Preparation method of low-cobalt single-crystal positive electrode material

A positive electrode material and single crystal technology, which is applied in the field of preparation of low-cobalt single crystal positive electrode materials, can solve the problems of positive electrode material crystal structure, valence state defects, affecting cycle performance, discharge capacity, crystal structure deterioration, etc., to achieve suppression of high temperature Oxygen loss reaction, short preparation cycle, and the effect of improving the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The first aspect of the present invention provides a method for preparing a low-cobalt single crystal positive electrode material, comprising:

[0034]The nickel-cobalt-manganese precursor, the oxidizing lithium salt, and the additive are mixed together and roasted once to obtain an intermediate product modified by the oxidizing lithium salt.

[0035] In one embodiment, the molar ratio of the lithium moles in the oxidative lithium salt of the present invention to the total moles of nickel, cobalt, and manganese in the nickel-cobalt-manganese precursor is (1.02-1.3): 1, for example There are 1.02:1, 1.06:1, 1.1:1, 1.2:1, 1.3:1.

[0036] The oxidizing lithium salt is a lithium salt with a high-valence element, and has the ability to obtain electrons. The anion in the oxidizing lithium salt provided by the invention contains a high-valence element, for example, lithium perchlorate (LiClO 4 ), lithium permanganate (LiMnO 4 ·3H 2 O), lithium peroxide (Li 2 o 2 ), lithiu...

