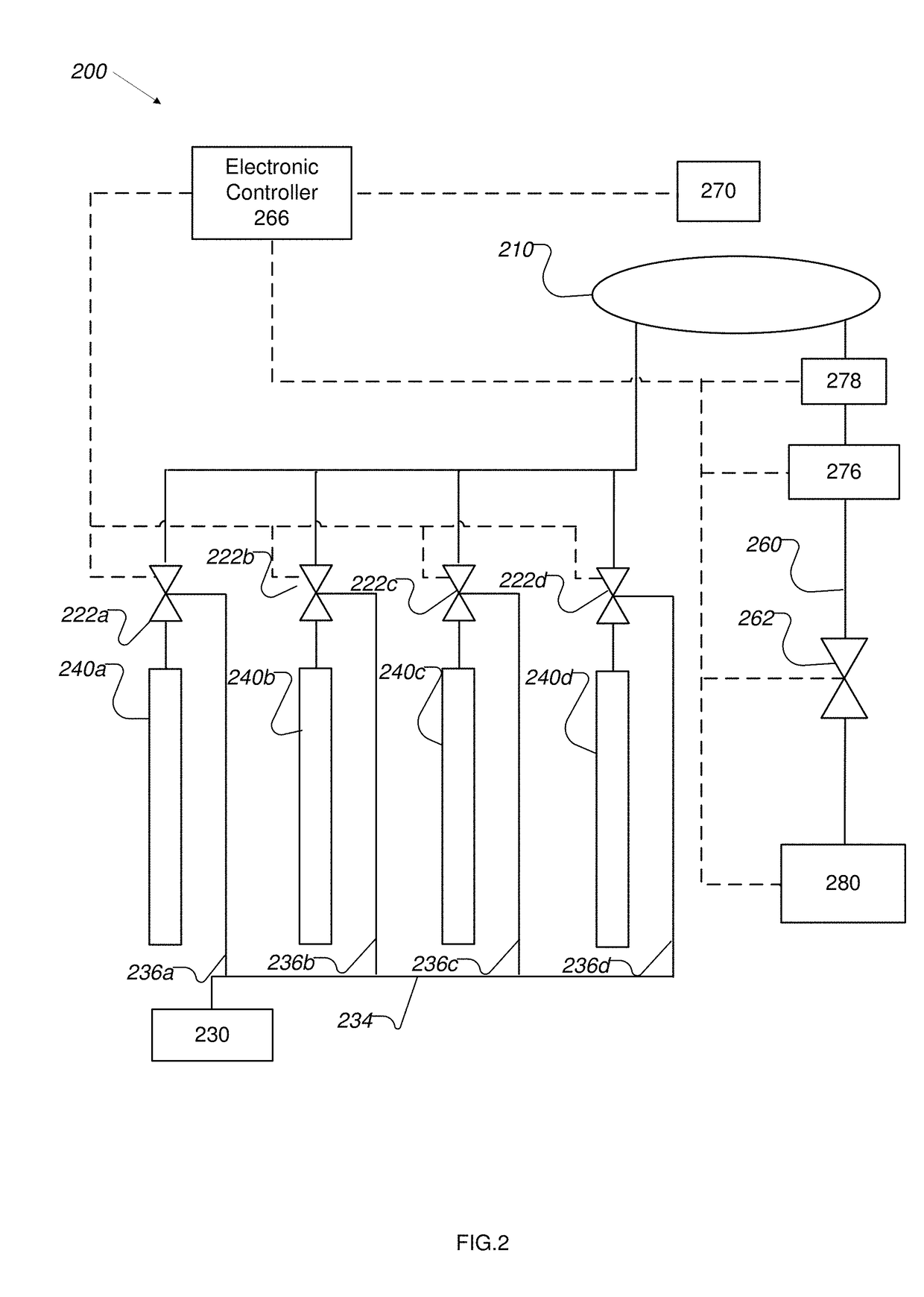

Atomic Layer Deposition (ALD) is used for heteroepitaxial film growth at reaction temperatures ranging from 80-400° C. The substrate and film materials are preferably selected to take advantage of Domain Matched Epitaxy (DME). A laser annealing system is used to thermally anneal deposition layers after deposition by ALD. In preferred embodiments a silicon substrate is overlaid with an AIN nucleation layer and laser annealed. Thereafter a GaN device layers is applied over the AIN layer by an ALD process and then laser annealed. In a further example embodiment a transition layer is applied between the GaN device layer and the AIN nucleation layer. The transition layer comprises one or more different transition material layers each comprising a AlxGa1-x compound wherein the composition of the transition layer is continuously varied from AIN to GaN.

Owner:VEECO INSTR

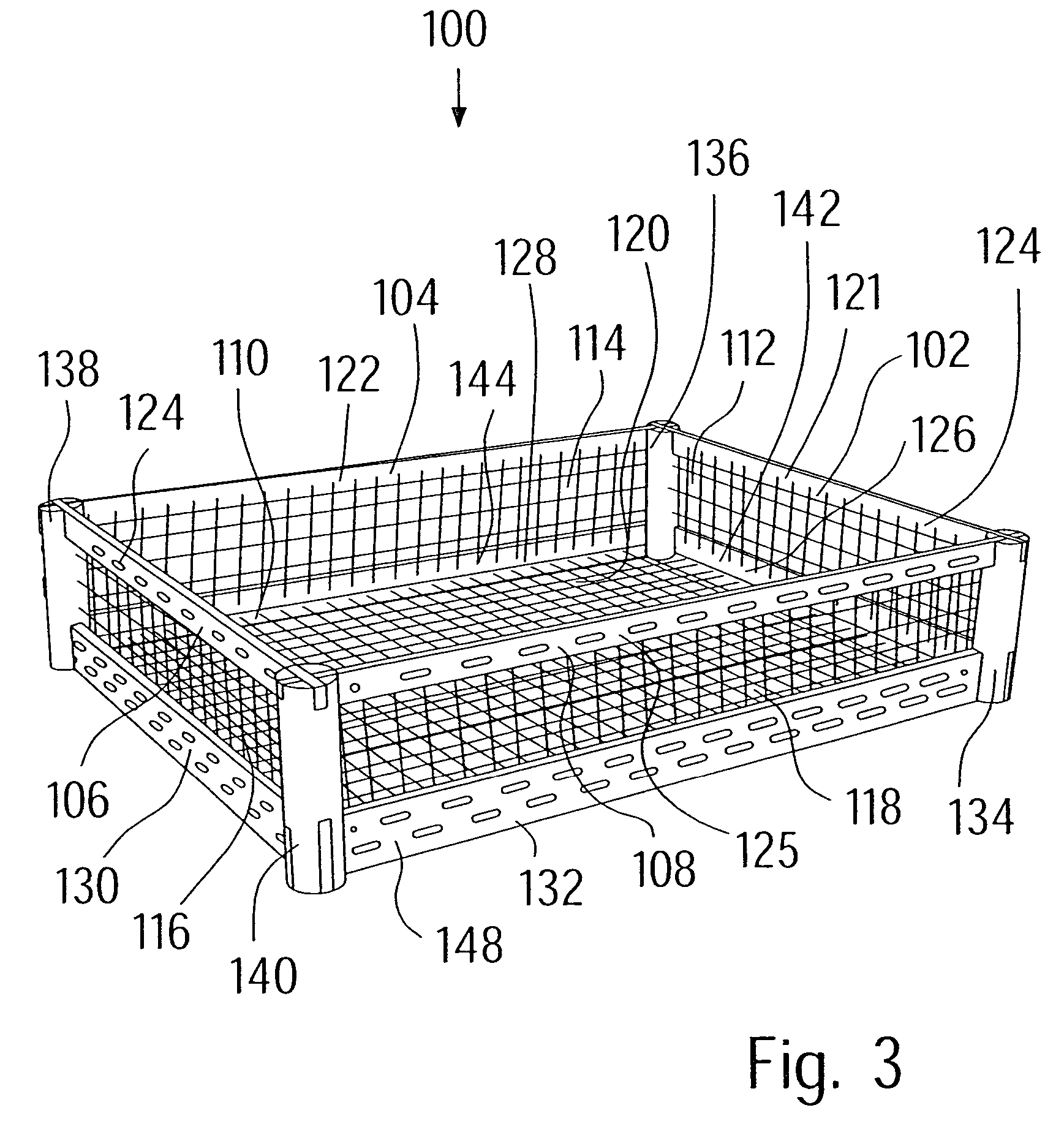

Support for structural components and method for producing the same

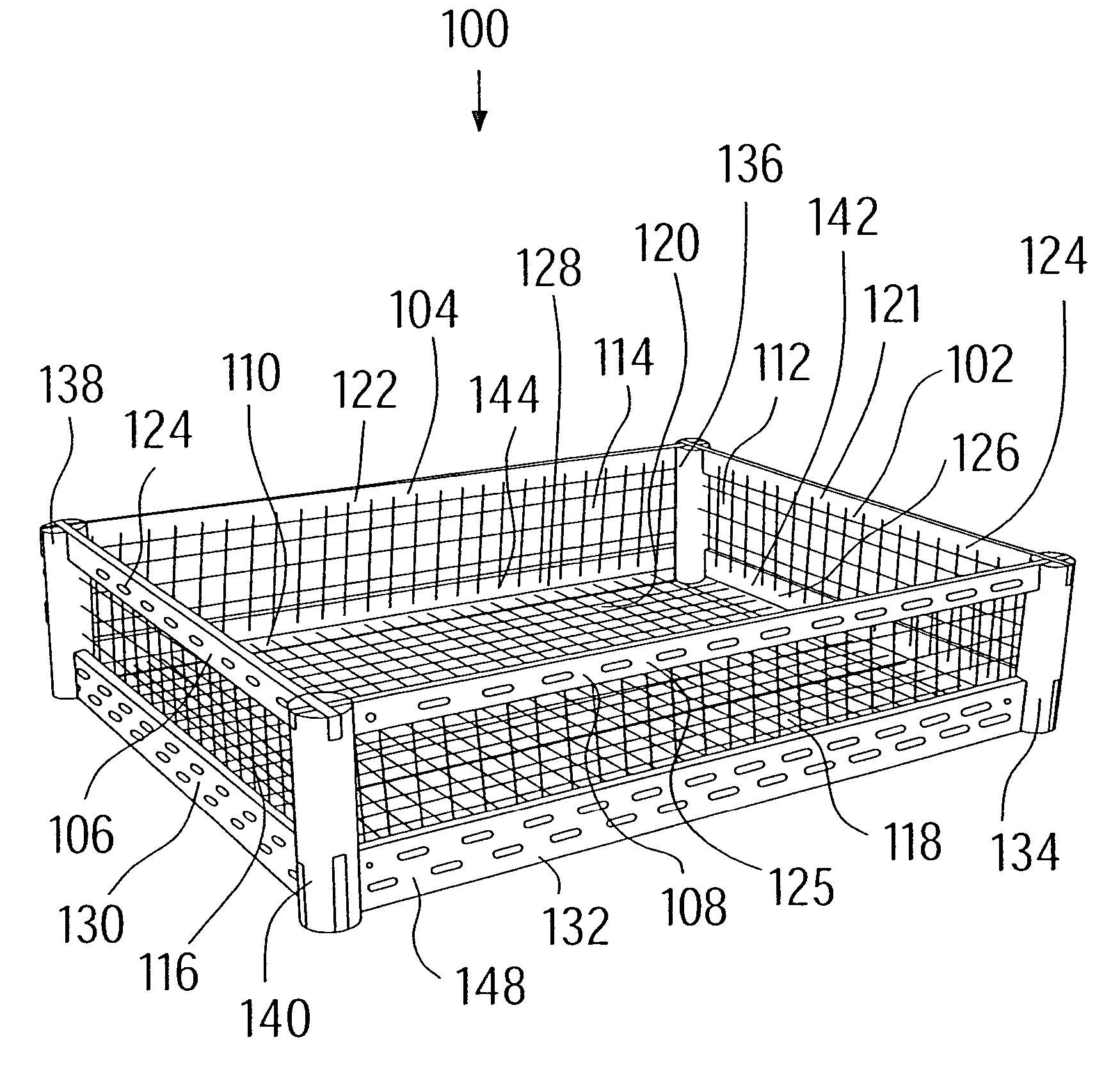

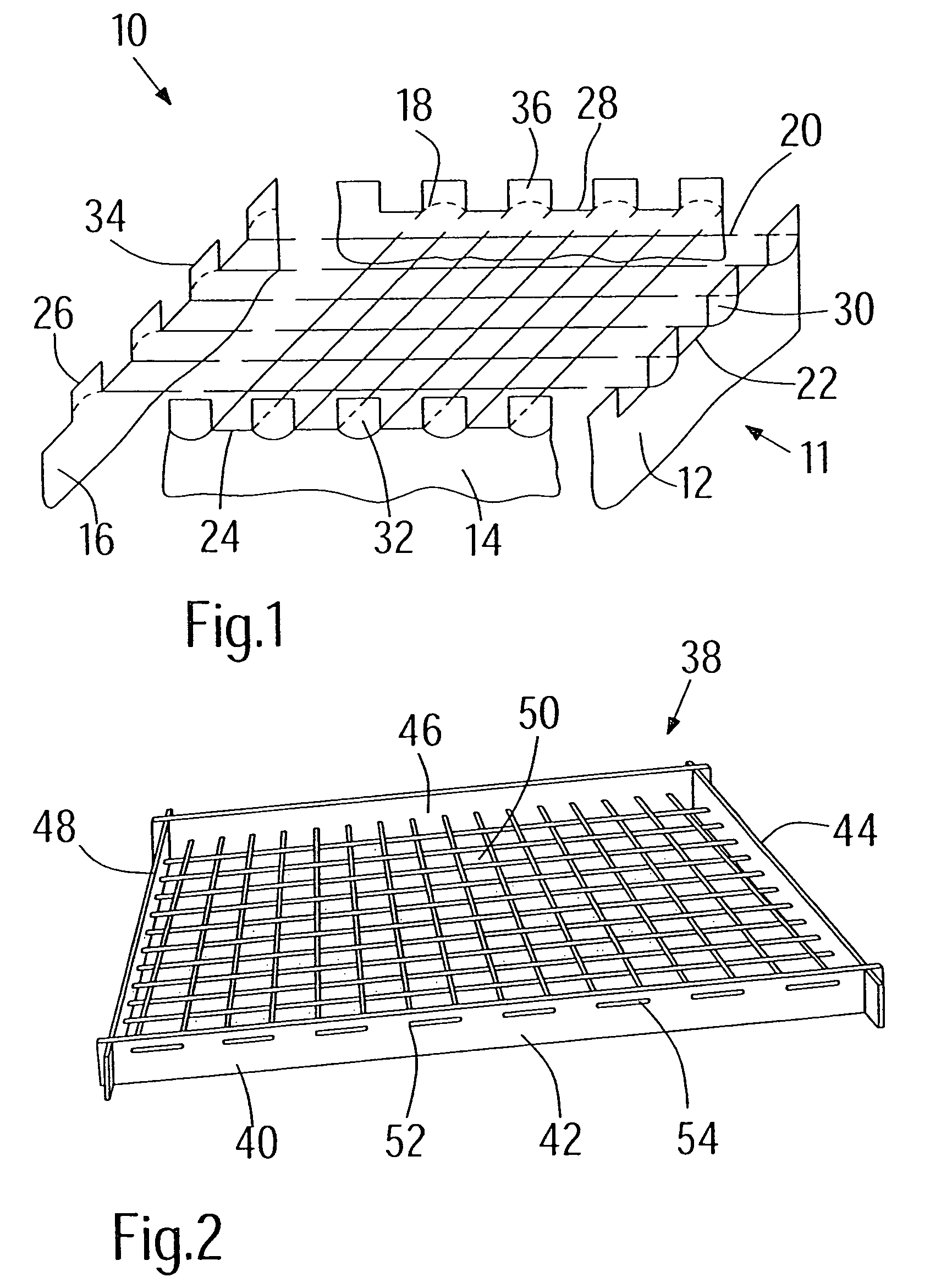

A support for structural components that are subjected to a thermal treatment process. The support includes a frame having limbs and extending therefrom a grid of intersecting strands. In order to prevent the support from warping even when subjected to strong thermal loads or variations in temperature, the frame is produced from a temperature-resistant material and the strands are produced from carbon fibers or ceramic fibers that form the grid, extending from the limbs of the frame.

Owner:SCHUNK KOHLENSTEOFFTECHNIK GMBH

Method and apparatus for forming device quality gallium nitride layers on silicon substrates

InactiveUS20170213718A1Improved lattice structurePolycrystalline material growthSemiconductor/solid-state device manufacturingReaction temperatureNucleation

Atomic Layer Deposition (ALD) is used for heteroepitaxial film growth at reaction temperatures ranging from 80-400° C. The substrate and film materials are preferably matched to take advantage of Domain Matched Epitaxy (DME). A laser annealing system is used to thermally anneal deposition layer after deposition by ALD. In preferred embodiments, a silicon substrate is overlaid with an AlN nucleation layer and laser annealed. Thereafter a GaN device layer is applied over the AlN layer by an ALD process and then laser annealed. In a further example embodiment, a transition layer is applied between the GaN device layer and the AlN nucleation layer. The transition layer comprises one or more different transition material layers each comprising a AlxGa1-xN compound wherein the composition of the transition layer is continuously varied from AlN to GaN.

Owner:VEECO INSTR

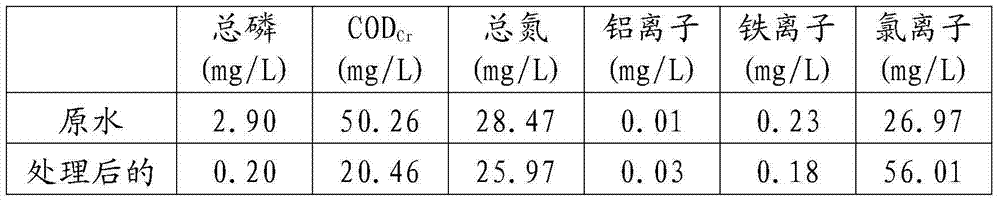

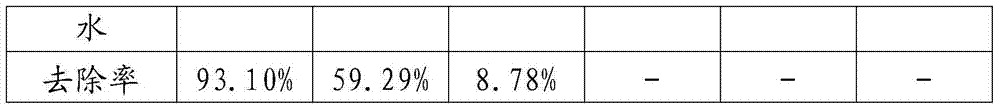

Preparation method of ecological security flocculating agent for effectively removing phosphorus and algae in eutrophic water body

ActiveCN104773804APromote destabilizationImprove removal efficiencyWater/sewage treatment by flocculation/precipitationPhylum CyanobacteriaAluminium chlorohydrate

The invention relates to a preparation method of an ecological security flocculating agent for effectively removing phosphorus and algae in a eutrophic water body. The preparation method comprises the following steps of preparing materials, uniformly mixing original clay with water to obtain clay suspension, adjusting the basicity to 50-90% by dropping dilute acid into the clay suspension, uniformly mixing aluminium polychlorid powder with water to prepare aluminium polychlorid solution, adjusting the basicity to 50-90% by dropping dilute acid or dilute alkali into the aluminium polychlorid solution, pouring the aluminium polychlorid solution into the clay suspension, standing and curing at 50-80 DEG C to obtain curing solution, drying the curing solution at 50-80 DEG C, and crushing and sieving to obtain the flocculating agent. According to the invention, the removal rate of total phosphorus is 93% or more; the removal rate of CODCr is 53% or more; the removal rate of total nitrogen is also above 3%; the removal rate of water-blooming cyanobacteria is 96% or more; the removal rate of algal toxin MC-LR is 7% or more; and the risk in rapidly releasing algal toxin is not caused.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

