Method for preparing high-thermal-conductivity graphene radiating fin

A technology of high thermal conductivity graphite and heat sink, applied in graphene, chemical instruments and methods, modification by conduction and heat transfer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

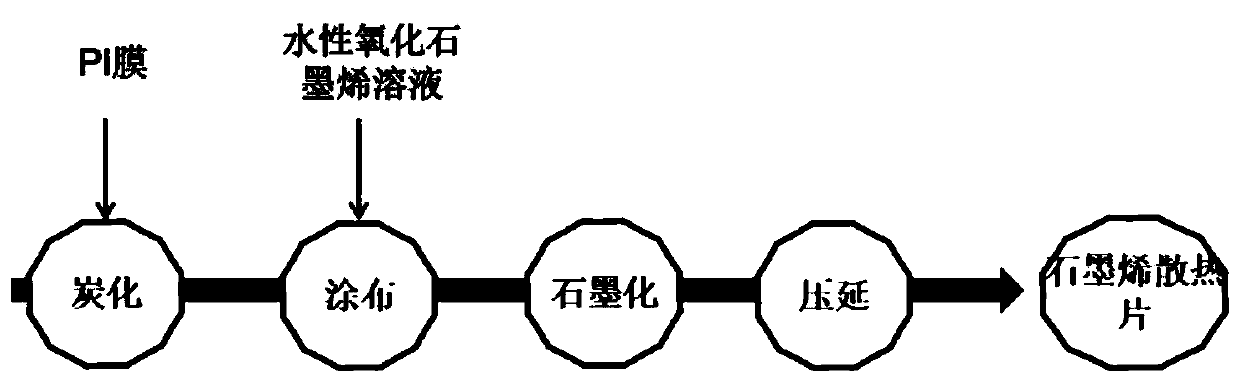

[0040] In a specific embodiment, refer to figure 1 , the preparation method of the high thermal conductivity graphene heat sink includes the following five steps: the first step is to add graphite oxide to deionized water, then add a dispersant, and prepare an aqueous graphene oxide solution through stirring, oscillation or ultrasonic; the second step In the second step, the polyimide film (PI film) is placed in a carbonization furnace, filled with inert gas, and then subjected to high-temperature carbonization treatment; in the third step, the aqueous graphene oxide solution is coated on the carbonized On the polyimide film, obtain the composite graphene oxide-polyimide film; the 4th step, put described graphene oxide-polyimide film into the graphitization furnace, fill inert gas, then carry out Graphitization treatment; in the fifth step, the film obtained after the graphitization treatment is rolled / calendered to obtain a graphene heat sink.

[0041] In a specific embodime...

