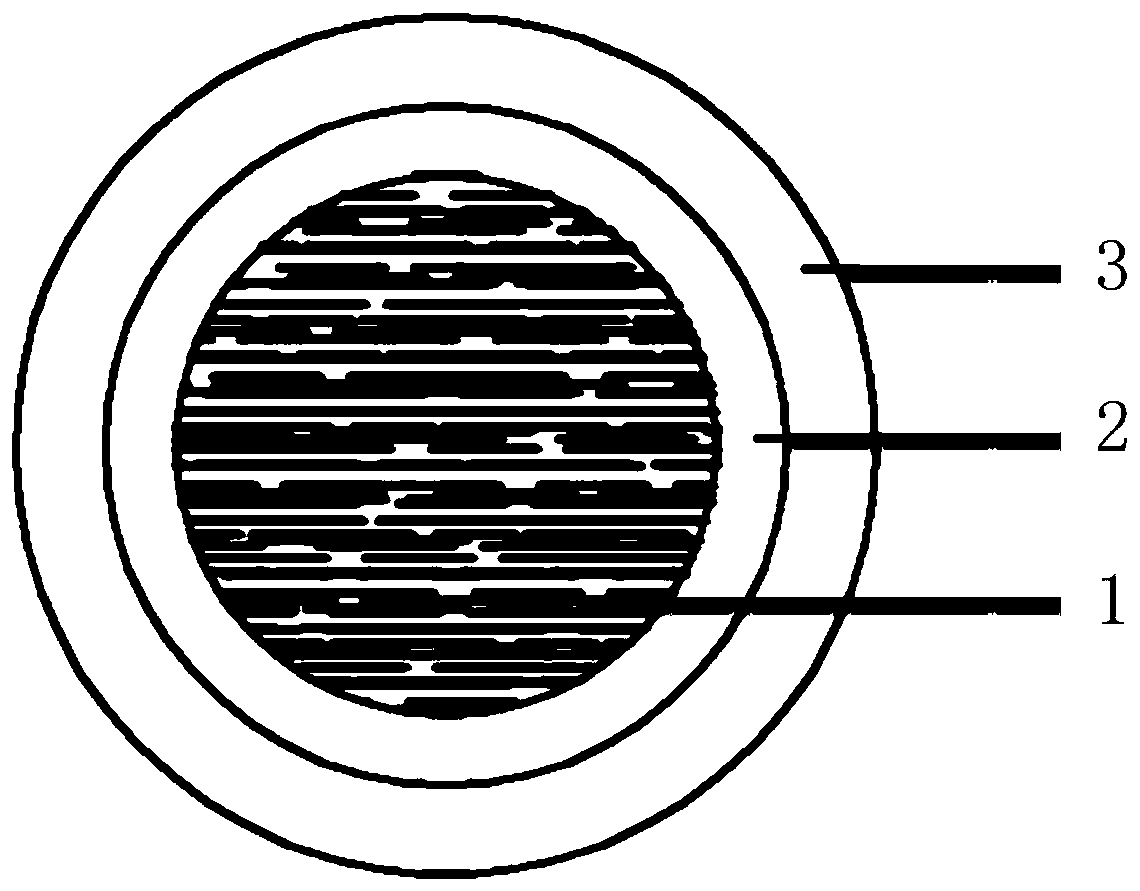

Lithium ion battery, lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as not fully meeting service life requirements, cycle life decay, electrode cracking, etc. Achieve the effects of improving the first Coulomb efficiency, inhibiting volume expansion, and reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

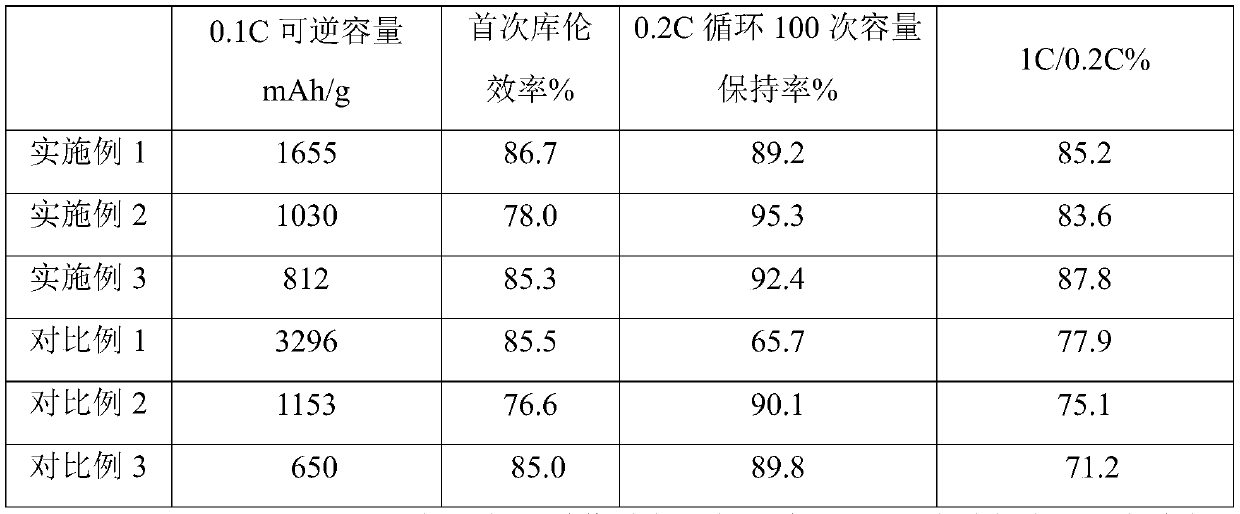

Embodiment 1

[0041] 1. Spray granulation:

[0042] Silicon source: nano silicon powder, particle size 150nm, purity > 99.9%; graphite source: artificial graphite, particle size 12 μm, purity > 99.9%; dispersant: polyethylene glycol 1500, analytically pure; organic carbon source: sucrose, analytically pure ;

[0043] Fully disperse 5 parts of silicon source, 5 parts of graphite source, 1 part of polyethylene glycol 1500, and 2 parts of sucrose in deionized water to obtain a spray slurry with 25% solid content; when the inlet temperature is 185 °C and the outlet temperature is 103 The above-mentioned slurry was subjected to spray granulation on a two-fluid spray dryer at ℃ to obtain the first precursor.

[0044] 2. Pyrolysis of the first precursor:

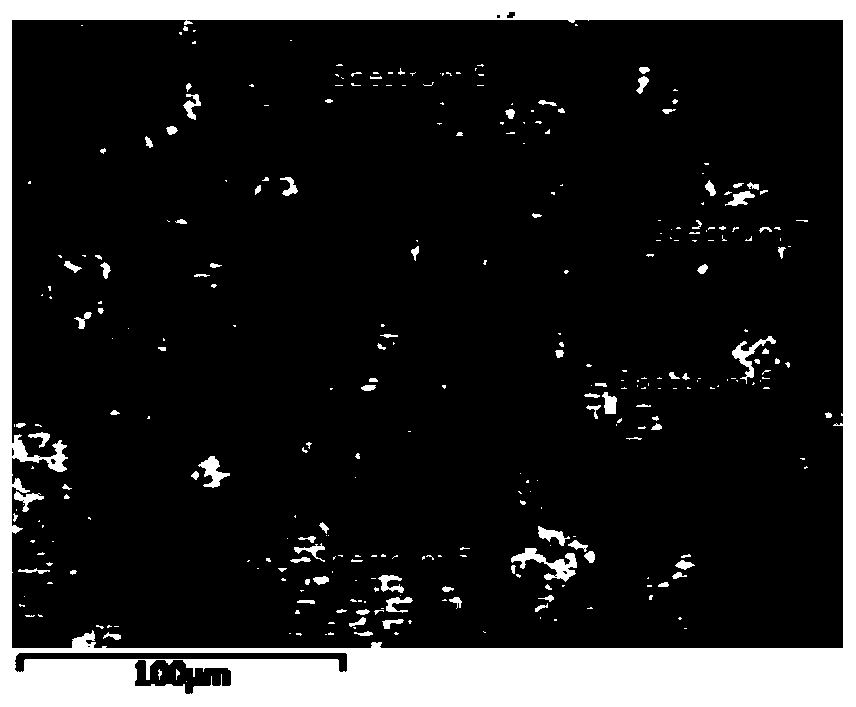

[0045] The above-mentioned first precursor was subjected to high-temperature pyrolysis at 800° C. for 5 h in a nitrogen atmosphere to obtain a second precursor coated with amorphous carbon. The amount of carbon coating was about 5% based on th...

Embodiment 2

[0049] 1. Spray granulation:

[0050] Silicon source: silicon oxide (x is 1), particle size 5 μm, purity > 99.9%; graphite source: flake graphite, particle size 10 μm, purity > 99.9%; dispersant: polyethylene glycol 2000, analytically pure; organic carbon source : Glucose, analytically pure;

[0051] Fully disperse 5 parts of silicon source, 2 parts of graphite source, 1 part of polyethylene glycol 2000, and 3 parts of glucose in deionized water to obtain a spray slurry with a solid content of 15%; when the inlet temperature is 175 °C and the outlet temperature is 92 In a centrifugal spray dryer at ℃, spray granulate the above slurry to obtain the first precursor.

[0052] 2. Pyrolysis of the first precursor:

[0053] The above-mentioned first precursor was subjected to high-temperature pyrolysis at 900° C. for 6 hours under an argon atmosphere to obtain a second precursor coated with amorphous carbon. The amount of carbon coating was about 2% based on the residual carbon af...

Embodiment 3

[0057] 1. Spray granulation:

[0058] Silicon source: nano silicon powder, particle size 100nm, purity>99.9%; graphite source: artificial graphite, particle size 8μm, purity>99.9%; dispersant: polyvinylpyrrolidone k13-18, analytically pure; organic carbon source: phenolic resin, Analytical pure;

[0059] Fully disperse 1 part of silicon source, 5 parts of graphite source, 2 parts of polyvinylpyrrolidone k13-18, and 1.5 parts of phenolic resin in absolute ethanol to obtain a spray slurry with a solid content of 20%; On a closed-loop three-fluid spray dryer at a temperature of 80° C., the above slurry was subjected to spray granulation to obtain a first precursor.

[0060] 2. Pyrolysis of the first precursor:

[0061] The above-mentioned first precursor was subjected to high-temperature pyrolysis at 900° C. for 10 h in an argon atmosphere to obtain a second precursor coated with amorphous carbon. The amount of carbon coating was 11.75% based on the residual carbon after pyroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com