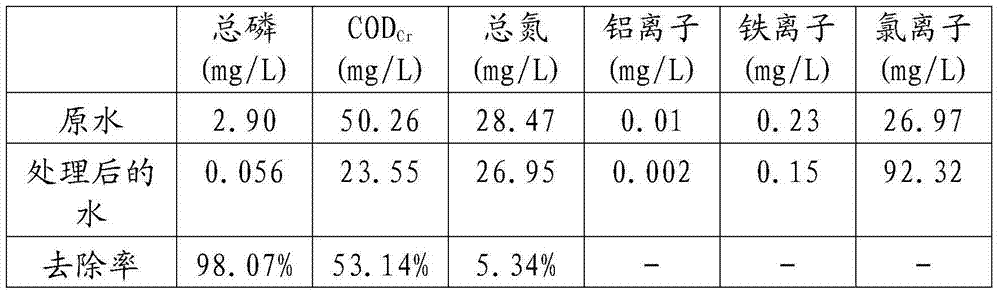

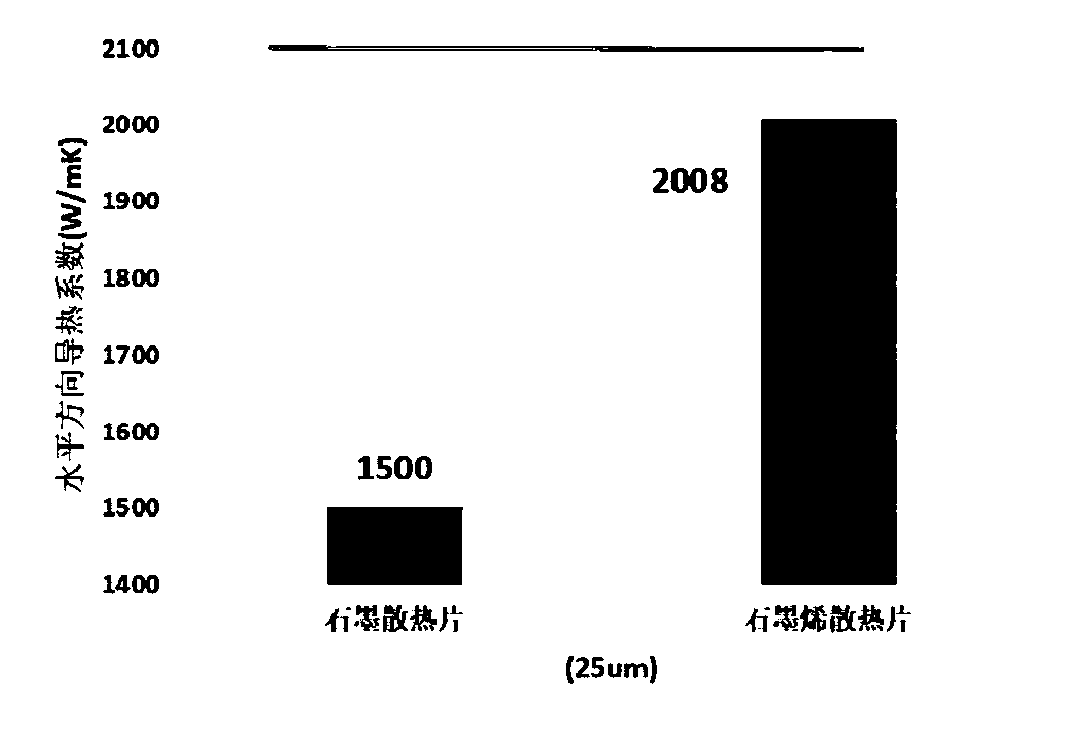

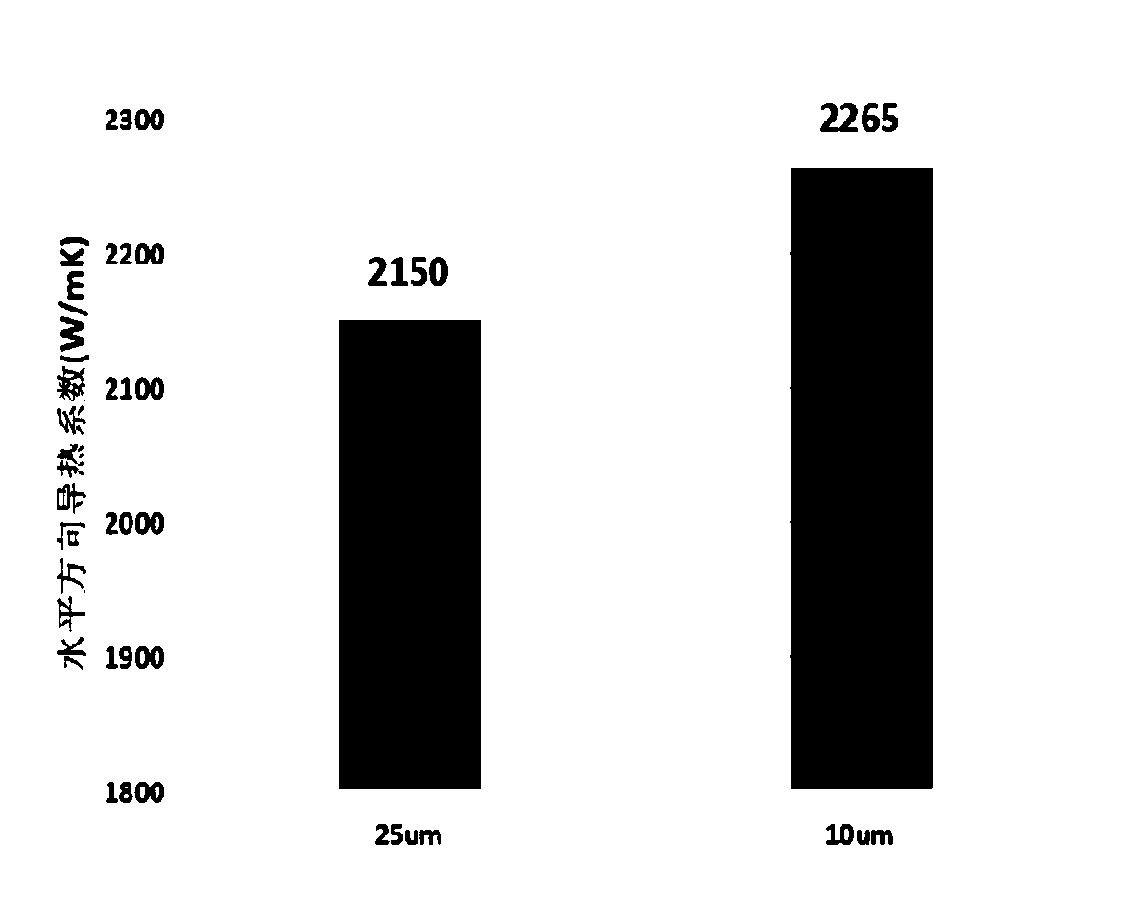

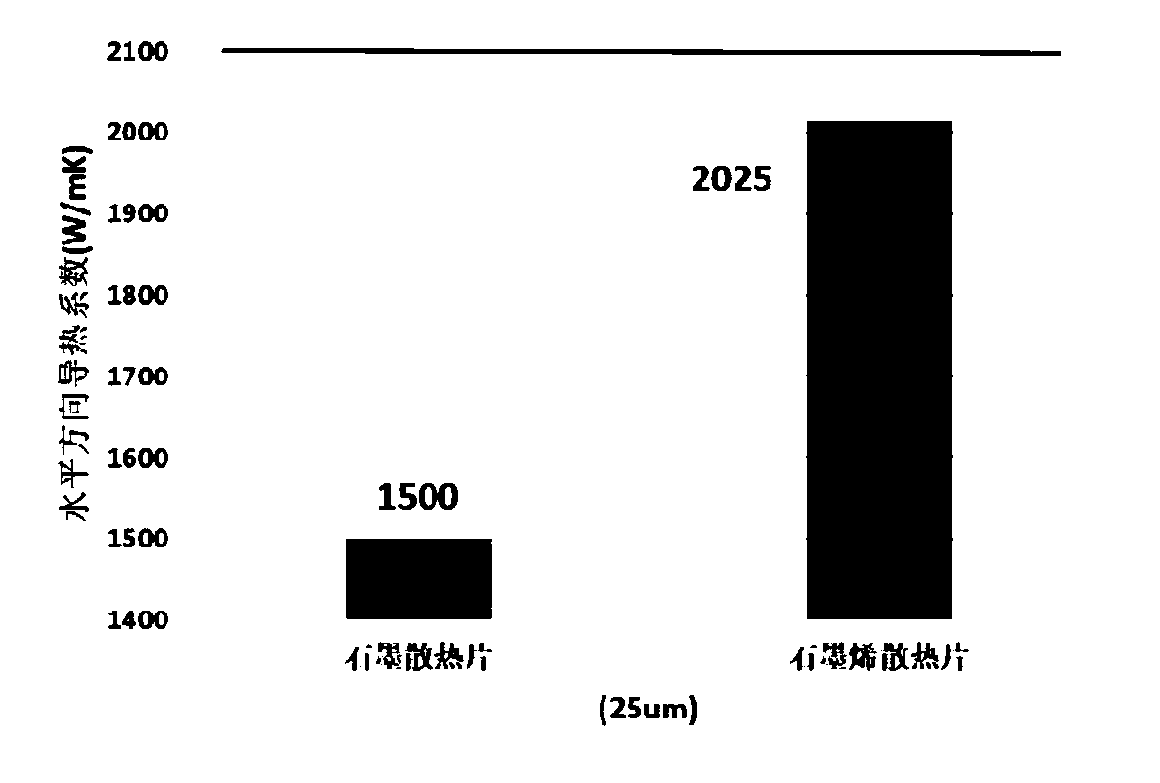

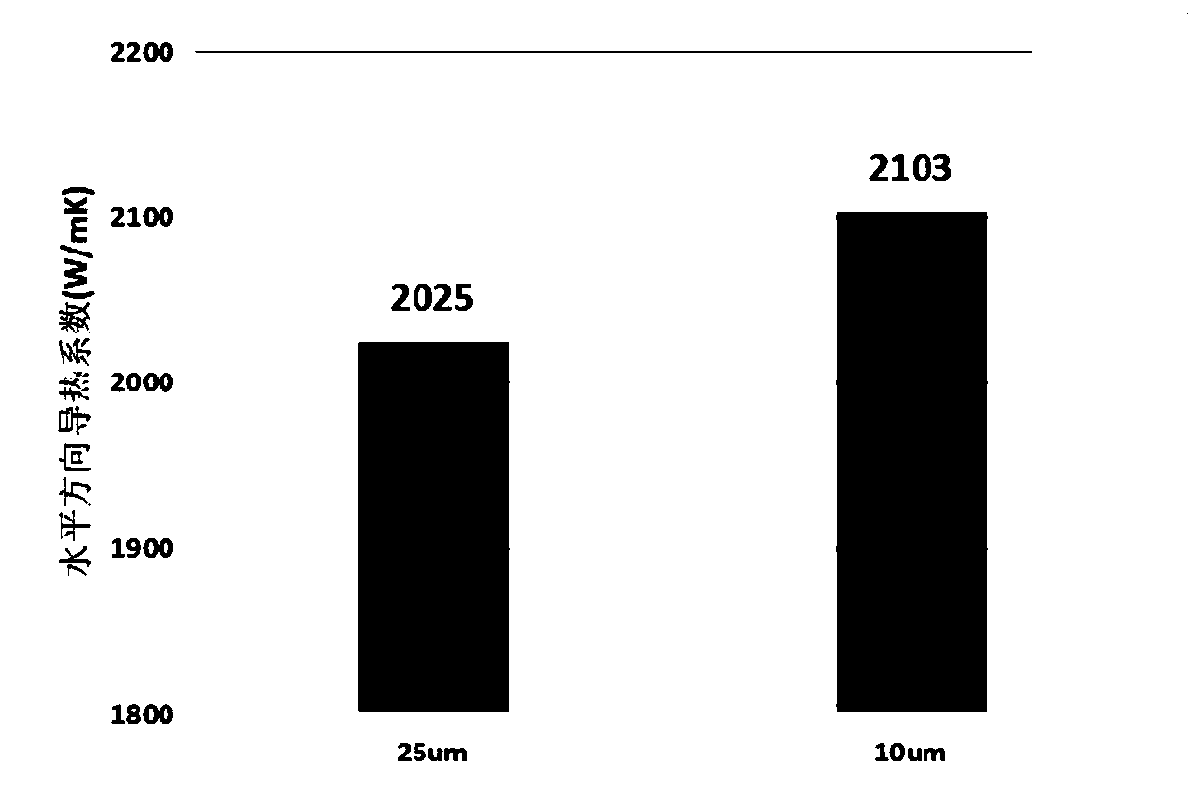

Method for preparing high-thermal-conductivity graphene radiating fin

ActiveCN110182793ALower interface thermal resistanceImproved lattice structureGrapheneModifications by conduction heat transferCvd grapheneIon

The invention discloses a method for preparing a graphene radiating fin, comprising the steps: adding graphite oxide to deionized water, adding a dispersing agent, and performing stirring, shaking orultrasonicizing to prepare an aqueous graphene oxide solution; placing a polyimide film in a carbonization furnace, introducing an inert gas, and then performing carbonization treatment; coating the carbonized polyimide film with the aqueous graphene oxide solution to obtain a graphene oxide-polyimide film; placing the graphene oxide-polyimide film in a graphitization furnace, introducing an inertgas, and then performing graphitization treatment; and rolling the the film obtained by the graphitization treatment to obtain a graphene radiating fin. According to the invention, a graphene radiating fin with excellent heat dissipation performance can be prepared by adopting a technology of combining graphene oxide with a carbonized polyimide film, the process is easy to control, and the purityis high.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