Embodiment 1

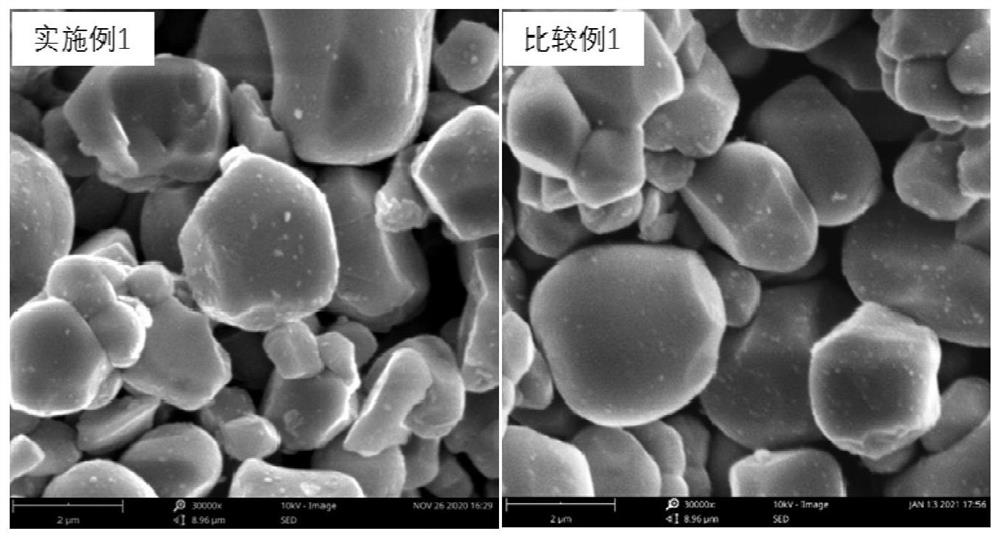

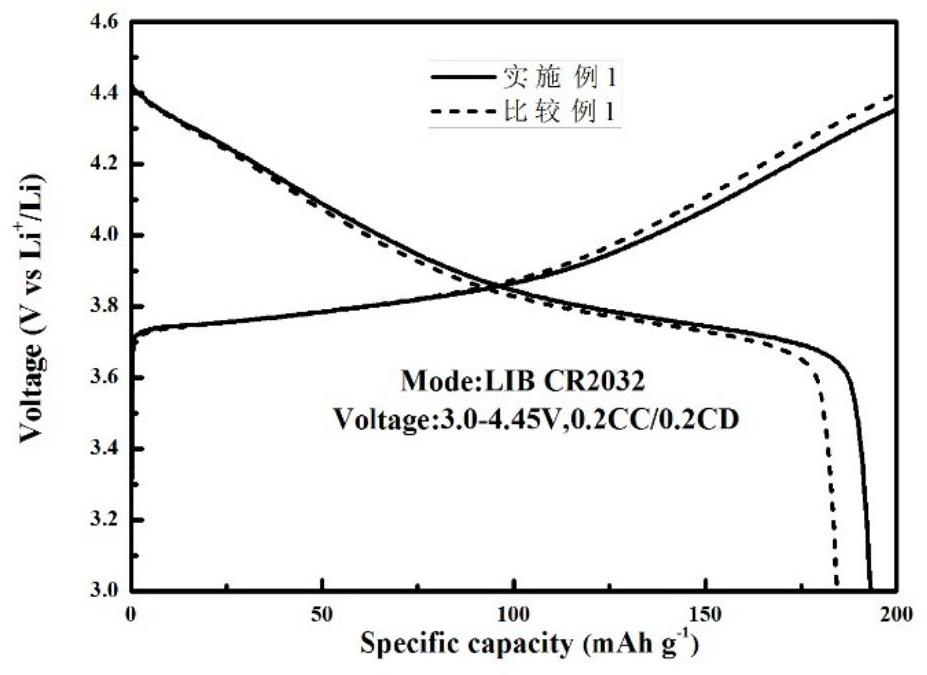

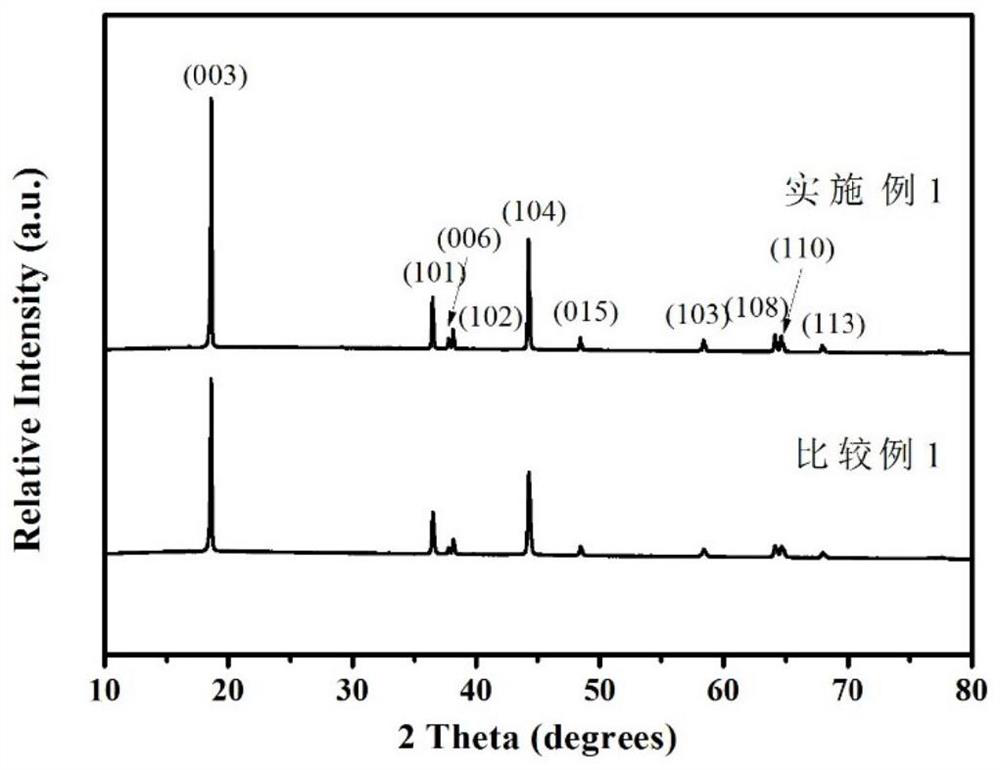

[0049] This example provides a preparation method of a low-cobalt single crystal positive electrode material, including: nickel-cobalt-manganese precursor Ni 0.6 co 0.02 mn 0.38 (OH) 2 , the oxidative lithium salt lithium thiosulfate mixed (the molar ratio of the lithium in the oxidative lithium salt to the total molar number of nickel, cobalt, and manganese in the nickel-cobalt-manganese precursor is 1.06:1), adding a percentage of nickel-cobalt 0.2 wt% MgCO in total weight of manganese precursor and oxidizing lithium salt 3 , roasted at 1000°C for 10h, after crushing, the oxidized lithium salt modified intermediate product was obtained, mixed with ZrO accounting for 0.2wt% of the weight of the oxidized lithium salt modified intermediate product, sintered at 700°C for 6h, crushed, sieved and demagnetized , to get LiNi 0.60 co 0.02 mn 0.38 o 2 Single crystal low cobalt single crystal cathode material.

[0050] This example also provides the low-cobalt single crystal po...

Embodiment 2

[0052] This example provides a method for preparing a low-cobalt single crystal positive electrode material. The preparation method is the same as in Example 1, except that the precursor is Ni 0.60 mn 0.40 (OH) 2 .

[0053] This example also provides the low-cobalt single crystal positive electrode material prepared by the above-mentioned preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com