Method for in-situ preparation of coal-biomass prepared carbon base NOx adsorption reduction catalyst

An in-situ preparation and biomass technology, which is applied in the field of air pollution control technology and environmental protection catalytic materials, can solve the problems that cannot meet the requirements of NOx adsorption-reduction dual-functional catalytic technology, and achieve the effect of excellent lattice structure and promoting molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

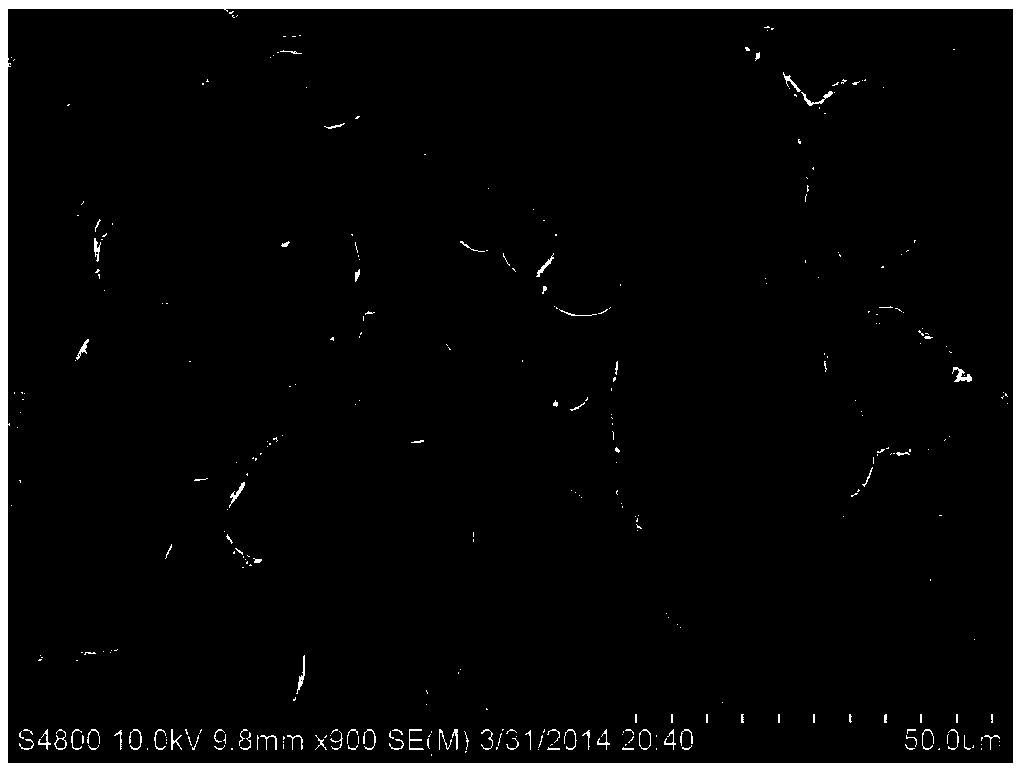

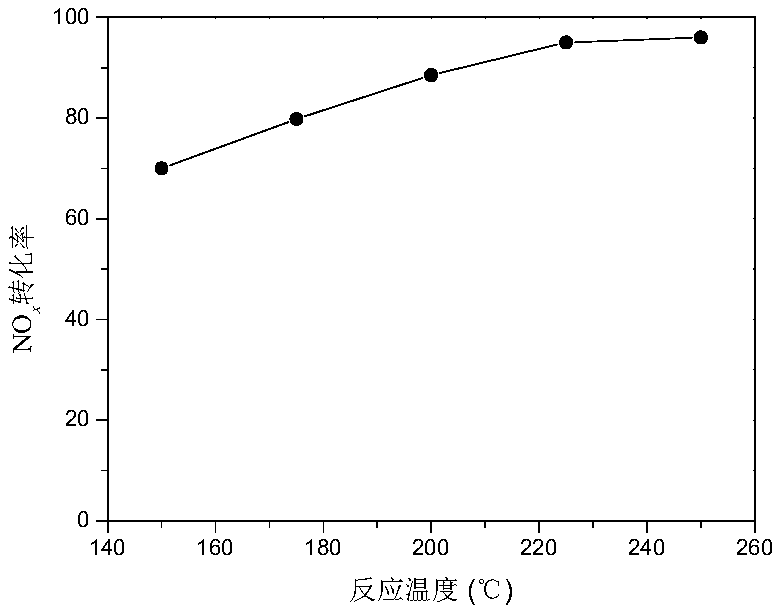

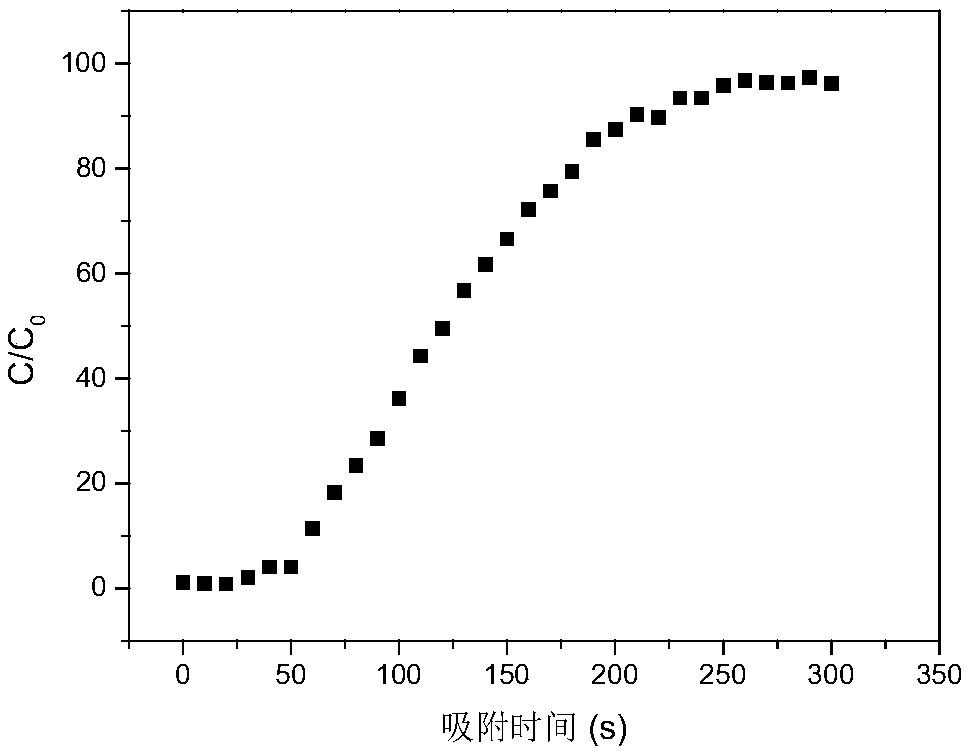

[0034] An in-situ prepared carbon-based NO from coal-biomass x The carbon carrier material of the adsorption reduction catalyst adopts a temperature-segment sedimentation pyrolysis process, that is, a carbon-containing precursor material with certain functions is selected in a targeted manner, and the carbon-containing precursor is formed, pore structure optimized, and activated in low-temperature, medium- and high-temperature stages. into a carbon-based support with excellent adsorption activity. The carrier preparation precursor is a mixture of coal and biomass, and the coal is made of inferior coal with high volatile and ash content to ensure excellent pore structure and high mechanical strength during the preparation process. Biomass uses straw, grass and other powders with high basic metal salt content to ensure that the carbon materials contain more basic active functional groups during the pyrolysis process. While pyrolyzing at different temperatures, active metal salt...

Embodiment 1

