Molybdenum disulfide/sulfur-doped graphene composite material as well as preparation method and application thereof

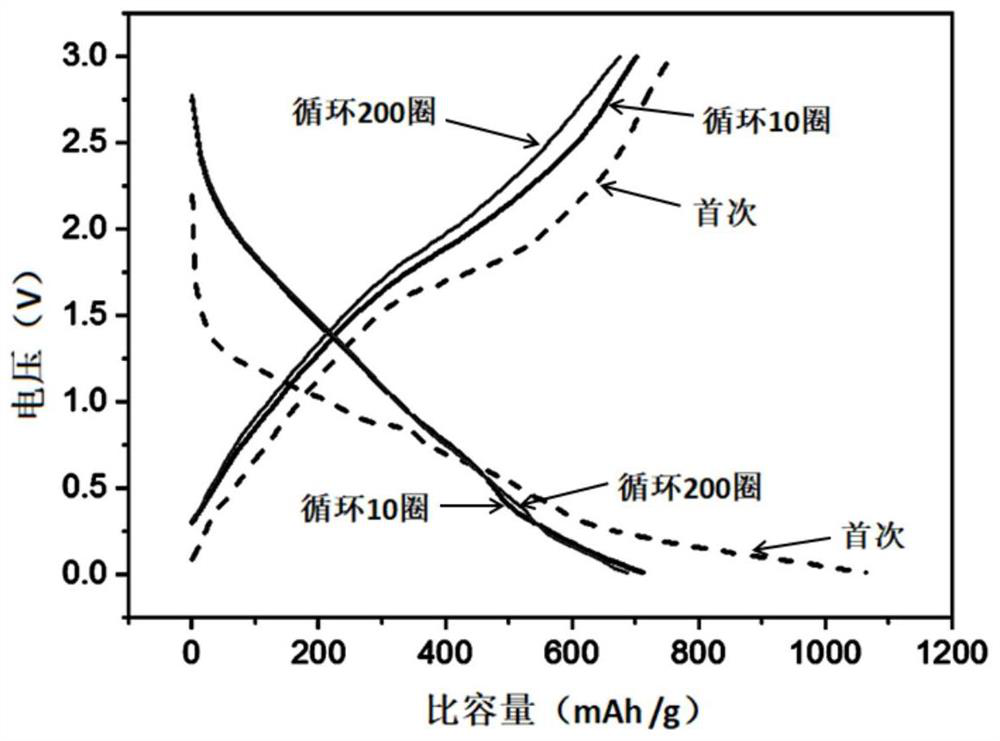

A technology of sulfur-doped graphene and molybdenum disulfide, applied in secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problems of poor conductivity and low specific capacity, and achieve increased specific capacity and ionic conductivity. , the effect of expanding the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

