Method for preparing cubic indium oxide single-crystal film on yttrium-doped zirconia substrate

A technology of single crystal thin film and cubic structure, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of material stability, low carrier mobility, unsuitable for industrial production, etc., to achieve Good uniformity and repeatability, broad application prospects, and excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

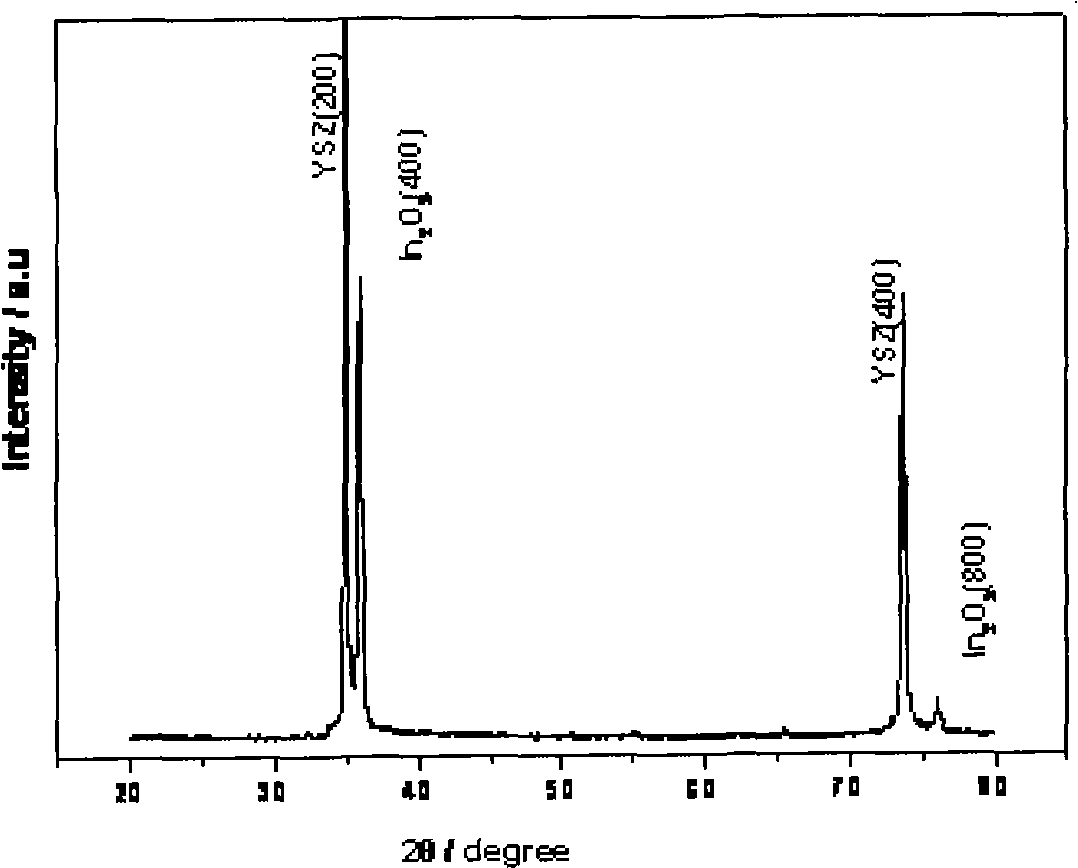

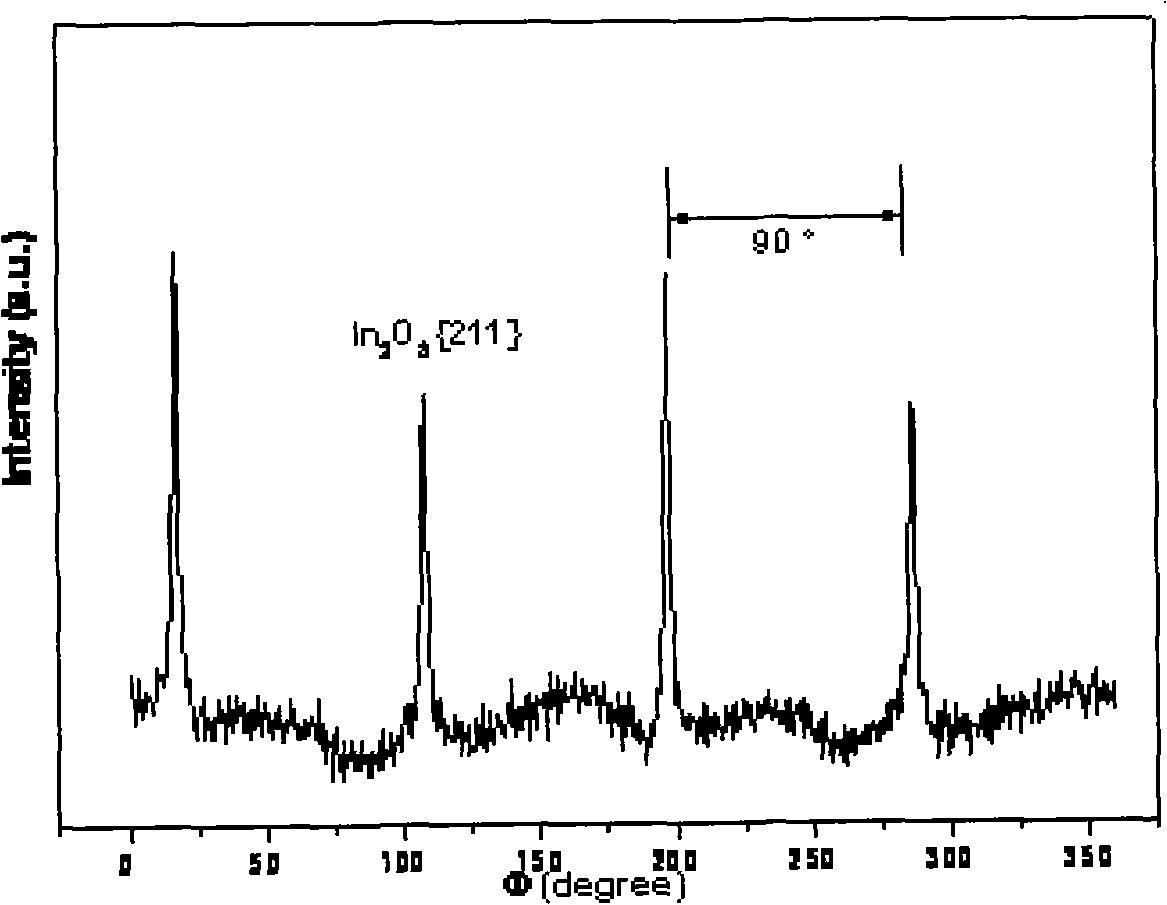

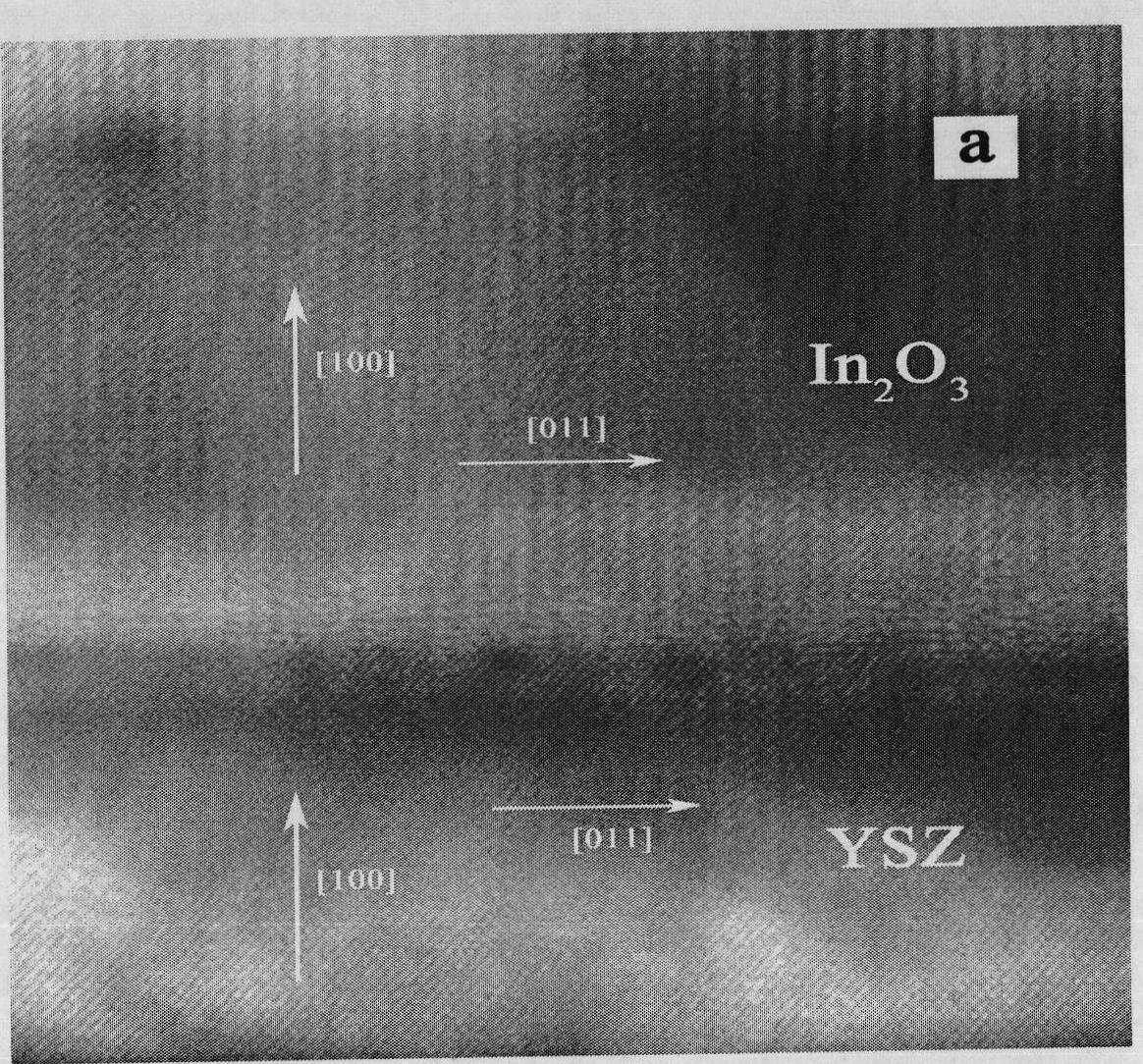

[0057] Example 1: Preparation of Cubic Indium Oxide Single Crystal Thin Film Material by MOCVD Technology