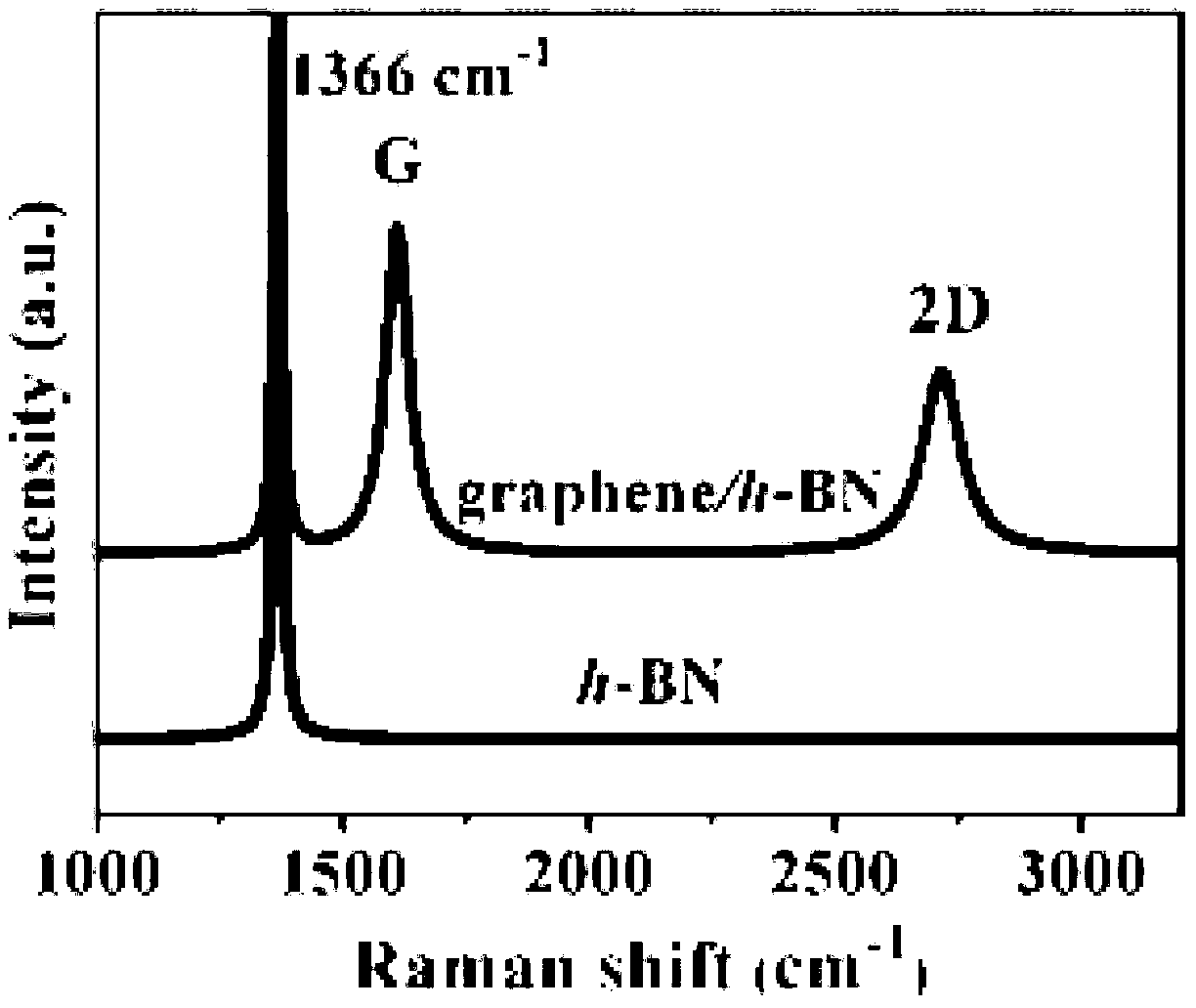

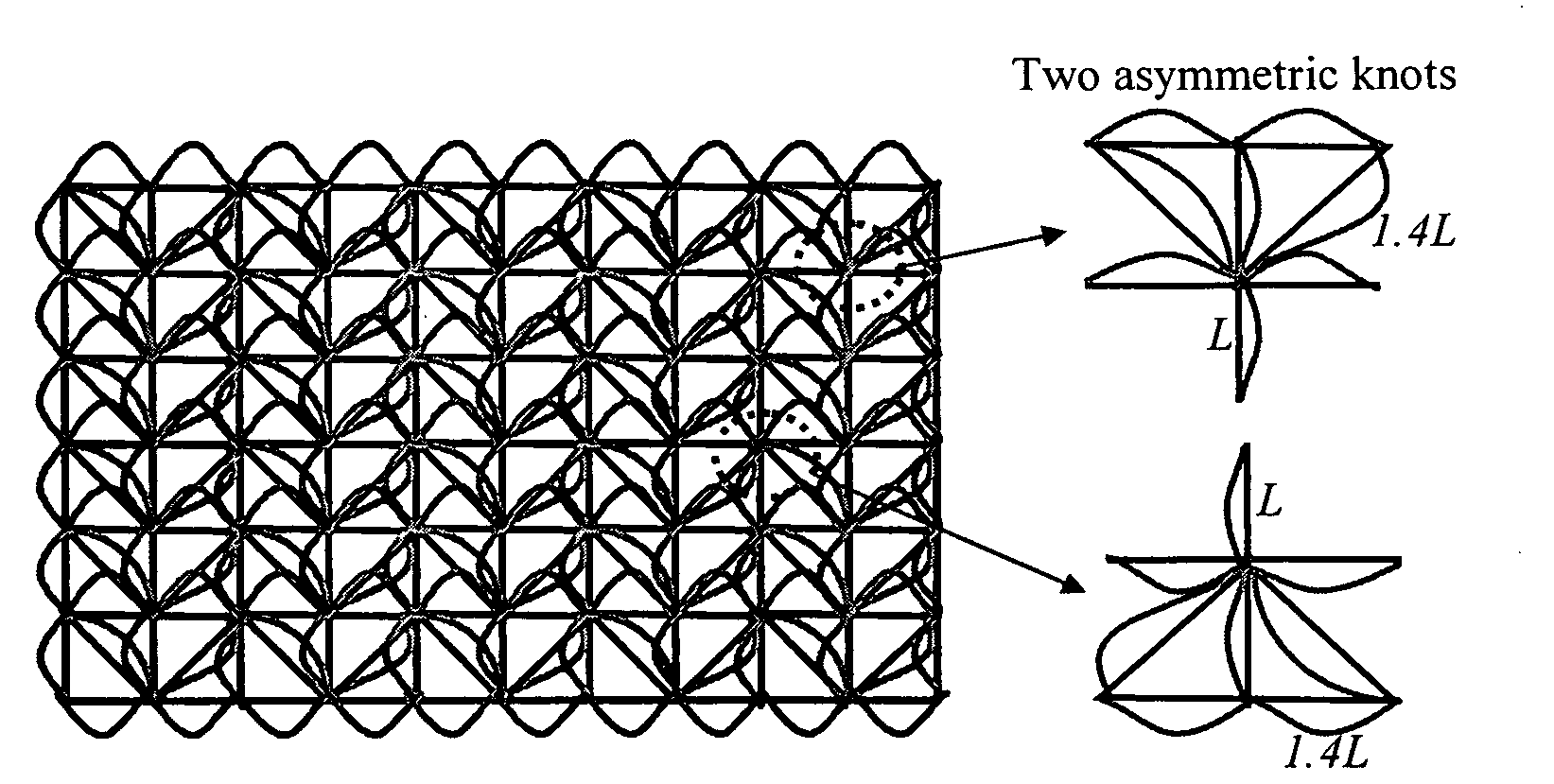

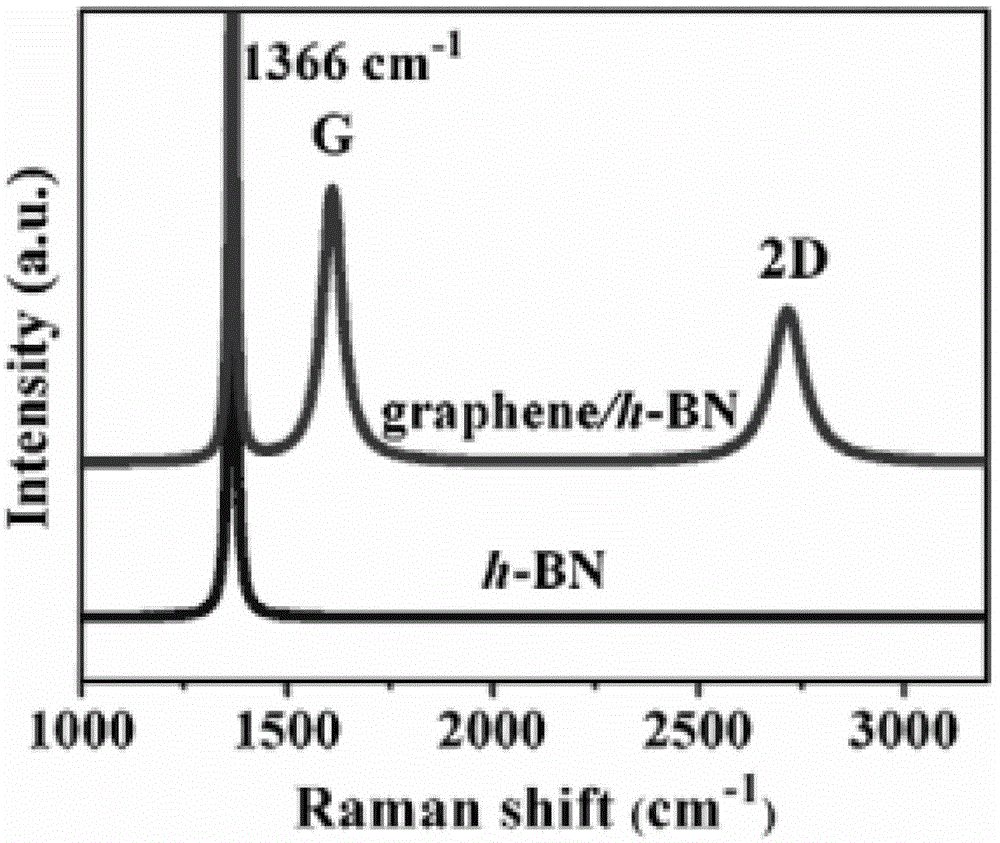

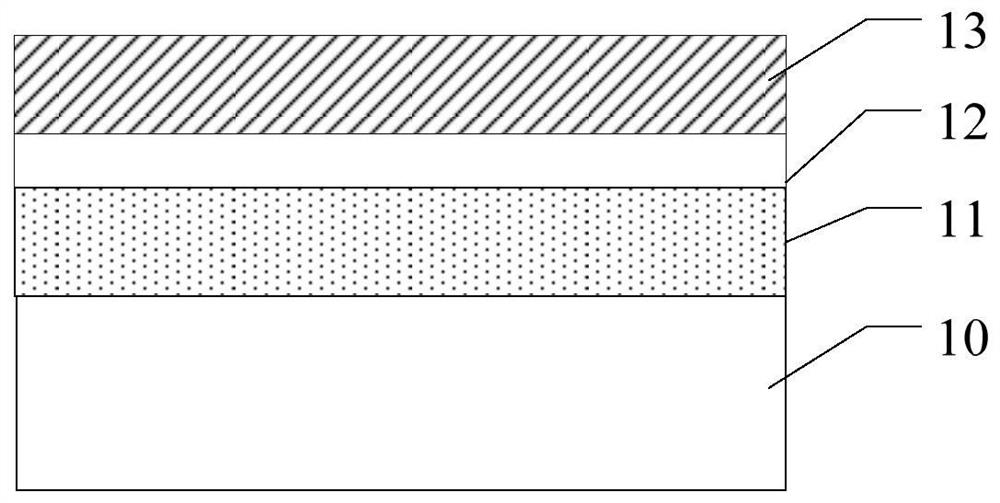

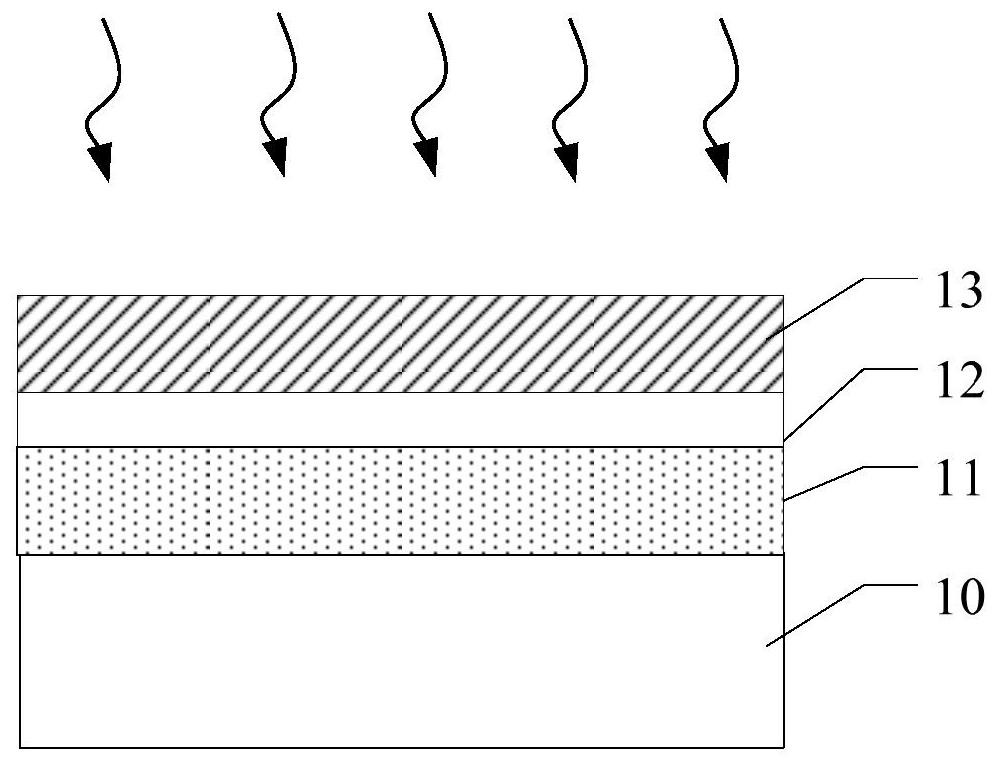

Large-size graphene stack structure wafer and preparation method thereof

InactiveCN103227194AImproved lattice structurePreserve ultra-high mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesHexagonal boron nitrideCharge carrier

The invention discloses a large-size graphene stack structure wafer which is characterized in that a wafer structure comprises a graphene single crystal layer, an h-BN (hexagonal boron nitride) single crystal layer, an h-BN buffer layer and SiO2 / Si wafer substrates from the top down sequentially. The wafer and the preparation method have the benefits that the wafer can be compatible with a production technique of the available silicon substrate semiconductor device sufficiently, and can take full advantage of the characteristic of a hexagonal boron nitride substrate material; growing graphene has a most perfect crystal structure and a carrier transport environment with the weakest scattering; the super-high mobility of carriers in graphene is kept at the utmost; and the performance of a graphene substrate electronic device is improved greatly.

Owner:XIDIAN UNIV

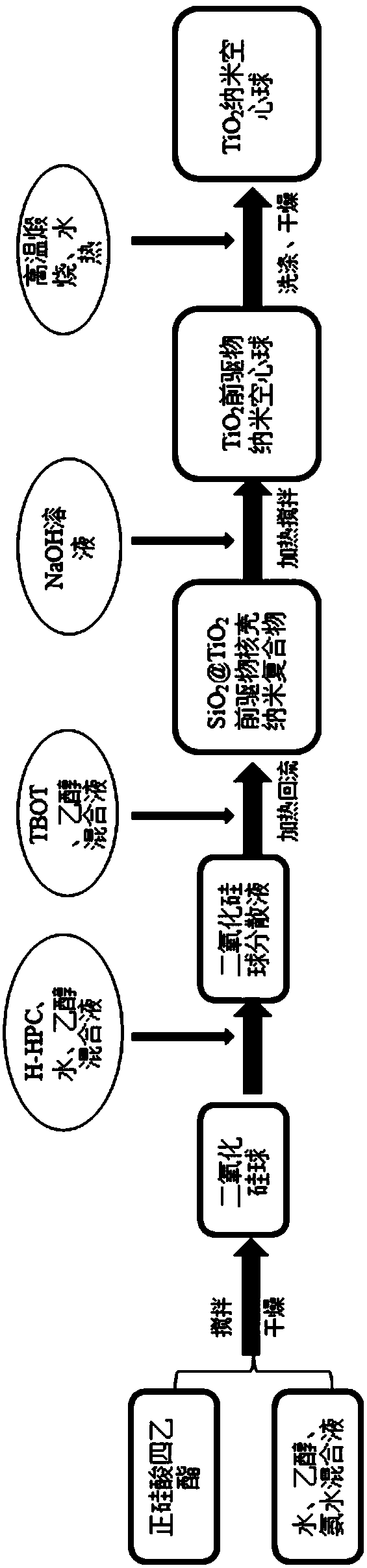

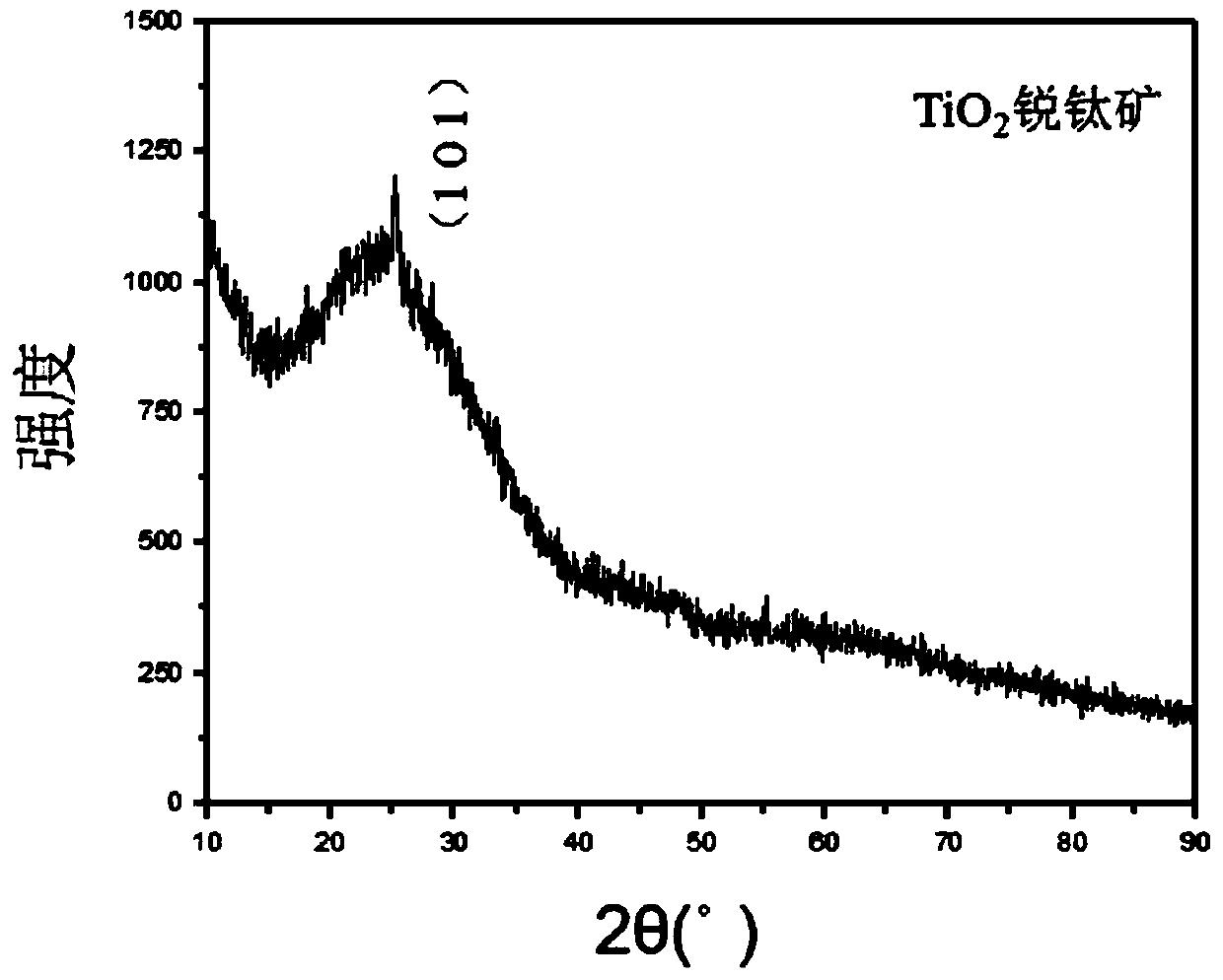

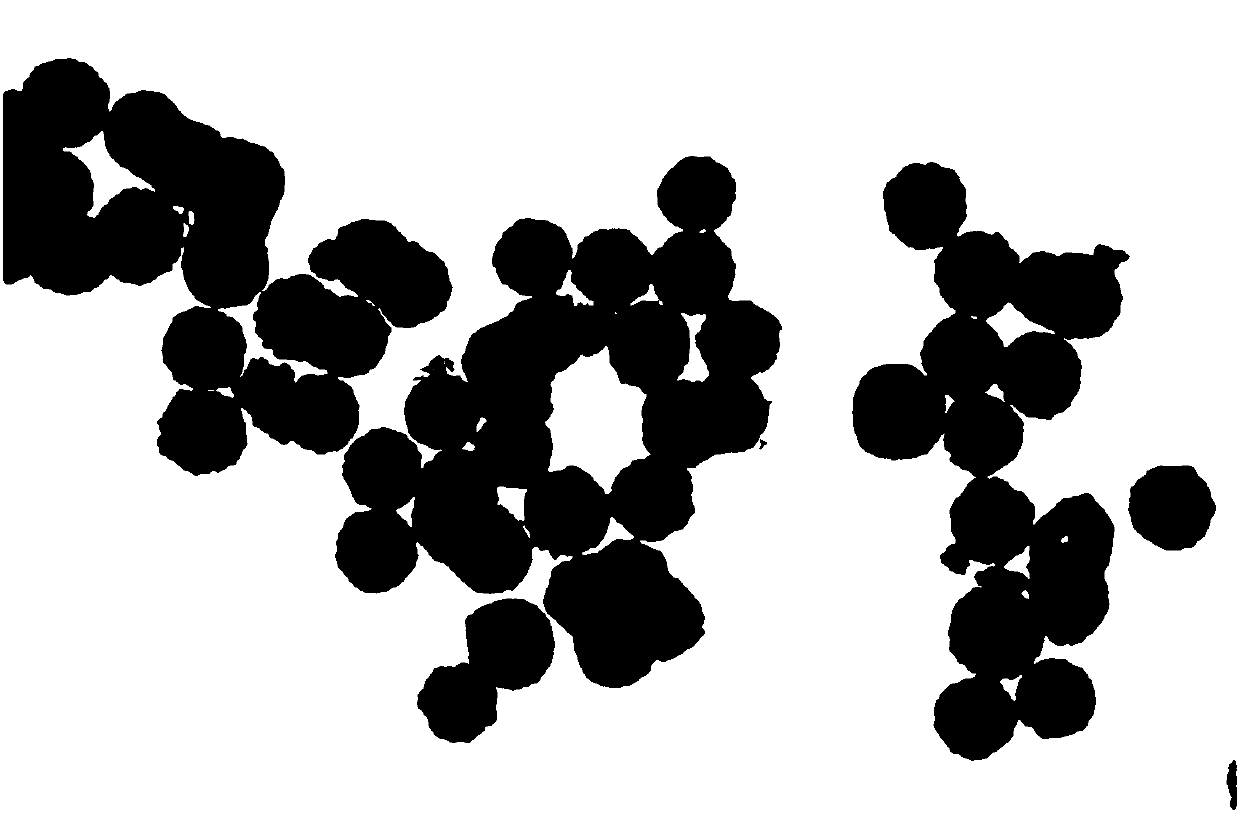

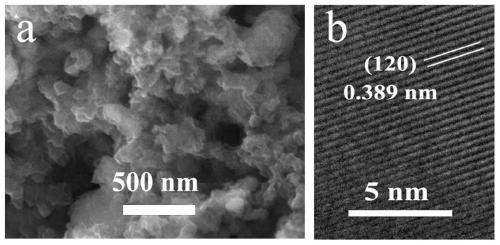

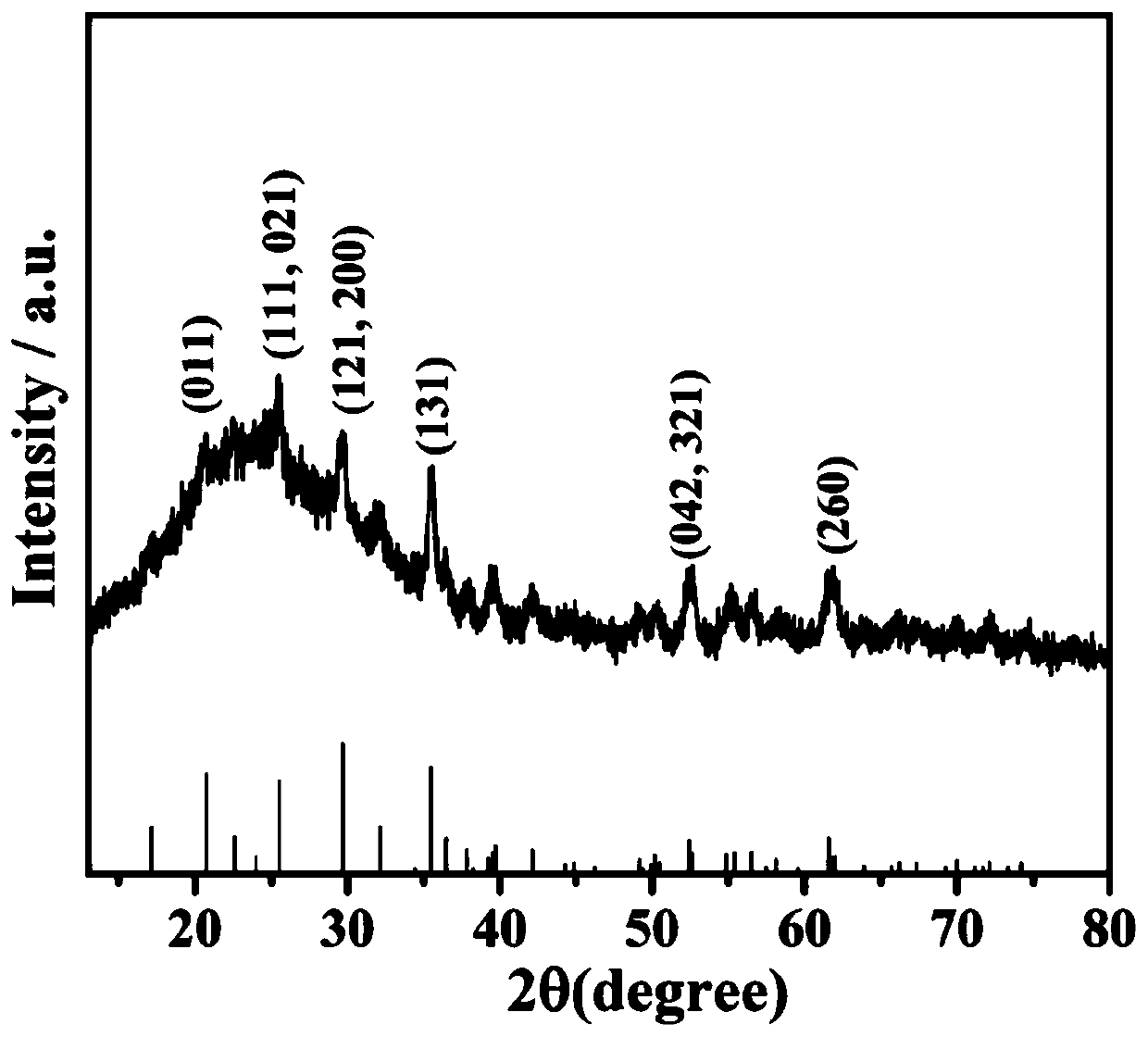

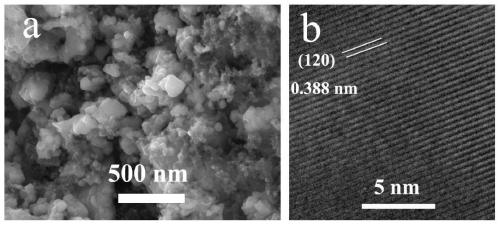

Titanium dioxide hollow nanospheres and preparation method thereof

InactiveCN108675345AGrowth inhibitionInhibition of coagulationSilicaPhysical/chemical process catalystsMicrosphereSilicon dioxide

The invention discloses a preparation method of titanium dioxide hollow nanospheres. The preparation method comprises the following steps: firstly, taking tetraethyl orthosilicate as a silicon sourceand preparing silicon dioxide microspheres by adopting a Stobe method; then cladding the surfaces of the silicon dioxide microspheres with a titanium dioxide precursor; then removing a silicon dioxideinner core by adopting strong alkali corrosion; finally, carrying out calcination and hydrothermal treatment to prepare anatase form titanium dioxide hollow nanospheres. The invention further discloses the titanium dioxide hollow nanospheres prepared by the preparation method provided by the invention. The method disclosed by the invention is simple to operate, low in production cost, small in process pollution, high in product yield, good in repeatability and suitable for large-scale production. A titanium dioxide nano-product prepared by the method has the advantages of high purity, good crystallization, controllable crystal form, fine particle granularity, uniform particles, good monodispersity, small particle size, large specific surface area and high photocatalytic activity.

