Lithium-rich lithium iron phosphate material as well as preparation method and application thereof

A lithium iron phosphate, lithium-rich technology, applied in the field of materials, can solve problems such as high cost, unfavorable large-scale production and use, and achieve the effects of long cycle life, easy commercial application, high sensitivity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

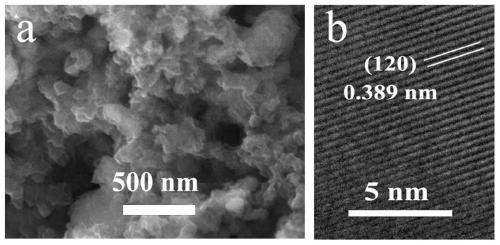

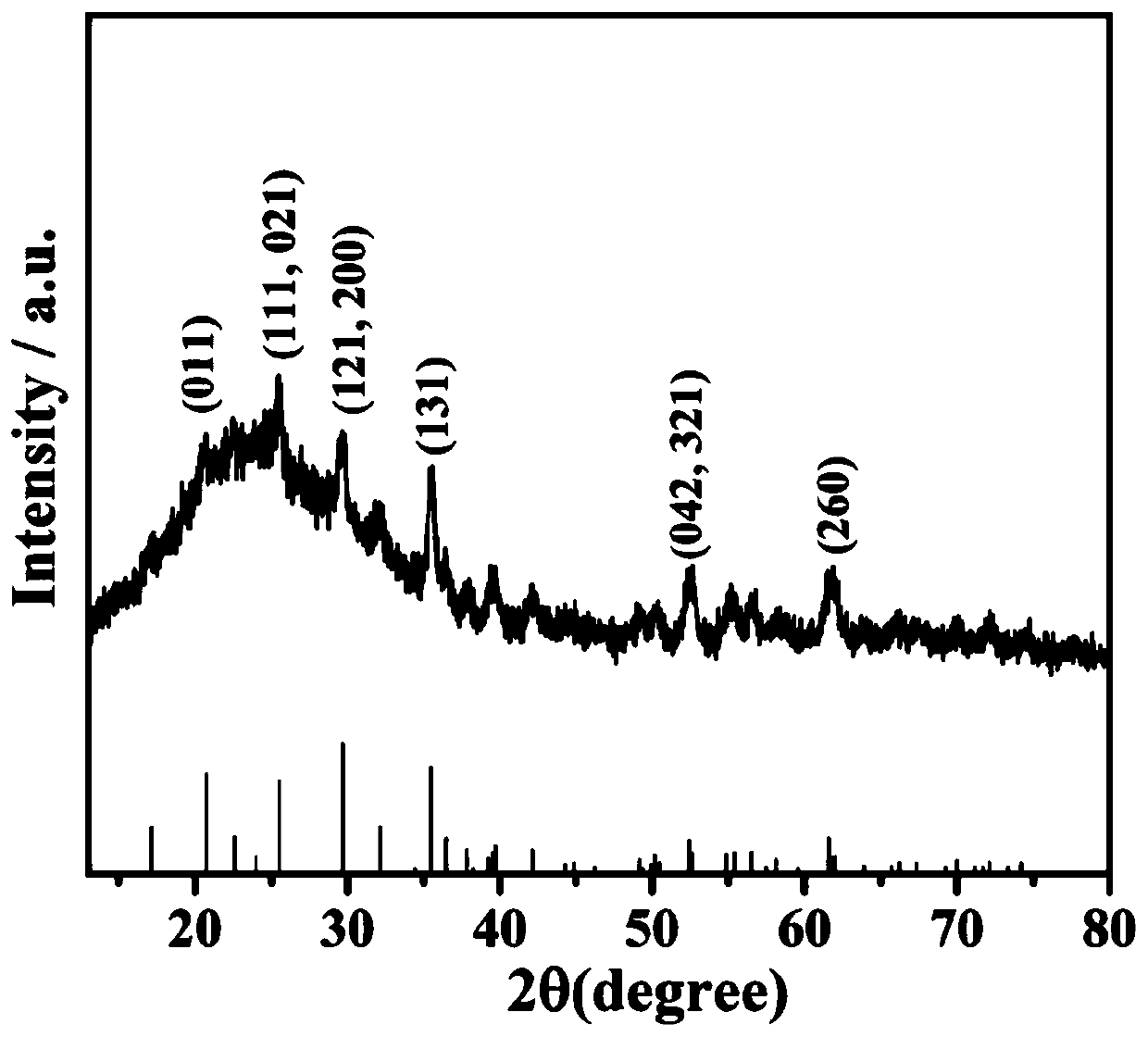

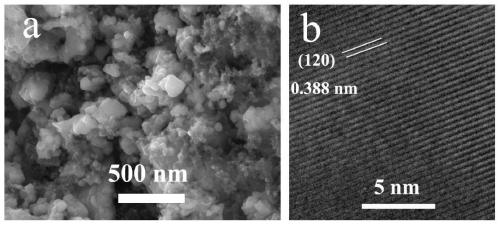

Image

Examples

Embodiment 1

[0037] Preparation of lithium-rich lithium iron phosphate material and working electrode coated with the material, and construction of an electrochemical sensor for nitric oxide

[0038] (1) Add lithium iron phosphate, conductive carbon black and polyvinylidene fluoride to N-methylpyrrolidone according to the mass ratio of lithium iron phosphate, conductive carbon black and polyvinylidene fluoride as 8:1:1, and mix well The mixture was obtained, and the mixture was coated on an aluminum foil with a thickness of 170 μm and dried at 120° C. for 12 hours to obtain an aluminum foil loaded with lithium iron phosphate. The aluminum foil loaded with lithium iron phosphate was used as the positive electrode, and the lithium metal sheet was used as the counter electrode. Ethylene microporous membrane is used as the separator, lithium hexafluorophosphorous lithium electrolyte with a concentration of 1M is used as the electrolyte, and a CR250 button battery is assembled in a glove box fil...

Embodiment 2

[0043] Preparation of lithium-rich lithium iron phosphate material and working electrode coated with the material, and construction of an electrochemical sensor for nitric oxide

