Low-temperature carbon-coated composite material, its preparation method and application

A technology of composite materials and coating materials, which is applied in the field of materials, can solve the problems of high-valence elements being reduced and the degree of graphitization is not high, and achieve the effects of increasing specific capacity and specific energy, ensuring cyclicity, and improving electronic conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Lithium titanate battery without low-temperature carbon coating

[0052] According to Li 4 Ti 5 o 12 Materials, acetylene black and polyvinylidene fluoride (PVDF) account for 80wt%, 10wt% and 10wt% respectively to prepare electrodes as an electrode of the half-cell. The counter electrode uses metal Li, and 1mol / L LiPF 6 / Ethylene carbonate (EC)-diethylene carbonate (DEC) as the electrolyte, wherein the volume ratio of EC and DEC is 1:1, assembled into a battery in a glove box and tested its charge and discharge performance, the voltage range is 1-3V, test results see Image 6 and Figure 7 , indicating that the lithium titanate material without low-temperature carbon coating has poor rate performance, with a capacity of only 30mAh / g at 10C rate, 60mAh / g capacity at 5C rate, and only 120mAh / g capacity at 2C rate after 120 cycles. is 100mAh / g.

Embodiment 2

[0053] Example 2: Low-temperature carbon-coated lithium titanate battery

[0054] First, the C source 10,10'-dibromo-9,9'-bianthrene was dissolved in tetrahydrofuran to obtain a clear solution, and the Li 4 Ti 5 o 12 According to the mass ratio of C source to 9:1, add it to the above solution, stir evenly, and heat to 40°C to completely volatilize tetrahydrofuran to obtain Li 4 Ti 5 o 12 and C source precursors, the precursors were heated in argon at 400°C, and kept for 2 hours to obtain low-temperature carbon-coated Li 4 Ti 5 o 12 composite material.