Owner:NORTHEASTERN UNIV

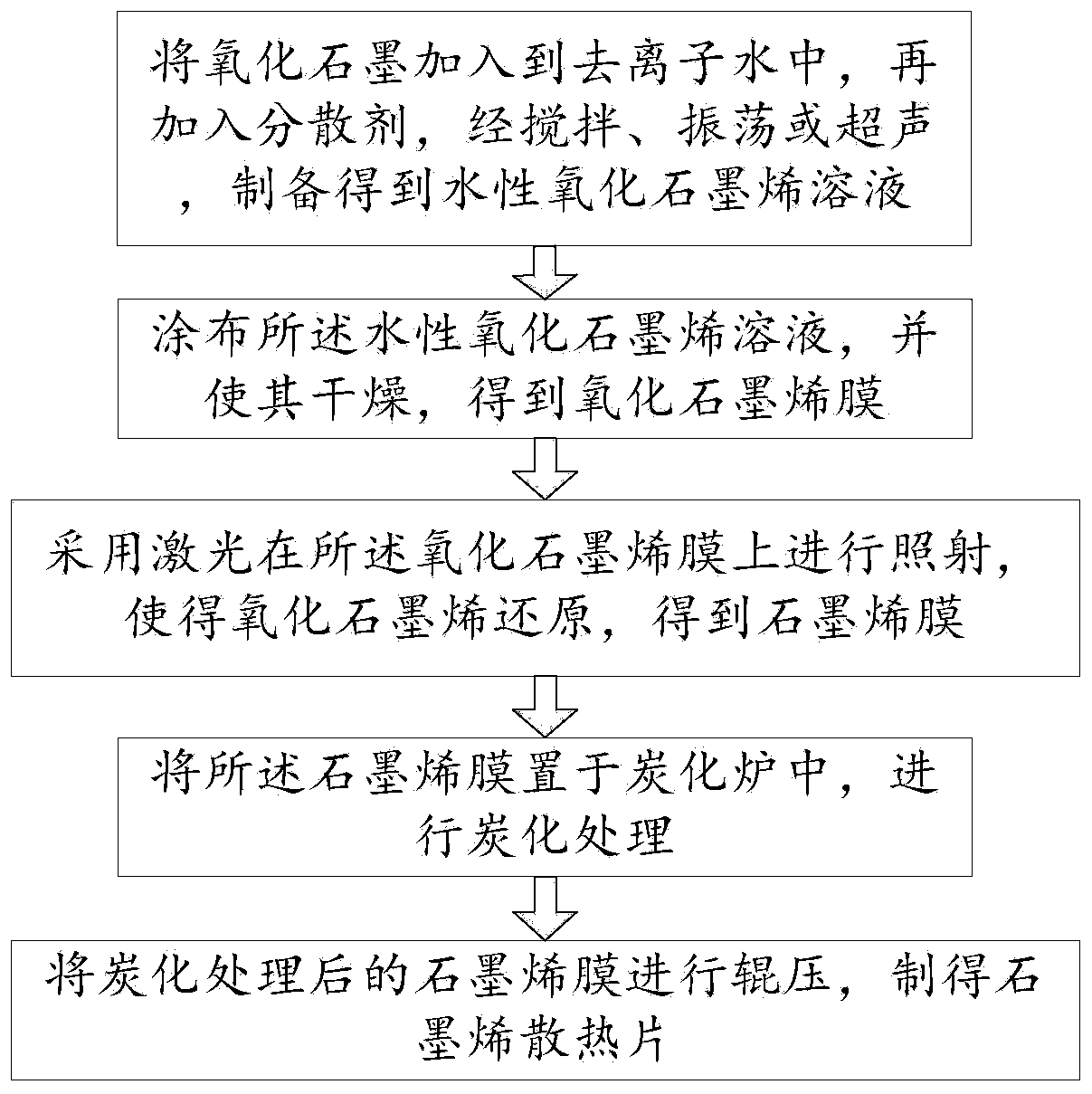

Preparation method of graphene heat dissipating fin

The invention discloses a preparation method of a graphene heat dissipating fin, which comprises the following steps: adding graphite oxide into deionized water, adding a dispersant, and preparing an aqueous graphene oxide solution by stirring, oscillating or ultrasonic wave; coating a substrate by the aqueous graphene oxide solution, drying the aqueous graphene oxide solution to obtain a graphene oxide film, and peeling the graphene oxide film off the substrate; irradiating the stripped graphene oxide film by laser to reduce graphene oxide to obtain a graphene film; placing the graphene film in a carbonization furnace for carbonization treatment; rolling the carbonized graphene film to obtain the graphene heat dissipating fin. The graphene heat dissipating fin having excellent heat dissipation performance can be prepared by reducing graphene oxide by laser and carbonizing the graphene oxide, and the process is easy to control and has high purity.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

