Preparation method of graphene heat dissipating fin

A technology of graphene and heat sink, which is applied in the field of preparation of high thermal conductivity graphene heat sink, can solve the problems of high cost and difficult preparation, and achieve the effects of easy control, heat conduction penetration, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

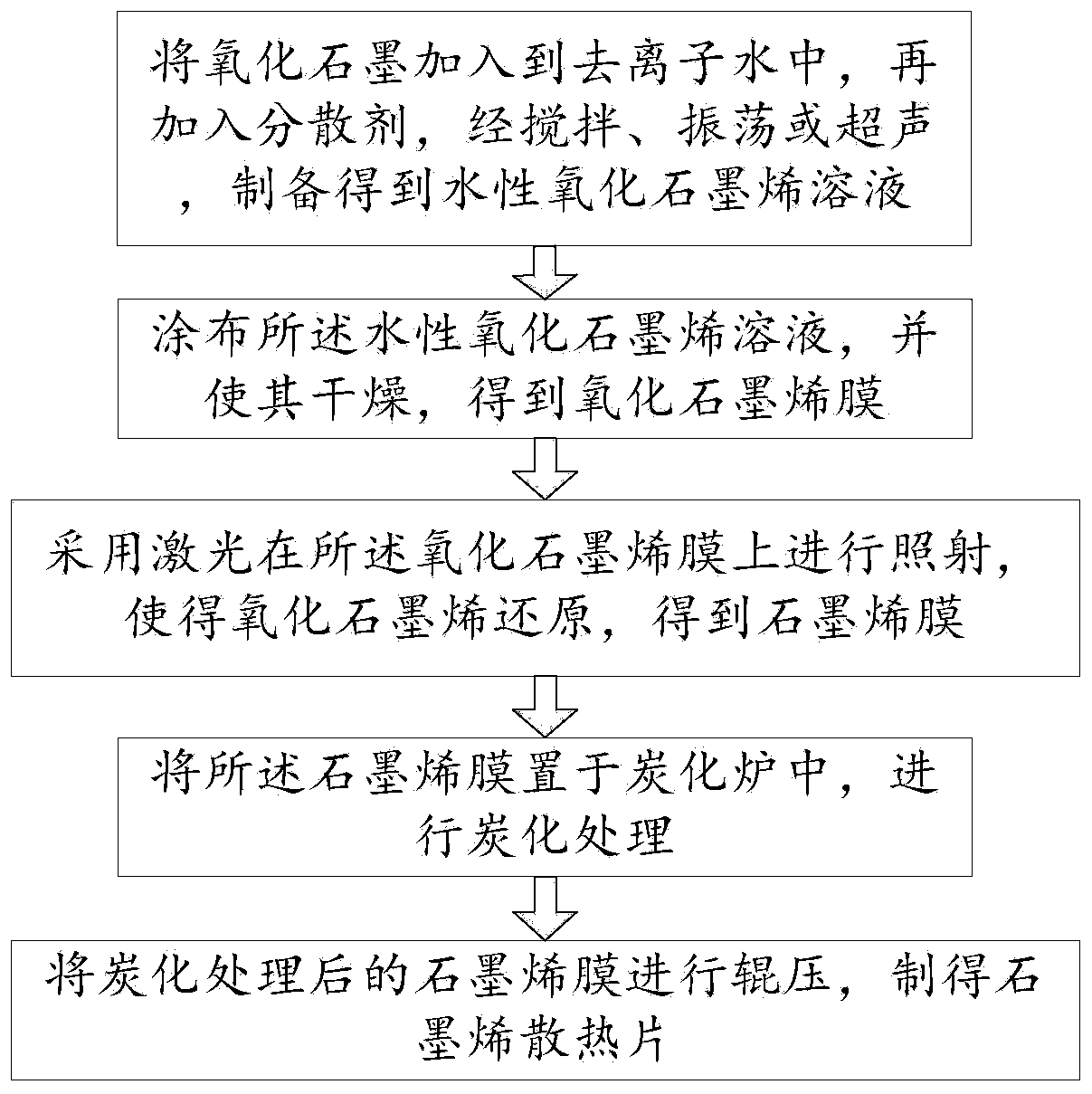

[0036] In a specific embodiment, refer to figure 1 , the preparation method of the graphene heat sink of the present invention comprises the following five steps: the first step, using graphene oxide and an aqueous solvent to prepare an aqueous graphene oxide solution; the second step, coating the aqueous graphene oxide solution on the substrate, and make it dry to obtain a graphene oxide film, and the graphene oxide film is peeled off from the substrate; in the third step, the graphene oxide film peeled off is irradiated with a laser, so that the graphene oxide is reduced , to obtain a graphene film; the fourth step, placing the graphene film in a carbonization furnace for carbonization; the fifth step, rolling the carbonized graphene film to obtain a graphene heat sink.

[0037] In a specific embodiment, the preparation process of the aqueous graphene oxide solution is as follows: adding graphite oxide to deionized water, then adding a dispersant, stirring, vibrating or ultr...