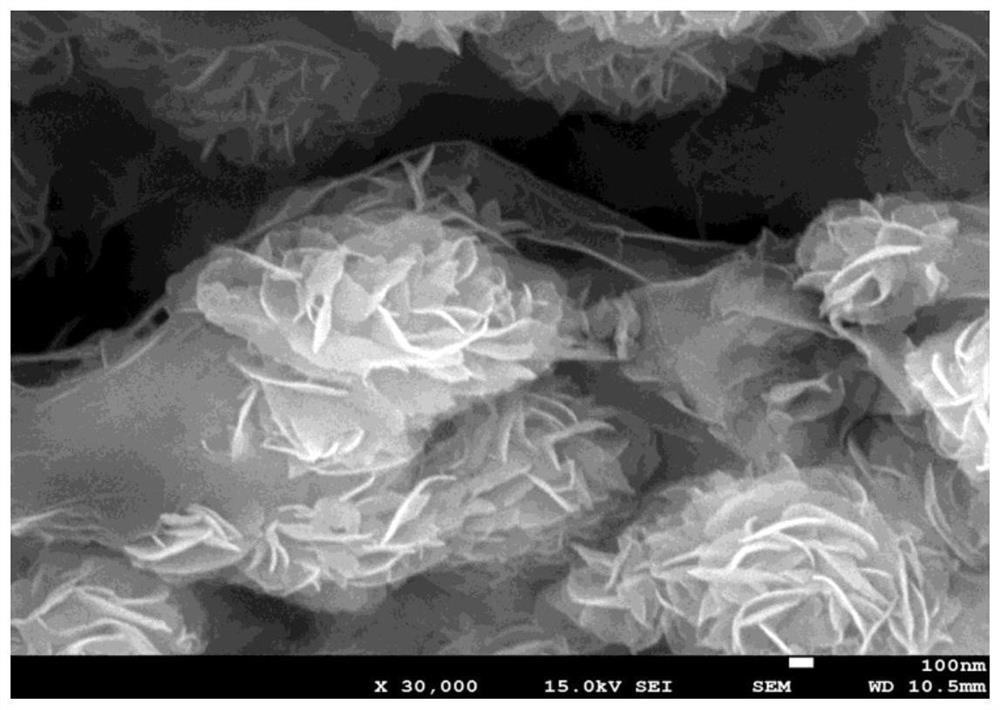

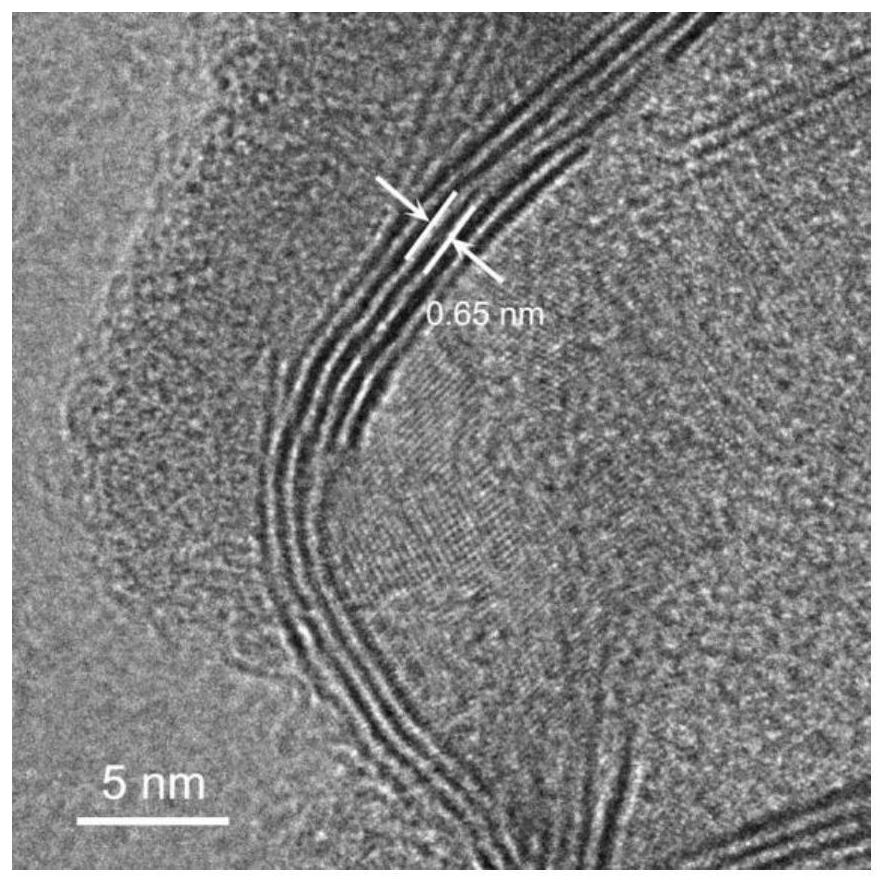

[0065] The present embodiment provides a kind of preparation method of molybdenum disulfide / sulfur-doped graphene composite material, and described preparation method comprises the following steps:

[0066] (1) mix ammonium molybdate, graphene oxide dispersion, dimethyl trisulfide and glucose, and stir to obtain a mixed solution; the concentration of molybdenum ions in the mixed solution is 0.02mol / L; the graphite oxide The mass concentration of alkene dispersion liquid is 2mg / mL; The atomic ratio of sulfur in the dimethyl trisulfide and molybdenum in the mixed solution is 2:1; The carbon atom molar concentration of glucose in the mixed solution is 1mol / L;

[0067] (2) The mixed solution described in step (1) is subjected to a hydrothermal reaction at a temperature of 200° C. for 24 hours in a closed reaction kettle placed in an oven, and the reacted solution is centrifuged and washed to obtain a precursor;

[0068] (3) Put the precursor described in step (2) into a closed rea...

Embodiment 2

[0072] The present embodiment provides a kind of preparation method of molybdenum disulfide / sulfur-doped graphene composite material, and described preparation method comprises the following steps:

[0073] (1) mix ammonium thiomolybdate, graphene oxide dispersion, dimethyl trisulfide and sucrose, and stir to obtain a mixed solution; the concentration of molybdenum ions in the mixed solution is 0.0005mol / L; The mass concentration of the graphene oxide dispersion is 0.1 mg / mL; the atomic ratio of sulfur in the dimethyl trisulfide to molybdenum in the mixed solution is 3:1; the carbon atom molar concentration of sucrose in the mixed solution is 0.0005 mol / L;

[0074] (2) The mixed solution described in step (1) is subjected to a hydrothermal reaction at a temperature of 290° C. for 3 hours in a closed reaction kettle placed in an oven, and the reacted solution is subjected to suction filtration and washing treatment to obtain a precursor;

[0075] (3) Put the precursor describe...

Embodiment 3

[0077] The present embodiment provides a kind of preparation method of molybdenum disulfide / sulfur-doped graphene composite material, and described preparation method comprises the following steps:

[0078] (1) mix molybdenum acetylacetonate, graphene oxide dispersion, dimethyl trisulfide and epoxy resin, and stir to obtain a mixed solution; the concentration of molybdenum ions in the mixed solution is 4mol / L; the oxidation The mass concentration of graphene dispersion liquid is 5mg / mL; The atomic ratio of sulfur in the described dimethyl trisulfide and molybdenum in the mixed solution is 4:1; The carbon atom molar concentration of epoxy resin in the described mixed solution is 2.5 mol / L;

[0079] (2) The mixed solution described in step (1) is subjected to a hydrothermal reaction at a temperature of 110°C for 70 hours in a closed reaction kettle placed in an oven, and the reacted solution is centrifuged and washed to obtain a precursor;

[0080](3) Put the precursor describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com