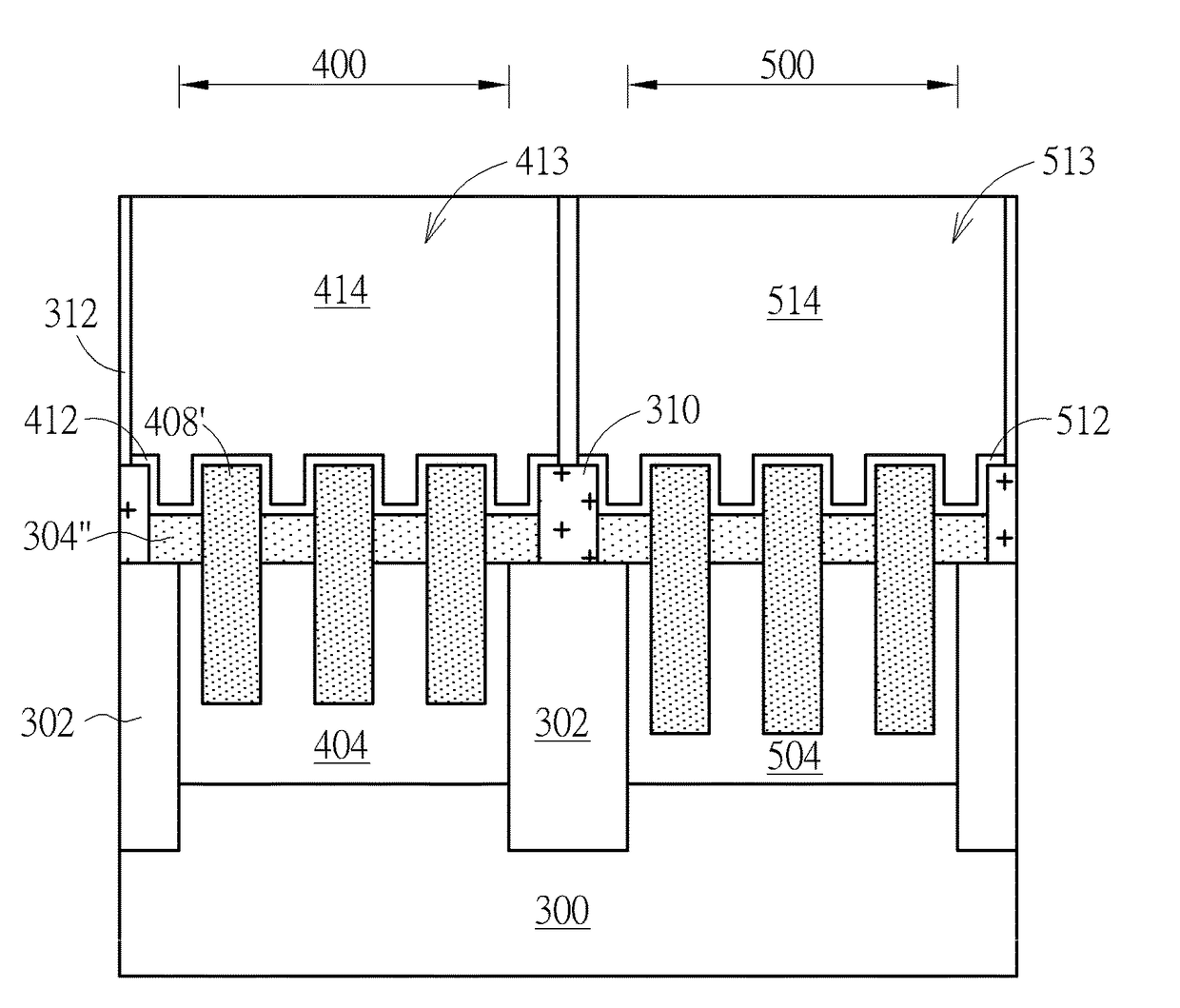

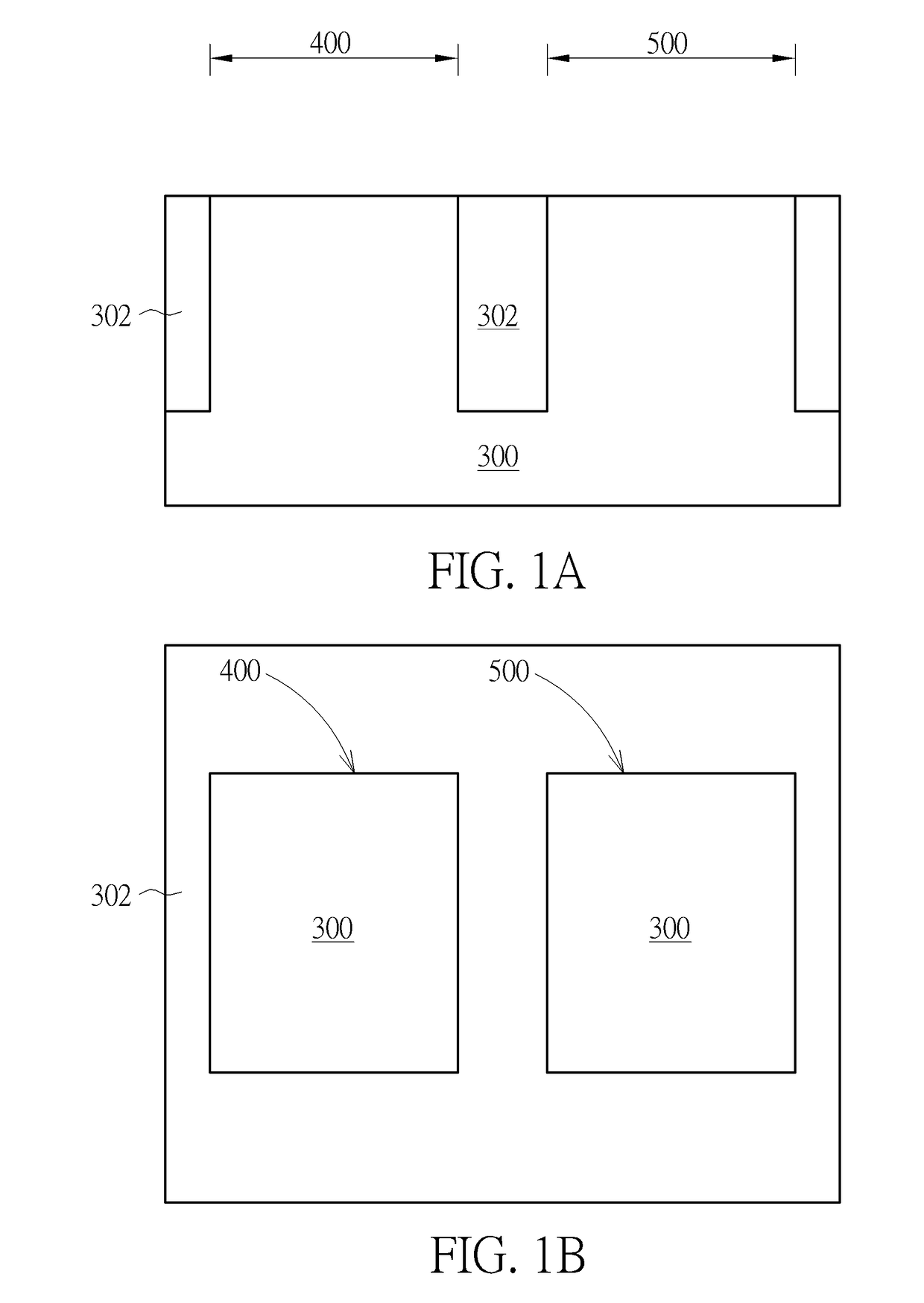

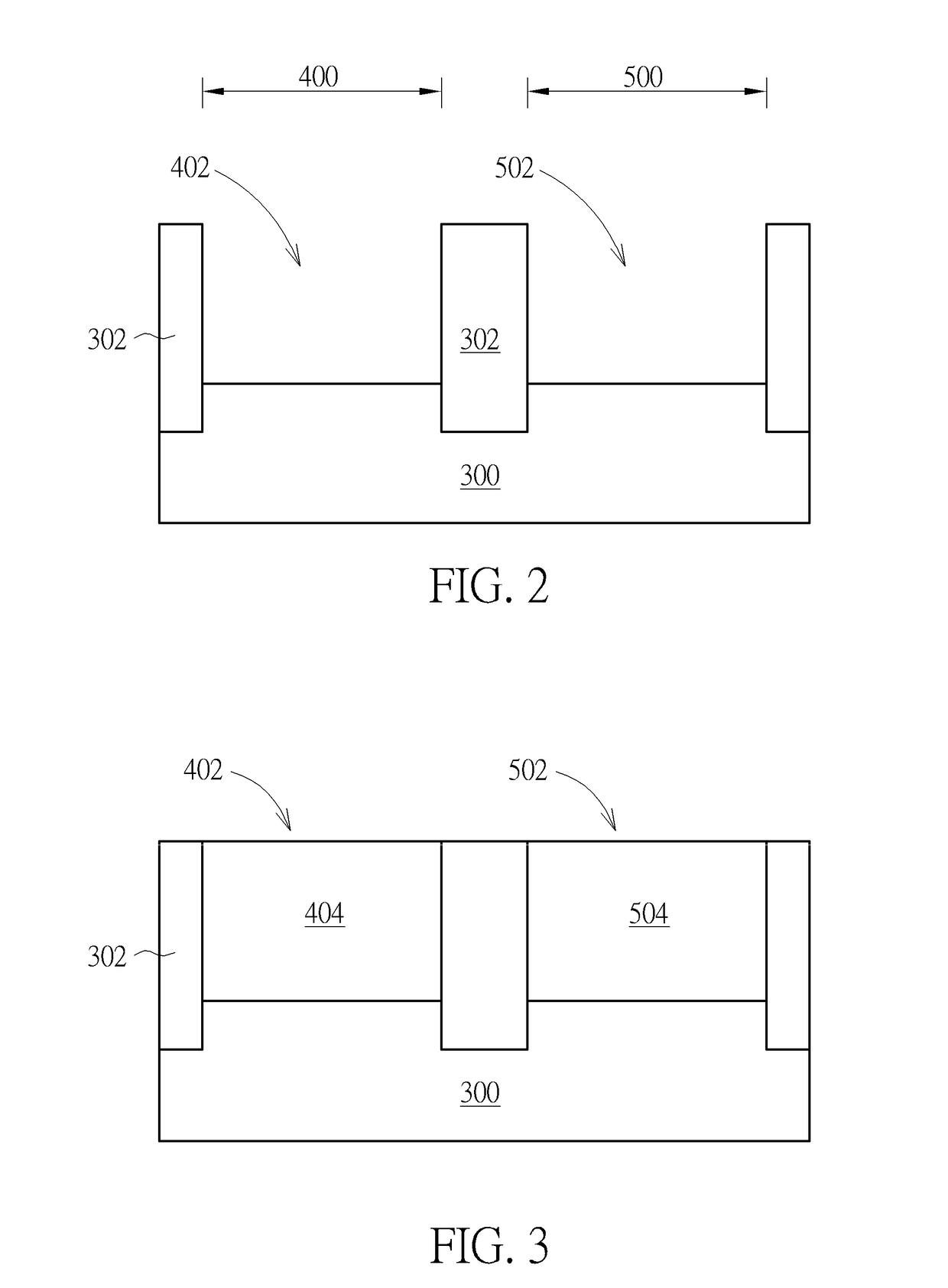

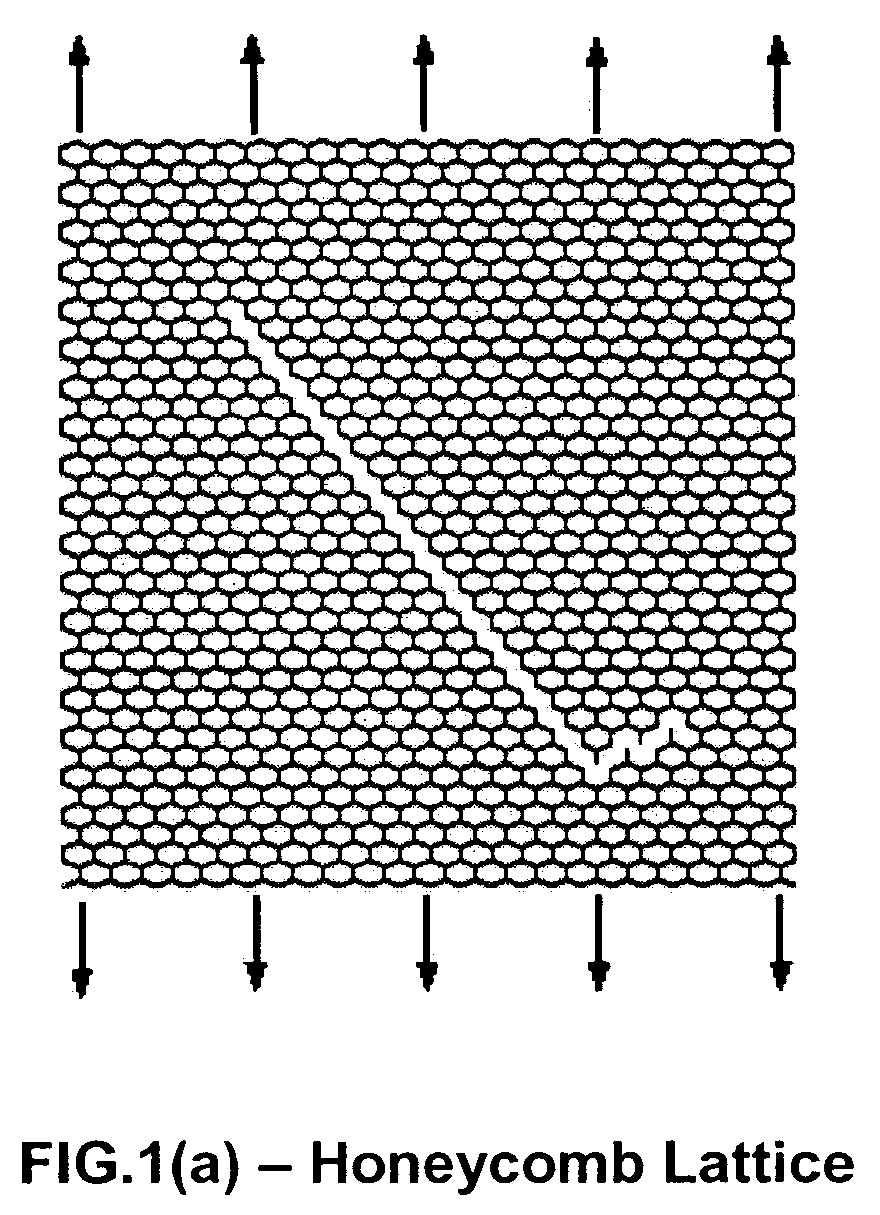

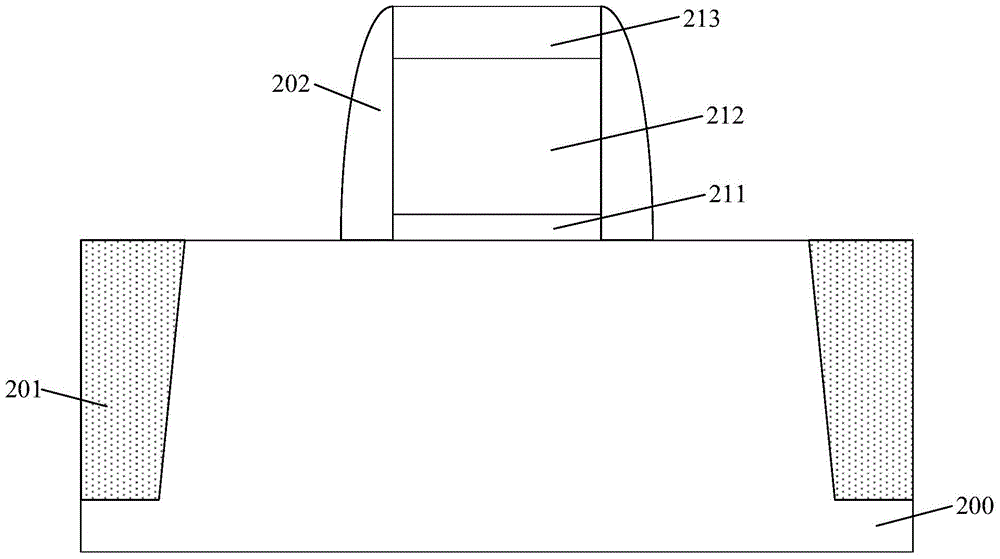

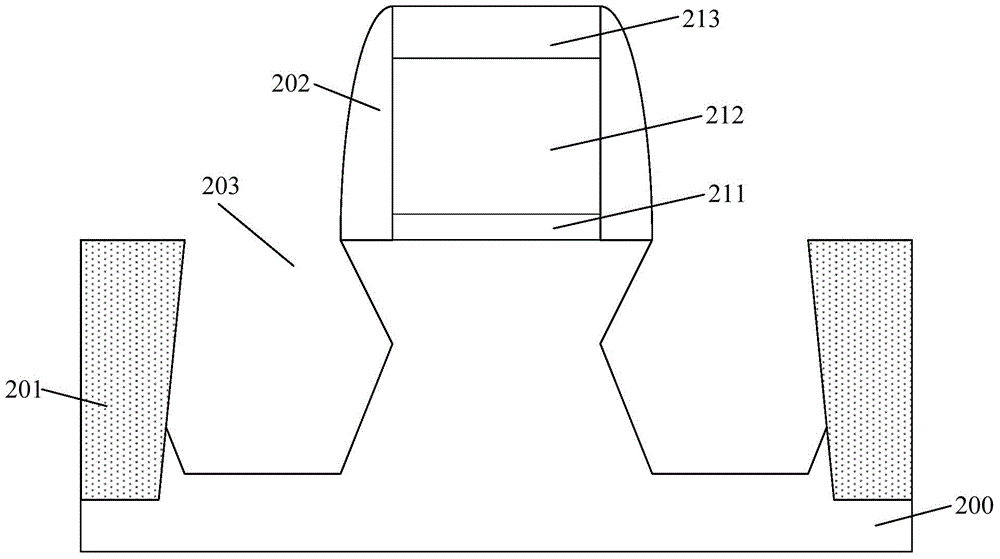

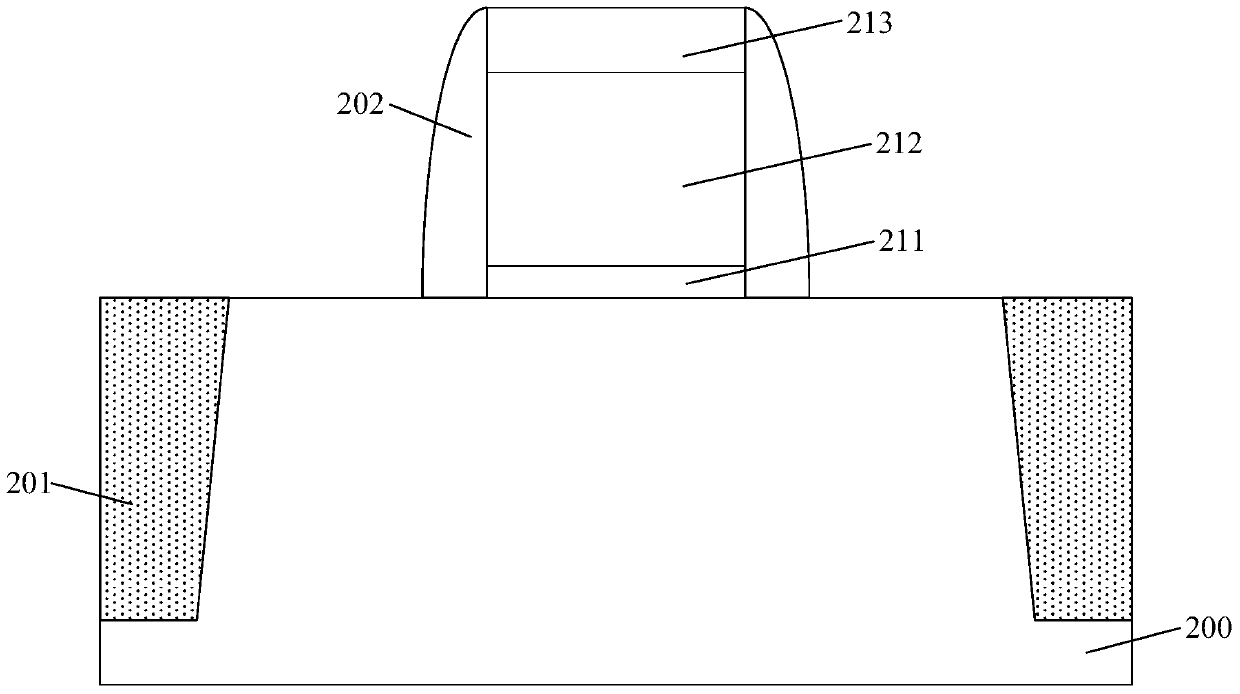

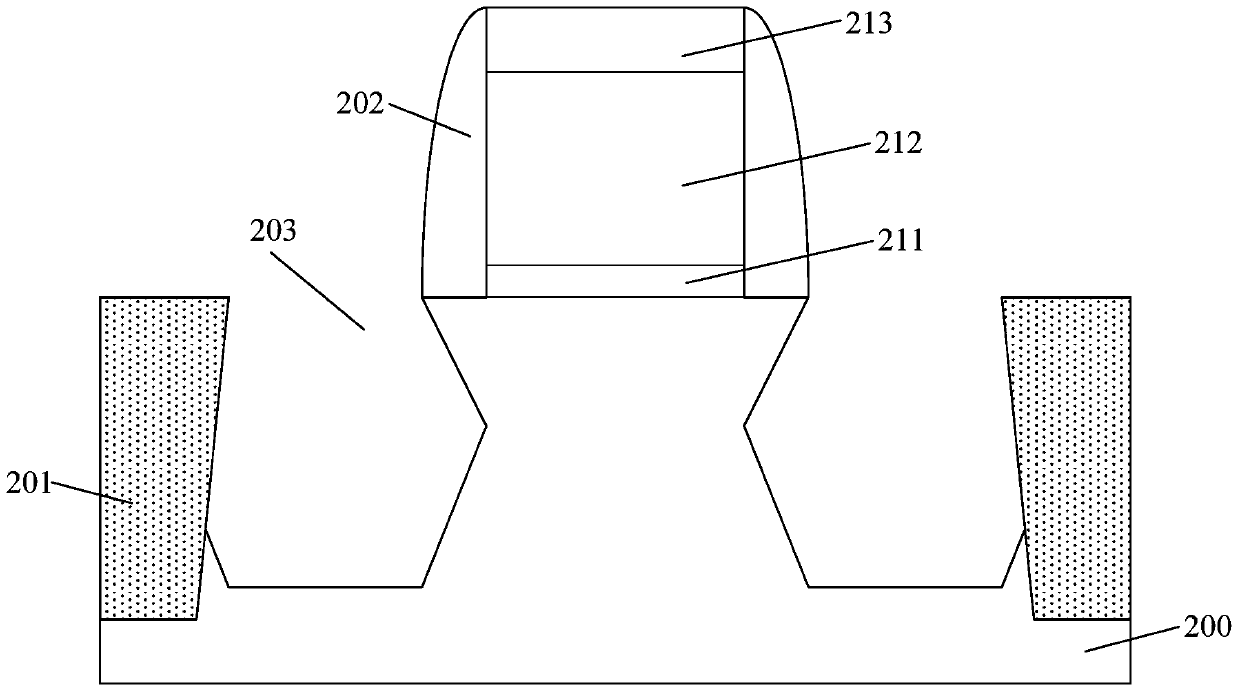

Method of forming semiconductor device

ActiveUS20180308933A1Improved lattice structureSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

The present invention provides a semiconductor device, including a substrate, a first semiconductor layer, a plurality of first sub recess, a plurality of insulation structures and a first top semiconductor layer. The substrate has a first region disposed within an STI. The first semiconductor layer is disposed in the first region. The first sub recesses are disposed in the first semiconductor layer. The insulation structures are disposed on the first semiconductor layer. The first top semiconductor layer forms a plurality of fin structures, which are embedded in the first sub recesses, arranged alternatively with the insulation structures and protruding over the insulation structures.

Owner:UNITED MICROELECTRONICS CORP

Porous titanium-tantalum-niobium-zirconium stent for bone defect repair

InactiveCN109621000AImproved lattice structureHigh strengthTissue regenerationProsthesisOsseointegrationNiobium

The invention discloses a porous titanium-tantalum-niobium-zirconium stent for bone defect repair. The porous titanium-tantalum-niobium-zirconium stent contains, by weight, 55%-65% of titanium, 1%-5%of tantalum, 30%-35% of niobium and 2%-6% of zirconium; the porous titanium-tantalum-niobium-zirconium stent has a regular porous structure, pores are completely communicated, the pores are 300-500 microns, and the porosity is 78.3 + / - 1.6%. The elastic modulus of the porous titanium-tantalum-niobium-zirconium stent is 2.27-18.96 GPa. The porous titanium-tantalum-niobium-zirconium stent has the effect of promoting bone defect repair. The regular porous structure and the completely communicated pores facilitate the growth of a new bone into a material, and a better osseointegration effect is obtained. The pores of 300-500 microns and the porosity of 78.3 + / - 1.6% promote cell adhesion, promote the healing of bone defects and the growth of bone tissues.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Reducing series resistance between source and/or drain regions and a channel region

ActiveUS20190097050A1Reduce series resistanceIncrease lattice structureTransistorSemiconductor/solid-state device manufacturingDopantElectrical and Electronics engineering

A method for reducing series resistance for transistors includes forming a conductive gate over and insulated from a semiconductor substrate, forming source and / or drain extension regions within the substrate and adjacent to respective source and / or drain regions, and forming source and / or drain regions within the substrate. The source and / or drain extension regions are formed from a material alloyed with a first dopant and a second dopant, the first dopant configured to increase a lattice structure of the material forming the source and / or drain extension regions.

Owner:IBM CORP

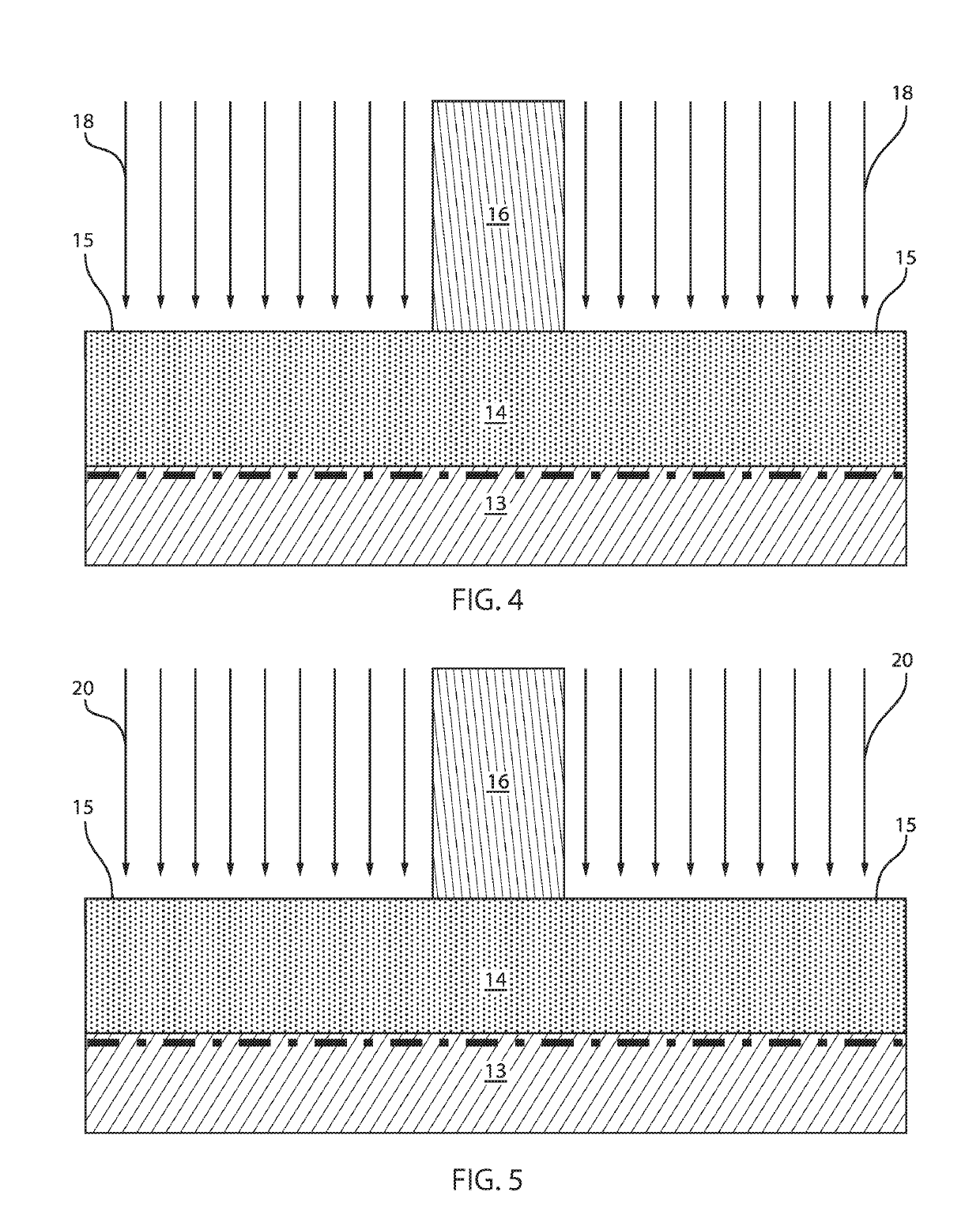

Bistable bond lattice structures for blast resistant armor appliques

Owner:THE UNIVERSITY OF AKRON

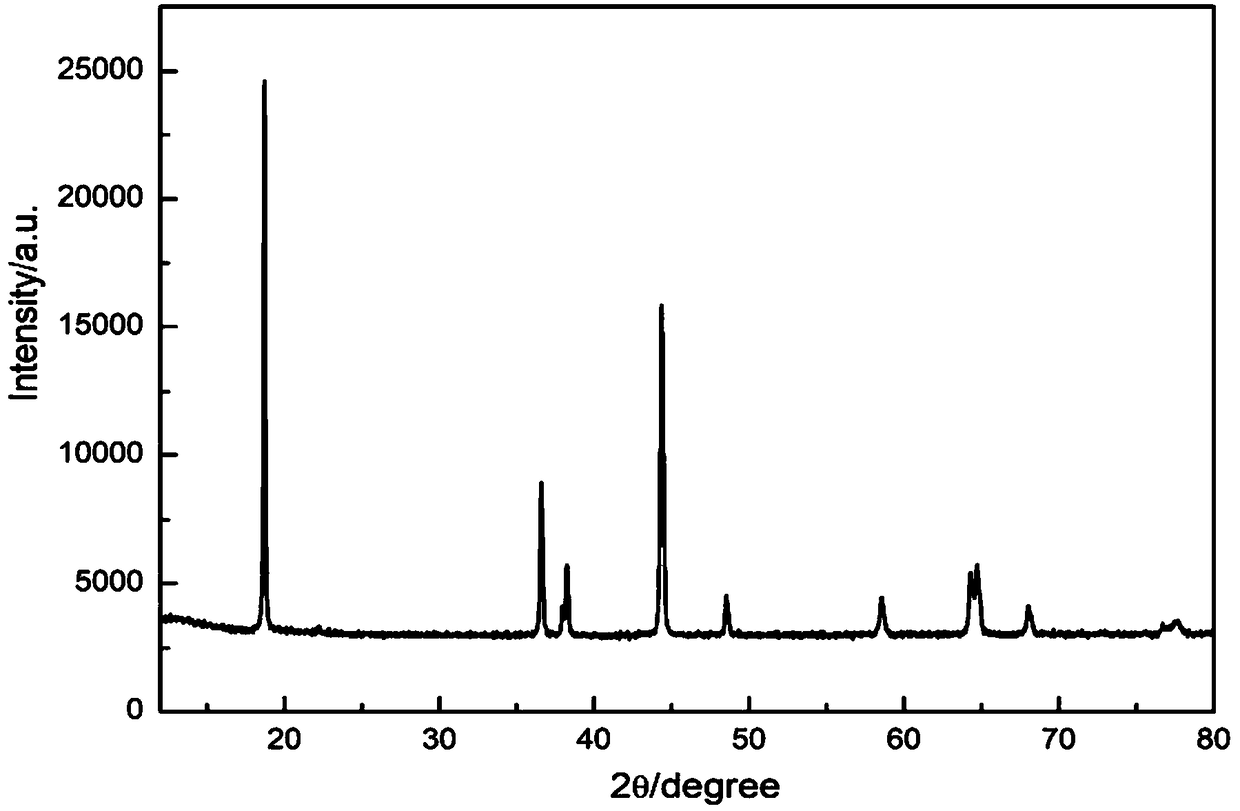

Selenium and silicate co-doped high-nickel cathode material, and preparation method and application thereof

ActiveCN109638275AImprove electrochemical performanceImproved lattice structureCell electrodesSecondary cellsStructural stabilitySe element

The invention relates to a selenium and silicate co-doped high-nickel cathode material, and a preparation method and application thereof. The cathode material is a selenium and silicate co-doped modified high-nickel cathode material, and has a chemical formula of LiNixM1-xSea (SiO4) bO2-a-b, wherein M is at least one of Mn, Co or Al, and 0.5 <= x < 1, 0 < a <= 0.05, 0 < b <=0.05. The high-nickel cathode material is doped with low-valence anions by the selenium and silicate so as to improve the lattice structure of the material. The selenium and the silicate have good synergistic effect, can improve the structural stability of the material under high voltage, and obviously improve the electrochemical performance of the high-nickel cathode material. The obtained cathode material has a firstcycle discharge specific capacity greater than or equal to 185mAh / g and a capacity retention rate greater than or equal to 85% after 200 cycles at a 2.5-4.2V voltage window and 0.1C current density, and has a good application prospect.

