Flame-retardant solid-liquid mixed solid electrolyte, preparation method and lithium battery containing flame-retardant solid-liquid mixed solid electrolyte

A solid-state electrolyte and solid-liquid mixing technology, applied in the field of electrolytes, can solve the problems of flammability of electrolytes, deterioration of electrode-electrolyte interface, reduction of mechanical strength of electrolytes, etc. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0074] The synthesis of preparation example 1 phosphorus-containing organic compound 1#

[0075] In a four-neck flask equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a condenser, add 54g (0.4mol) of pentaerythritol and 50ml of solvent toluene, heat up to 50°C, add phosphorus trichloride dropwise, and then heat up to reflux. During this process, a slight negative pressure should be maintained in the system. After the reflux, the unreacted phosphorus trichloride, solvent and hydrogen chloride were distilled off under reduced pressure to obtain a yellow transparent viscous liquid, which was cooled to room temperature and solidified to obtain the intermediate product (I). The yield was 95%. Selection of material ratio The molar ratio of phosphorus trichloride to pentaerythritol is 2.5:1.

[0076] Add 60mL of solvent to the intermediate product (I) in the first step, raise the temperature to about 50°C and wait for it to completely dissolve, then ...

preparation example 2

[0079] The synthesis of preparation example 2 phosphorus-containing organic compound 2#

[0080] 2,2-Bis(bromomethyl)-1,3-bis[(2-bromopropyl-2-chloropropyl)phosphate]propane

[0081] In a four-necked beaker equipped with a stirrer, a thermometer, a dropping funnel, and a condenser, add 34g (0.25mol) of pentaerythritol and solvent toluene. Add 1 / 2 amount of phosphorus trichloride dropwise, while slowly raising the temperature to 50°C, and react for 2 hours. Then warm to reflux. At the same time, add another 1 / 2 amount of phosphorus trichloride dropwise. During this process, a certain low vacuum is maintained from time to time. After reflux reaction for 3 hours, filter while it is hot, and evaporate unreacted phosphorus trichloride, solvent and hydrogen chloride under reduced pressure to obtain a yellow transparent viscous liquid, which is recorded as intermediate (I). The crude yield is 98%, and no purification is necessary. The molar ratio of phosphorus chloride to pentaer...

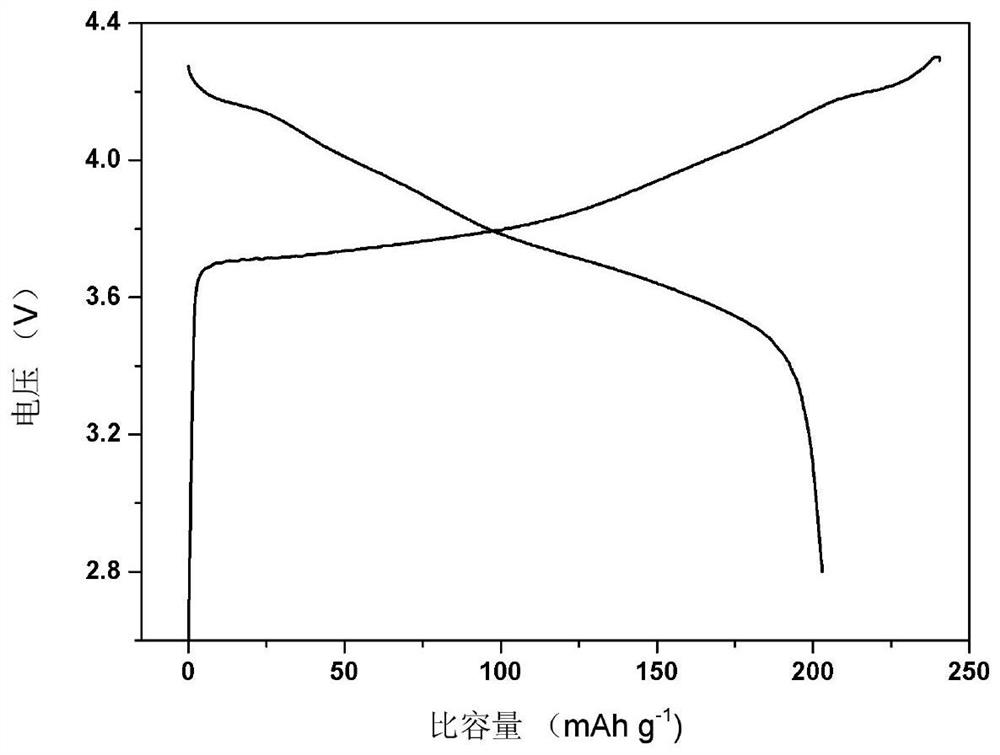

Embodiment 1

[0086] Take lithium bistrifluoromethanesulfonylimide at a molar concentration of 1 mol / L and dissolve it in a mixed solution of triethyl phosphate and vinylene carbonate (volume ratio: 1.5:1), and stir to completely dissolve it under dry conditions , and then, add azobisisobutyronitrile (0.1%, molar ratio to vinylene carbonate) into the mixed solution, stir and dissolve to obtain a transparent and uniform solution, namely the precursor solution. The precursor solution is polymerized at 45 degrees Celsius to obtain a flame-retardant solid-liquid mixed solid electrolyte. Put the battery filled with the precursor solution at 45 degrees Celsius to initiate the polymerization of the precursor electrolyte, and then a battery using a flame-retardant solid-liquid mixed solid electrolyte can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com