[0058] (1) First pump the reaction chamber of the MOCVD equipment to a high vacuum state of 5×10 -4 Pa, heat the substrate to 650°C;

[0059] (2) Open the valve of the nitrogen cylinder and feed nitrogen into the reaction chamber (background N 2 450sccm) for 20 minutes, the reaction chamber pressure was stabilized at 40Torr;

[0060] (3) Open the valve of the oxygen cylinder, adjust the flow rate of oxygen to 50 sccm, and keep it for 5 minutes;

[0061] (4) Set the pressure of the organometallic source bottle to 240 Torr, open the valve of the indium source bottle, adjust the flow rate of the carrier gas (nitrogen) to 25 sccm, and keep for 5 minutes;

[0062] (5) Pass oxygen and organometallic indium sources into the reaction chamber at the same time, and keep the film growth time at 180 minutes;

[0063] (6) After the reaction, close the valves of the indium source ...

Embodiment 2

[0068] Monocrystalline indium oxide thin film material was prepared by MOCVD technology, and the preparation process was the same as in Example 1, except that the reaction chamber pressure was 30 Torr, the substrate temperature (growth temperature) was 700° C., and the film growth time was 180 minutes. Using polished YSZ (100) as the substrate material, the prepared indium oxide film has a single crystal structure, the thickness of the film is 157nm, and the carrier mobility of the film is 61.2cm 2 V -1 the s -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com