Owner:LANGFANG GREEN IND TECH CENT +1

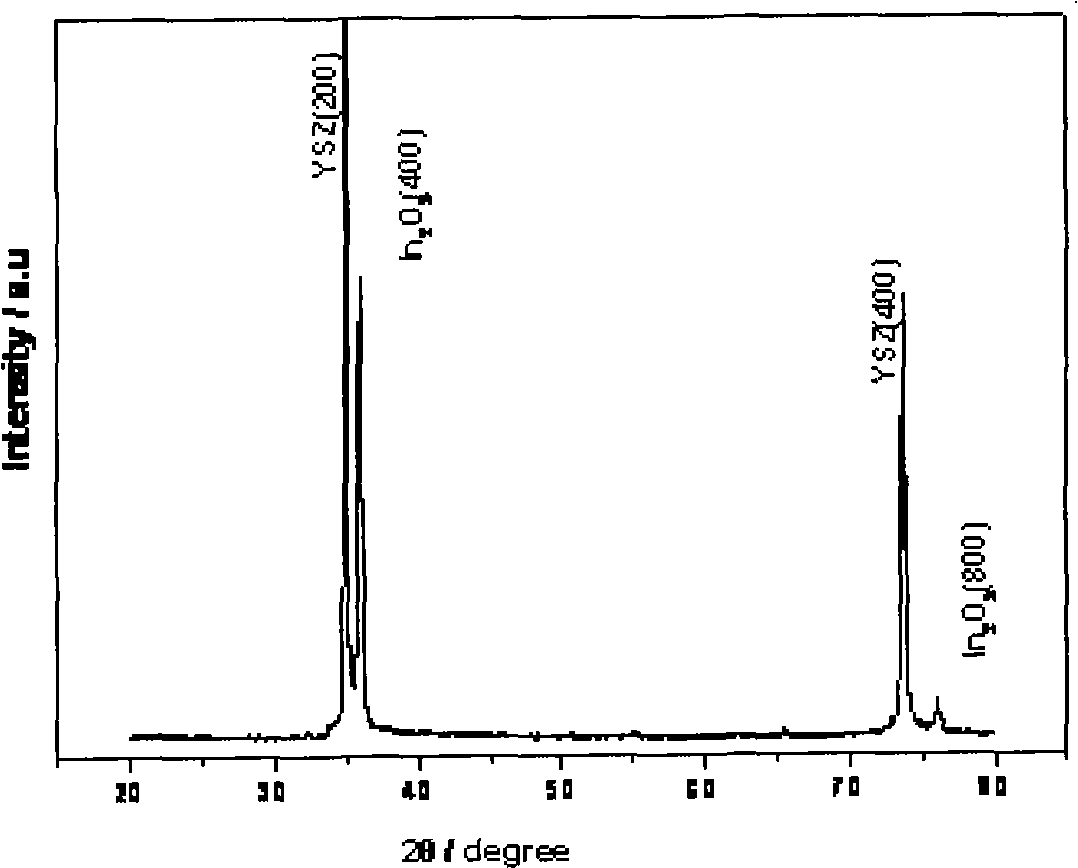

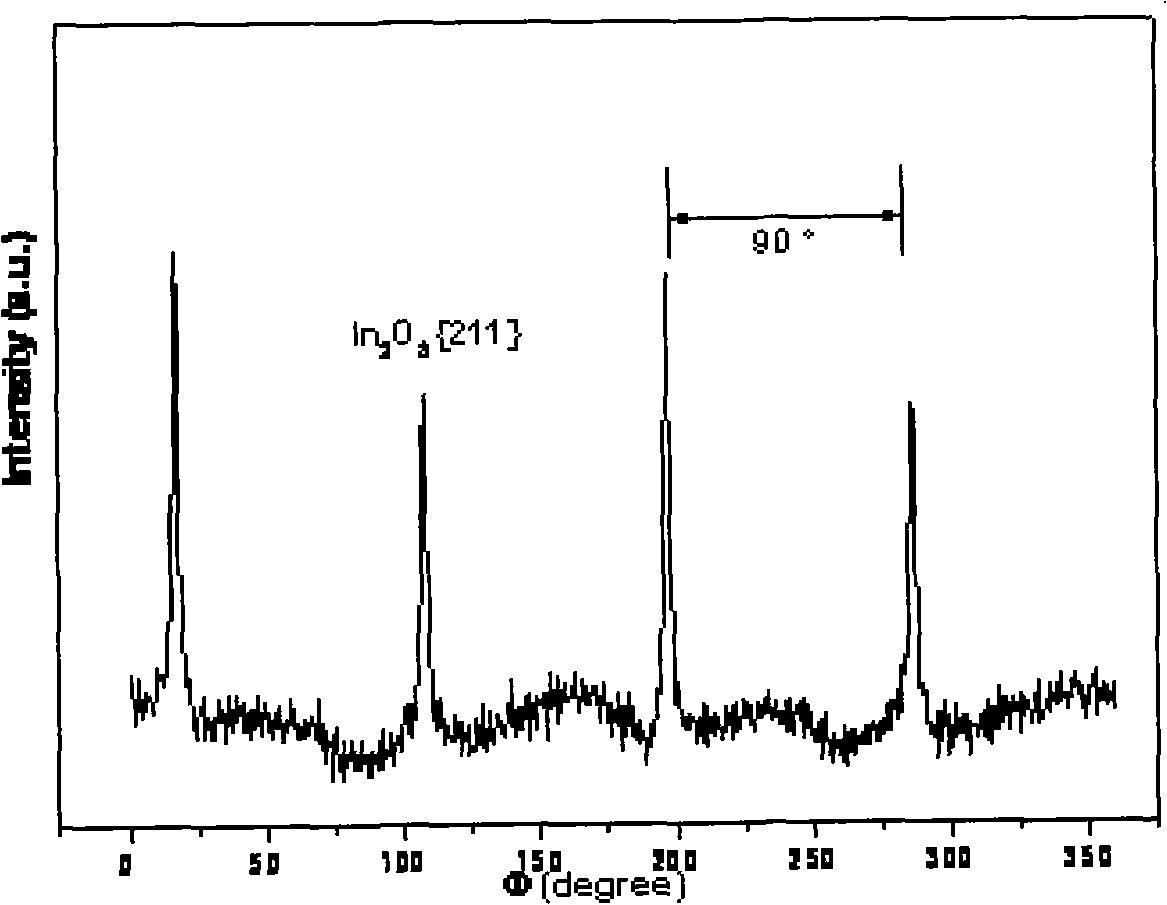

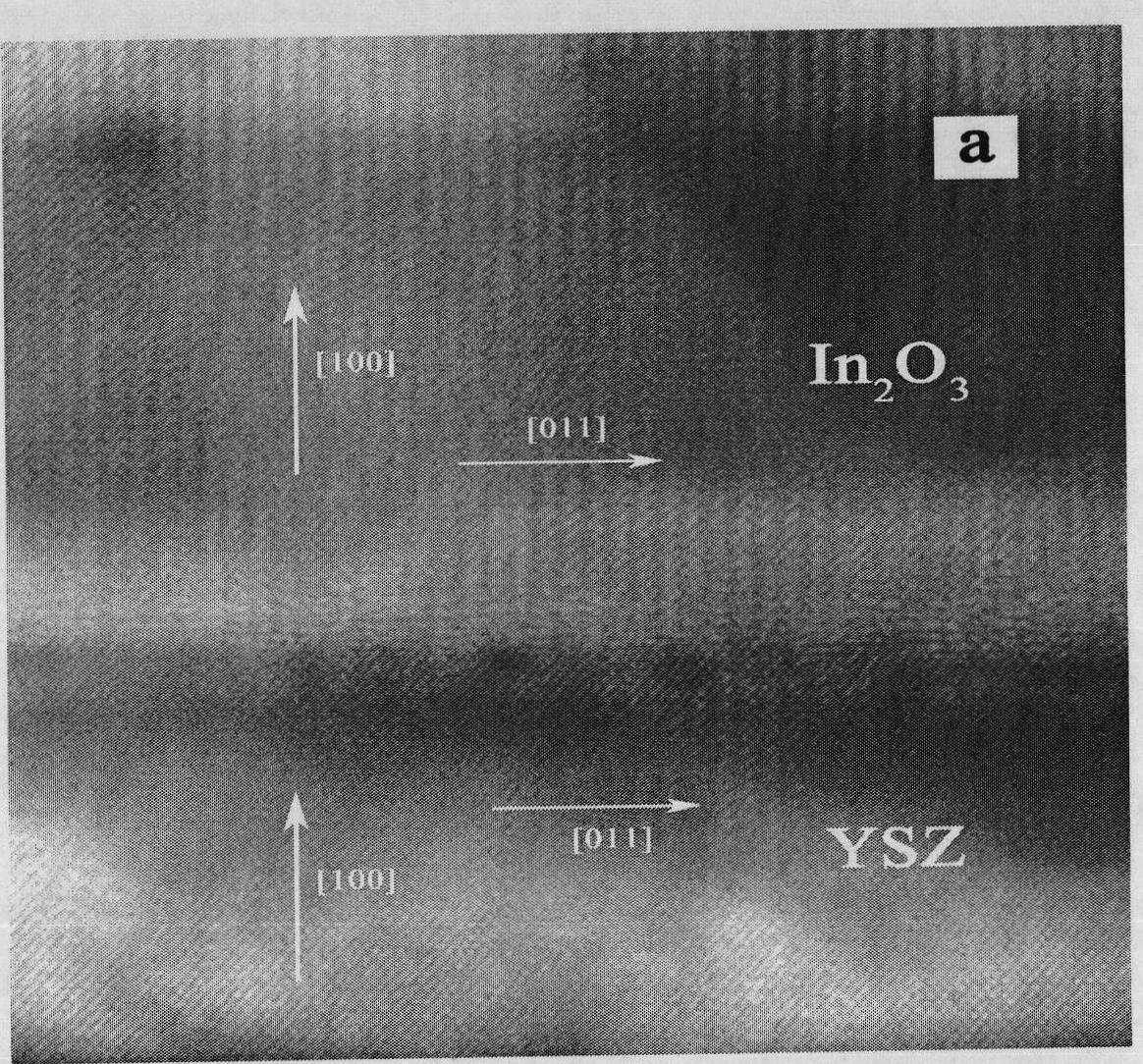

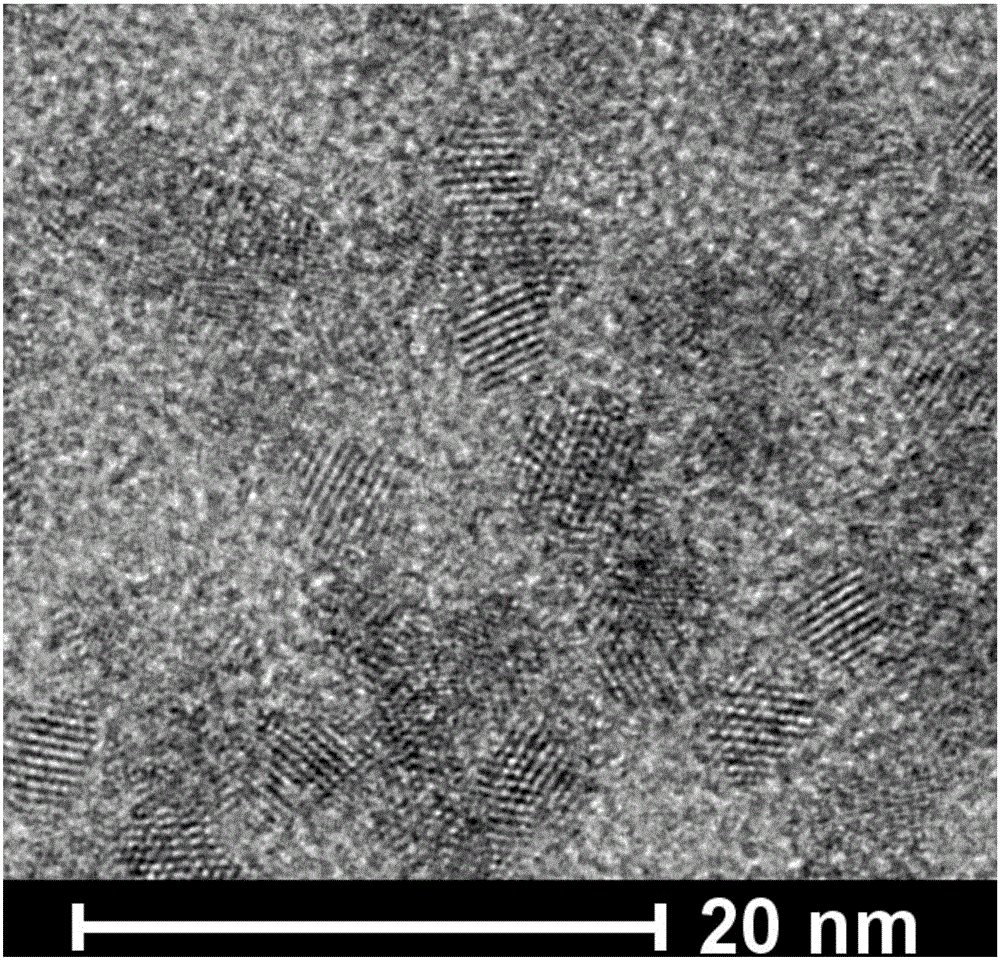

Method for preparing cubic indium oxide single-crystal film on yttrium-doped zirconia substrate

InactiveCN101792901AGood adhesionImprove photoelectric performanceChemical vapor deposition coatingOrganometallic chemistryIndium

The invention relates to a preparation method for a cubic indium oxide single-crystal epitaxial film. By adopting the organic metal chemical gas deposition technology, trimethylindium is used as an organic metal source, nitrogen is used as carrier gas, oxygen is used as oxidizing gas and an organic metal chemical gas deposition device is used to epitaxially grow indium oxide single-crystal film on an yttrium-doped zirconia substrate under vacuum conditions. The film is the epitaxial material with single-crystal structure, twin crystals and domain structures do not exist in the film, and the mobility of the current carrier of the film is higher than 61.2 cm<2>V<-1>s<-1>.

Owner:SHANDONG UNIV

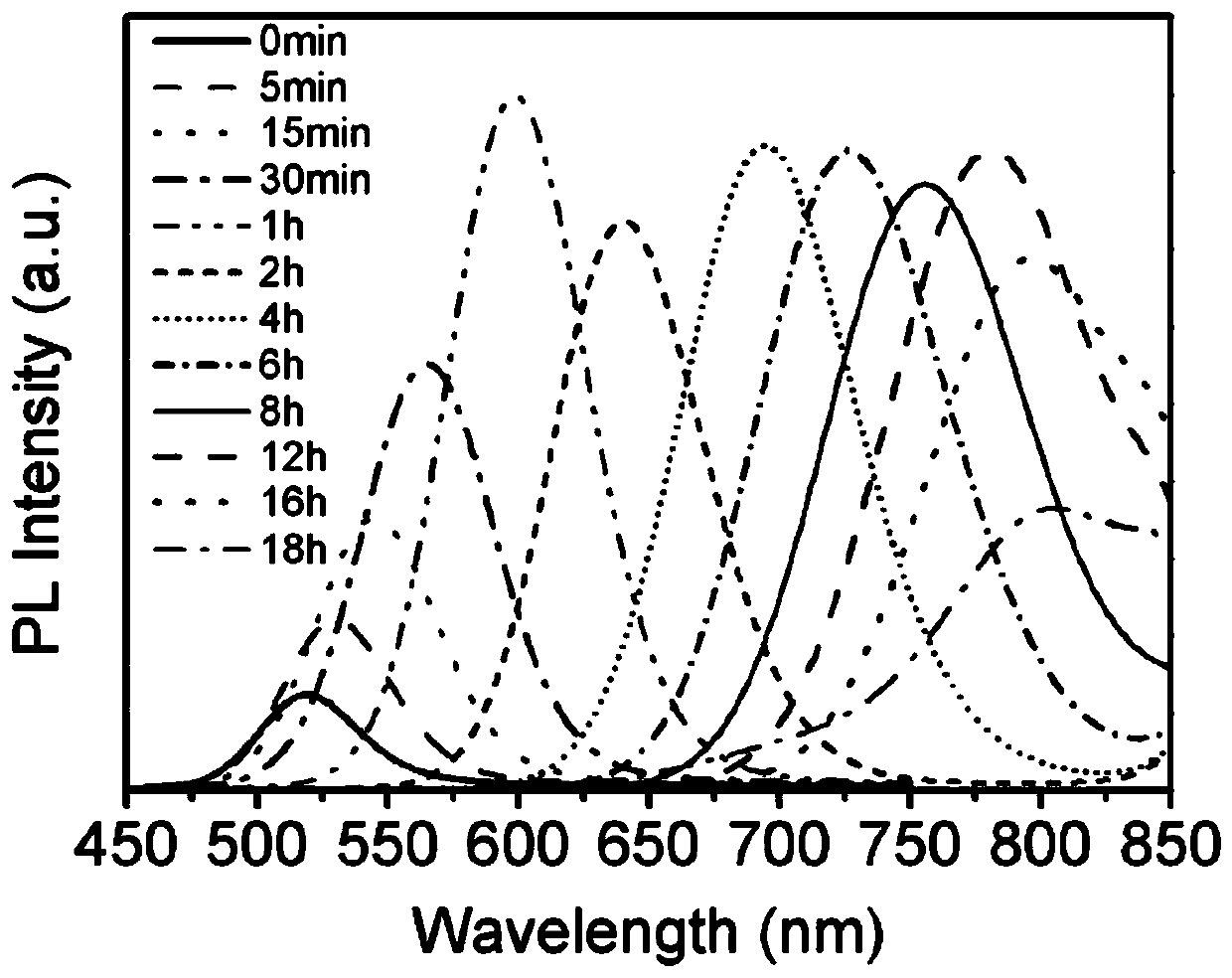

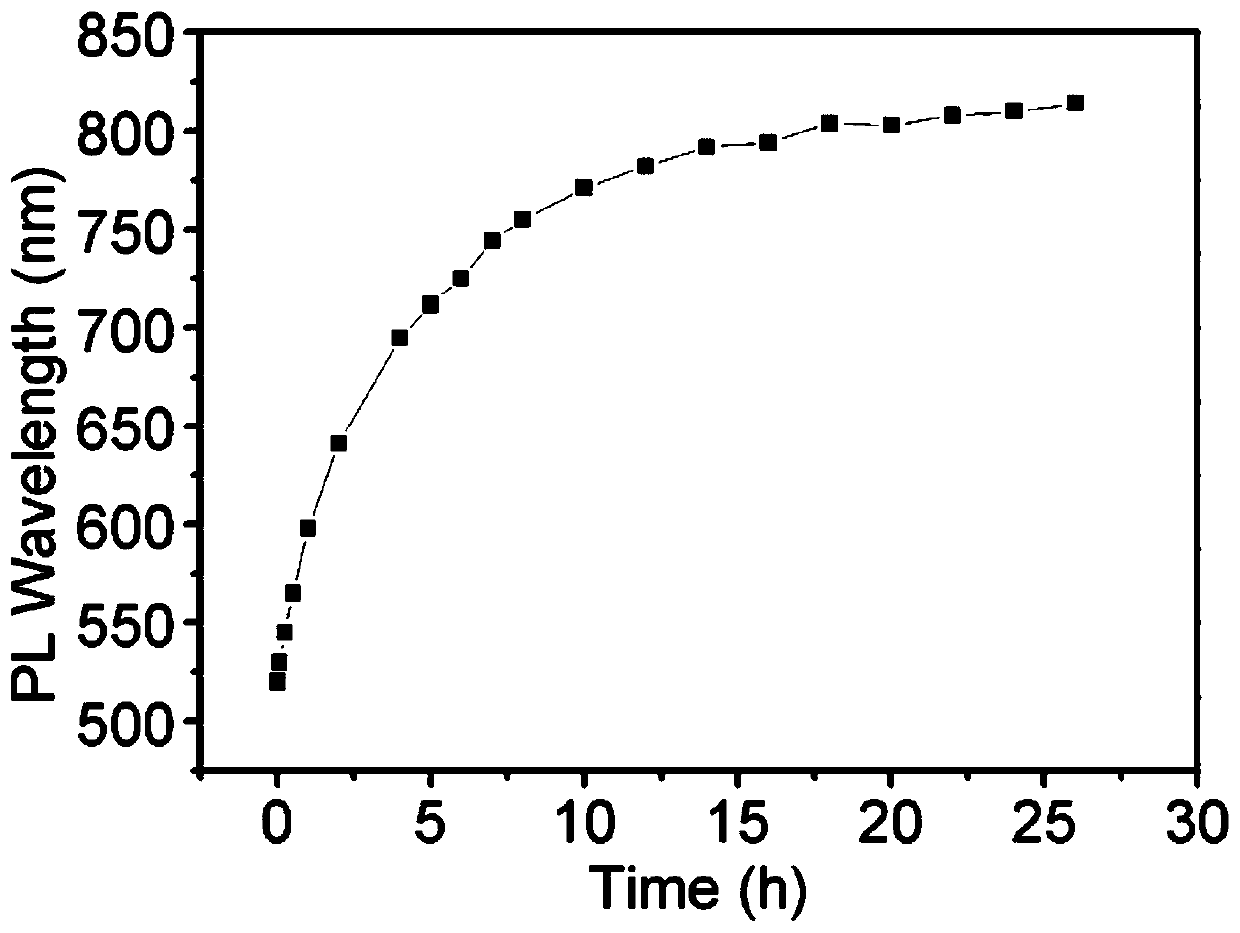

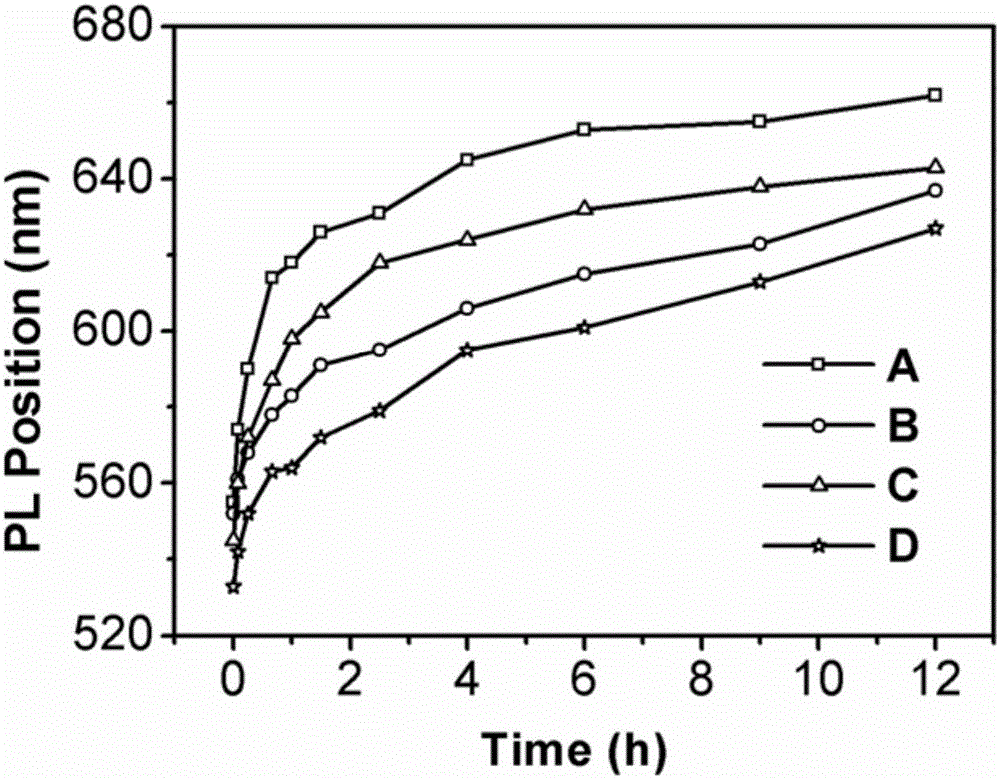

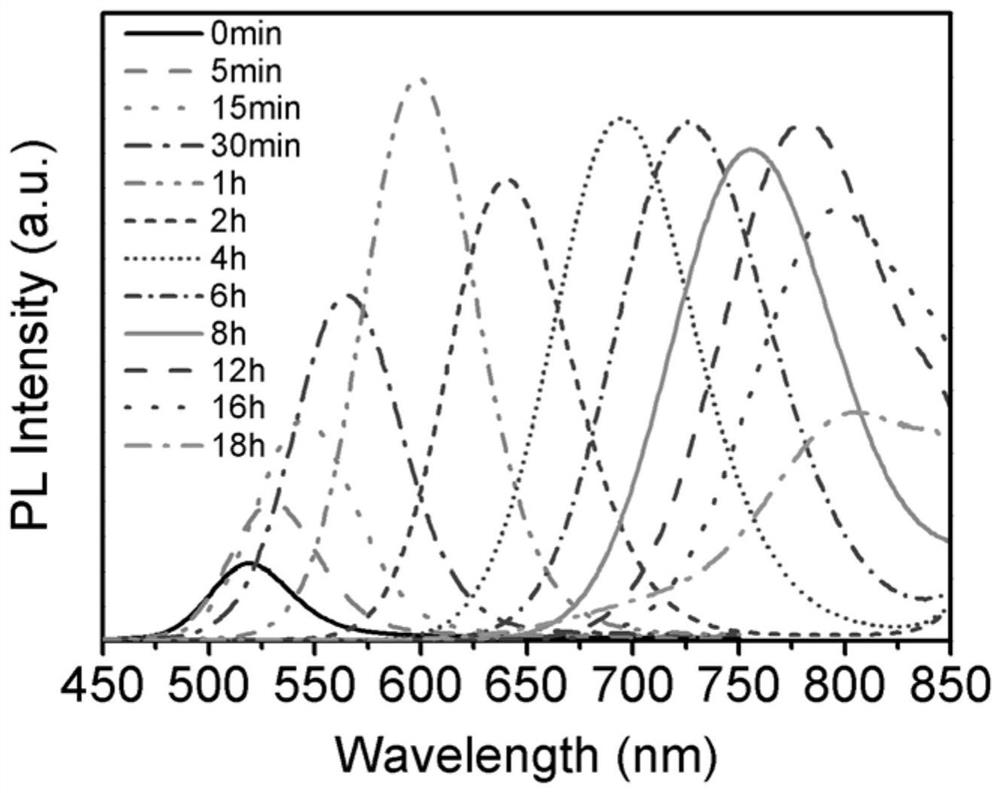

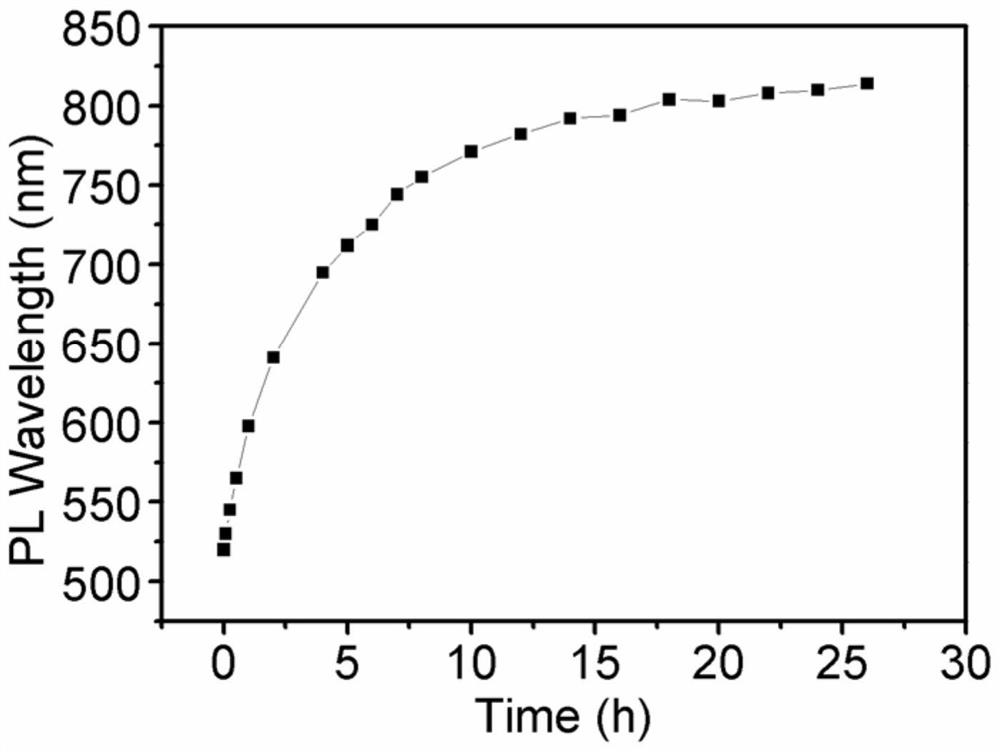

Method for preparing near-infrared cadmium telluride quantum dots through hydrothermal treatment