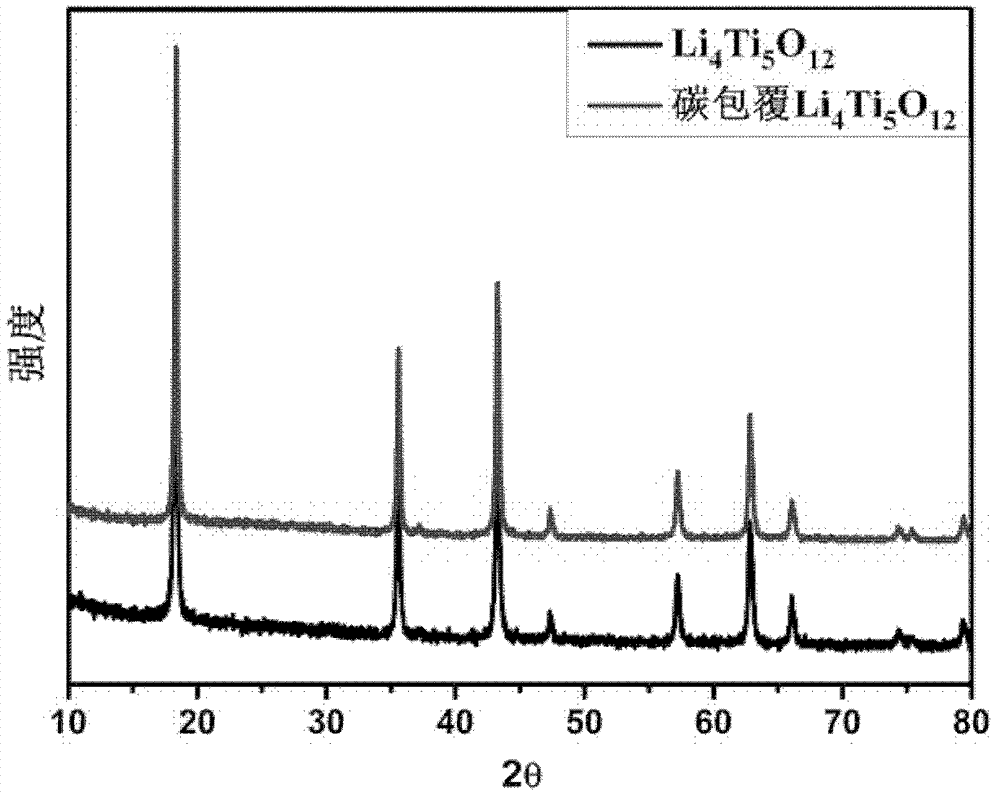

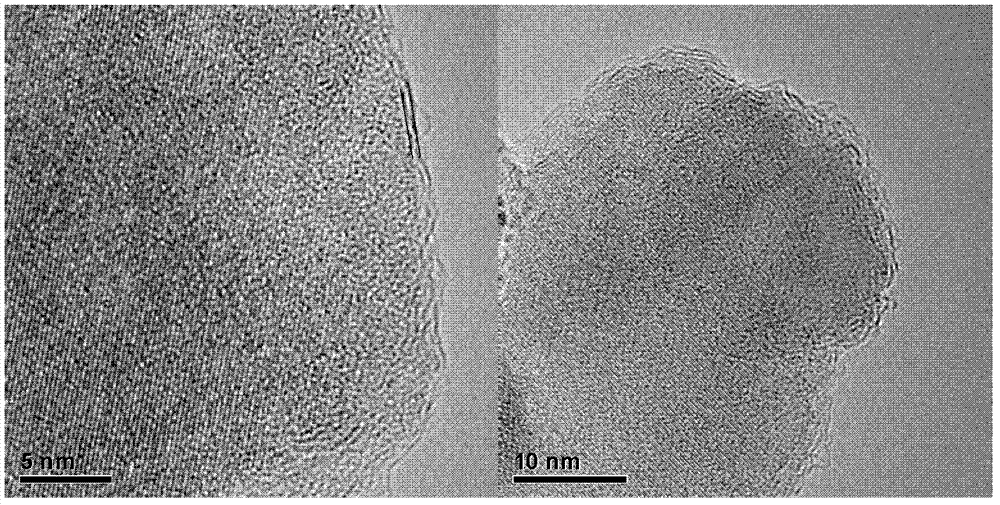

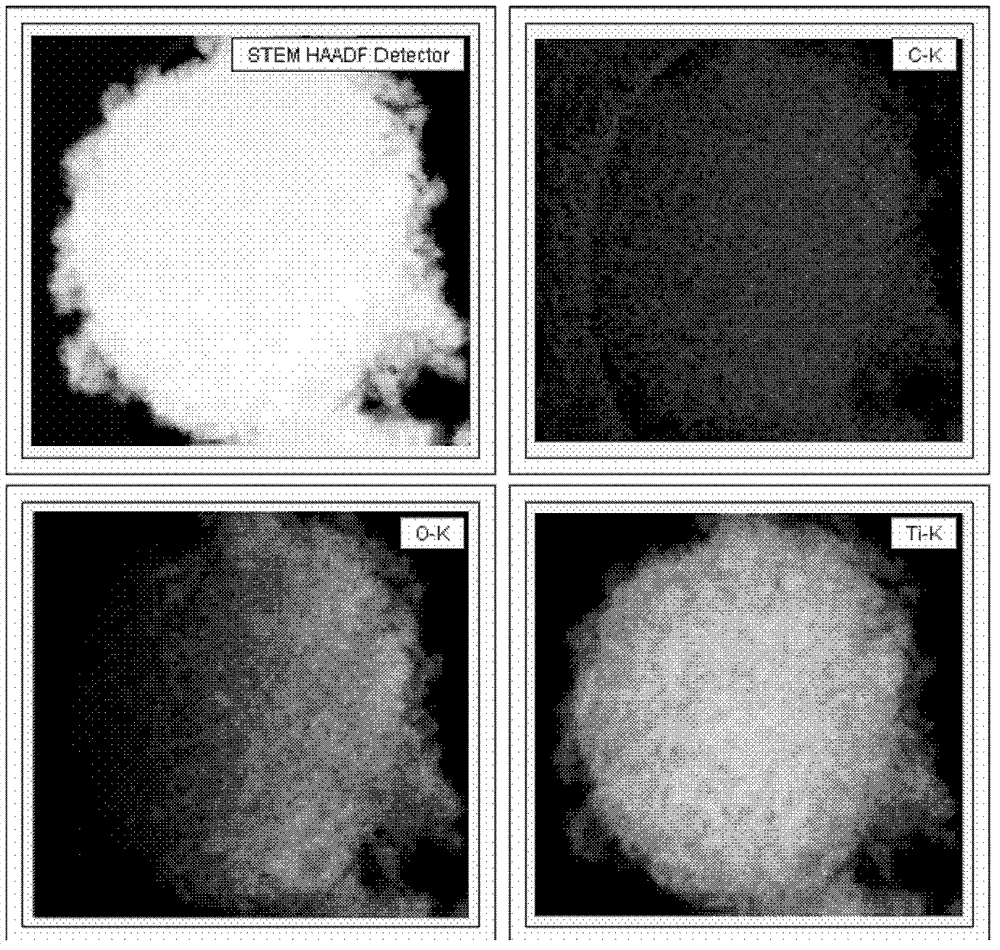

[0055] Will wrap the former Li 4 Ti 5 o 12 and low-temperature carbon-coated Li 4 Ti 5 o 12 Composites were tested by XRD ( figure 1 ), the results show that the coating does not change the Li 4 Ti 5 o 12 Structure. Low-temperature carbon coated Li 4 Ti 5 o 12 The composite material was subjected to high-resolution TEM ( figure 2 ) and the Ramam test ( Figure 5 ), the results are shown in Li 4 Ti 5 ...

Embodiment 3

[0057] Example 3: Lithium cobalt oxide battery without low-temperature carbon coating

[0058] Follow Example 1 to prepare LiCoO 2 Battery, the battery is cycled at 2.5-4.5V, see the battery test results Figure 10 , The battery capacity decays quickly, and after 50 weeks, the capacity is only 80mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com