Preparation method and application of porous SiO2 microspheres for lithium ion battery diaphragm

A lithium-ion battery and separator technology, which is applied in the field of preparation of porous SiO2 microspheres, can solve the problems of lower gas permeability, achieve the effect of improved ion conductance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

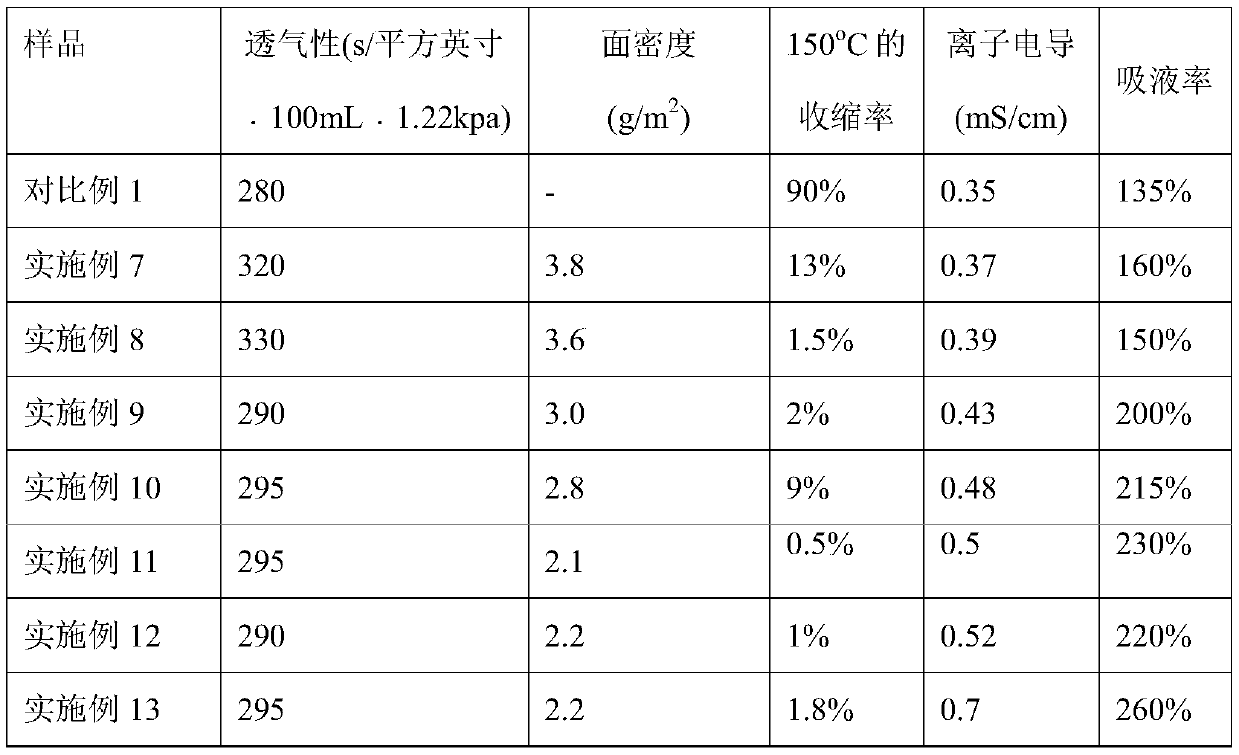

Examples

Embodiment 1

[0056] (1) Preparation of spherical SiO 2 Particles: Mix 5mLTEOS and 5mL ethanol to obtain mixture 1; add mixture 1 to a mixed solvent composed of 3mL ammonia water, 15mL ethanol and 4mL water to obtain mixture 2; heat mixture 2 to 50 degrees, first stir at 1100rpm for 10min, then turn to Stir at 400rpm for 2 hours, centrifuge, and wash to obtain spherical SiO 2 particles;

Embodiment 2

[0058] The difference between this example and Example 1 is that in (1) TEOS is 1 mL, and ammonia water is 1 mL; in (1), mixture 2 is heated to 25 degrees, and the rest are the same as in Example 1.

Embodiment 3

[0060] The spherical SiO prepared by embodiment 1 2 Add 0.5g of particles into 50g of water, add 1g of PVP, heat up to 90 degrees, reflux for 2 hours, then add 1g of 2mol / L NaOH solution after cooling down to room temperature, stir for 30 minutes, centrifuge and wash to obtain porous SiO 2 Microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com