ActiveCN110684534AReduce electrostatic repulsionPromote mature growthNanoopticsLuminescent compositionsNear infrared luminescenceLight emission

The invention discloses a method for preparing near-infrared cadmium telluride quantum dots through hydrothermal treatment. The method comprises the following steps: respectively adding a cadmium saltsolution and a sulfydryl ligand into an aqueous solution, and performing uniform mixing so as to obtain a mixed solution, wherein the mole ratio of the sulfydryl ligand to the cadmium salt is (2-4):1; adjusting the pH value of the mixed solution to 9-11, introducing nitrogen for 30 minutes or longer, adding a sodium hydrogen telluride aqueous solution, and performing uniform mixing so as to obtain a cadmium telluride precursor solution, wherein the mole ratio of the cadmium telluride to cadmium ions is (0.1-0.2):1; heating the cadmium telluride precursor solution for 5 minutes, adding a precipitant, performing centrifugation, removing supernate, adding water, and performing secondary dissolution; adding the cadmium salt solution and the sulfydryl ligand into the dissolved cadmium telluride quantum dots, wherein the mole ratio of thiohydracrylic acid to cadmium chloride is (2-4):1; and adjusting the pH value of the mixed solution to 9-11, and performing heating for a certain time, so as to obtain the cadmium telluride quantum dots with near-infrared light emission. By adopting the method disclosed by the invention, near-infrared cadmium telluride quantum dots can be prepared, and the obtained cadmium telluride quantum dots have good lattice structures.

Owner:HANGZHOU DIANZI UNIV

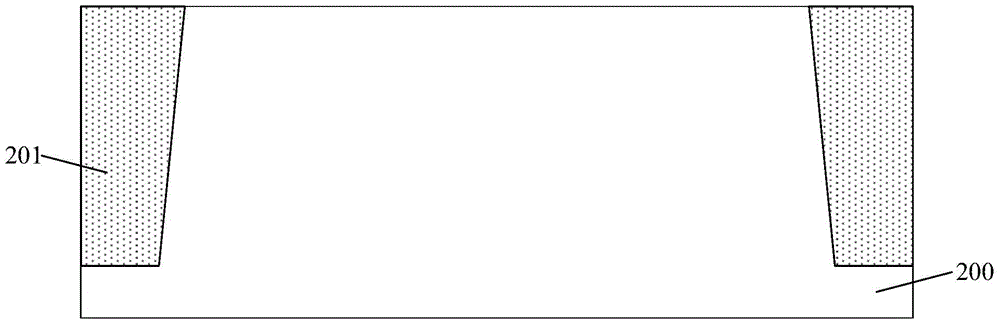

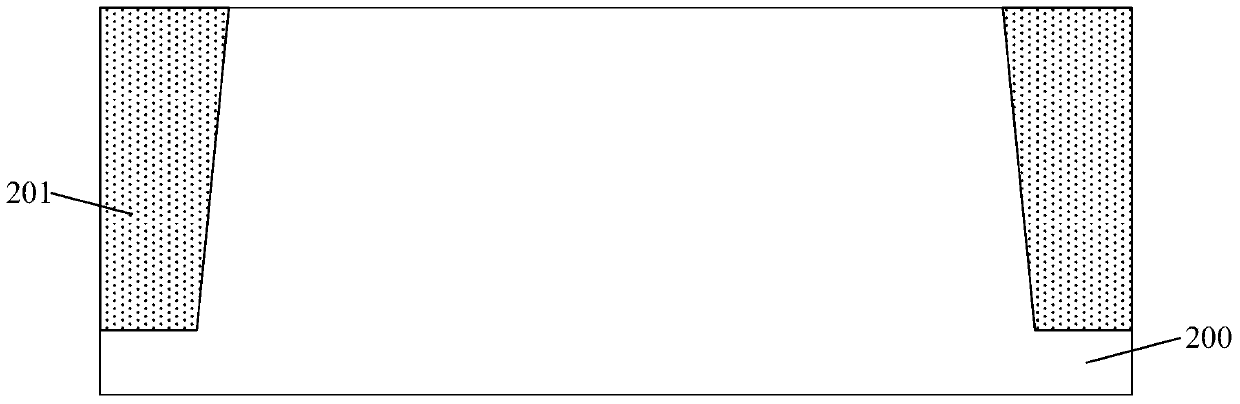

Formation method of semiconductor device

ActiveCN105719971AReduce width sizeImprove electrical isolationSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a formation method of a semiconductor device. The formation method of a semiconductor device comprises the steps: providing a substrate with isolation structures; forming a gate structure on the surface of part of the substrate between the adjacent isolation structures; forming a groove exposing the side wall of the isolation structure in the substrate at two sides of each gate structure; nitriding the side wall of the exposed isolation structure, and forming an anti-corrosion layer on the surface of the side wall of the isolation structure; after forming the anti-corrosion layer, cleaning the surface of the bottom and the side wall of the groove; and forming a stress layer filling the groove. The formation method of a semiconductor device can prevent cleaning from etching the isolation structure so as to enable the isolation structure to maintain good shape and provide good interface performance for forming the stress layer, and can enable the isolation structure to maintain good electrical isolation performance and can optimize the electrical properties for the formed semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Positively charged water-soluble cadmium telluride quantum dot preparation method

ActiveCN106544030AFast preparationShorten the timeNanoopticsLuminescent compositionsNitrogenWater soluble

The invention discloses a positively charged water-soluble cadmium telluride quantum dot preparation method, which comprises: respectively adding a cadmium salt solution and a mercapto ligand to an aqueous solution, and uniformly mixing to obtain a mixed solution, wherein a molar ratio of mercaptopropionic acid to cadmium chloride is 2-4:1; adjusting the pH value of the mixed solution to 9-11, introducing nitrogen for more than 30 min, adding a sodium hydrogen telluride aqueous solution, and uniformly mixing to obtain a cadmium telluride precursor solution, wherein a molar ratio of sodium hydrogen telluride to cadmium ions is 0.1-0.2:1; and diluting the cadmium telluride precursor solution by using an aqueous solution, and heating to obtain the water-soluble cadmium telluride quantum dots. With the method of the present invention, the water-soluble quantum dots can be prepared quickly, the fastest red cadmium telluride quantum dot obtaining time is only 1 h, and the obtained cadmium telluride quantum dots have the good lattice structure.

Owner:芜湖启博知识产权运营有限公司

Method and apparatus for forming device quality gallium nitride layers on silicon substrates

InactiveUS9960036B2Improved lattice structurePolycrystalline material growthSemiconductor/solid-state device manufacturingReaction temperatureNucleation

Atomic Layer Deposition (ALD) is used for heteroepitaxial film growth at reaction temperatures ranging from 80-400° C. The substrate and film materials are preferably matched to take advantage of Domain Matched Epitaxy (DME). A laser annealing system is used to thermally anneal deposition layer after deposition by ALD. In preferred embodiments, a silicon substrate is overlaid with an AlN nucleation layer and laser annealed. Thereafter a GaN device layer is applied over the AlN layer by an ALD process and then laser annealed. In a further example embodiment, a transition layer is applied between the GaN device layer and the AlN nucleation layer. The transition layer comprises one or more different transition material layers each comprising a AlxGa1-xN compound wherein the composition of the transition layer is continuously varied from AlN to GaN.

Owner:VEECO INSTR

Lithium-rich lithium iron phosphate material as well as preparation method and application thereof

ActiveCN110078042AImprove electrochemical performanceQuick and easy to manufacturePhosphorus compoundsMaterial electrochemical variablesMicro nanoMaterials preparation

The invention relates to a lithium-rich lithium iron phosphate material as well as a preparation method and the application thereof, and belongs to the technical field of materials. The preparation method comprises the following steps: taking lithium iron phosphate as a raw material in the material preparation process, assembling the lithium iron phosphate in a button cell and then performing charge-discharge cycles on the button cell to obtain the lithium-rich lithium iron phosphate material. The lithium-rich lithium iron phosphate material has a micro-nano-scale size, has a good lattice structure, is used for coating an electrode to form a working electrode and constructing an NO electrochemical biosensor; the sensor can be used for the direct growth of cells, can perform real-time in-situ detection on NO molecules released by the cells, shows extremely-high sensitivity and selectivity in the actual detection and is stable in electrochemical property and longer in cycle life. The material is simple and convenient in preparation process, low in raw material cost and convenient for commercial application.

Owner:SOUTHWEST UNIV

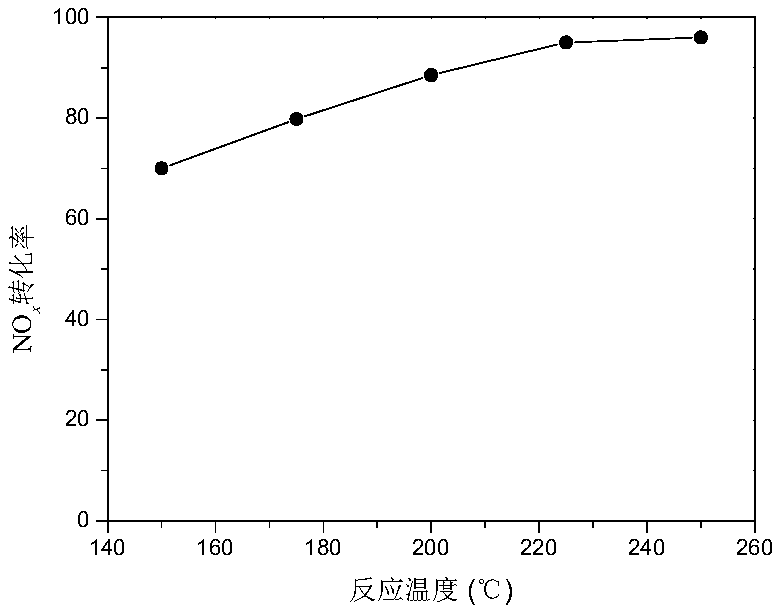

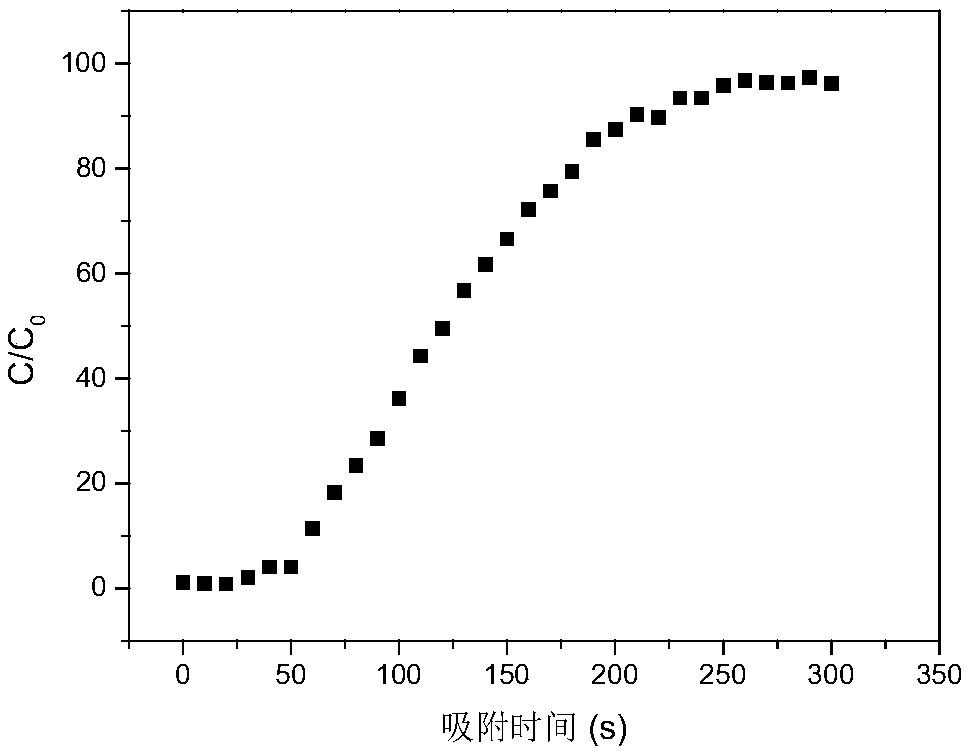

Method for in-situ preparation of coal-biomass prepared carbon base NOx adsorption reduction catalyst

ActiveCN109248688AImprove adsorption capacityMany catalytically active sitesOther chemical processesDispersed particle separationAlkaline earth metalMixed materials

The invention discloses a method for the in-situ preparation of coal-biomass prepared carbon base NOx adsorption reduction catalyst. The catalyst selects specific coal and biomass as a carrier precursor, and selects specific metal as forming accessory ingredient and active ingredient precursor so as to finish technologies including activation, forming and the like in situ in a drop furnace. The prepared catalyst has high NOx adsorption performance, meanwhile, the catalyst can catalyze micromolecule flammable gas (carbon monoxide, methane and the like) to react with NOx, realizing high NOx removal rate. According to the active ingredients of the catalyst, cheap metal is adopted to solve the problems that traditional commercial catalyst has poor replaceability, environment pollution and thelike. Compared with the conventional selective adsorption-catalytic reduction catalyst, the catalyst disclosed by the invention has the following advantages that the coal and biomass mixed material isadopted as the carrier precursor so as to omit alkali metal or alkaline earth commonly used by the NOx adsorption catalyst. The catalyst has the advantages of high nitric oxide adsorption performance, high adsorption performance and high NOx catalytic reduction performance (98% or above).

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Large-size graphene stack structure wafer and preparation method thereof

InactiveCN103227194BImproved lattice structurePreserve ultra-high mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesHexagonal boron nitrideCharge carrier

The invention discloses a large-size graphene stack structure wafer which is characterized in that a wafer structure comprises a graphene single crystal layer, an h-BN (hexagonal boron nitride) single crystal layer, an h-BN buffer layer and SiO2 / Si wafer substrates from the top down sequentially. The wafer and the preparation method have the benefits that the wafer can be compatible with a production technique of the available silicon substrate semiconductor device sufficiently, and can take full advantage of the characteristic of a hexagonal boron nitride substrate material; growing graphene has a most perfect crystal structure and a carrier transport environment with the weakest scattering; the super-high mobility of carriers in graphene is kept at the utmost; and the performance of a graphene substrate electronic device is improved greatly.

Owner:XIDIAN UNIV

Making process of peanut-flavored sauce capable of being used with sauce gun

The invention discloses a making process of peanut-flavored sauce capable of being used with a sauce gun. The making process comprises the following steps: through the scientific formula combination,after heating and stirring and mixing uniformly, controlling the cooling speed and temperature through a unique pipeline cooling process and controlling the packaging temperature time, filling the product into a special triangular bag, thereby making the product form a stable lattice structure to obtain the peanut-flavored sauce which is appropriate in softness and hardness, and conveniently usedwith the sauce gun. The product is convenient to use and accurate in use amount control, and standardized control of the product is realized.

Owner:基快富食品(中国)有限公司

Formation method of semiconductor structure

PendingCN113497084AImproved lattice structureImprove interface stateMagnetic-field-controlled resistorsSolid-state devicesSemiconductor structureEngineering physics

A forming method of a semiconductor structure comprises the following steps: providing a substrate; forming a first electromagnetic film on the substrate; forming a tunnel film on the surface of the first electromagnetic film; performing heat treatment on the first electromagnetic film and the tunnel film by adopting a first heating process; and after the first electromagnetic film and the tunnel film are subjected to heat treatment, forming a second electromagnetic film on the surface of the tunnel film. Therefore, the performance of the magnetic tunnel junction is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Reducing series resistance between source and/or drain regions and a channel region

ActiveUS10319855B2Reduced series resistanceImproved lattice structureTransistorSemiconductor/solid-state device manufacturingDopantEngineering

Owner:INT BUSINESS MASCH CORP

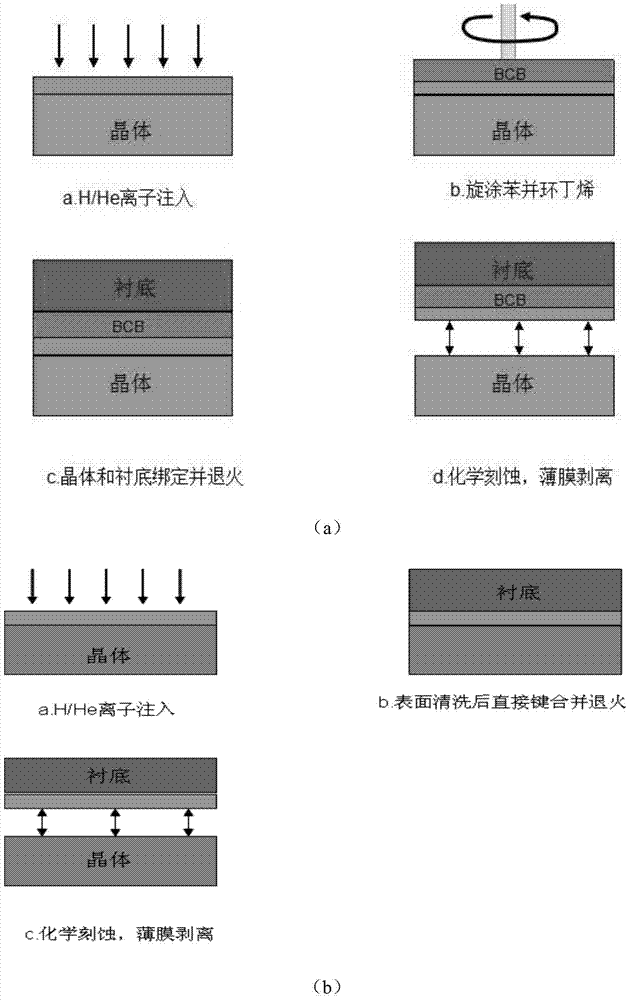

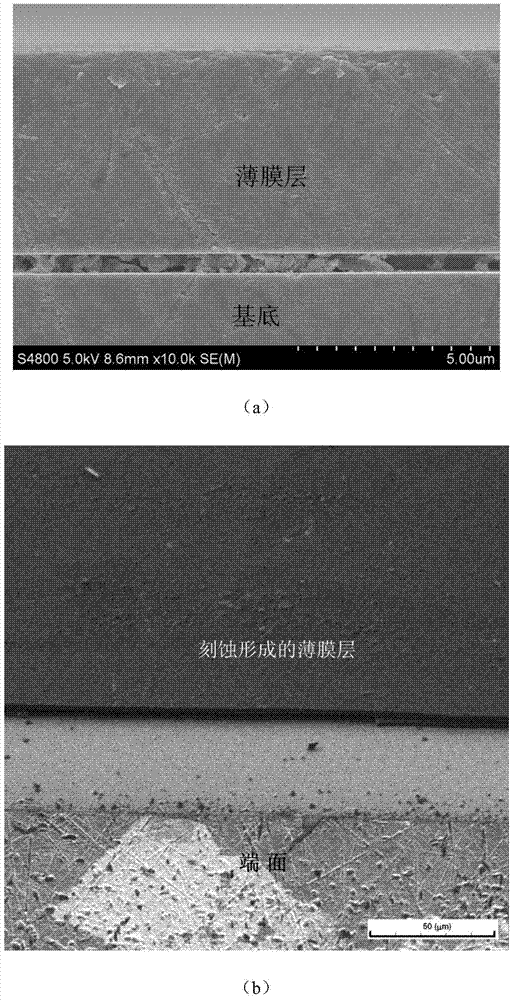

A preparation of ktiopo by ion implantation combined with chemical etching 4 single crystal thin film method

InactiveCN105002471BEasy to peelFast etch rateVacuum evaporation coatingSputtering coatingEtchingPhosphoric acid

The invention relates to a method for preparing a KTiOPO4 single crystal thin film through ion implantation in combination with chemical etching. According to the method, H or He ions are injected into a crystal sample within the low-energy range (100-60,000 keV), the injected ion dosage ranges from 1*1,016 ions / square centimeter to 10*1,016 ions / square centimeter, and the injection temperature is a room temperature or a low temperature; then, annealing treatment is conducted on the sample, the annealing temperature ranges from 200 DEG C to 600 DEG C, the total duration of annealing ranges from 10 seconds to 2 hours; etching is conducted on the sample through a chemical reagent, and crystal thin film stripping is achieved. By the adoption of the method, after He ions with the energy of 2,000 keV and the dosage of 4*1,016 are injected into the Z-tangential KTP sample, the annealed sample is put into an HF solution to be etched, and thin film stripping is achieved. By the adoption of the method, the KOTiPO4 crystal thin film with the thickness of 5 micrometers is obtained, and the way of obtaining the KTP single crystal thin film by conducting ion injection in combination with chemical etching is utilized for the first time so far.

