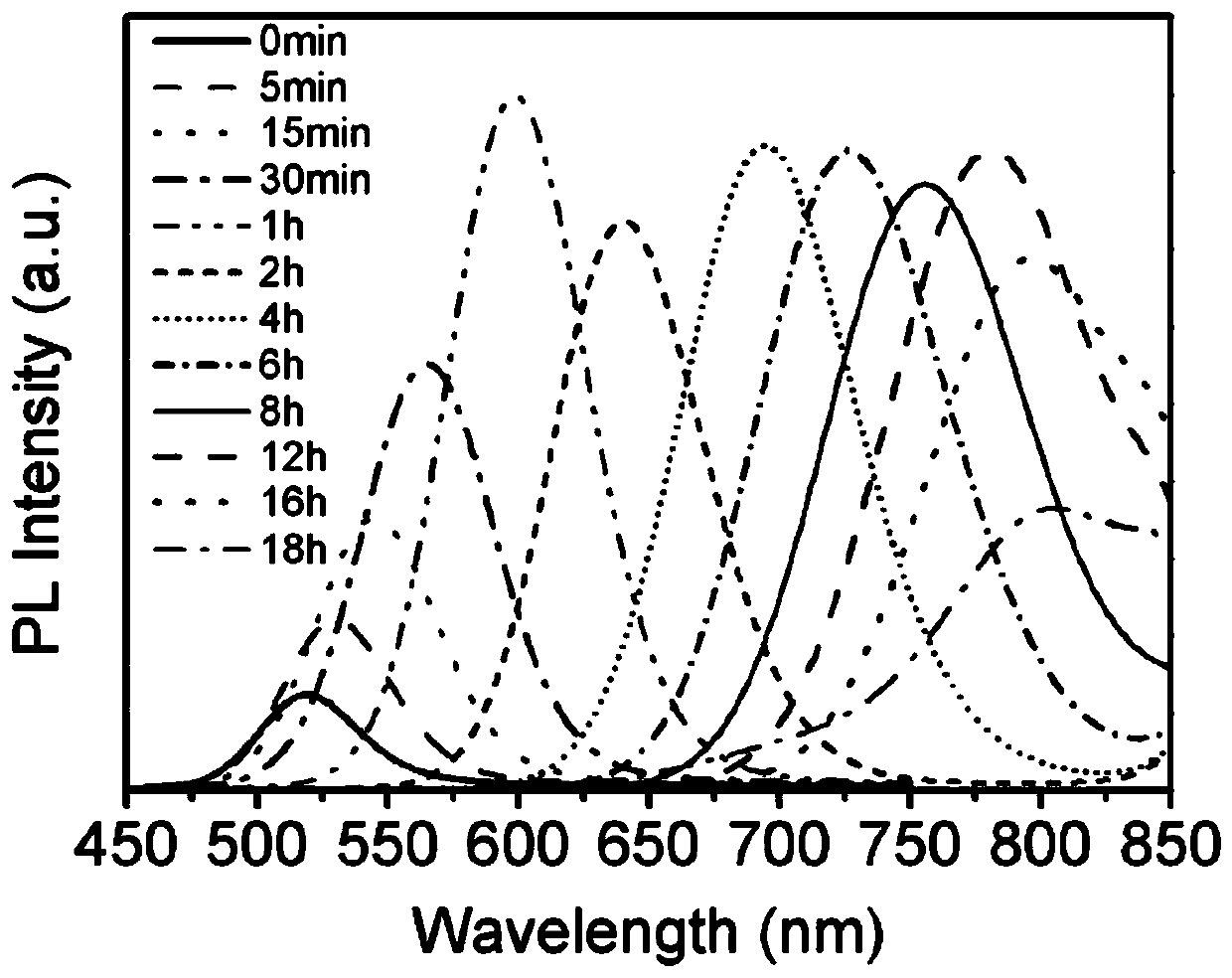

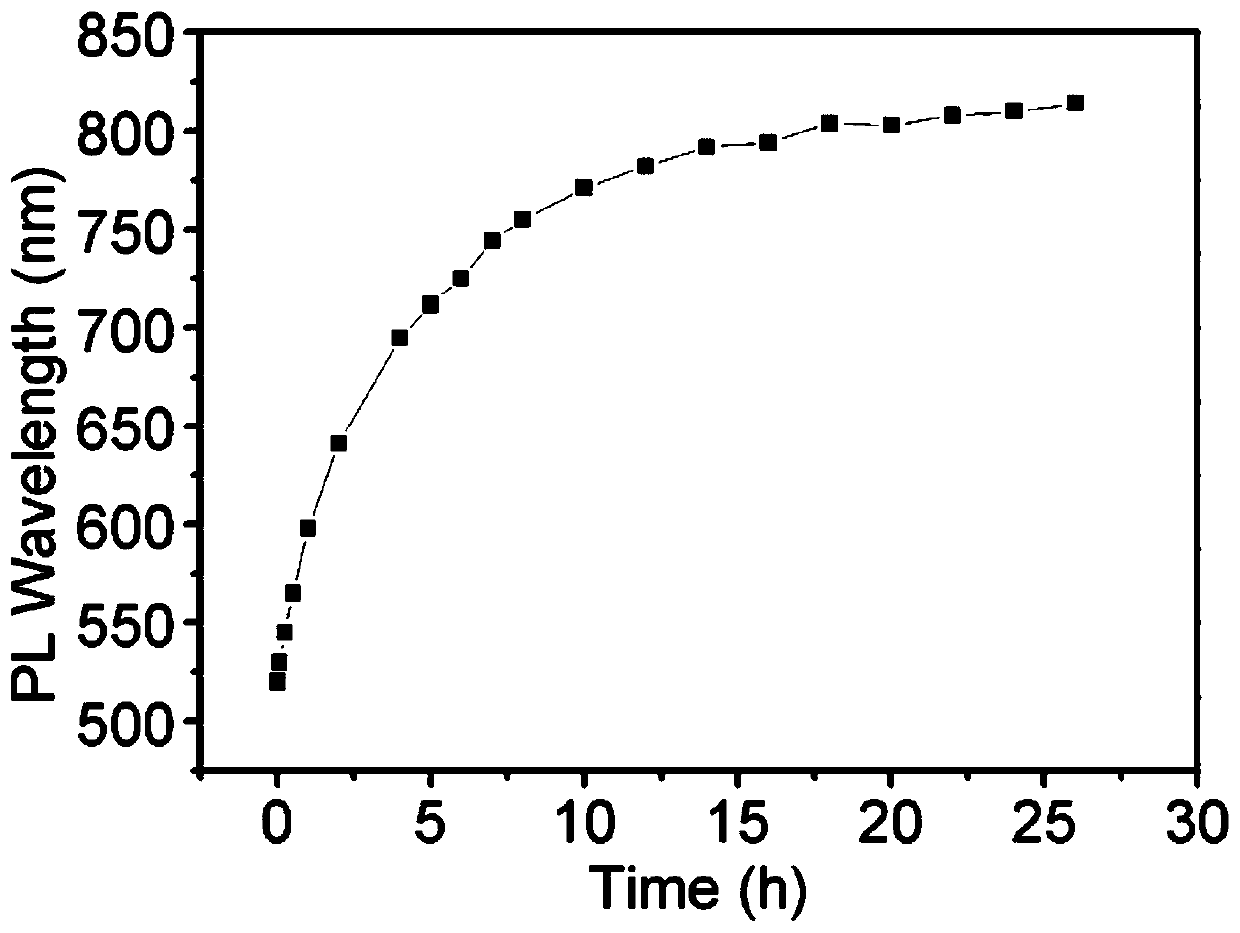

Method for preparing near-infrared cadmium telluride quantum dots through hydrothermal treatment

A cadmium telluride quantum dot, near-infrared technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of water-soluble quantum dots, such as the limitation of the luminous range, and achieve low raw material prices, simple equipment, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a. Add 0.5mL of 0.1M cadmium chloride aqueous solution and 10uL of mercaptopropionic acid solution into 4.5mL of water, and stir evenly.

[0033] b. Adjust the pH value of the mixed solution to 9.1 with a 1.0M aqueous sodium hydroxide solution, and then pass nitrogen gas for 30 minutes. After injecting 15uL of the 0.667M sodium hydride telluride solution just prepared, the precursor solution of cadmium telluride can be obtained. In this embodiment, the molar ratio of cadmium chloride: mercaptopropionic acid: sodium hydride telluride is 1:2.4:0.2, and the concentration of cadmium ions is 10 mM.

[0034] c. After heating the precursor solution for five minutes, add 3 mL of isopropanol to mix, remove the supernatant after centrifugation, and disperse the precipitated quantum dots in 200 mL of deionized water.

[0035] d. Add 0.5mL cadmium chloride solution and 10uL mercaptopropionic acid solution, and then adjust the pH value of the mixed solution to 9.1 with 1.0M aqueous...

Embodiment 2

[0037] a. Add 5mL of 0.1M cadmium chloride aqueous solution and 0.1mL of mercaptopropionic acid solution into 45mL of water, and stir evenly.

