Preparation method of MOFs derivative NiO electrochromic film

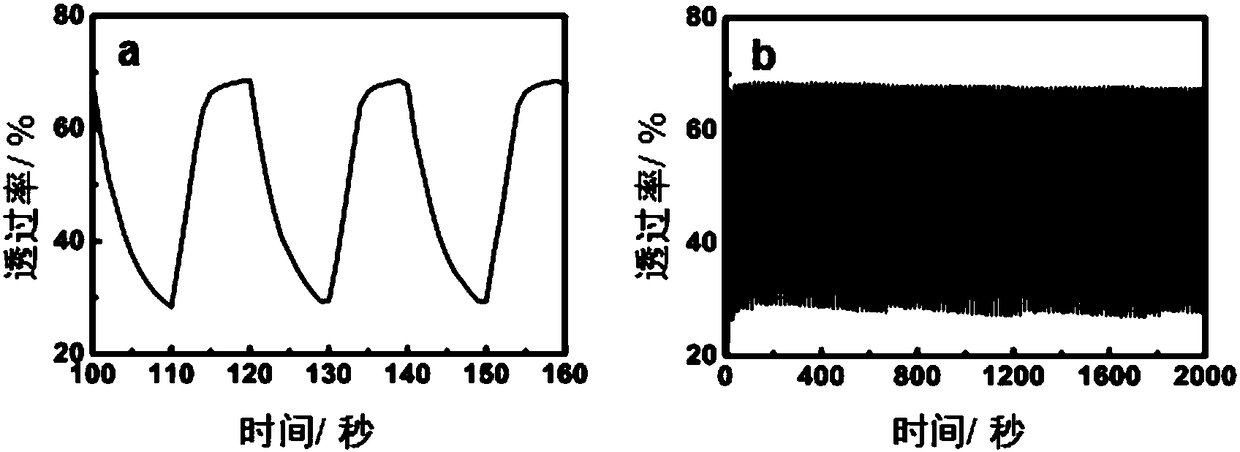

An electrochromic and thin-film technology, which is applied in the field of preparation of MOFs-derived NiO electrochromic thin films, can solve the problems affecting the material's discoloration speed and optical modulation range, affecting the electron/ion double insertion and double extraction process, etc., to achieve cycle stability Good performance, simple and convenient preparation method, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

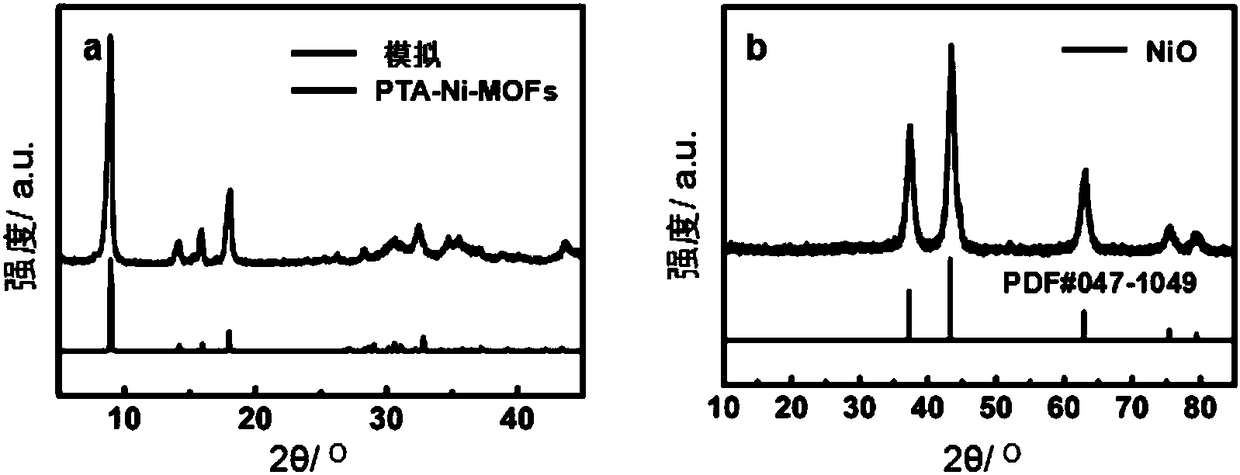

[0028] (1) Dissolve 0.083g of PTA and 0.119g of nickel chloride hexahydrate in 20mL of DMF, and add 2ml of deionized water dropwise to obtain a PTA-Ni-MOFs precursor solution.