Owner:SHANDONG UNIV

Hydrothermal method for preparing near-infrared cadmium telluride quantum dots

ActiveCN110684534BReduce electrostatic repulsionPromote mature growthNanoopticsLuminescent compositionsNitrogen gasNear infrared luminescence

The invention discloses a hydrothermal method for preparing near-infrared cadmium telluride quantum dots, which comprises the following steps: respectively adding cadmium salt solution and mercapto ligands into an aqueous solution, and mixing uniformly to obtain a mixed solution, wherein the mercapto ligands and cadmium The molar ratio of salt is 2-4:1; adjust the pH value of the mixed solution to 9-11, pass nitrogen gas for more than 30 minutes, then add sodium telluride hydride aqueous solution, mix well to obtain cadmium telluride precursor solution, wherein, sodium telluride hydride The molar ratio to cadmium ions is 0.1 to 0.2:1; after heating the cadmium telluride precursor solution for 5 minutes, add a precipitant and centrifuge, remove the supernatant and add water to redissolve; in the dissolved cadmium telluride quantum dots Add cadmium salt solution and mercapto ligand, wherein the molar ratio of mercaptopropionic acid to cadmium chloride is 2 to 4:1, adjust the pH value of the mixed solution to 9 to 11, and then heat for a period of time to obtain near-infrared luminescent telluride Cadmium quantum dots. The method of the invention can be used to prepare near-infrared cadmium telluride quantum dots, and the obtained cadmium telluride quantum dots have a good lattice structure.

Owner:HANGZHOU DIANZI UNIV

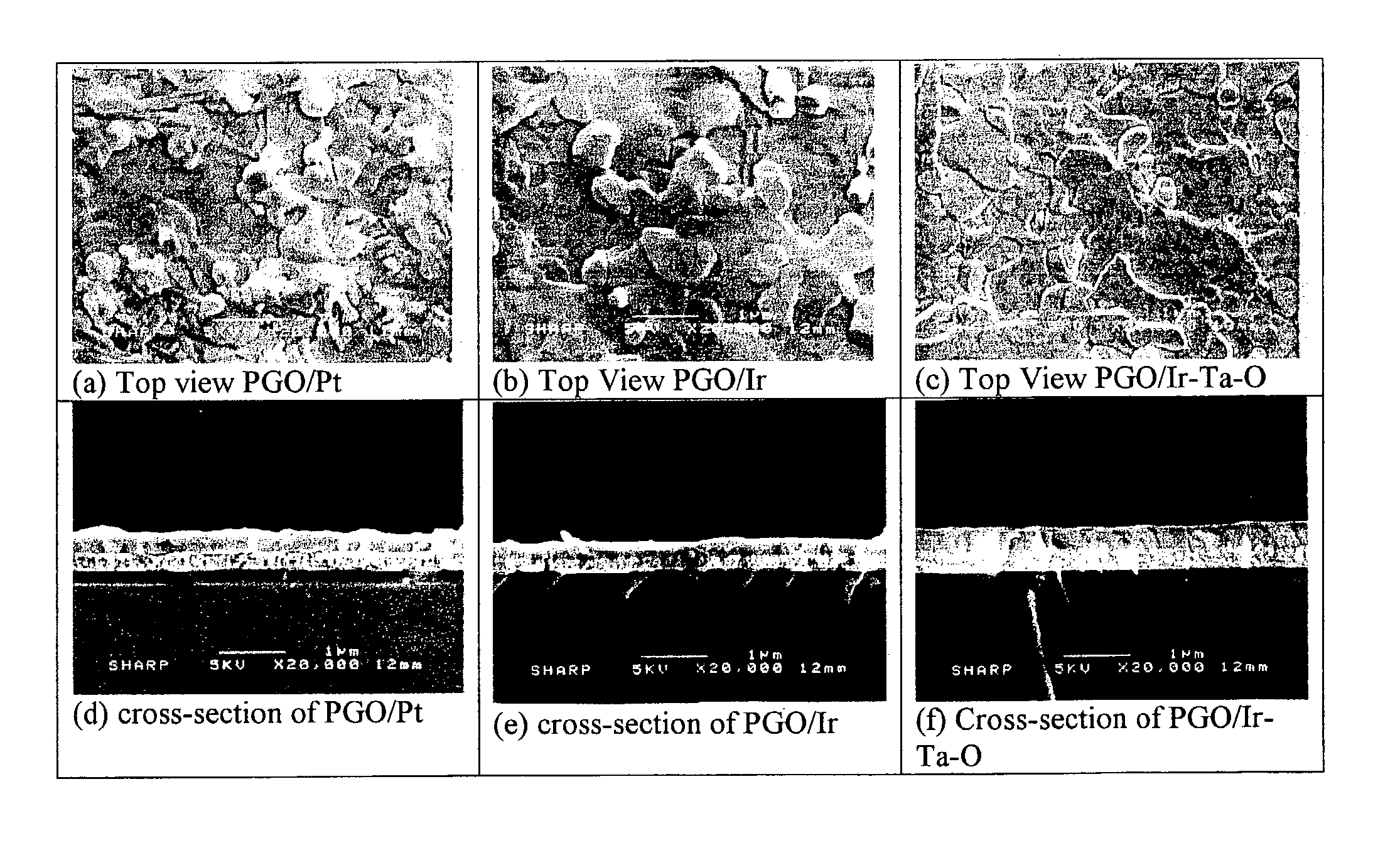

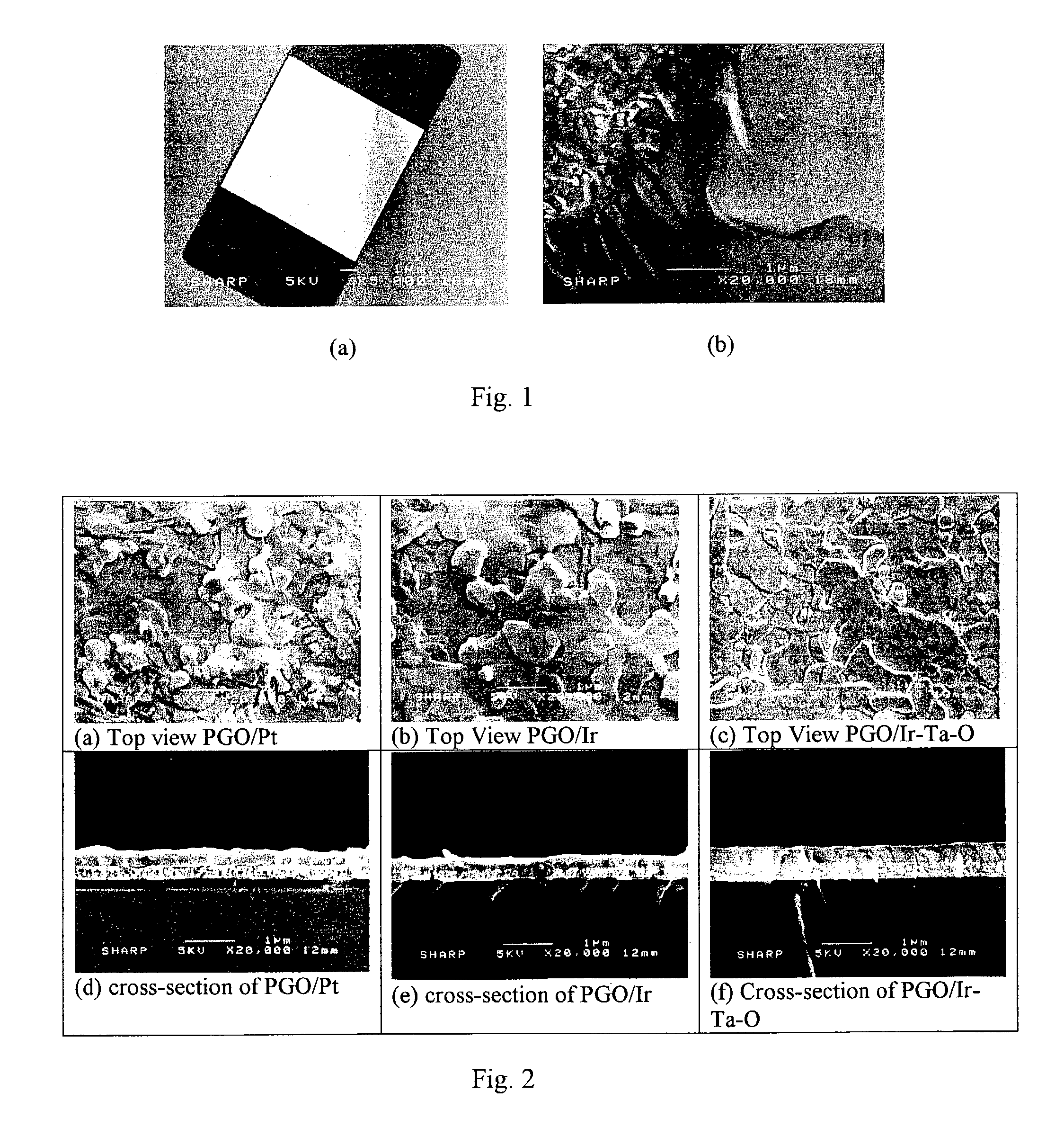

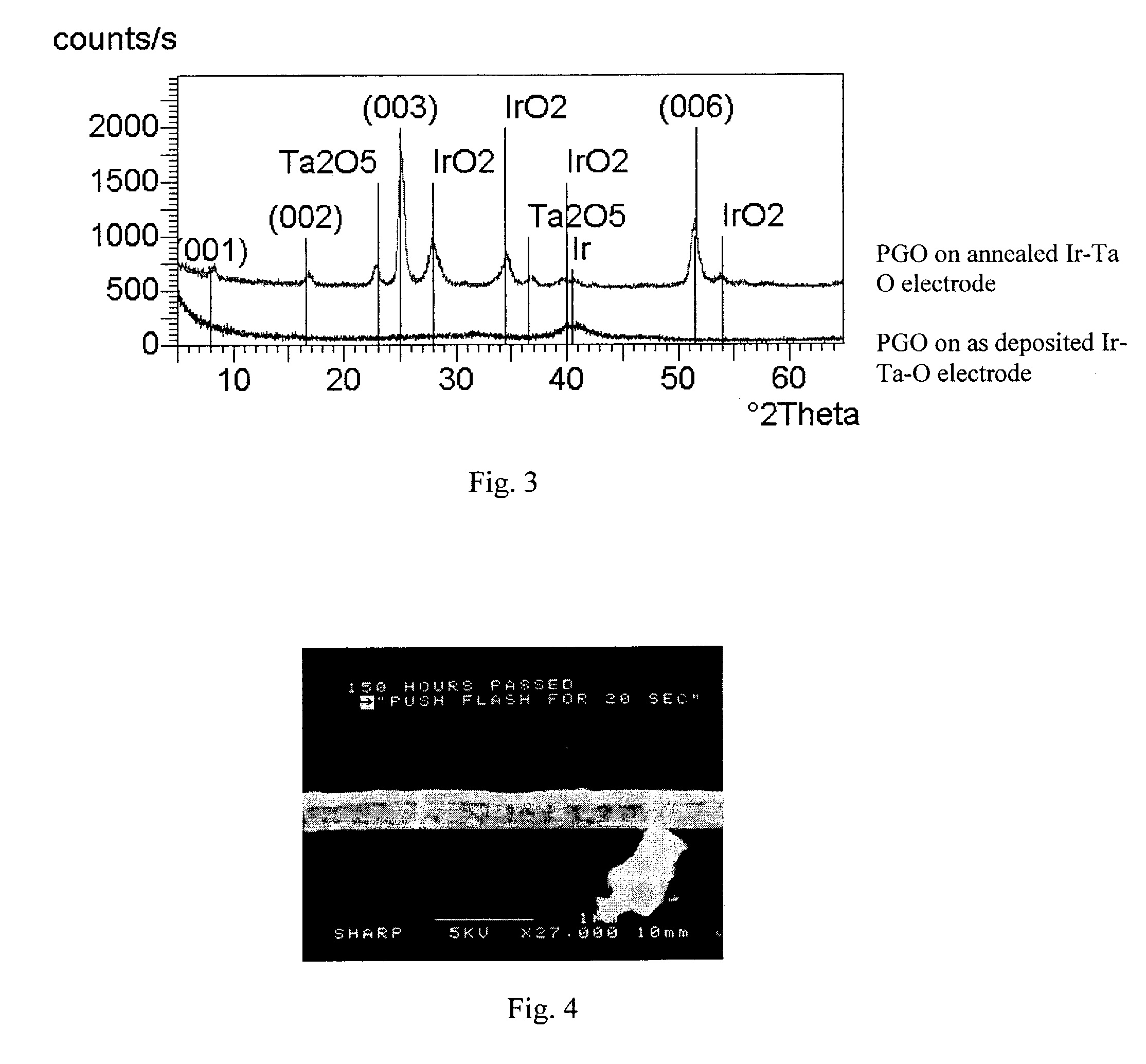

Integrated circuit structure including electrodes with PGO ferroelectric thin film thereon

InactiveUS6998661B2Uniform smoothnessImprove surface characteristicTransistorSolid-state devicesIridiumFerroelectric thin films

A method of forming an electrode and a ferroelectric thin film thereon, includes preparing a substrate; depositing an electrode on the substrate, wherein the electrode is formed of a material taken from the group of materials consisting of iridium and iridium composites; and forming a single-phase, c-axis PGO ferroelectric thin film thereon, wherein the ferroelectric thin film exhibits surface smoothness and uniform thickness. An integrated circuit includes a substrate; an electrode deposited on the substrate, wherein the electrode is formed of a material taken from the group of materials consisting of iridium and iridium composites, wherein the iridium composites are taken from the group of composites consisting of IrO2, Ir—Ta—O, Ir—Ti—O, Ir—Nb—O, Ir—Al—O, Ir—Hf—O, Ir—V—O, Ir—Zr—O and Ir—O; and a single-phase, c-axis PGO ferroelectric thin film formed on the electrode, wherein the ferroelectric thin film exhibits surface smoothness and uniform thickness.

Owner:SHARP KK

Method of forming semiconductor device

ActiveCN105719971BReduce width sizeImprove electrical isolationSemiconductor/solid-state device manufacturingEngineeringSemiconductor device

The invention provides a formation method of a semiconductor device. The formation method of a semiconductor device comprises the steps: providing a substrate with isolation structures; forming a gate structure on the surface of part of the substrate between the adjacent isolation structures; forming a groove exposing the side wall of the isolation structure in the substrate at two sides of each gate structure; nitriding the side wall of the exposed isolation structure, and forming an anti-corrosion layer on the surface of the side wall of the isolation structure; after forming the anti-corrosion layer, cleaning the surface of the bottom and the side wall of the groove; and forming a stress layer filling the groove. The formation method of a semiconductor device can prevent cleaning from etching the isolation structure so as to enable the isolation structure to maintain good shape and provide good interface performance for forming the stress layer, and can enable the isolation structure to maintain good electrical isolation performance and can optimize the electrical properties for the formed semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

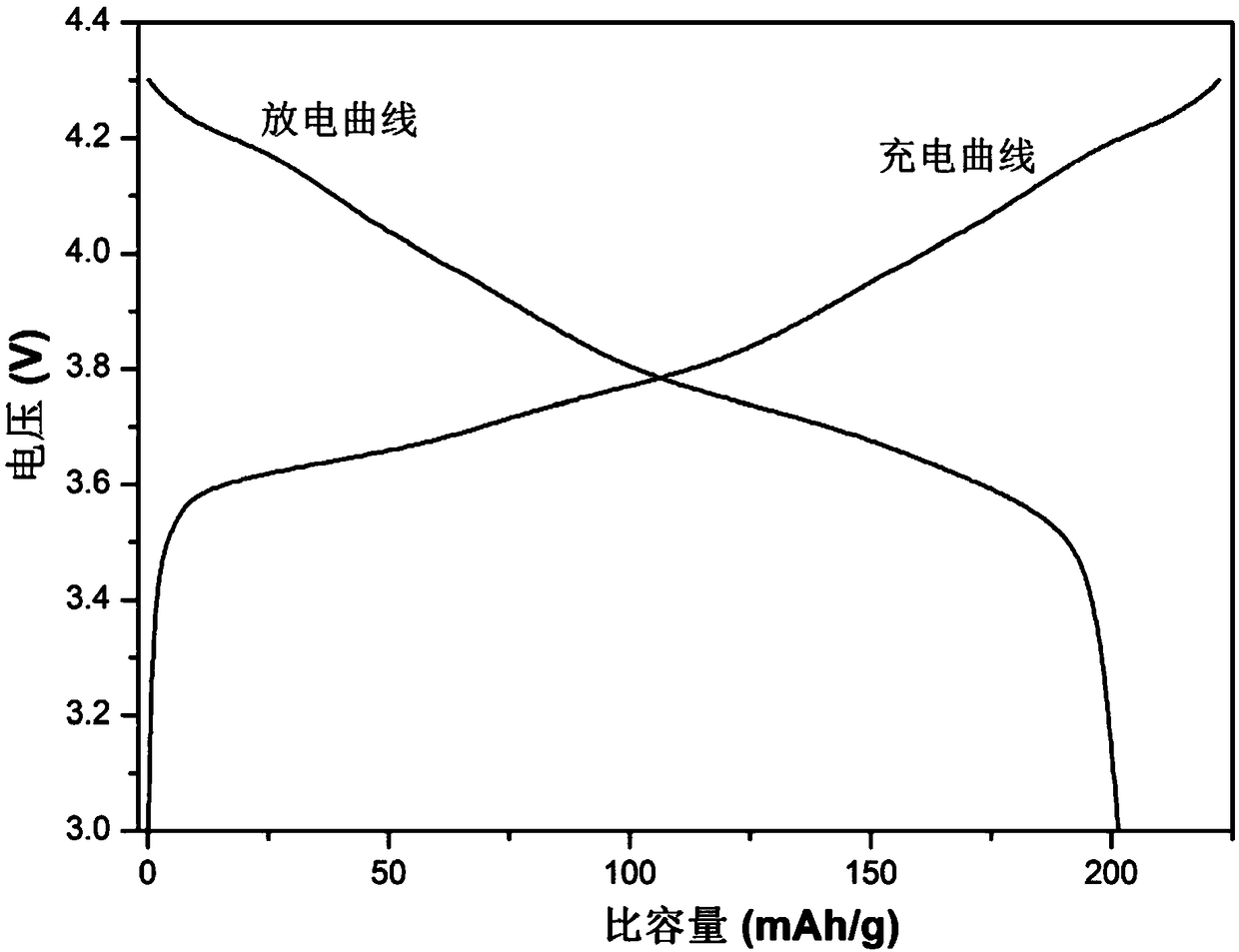

Lithium iron phosphate prepared with chemical precipitation method

InactiveCN108046232AImproved lattice structureImprove conductivityCell electrodesPhosphorus compoundsLithium iron phosphateTube furnace

The invention provides lithium iron phosphate prepared with a chemical precipitation method. Lithium iron phosphate is prepared through steps as follows: steps 1, solutions with certain concentrationsare prepared from LiOH.H2O and NH4H2PO4 in a stoichiometric ratio respectively, and a suspension with certain content is prepared from FeC2O4.2H2O; step 2, a LiOH solution is slowly dropwise added toa mixed solution of FeC2O4.2H2O and NH4H2PO4 at normal temperature and normal pressure for a reaction; step 3, a reaction liquid is filtered, and dark green precipitate is obtained; step 4, the precipitate is put in a tube furnace, dried for 5 h at 150 DEG C in N2 atmosphere, pre-decomposed for 5 h at 350 DEG C, calcined for 10 h at 700 DEG C and cooled with the furnace, and a lithium-ion batterycathode material LiFePO4 is obtained. Lithium iron phosphate prepared with the chemical precipitation method is of a single olivine crystal structure, has stable discharge plateau and good cycle performance and has a discharge voltage plateau of about 3.4 V.

Owner:DALIAN ZINTELLIGENCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com