Layer-structured ternary material with rich lithium and high manganese as well as preparation method and application thereof

A ternary material, layered structure technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve problems such as the decline of electrochemical performance of materials, and achieve low cation mixing, good volume energy density, and low material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

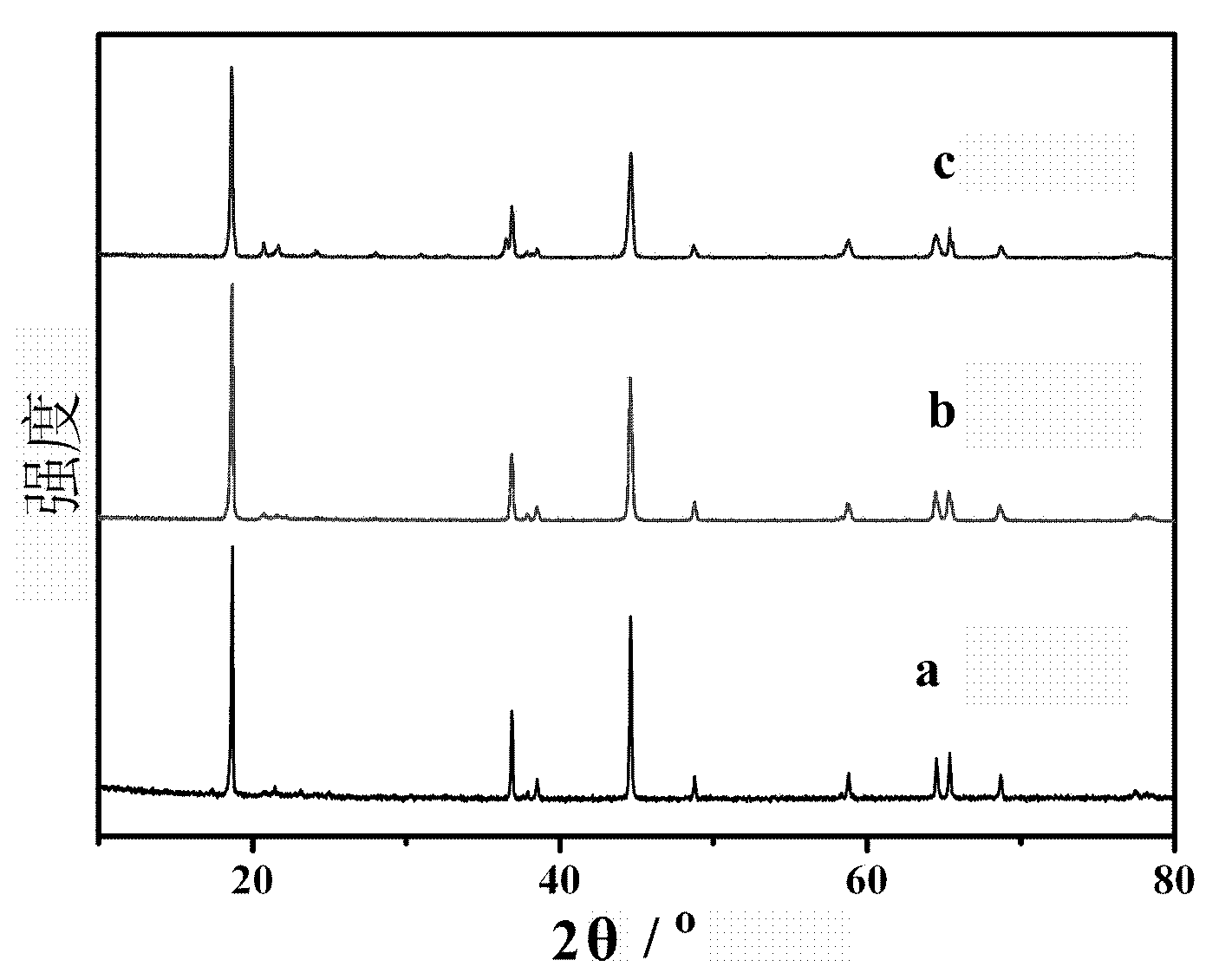

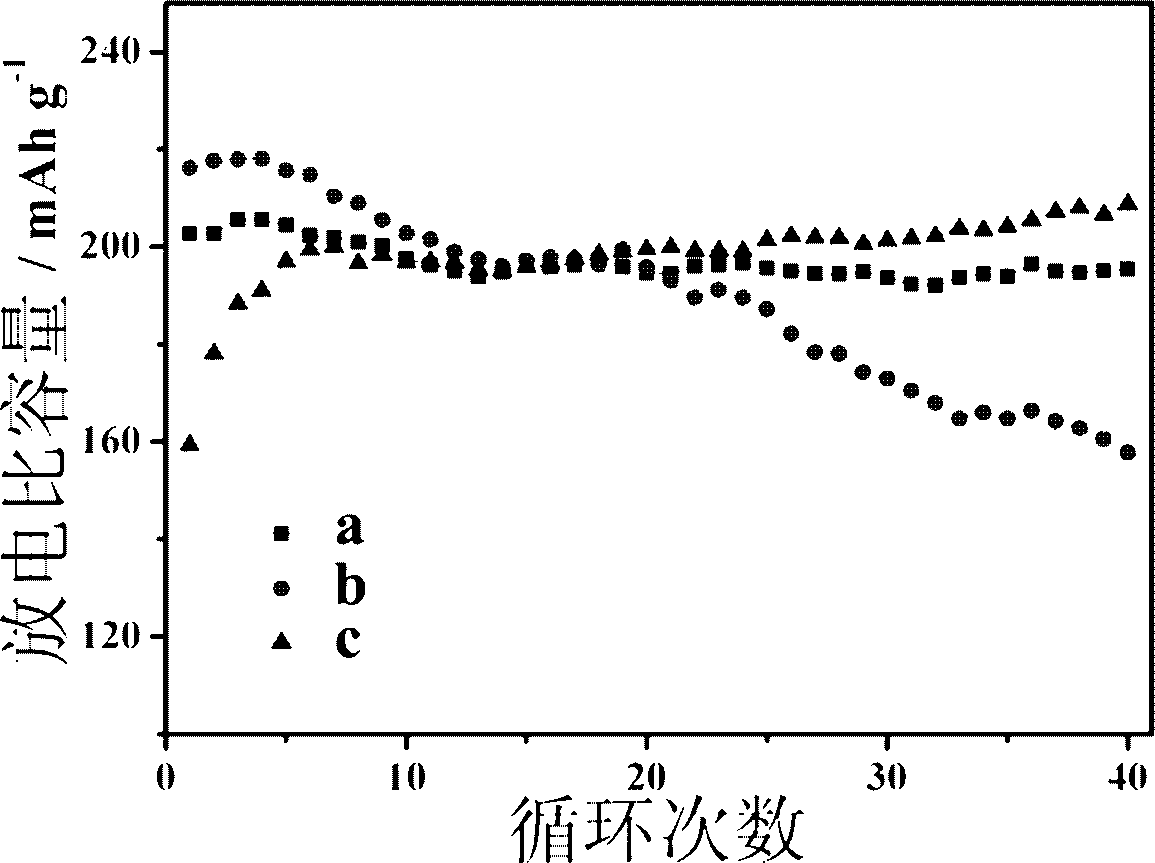

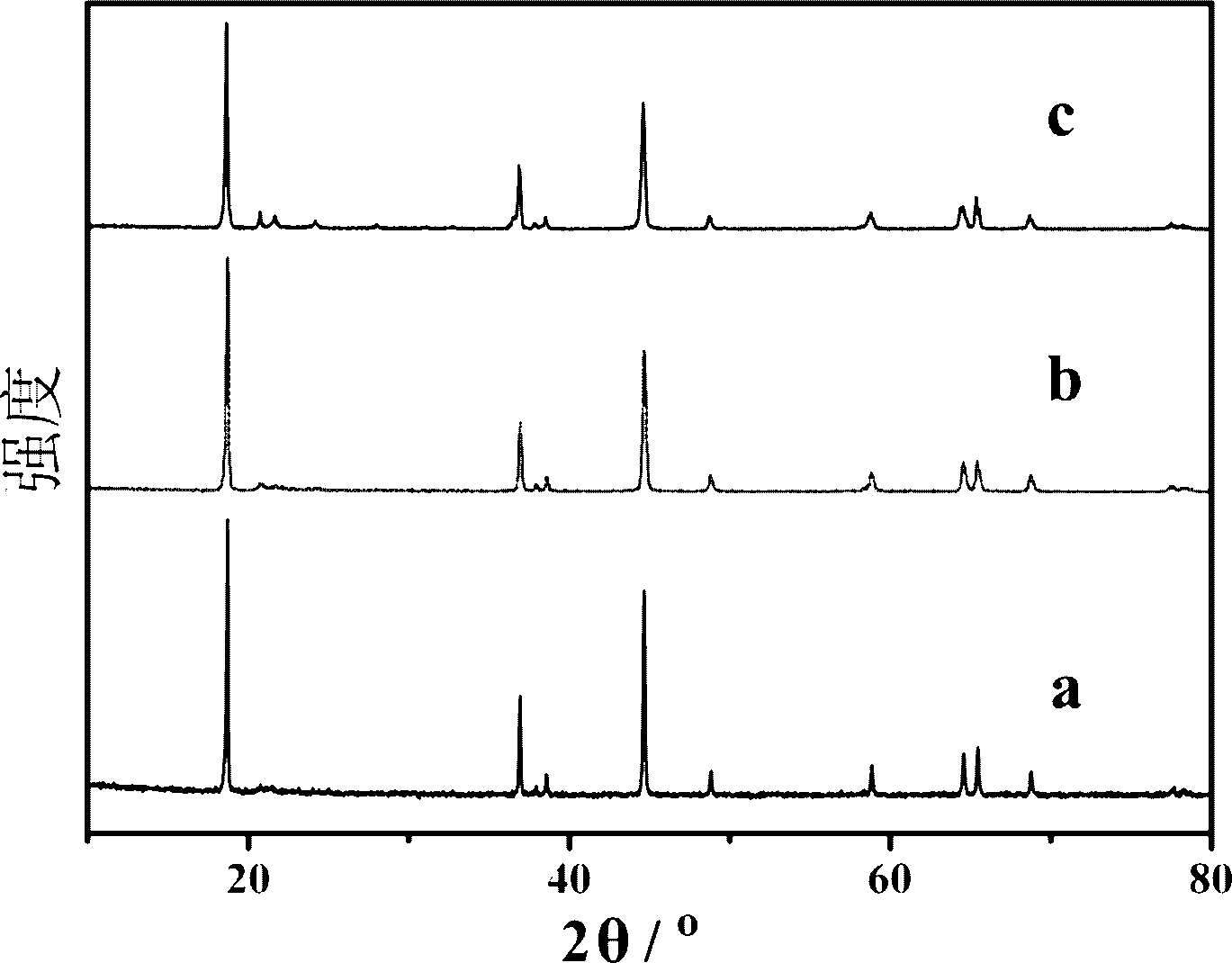

Embodiment 1

[0022] 0.25 mol of nickel sulfate, 0.25 mol of cobalt sulfate and 0.5 mol of manganese sulfate were dissolved in 500 mL of deionized water to obtain transition metal mixed solution I. Feed N into the reactor 2 Air was used for 30 minutes to remove the oxygen in the system, and at the same time, the reactor was heated to 50°C with a water bath. Add the prepared 2mol / L ammonia solution into the reactor to a height of about 5cm, turn on the stirrer and start the reaction. Add the NaOH solution of transition metal mixed solution 1, 2mol / L ammonia solution and 2mol / L dropwise in the reactor at the speed of 0.5d / s simultaneously, in