Large-size graphene stack structure wafer and preparation method thereof

A stacked structure and graphene technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of fragile structures and impractical device production, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

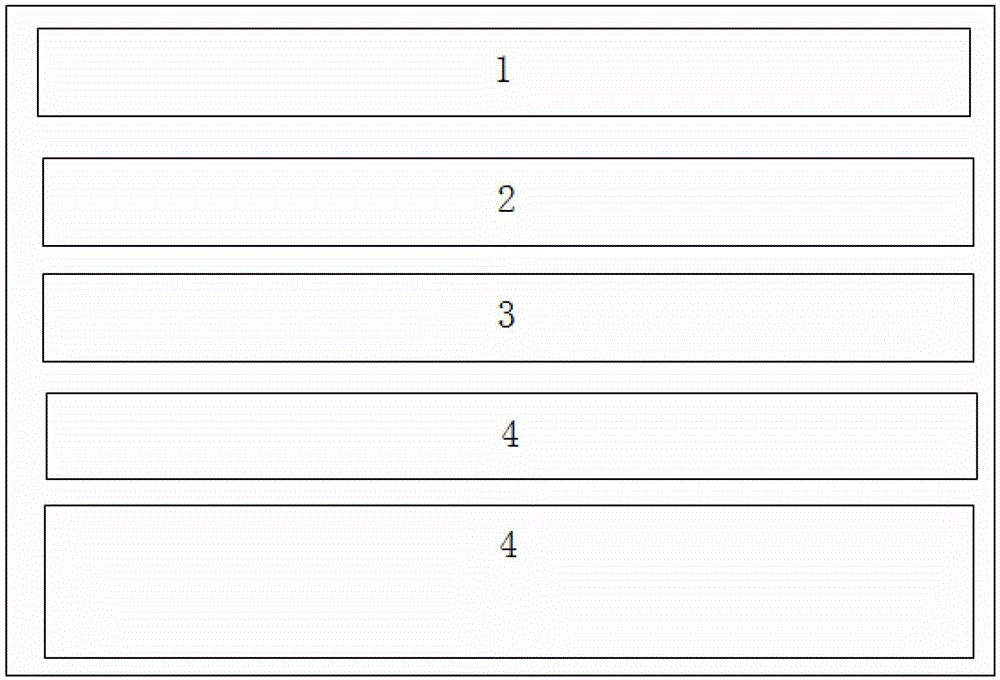

[0025] Such as figure 1 As shown, the present invention is a large-scale graphene stacked structure wafer, and the wafer structure is as follows from top to bottom: graphene single crystal layer 1, h-BN single crystal layer 2, h-BN buffer layer 3 , and SiO 2 / Si wafer substrate 4 .

[0026] It should be noted that the size of the wafer is 2 inches to 30 inches, the thickness of the graphene single crystal layer 1 is 0.335 to 4 nm, the thickness of the h-BN single crystal layer 2 is 0.6 to 50 nm, and the h- The BN buffer layer 3 has a thickness of 0.1-100 μm.

[0027] The method for preparing above-mentioned large-scale graphene stacked structure wafer, comprises the following steps:

[0028] (1) Preparation of the SiO 2 / Si wafer substrate, where Si wafers are selected and SiO is formed by dry oxidation process 2 film;

[0029] (2) Preparation of polyborazane pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com