A preparation of ktiopo by ion implantation combined with chemical etching 4 single crystal thin film method

A technology of ion implantation and chemical etching, applied in ion implantation plating, metal material coating process, vacuum evaporation plating, etc., to achieve the effect of easy peeling, easy realization and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

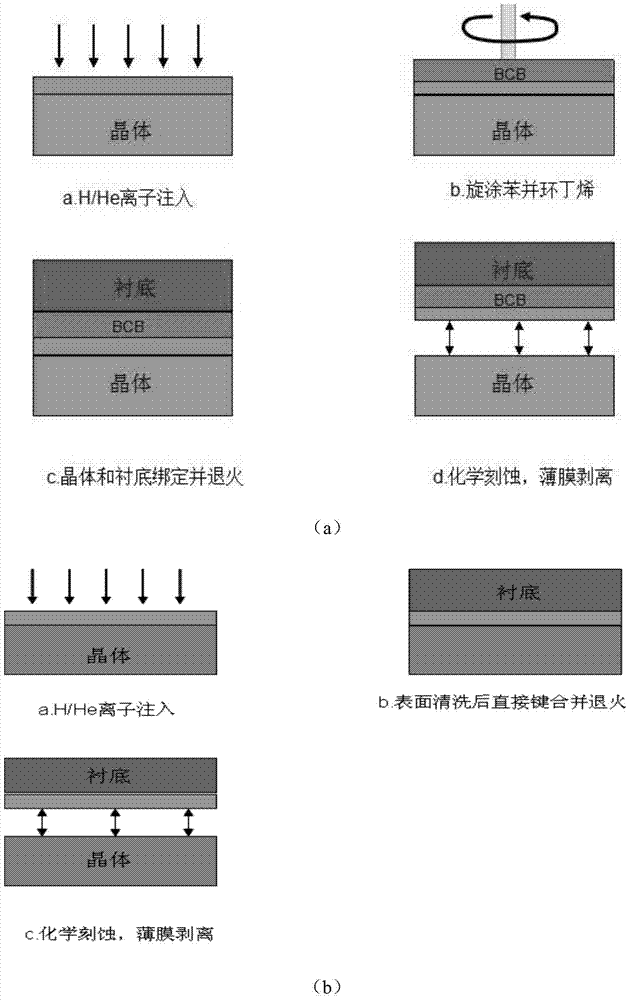

Method used

Image

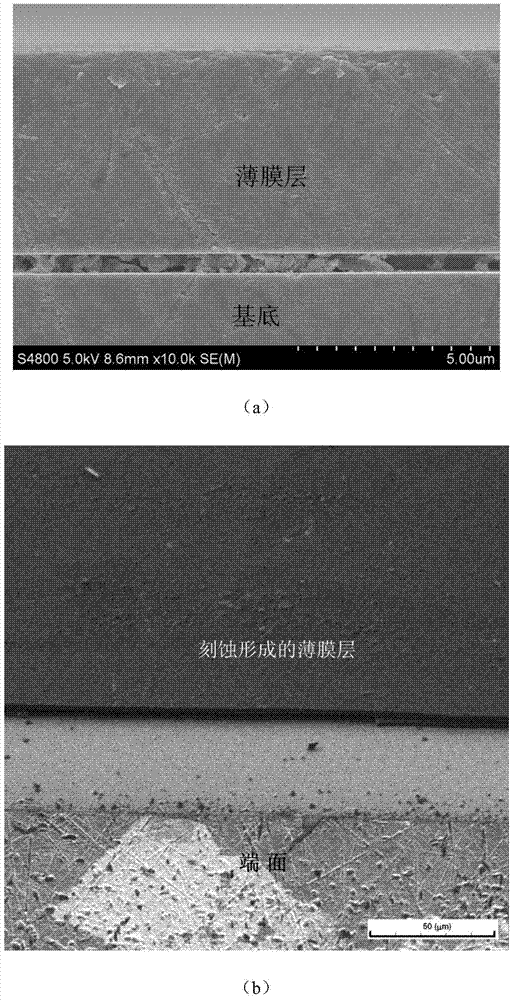

Examples

Embodiment 1

[0037] Potassium titanyl phosphate material (size: 10mm×10mm×1mm) was cleaned, and He ions with energy 2000keV were implanted into the Z-tangential potassium titanyl phosphate material at room temperature, and the implantation dose was 4×10 16 Ions / cm2; annealing treatment is carried out after implantation, the annealing temperature is gradually increased from room temperature to 350 degrees Celsius, kept at 350 degrees Celsius for 30 minutes, and finally etched in 5% HF solution at 20 degrees Celsius for 2 hours to achieve film peeling.

Embodiment 2

[0039] Clean the potassium titanyl phosphate material (size: 10mm×10mm×1mm), and implant it into the Z-tangential potassium titanyl phosphate material at room temperature with He ions with an energy of 150keV, and the implantation dose is 8×10 16 Ions / square centimeter; annealing treatment is performed after implantation, the annealing temperature is gradually increased from room temperature to 350 degrees Celsius, kept at 350 degrees Celsius for 30 minutes, and finally etched in a nitric acid solution with a mass concentration of 5% at 60 degrees Celsius for 2 hours to achieve film peeling.

Embodiment 3

[0041] Clean the potassium titanyl phosphate material (size: 10mm×10mm×1mm), and implant it into the Z-tangential potassium titanyl phosphate material at room temperature with He ions with an energy of 6000keV, and the implantation dose is 1×10 17 Ions / cm²; annealing treatment is performed after implantation, the annealing temperature is gradually increased from room temperature to 400 degrees Celsius, kept at 400 degrees Celsius for 30 minutes, and finally etched in a molten potassium hydroxide solution with a mass concentration of 5% at 360 degrees Celsius for 2 hours to achieve Film peeled off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com