Positive electrode material modification method

A positive electrode material and modification technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of high cost, complicated process, time-consuming, etc., and achieve the effects of low cost, reduced erosion, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh a certain amount of Al(BOB) 3 , prepare 0.3 mol L -1 Al(BOB) 3 - EC / DEC electrolyte;

[0027] (2) Use the prepared electrolyte and LiNi 0.5 co 0.2 mn 0.3 o 2 Positive electrode sheet assembled button half battery;

[0028] (3) Adjust the constant current charge and discharge current density to 0.02 mA cm -2 , control the charge cut-off voltage to 4.3 V, discharge cut-off voltage to 3.5 V, that is, the charge and discharge voltage range is 3.5-4.3 V;

[0029] (4) Under the conditions of step (3), perform three electrochemical pre-cycle activations;

[0030] (5) After the cycle is over, take out the positive electrode and wash it with EC to obtain the modified LiNi 0.5 co 0.2 mn 0.3 o 2 Cathode material.

[0031] The modified positive electrode material was subjected to a phase characterization test, and a button half battery was assembled to test the cycle performance.

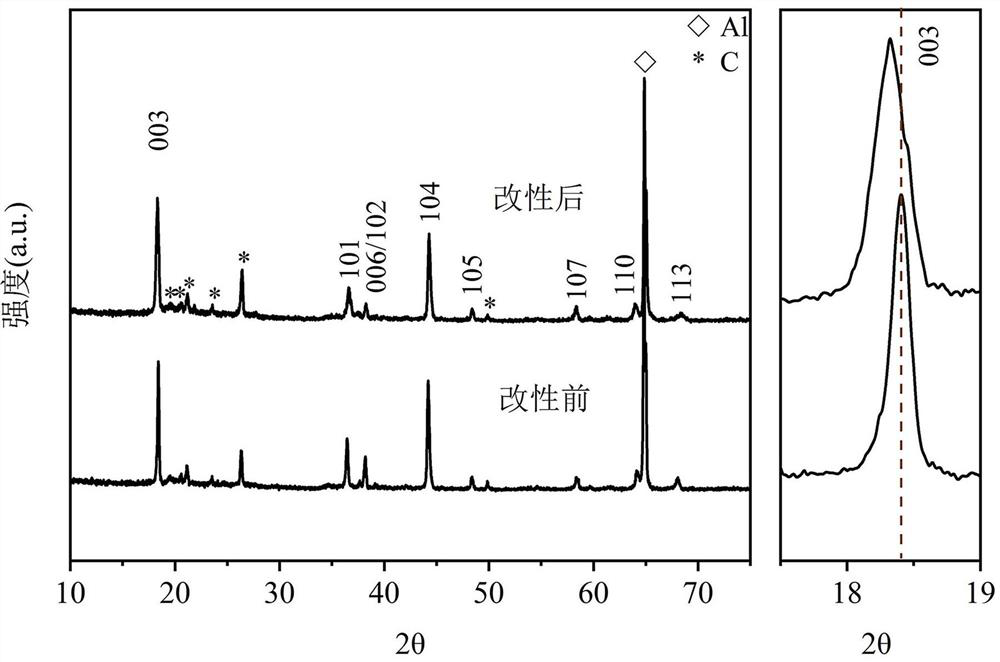

[0032] figure 1 XRD patterns of the material before and after modification...

Embodiment 2

[0037] (1) Weigh a certain amount of Mg(BOB) 2 , prepare 0.5 mol L -1 Mg(BOB) 2 - EC / DEC electrolyte;

[0038] (2) Use the electrolyte prepared in step (2) and the LiNi to be modified 0.5 co 0.2 mn 0.3 o 2 Positive electrode sheet assembled button half battery;

[0039] (3) Adjust the constant current charge and discharge current density to 0.05mA cm -2 , control charge cut-off voltage 4.4 V, discharge cut-off voltage 3.6 V, charge and discharge voltage range 3.6 - 4.4 V;

[0040] (4) Under the conditions of step (3), perform 5 electrochemical pre-cycles;

[0041] (5) After the cycle is over, take out the positive electrode and wash the positive electrode with EC to obtain the modified LiNi 0.5 co 0.2 mn 0.3 o 2 Cathode material.

[0042] The modified positive electrode material was assembled into a button half battery, and the cycle performance test was carried out.

[0043] Figure 5 The cycle performance diagram of the material before and after modification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com