[0044] Example 1: 55% lignite-45% rice straw based Cu-Fe catalyst

[0045] Weigh 15.037gFe(NO 3 ) 3 9H 2 O, 4.496g Cu(NO 3 ) 2 ·3H 2 O, dissolved in 150ml deionized water. Weigh 55g of lignite and 45g of rice straw, and grind them into particles below 2 μm in a coal mill. After the solvent is thoroughly mixed with the powder at room temperature, it is added to the settling furnace feeder. The lower part of the settling furnace is fed with an air stream containing 3vol.% oxygen, and after the reaction at low temperature (50-150°C), medium temperature (150-450°C), and high temperature (450-750°C), the catalyst forms spherical particles with a particle diameter of about 3mm . Since this example is a small-scale experiment, there is a rolling barrel structure in the feeding process, which promotes the formation of spherical particles.

Embodiment 2

[0046] Example 2: 55% lignite-15% rice straw-30% sawdust based Cu-Fe catalyst

[0047] Weigh 15.037gFe(NO 3 ) 3 9H 2 O, 4.496g Cu(NO 3 ) 2 ·3H 2 O, dissolved in 150ml deionized water. Weigh 55g of lignite, 15g of rice straw, and 30g of pine sawdust and grind them into particles below 2 μm in a coal mill. The top spraying form of the settling furnace is adopted to mix the solid with the liquid, and the shape of the particles is completed during the settling process. The lower part of the settling furnace is fed with an air stream containing 3vol.% oxygen, and after the reaction at low temperature (50-150°C), medium temperature (150-450°C), and high temperature (450-750°C), the catalyst forms irregular particles with a diameter of about 1mm. particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com