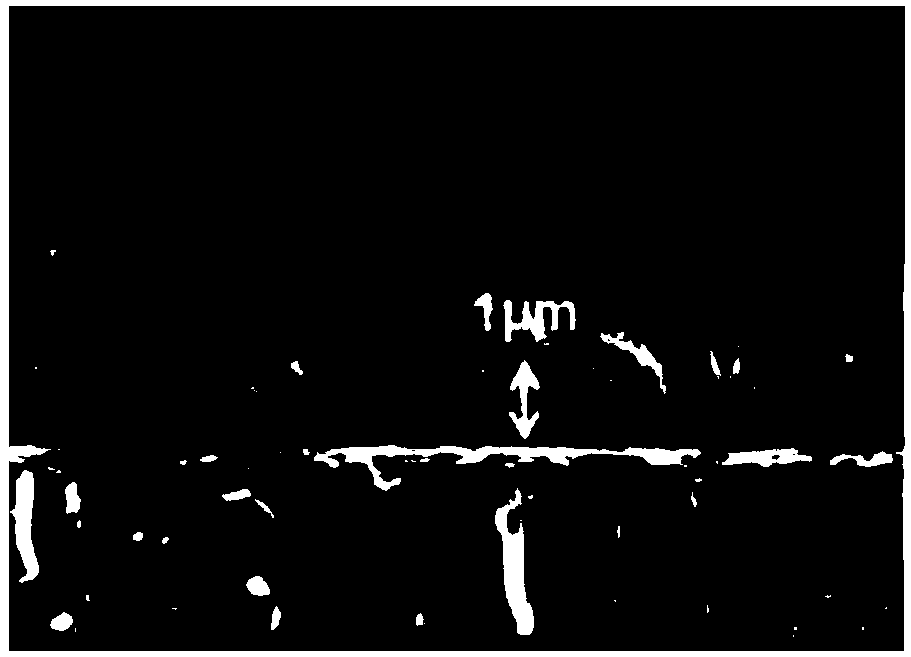

[0029] (2) Soak the FTO glass in the DMF solution of PTA to carry out acidification, then dry, place in the liner of 50mL polytetrafluoroethylene hydrothermal kettle, conductive side is down; The PTA-Ni- that step (1) obtains The MOFs precursor solution was poured into the liner of the hydrothermal kettle, and the hydrothermal reaction was performed at 180°C for 2 hours. After cooling to room temperature, the reacted FTO glass was taken out, soaked in DMF and absolute ethanol for cleaning, and then vacuum-dried at 60°C for 24 hours. The FTO glass with evenly grown light green PTA-Ni-MOFs film attached to the surface was obtained.

[0030] (3) Put the FTO glass with PTA-Ni-MOFs film on the surface obtained in step (2) for heat treatment in a muffle furnace, and heat it up to 550°C at a heating rate of 2...

Embodiment 2

[0034] (1) Dissolve 0.017g of PTA and 0.024g of nickel chloride hexahydrate in 20mL of DMF, and add 1ml of deionized water dropwise to obtain a PTA-Ni-MOFs precursor solution.

[0035] (2) Soak the FTO glass in the DMF solution of PTA for acidification, then dry it, place it in a 50mL polytetrafluoroethylene hydrothermal kettle liner, with the conductive side facing down; the PTA-Ni- The MOFs precursor solution was poured into the liner of a hydrothermal kettle, and subjected to a hydrothermal reaction at 100°C for 6 hours. After cooling to room temperature, the reacted FTO glass was taken out, washed by soaking in DMF and absolute ethanol, and then vacuum-dried at 100°C for 12 hours. The FTO glass with evenly grown light green PTA-Ni-MOFs film attached to the surface was obtained.

[0036] (3) Put the FTO glass with PTA-Ni-MOFs film on the surface obtained in step (2) for heat treatment in a muffle furnace, and heat it up to 400°C at a heating rate of 5°C / min and keep it for ...

Embodiment 3

[0039] (1) Dissolve 0.083g of PTA and 0.119g of nickel chloride hexahydrate in 20mL of DMF, and add 2ml of deionized water dropwise to obtain a PTA-Ni-MOFs precursor solution.

[0040](2) Soak the FTO glass in the DMF solution of PTA for acidification, then dry it, place it in a 50mL polytetrafluoroethylene hydrothermal kettle liner, with the conductive side facing down; the PTA-Ni- The MOFs precursor solution was poured into the liner of a hydrothermal kettle, and subjected to a hydrothermal reaction at 120°C for 3 hours. After cooling to room temperature, the reacted FTO glass was taken out, washed by soaking in DMF and absolute ethanol, and then vacuum-dried at 80°C for 20 hours. The FTO glass with evenly grown light green PTA-Ni-MOFs film attached to the surface was obtained.

[0041] (3) Put the FTO glass with PTA-Ni-MOFs film on the surface obtained in step (2) for heat treatment in a muffle furnace, and heat up to 500°C at a heating rate of 3°C / min and keep it for 60min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com