[0044](1) Add lithium iron phosphate, conductive carbon black and polyvinylidene fluoride to N-methylpyrrolidone according to the mass ratio of lithium iron phosphate, conductive carbon black and polyvinylidene fluoride as 4:3:3, and mix well The mixture was obtained, and the mixture was coated on an aluminum foil with a thickness of 180 μm and dried at 115° C. for 10 h to obtain an aluminum foil loaded with lithium iron phosphate. The aluminum foil loaded with lithium iron phosphate was used as the positive electrode, and the lithium metal sheet was used as the counter electrode. Ethylene microporous membrane is used as the separator, lithium hexafluorophosphorous lithium electrolyte with a concentration of 1M is used as the electrolyte, and a CR250 button battery is assembled in a glove box filled w...

Embodiment 3

[0049] Preparation of lithium-rich lithium iron phosphate material and working electrode coated with the material, and construction of an electrochemical sensor for nitric oxide

[0050] (1) Add lithium iron phosphate, conductive carbon black and polyvinylidene fluoride into N-methylpyrrolidone according to the mass ratio of lithium iron phosphate, conductive carbon black and polyvinylidene fluoride as 9:0.5:0.5, and mix well The mixture was obtained, and the mixture was coated on an aluminum foil with a thickness of 160 μm and dried at 110° C. for 11 h to obtain an aluminum foil loaded with lithium iron phosphate. The aluminum foil loaded with lithium iron phosphate was used as the positive electrode, and the lithium metal sheet was used as the counter electrode. Ethylene microporous membrane is used as the separator, lithium hexafluorophosphorous lithium electrolyte with a concentration of 1M is used as the electrolyte, and a CR250 button battery is assembled in a glove box f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com