Embodiment 1

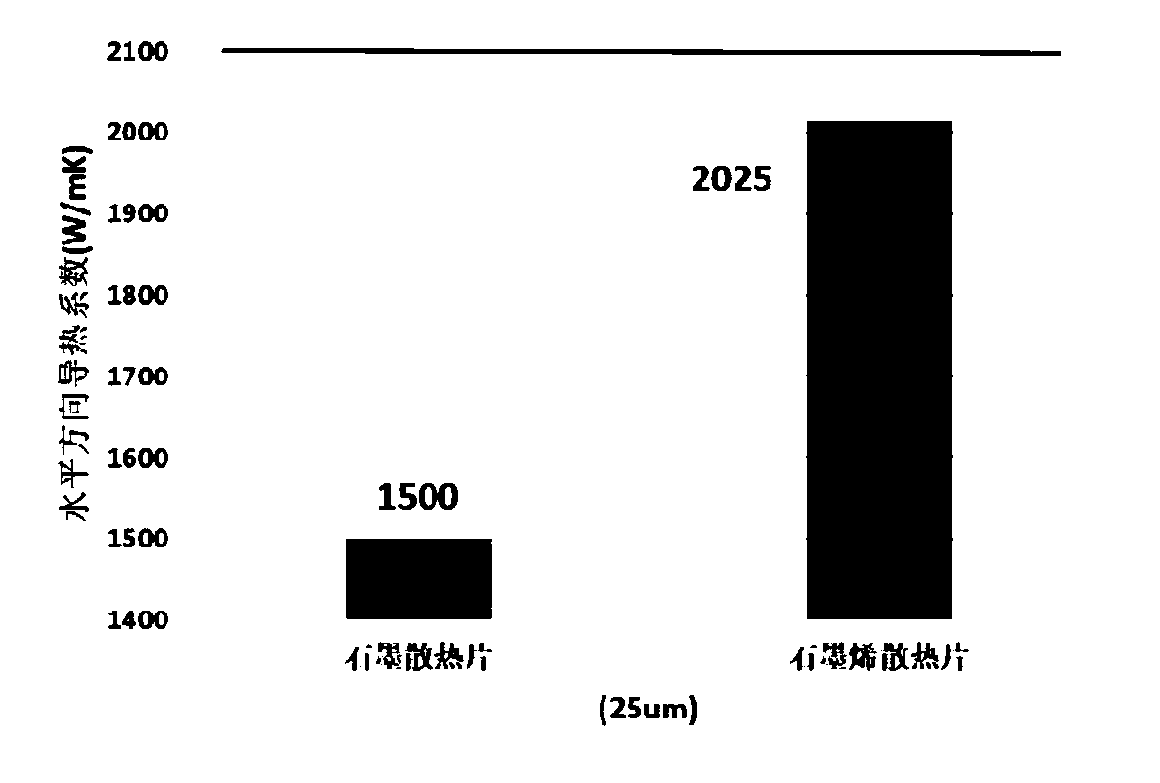

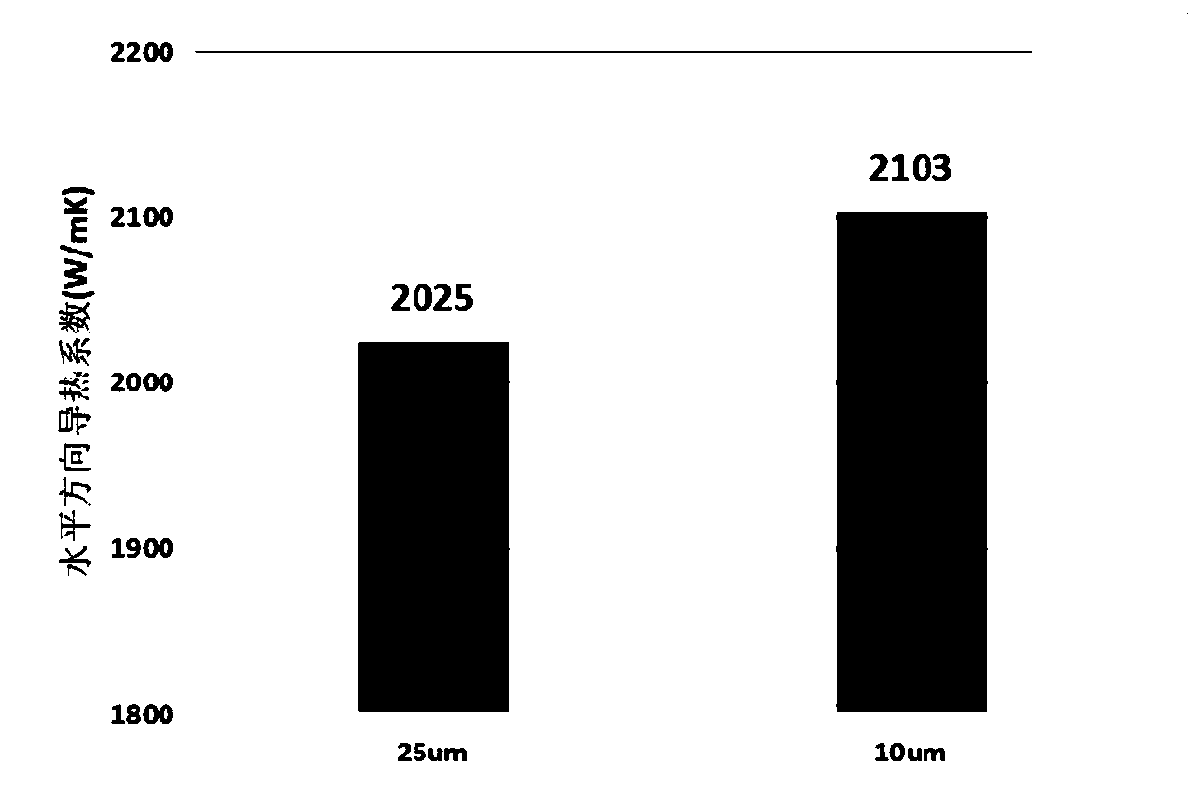

[0048] Add graphite oxide to deionized water, then add a dispersant, and stir, vibrate or sonicate to prepare an aqueous graphene oxide solution, wherein the graphene oxide sheet diameter is 90 μm, and the concentration of the graphene oxide solution is 0.5 mg / mL . The graphene oxide solution is coated on the substrate by means of transfer coating, and the graphene oxide film is obtained after drying, and the graphene oxide film is peeled off from the substrate. A high-energy laser with a wavelength of 788nm is used to irradiate the graphene oxide film to reduce the graphene oxide to obtain a graphene film. Put the graphene film above into a carbonization furnace, and carry out carbonization treatment at a temperature of 1250°C. The carbonized graphene film was rolled to obtain a graphene heat sink with a thickness of 10 μm. After testing, the obtained graphene heat sink has a horizontal thermal conductivity of 1928W / m·K.

Embodiment 2

[0050] Set the sheet diameter of graphene oxide to 50 μm, the concentration of graphene oxide solution to 1.5 mg / mL, the wavelength of high-energy laser to 418 nm, and the carbonization temperature to 1500 ° C to obtain a graphene composite heat sink Except that the thickness was set to 20 μm, a graphene heat sink was prepared in the same manner as in Example 1, and various evaluations were performed. After testing, the obtained graphene heat sink has a horizontal thermal conductivity of 1800W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com