the reaction process, adjust the rate of addition of NaOH solution to keep the pH value of reaction solution Between 10.5±0.5. During the reaction, N was continuously fed 2 The gas maintains the anaerobic condition of the reaction process and prevents the oxidation of transition metals. After the dropwise addition, the stirring reaction was continued...

Embodiment 2

[0025] Dissolve 0.2 mol of nickel sulfate, 0.2 mol of cobalt sulfate and 0.6 mol of manganese sulfate in 500 mL of deionized water to obtain transition metal mixed solution II. Feed N into the reactor 2Air was used for 30 minutes to remove the oxygen in the system, and at the same time, the reactor was heated to 50°C with a water bath. Add the prepared 2mol / L ammonia solution into the reactor to a height of about 5cm, turn on the stirrer and start the reaction. At the same time, drop transition metal mixed solution II, 2mol / L ammonia solution and 2mol / L NaOH solution into the reaction kettle at a rate of 0.5d / s. During the reaction, adjust the drop rate of NaOH solution to keep the pH value of the reaction solution. Between 11.5±0.5. During the reaction, N was continuously fed 2 The gas maintains the anaerobic condition of the reaction process and prevents the oxidation of transition metals. After the dropwise addition, the stirring reaction was continued for 15 h, and the...

Embodiment 3

[0028] 0.15 mol of nickel sulfate, 0.15 mol of cobalt sulfate and 0.7 mol of manganese sulfate were dissolved in 500 mL of deionized water to obtain transition metal mixed solution III. Feed N into the reactor 2 Air was used for 30 minutes to remove the oxygen in the system, and at the same time, the reactor was heated to 50°C with a water bath. Add the prepared 2mol / L ammonia solution into the reactor to a height of about 5cm, turn on the stirrer and start the reaction. At the same time, add transition metal mixed solution III, 2mol / L ammonia solution and 2mol / L NaOH solution dropwise to the reactor at a rate of 0.5d / s. During the reaction, adjust the drop rate of NaOH solution to keep the pH value of the solution at Between 12.5±0.5. During the reaction, N was continuously fed 2 The gas maintains the anaerobic condition of the reaction process and prevents the oxidation of transition metals. After the dropwise addition, the stirring reaction was continued for 20 h, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com