Solid-state lithium ion battery applying composite positive electrode as well as assembly method and application thereof

A lithium-ion battery, composite cathode technology, applied in secondary batteries, battery electrodes, battery assembly machines, etc., can solve the problems of low load of electrode active materials, volume changes of electrode materials, poor cycle stability, etc., to improve energy density, The effect of high energy density and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

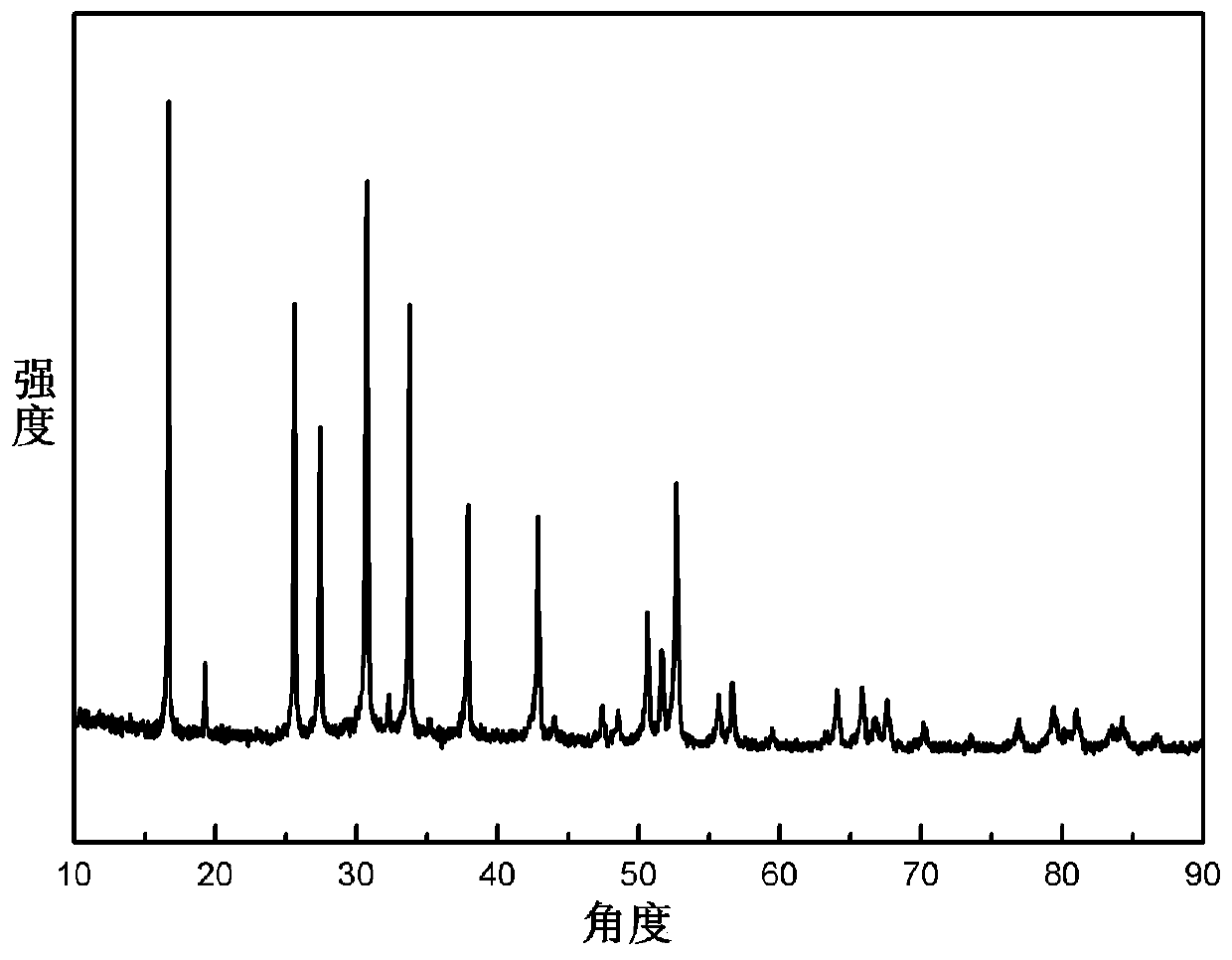

[0031] The present invention uses a sol-gel method to prepare a garnet-type solid electrolyte, preferably using anhydrous lithium nitrate, lanthanum nitrate hexahydrate, and zirconium acetylacetonate as metal sources for preparing LLZO. According to Li 7 Al 0.2 La 3 Zr 2 o 12 Weigh anhydrous lithium nitrate (excess 10% to 20%), lanthanum nitrate hexahydrate, zirconium acetylacetonate, add a small amount of aluminum nitrate, dissolve in water to prepare a solution and stir evenly with a magnetic stirrer. Dissolve the complexing agent citric acid in water and stir evenly with a magnetic force, and add a few drops of nitric acid to the citric acid solution. Add the complexing agent dropwise to the mixed liquid, heat and evaporate the solvent after the reaction is complete, the evaporation temperature is generally slightly lower than the boiling point of the solvent, so the evaporation temperature is preferably 80°C. As the solvent evaporated, a dark gel was obtained. The re...

Embodiment 2

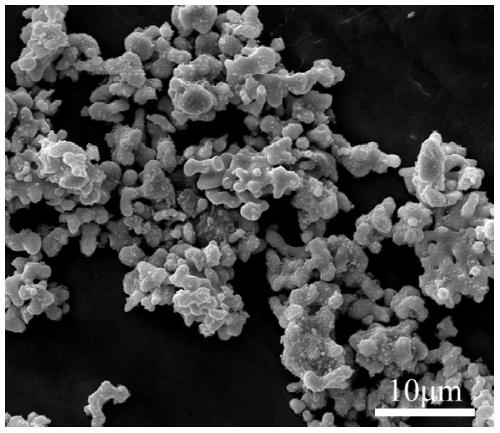

[0033] The morphology and particle size distribution of the solid electrolyte material were observed under a scanning electron microscope. figure 2 The experimental results given show that the particle size distribution is uniform, and the particles are finer than the solid-phase method.

Embodiment 3

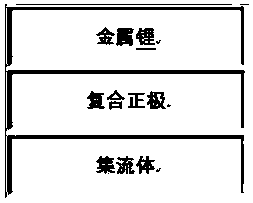

[0035] Mix and grind the solid electrolyte and binder evenly, add an appropriate amount of NMP solvent to disperse the solid electrolyte and binder uniformly, and then perform ultrasonic treatment. Drop the dispersion liquid on the positive electrode sheet, apply the dispersion liquid evenly on the surface of the positive electrode by the scraper film forming method to form a uniform coating, and then the composite positive electrode can be obtained, and then put it in a blast drying oven to dry spare. Using metal lithium as the negative electrode, compared with the liquid lithium-ion battery, reduces the interface between the positive electrode and the diaphragm, and assembles the button battery. image 3 A schematic diagram of the overall structure of the solid-state battery is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com