Embodiment 1

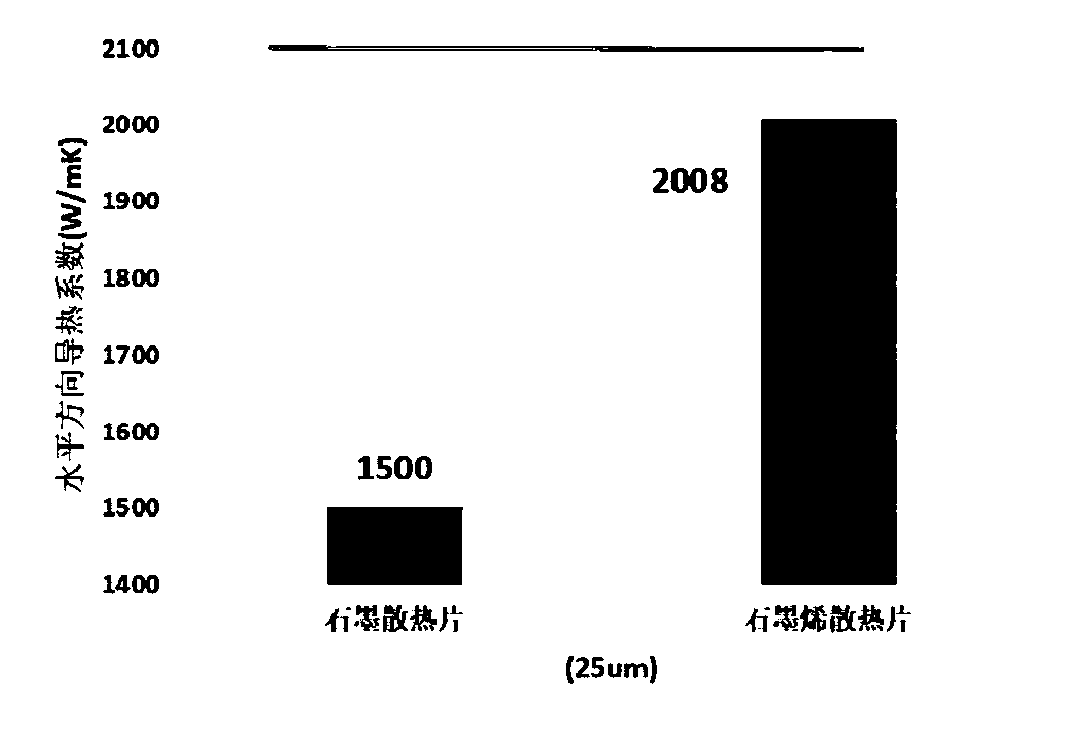

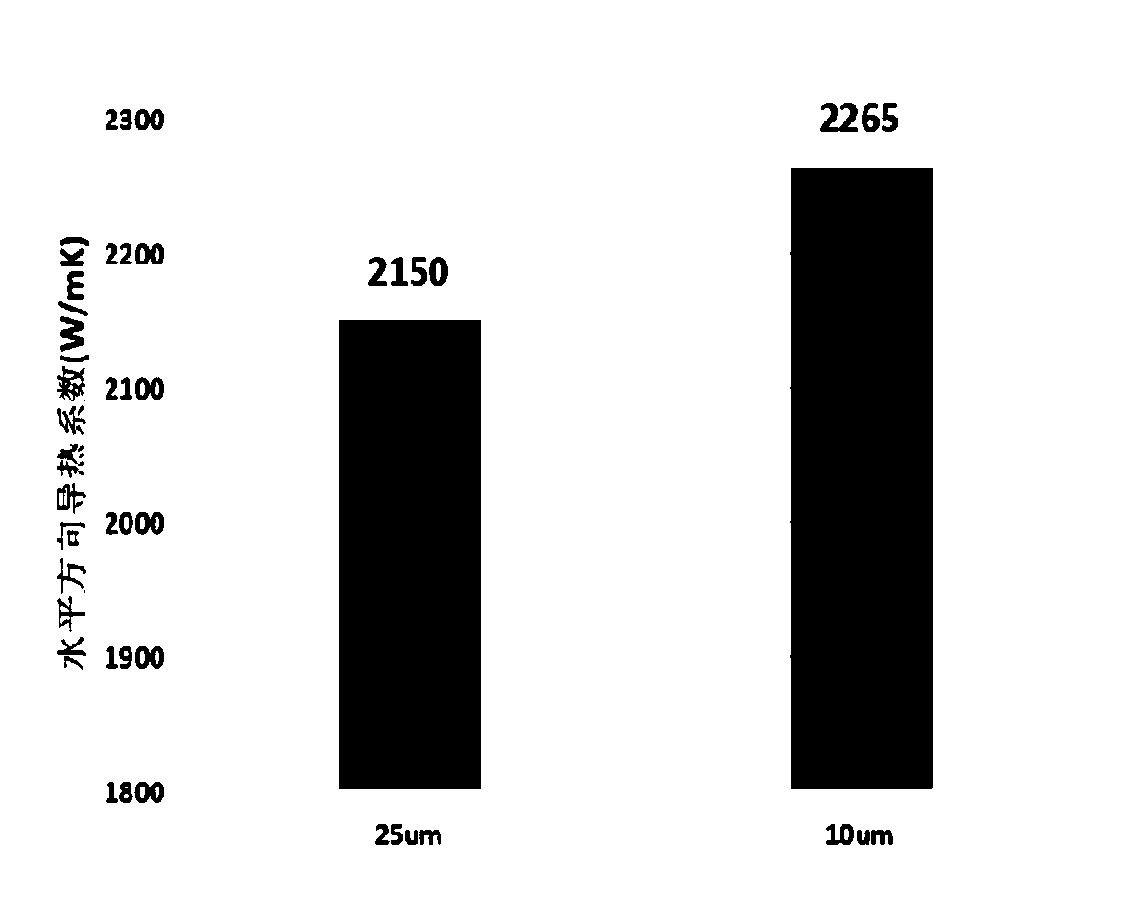

[0050] Graphite oxide was added to deionized water, then a dispersant was added, and an aqueous graphene oxide solution was prepared by stirring, shaking or ultrasonication, wherein the graphene oxide sheet diameter was 80 μm, and the concentration of the graphene oxide solution was 1 mg / mL. The polyimide film was placed in a carbonization furnace, filled with nitrogen, and carbonized. The carbonization temperature was 1250° C., and the carbonization time was 20 hours. The graphene oxide solution is coated on the carbonized polyimide film by means of transfer coating, and dried. Then put it into a graphitization furnace, fill it with argon gas, and carry out graphitization treatment. The graphitization treatment temperature is 2700° C., and the graphitization treatment time is 48 hours. The above film was rolled to obtain a graphene composite heat sink with a thickness of 10 μm. After testing, the obtained graphene heat sink has a horizontal thermal conductivity of 2265W / m·K....

Embodiment 2

[0052] Set the sheet diameter of graphene oxide to 50 μm, the concentration of graphene oxide solution to 0.5 mg / mL, the carbonization treatment temperature to 600°C, the graphitization treatment temperature to 2200°C, and the coating method to be gravure Printing, the thickness of the obtained graphene composite heat sink was set to 36 μm, except that, a graphene heat sink was prepared in the same manner as in Example 1, and various evaluations were performed. After testing, the obtained graphene heat sink has a horizontal thermal conductivity of 2001W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com