Coating modification method for reducing metal dissolution of high-voltage ternary positive electrode material

A positive electrode material and high-voltage technology, applied in the direction of electrical components, battery electrodes, non-metallic elements, etc., can solve problems such as increasing battery polarization and internal resistance, affecting battery cycle performance, and increasing electrode/electrolyte interface reactions. Achieve uniform coating, high strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

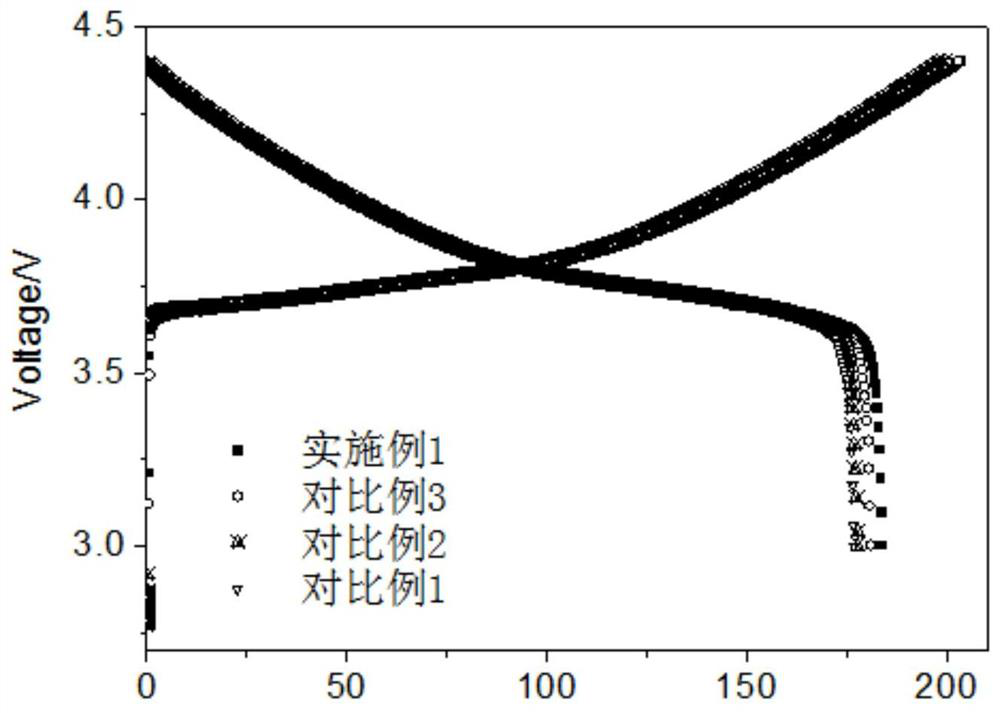

Embodiment 1

[0039] Prepare the NCM523 high-voltage positive electrode material with aluminum phosphate as the inner cladding layer and aluminum oxide-lithium fluoride as the outer cladding layer;

[0040] (1) Configure 0.2mol / L phosphoric acid solution, weigh aluminum hydroxide and phosphoric acid solution according to the molar ratio of aluminum element and phosphate root as 1:3, and slowly add aluminum hydroxide to the beaker containing phosphoric acid solution Stir to dissolve completely to obtain aluminum phosphate solution;

