Multi-element mixed doping coating modified ternary positive electrode material and preparation method thereof

A technology of positive electrode materials and ternary materials, which is applied in the field of multi-element mixed doping coating modified ternary positive electrode materials and its preparation, can solve lattice deformities, and it is difficult to ensure that the performance of ternary positive electrode materials is greatly improved or improved, etc. problems, to achieve good lattice structure, enhance electrochemical performance, and expand channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

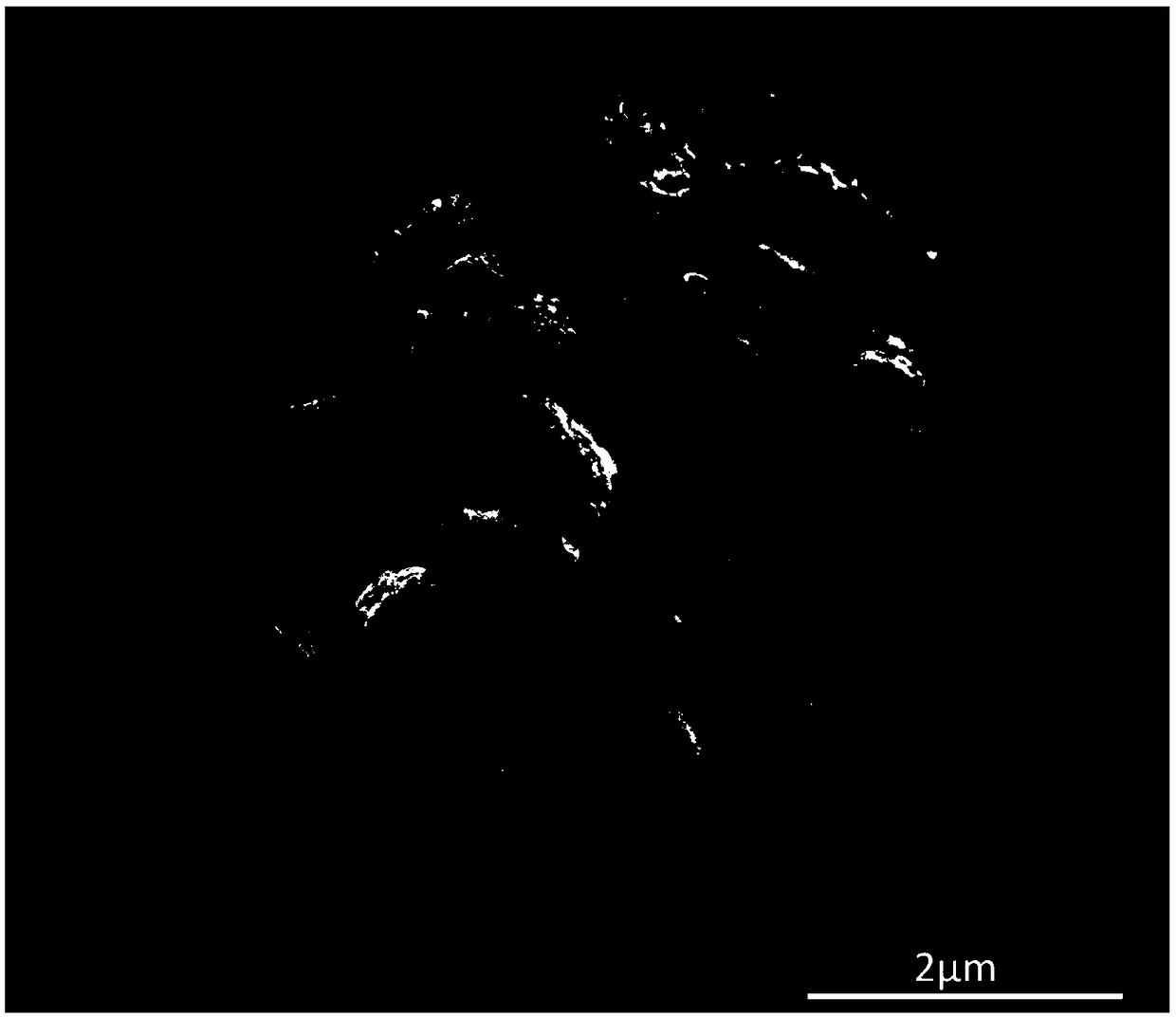

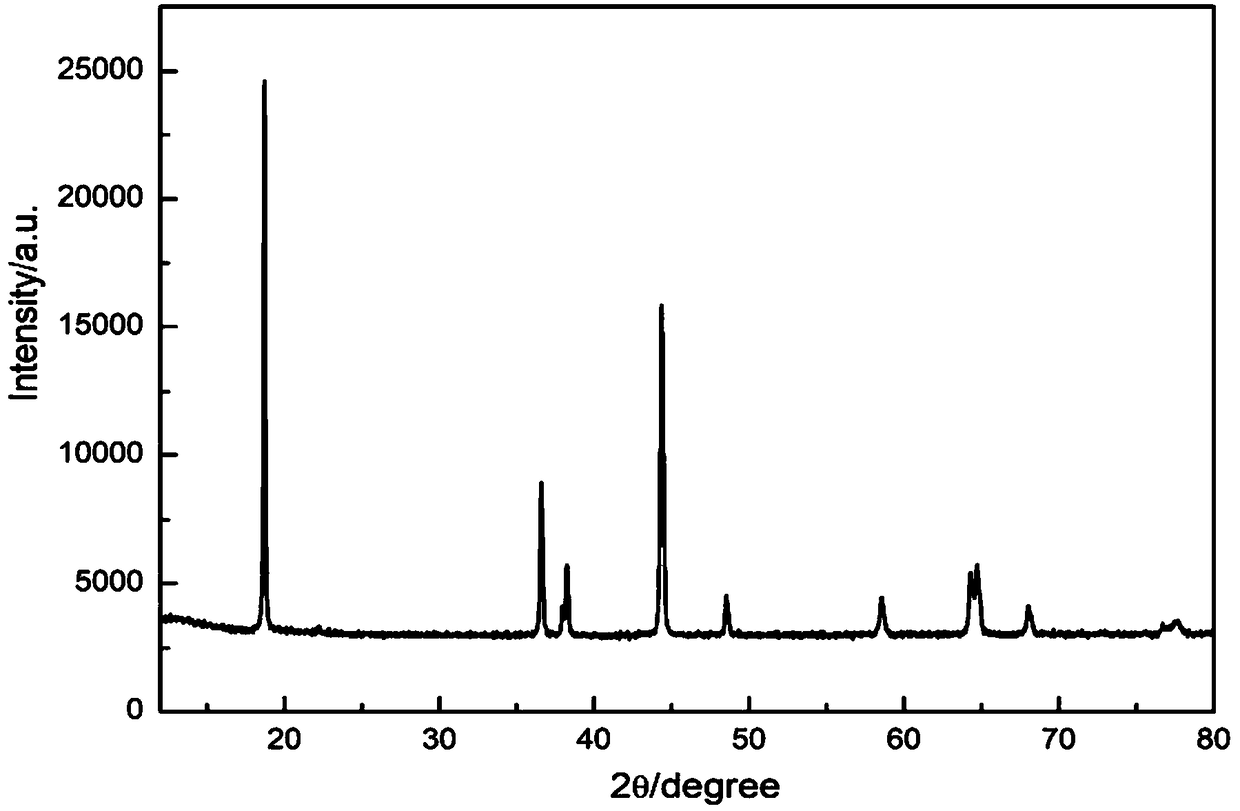

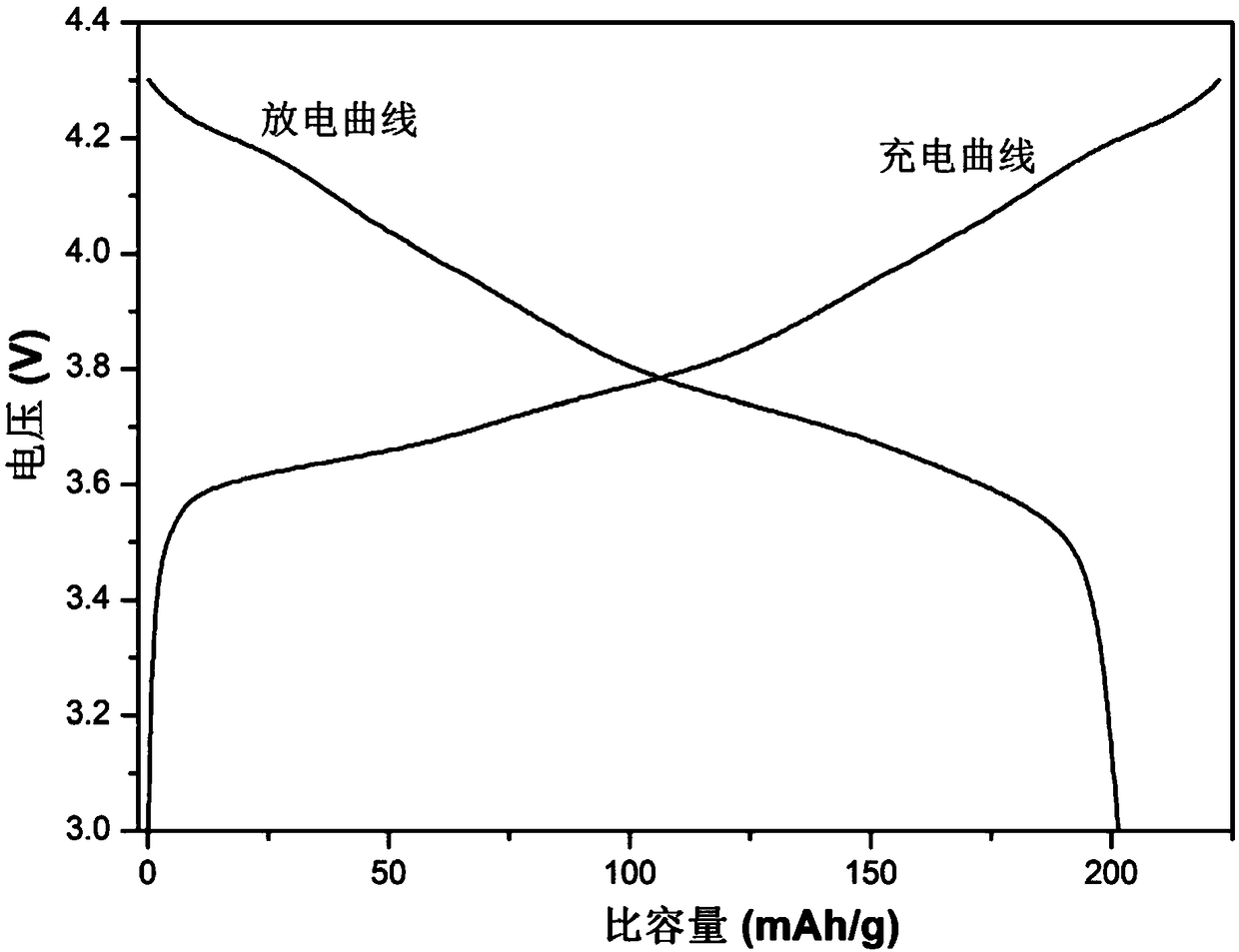

Image

Examples

Embodiment 1

[0027] This embodiment prepares Nb 5+ with Al 3+ Co-doped, ZrO 2 The ternary cathode material of coating modification comprises the following steps:

[0028] (1) Weigh 9.9mol of Ni 0.8 co 0.1 mn 0.1 (OH) 2 , 10.4 mol of lithium hydroxide, 0.05 mol of niobium oxalate hexahydrate, and 0.025 mol of aluminum sulfate octadecahydrate were placed in a high-speed mixer and fully mixed to obtain a uniform mixture A.

