Porous titanium-tantalum-niobium-zirconium stent for bone defect repair

A porous titanium and bone defect technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of lack of biological function, increase surgical trauma and operation time, stress shielding, etc., and achieve good osseointegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of porous titanium, tantalum, niobium, and zirconium scaffolds:

[0032] 1. Prepared by selective laser melting technology, where the powder components are 60% titanium, 2% tantalum, 34% niobium, and 4% zirconium; the melting temperature of printing titanium, tantalum, niobium, and zirconium alloys is 2500-3000 ° C; the electrostatic range of the platform 1KV-4KV;

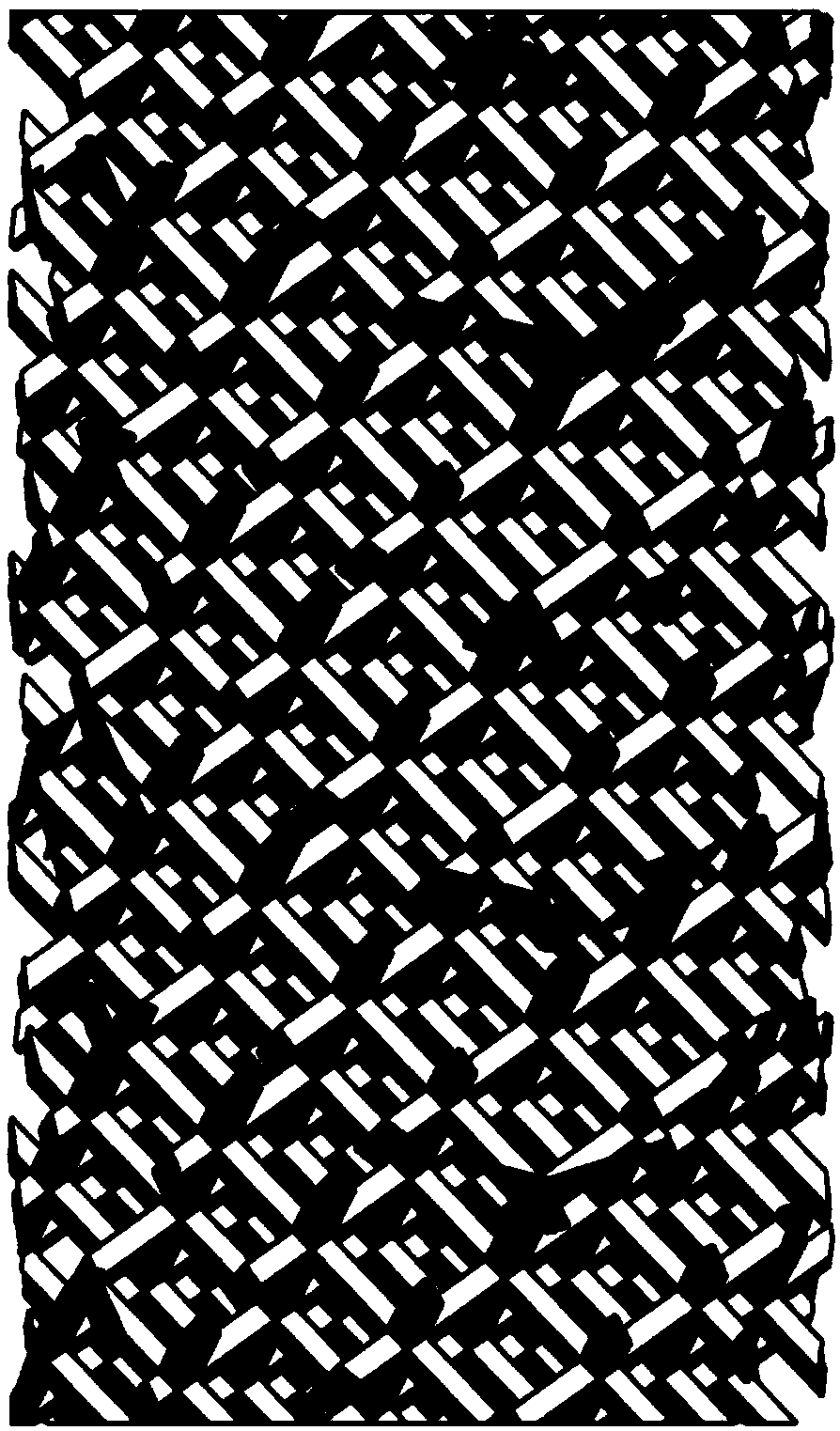

[0033] 2. The scaffold structure is printed according to the diamond molecular structure;

[0034] 3. The porous titanium tantalum niobium zirconium scaffold has a pore size of 400 μm and a porosity of 78.3%.

[0035] Such as figure 2 As shown, the porous scaffold has a regular porous structure, which is conducive to the growth of new bone into the material, and achieves a good osseointegration effect, thereby improving the repair quality of bone defects.

[0036] The present invention also provides comparison results of animal experiments between the porous titanium-tantalum-niobium-zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com