[0038] b. Adjust the pH value of the mixed solution to 9.1 with a 1.0M aqueous sodium hydroxide solution, and then pass nitrogen gas for 30 minutes. After injecting 0.15mL of the 0.667M sodium hydride telluride solution just prepared, the precursor solution of cadmium telluride can be obtained. In this embodiment, the molar ratio of cadmium chloride: mercaptopropionic acid: sodium hydride telluride is 1:2.4:0.2, and the concentration of cadmium ions is 10 mM.

[0039] c. After heating the precursor solution for five minutes, add 30 mL of isopropanol to mix, remove the supernatant after centrifugation, and disperse the precipitated quantum dots in 200 mL of deionized water.

[0040] d. Add 6.8mL cadmium chloride solution and 140uL mercaptopropionic acid solution, and then adjust the pH value of the mixed solution to 9.1 with 1.0M aqueo...

Embodiment 3

[0042] a. Add 10mL of 0.1M cadmium chloride aqueous solution and 140uL of thioglycolic acid solution into 50mL of water, and stir evenly.

[0043] b. Adjust the pH value of the mixed solution to 11 with a 1.0M aqueous sodium hydroxide solution, and then pass nitrogen gas for 30 minutes. After injecting 150uL of the 0.667M sodium hydride telluride solution just prepared, the precursor solution of cadmium telluride can be obtained. In this embodiment, the molar ratio of cadmium chloride: mercaptoacetic acid: sodium hydride telluride is 1:2:0.1, and the concentration of cadmium ions is 16.7mM.

[0044] c. After heating the precursor solution for five minutes, add 40 mL of isopropanol to mix, remove the supernatant after centrifugation, and disperse the precipitated quantum dots in 200 mL of deionized water.

[0045] d. Add 5mL of cadmium chloride solution and 70uL of mercaptopropionic acid solution, and then adjust the pH value of the mixed solution to 11 with 1.0M aqueous sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com