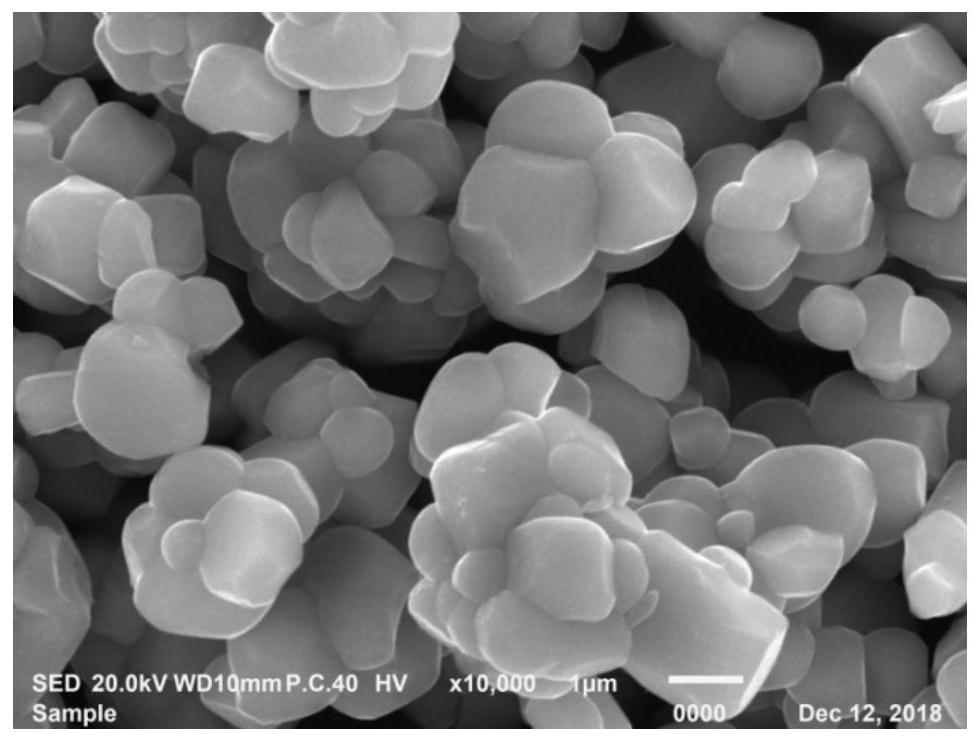

[0041] (2) According to the mass ratio of the mass of the aluminum element to the NCM523 positive electrode material is 1:0.02, add the 4.2 μm NCM523 positive electrode material to the aluminum phosphate solution in step (1), and spray dry it after stirring at 300rpm for 2h Processing to obtain a solid mixture of pre-coated aluminum phosphate;

[0042] (3) Physically mixing the solid mixture in step (2) with alumina and lithium fluoride according to a mass rati...

Embodiment 2

[0061] Prepare the NCM811 high-voltage positive electrode material with tungsten phosphate as the coating core layer and tungsten oxide-lithium fluoride as the coating shell layer.

[0062] (1) Prepare 0.1moL / L phosphoric acid solution, weigh tungsten hydroxide and phosphoric acid solution according to the molar ratio of tungsten element to phosphate radical of 1:3, slowly add tungsten hydroxide to the beaker containing phosphoric acid solution Stir until completely dissolved.

[0063] (2) According to the mass ratio of the mass of tungsten element to the NCM811 positive electrode material is 1:0.04, add 4.5 μm NCM811 positive electrode material to the solution in step (1), stir at 200rpm for 1h and then spray dry treatment to obtain a solid mixture of pre-coated tungsten phosphate.

[0064] (3) Sinter the mixed material in step (2) at a temperature of 400°C in an air atmosphere with a ventilation rate of 30L / min for 8h in a box furnace to obtain tungsten phosphate as the coa...

Embodiment 3

[0078] Preparation of zinc oxide-lithium fluoride / zinc phosphate coated NCM622 high-voltage cathode material.

[0079] (1), configure 0.5moL / L phosphoric acid solution, weigh zinc hydroxide and phosphoric acid solution according to the molar ratio of zinc element and phosphate root as 1:3, slowly add zinc hydroxide to the beaker containing phosphoric acid solution Stir until completely dissolved.

[0080] (2) According to the mass ratio of zinc element to NCM622 positive electrode material being 1:0.005, add 11 μm NCM622 positive electrode material to the solution in step (1), stir at 400rpm for 4h, then spray dry , to obtain a solid mixture of pre-coated zinc phosphate.

[0081] (3), the mixed material in step (2) is sintered in a box furnace for 15 hours at a temperature of 800° C. in an air atmosphere with a ventilation rate of 30 L / min to obtain zinc phosphate as a coating core layer, and zinc oxide- Lithium fluoride is the NCM622 high-voltage positive electrode material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com