[0029] (2) Put the mixture A prepared in step (1) in a high-temperature sintering furnace, raise the temperature to 760°C at a heating rate of 3°C / min in an oxidizing atmosphere and keep it for 20 hours, then stop heating. After natural cooling and crushing, the primary sintered product B is obtained.

[0030] (3) Weigh 0.05 mol of zirconium acetate, add 1 liter of ethanol, stir and mix thoroughly, then add the mixture to the primary sintered product B prepared in step (2), heat to 60°C, and use a high-speed stirrer to stir continuously, Until the solvent was evap...

Embodiment 2

[0039] This embodiment prepares Sn 4+ with V 5+ Co-doped, Al 2 o 3 The coated ternary cathode material comprises the steps of:

[0040] (1) Weigh 0.02mol of SnCl4, 0.02mol of ammonium metavanadate, add 1 liter of water, fully stir and dissolve; then weigh 9.96mol of Ni 0.6 co 0.2 mn 0.2 (OH) 2 . 5.15 mol of lithium carbonate was put into the suspension, heated to 90° C., and stirred continuously with a high-speed stirrer until the solvent was evaporated to dryness, and a homogeneous mixture A was obtained.

[0041] (2) Place the mixture A prepared in step (1) in a high-temperature sintering furnace, raise the temperature to 880°C at a heating rate of 2°C / min in an oxidizing atmosphere and keep it for 20 hours, then stop heating. After natural cooling and crushing, the primary sintered product B is obtained.

[0042] (3) Weigh 0.025mol of alumina, add 1 liter of ethanol, stir and mix thoroughly, then add the mixture to the primary sintered product B prepared in step (2)...

Embodiment 3

[0047] This embodiment prepares Mg 2+ 、Sc 3+ with Al 3+ 、Ti 4+ A co-doped, boron oxide-coated ternary cathode material, comprising the following steps:

[0048] (1) Weigh 9.9mol of Ni 0.6 co 0.2 mn 0.2 CO 3 , 5.20mol of lithium carbonate, 0.025mol of magnesium hydroxide, 0.025mol of scandium hydroxide, 0.0125mol of aluminum oxide, 0.025mol of TiO 2 , placed in a high-speed mixer, fully mixed to obtain a homogeneous mixture A.

[0049] (2) Put the mixture A prepared in step (1) in a high-temperature sintering furnace, raise the temperature to 900°C and keep it for 15h under an oxidizing atmosphere at a heating rate of 2°C / min, and then stop heating. After natural cooling and crushing, the primary sintered product B is obtained.

[0050] (3) Weigh 0.025 mol of diboron trioxide, add it to 1 liter of ethanol, stir and mix thoroughly, then add the mixture to the primary sintered product B prepared in step (2), heat to 60°C, and use a high-speed stirrer to Stir intermitten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com