Surface double-coated lithium-enriched material and preparation method thereof

A lithium-rich material, double-coated technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of not being able to fully coat material particles, high cost, and difficult to coat in large quantities, to avoid Redox reaction, efficiency improvement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

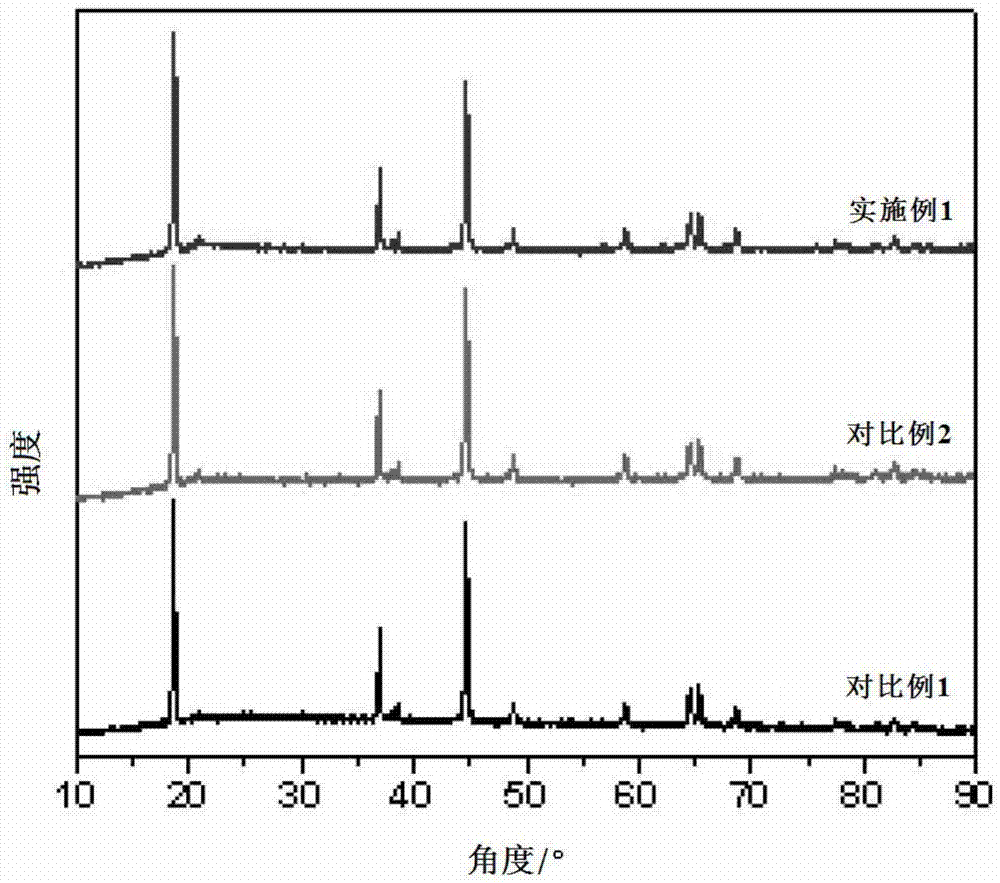

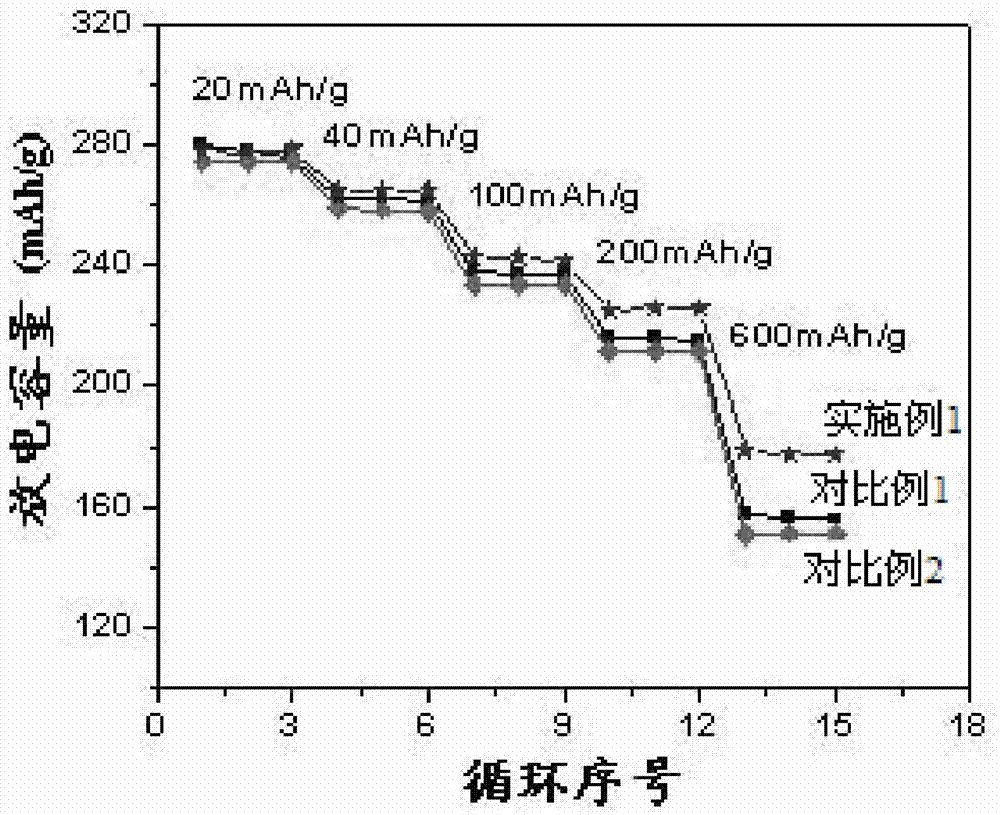

Embodiment 1

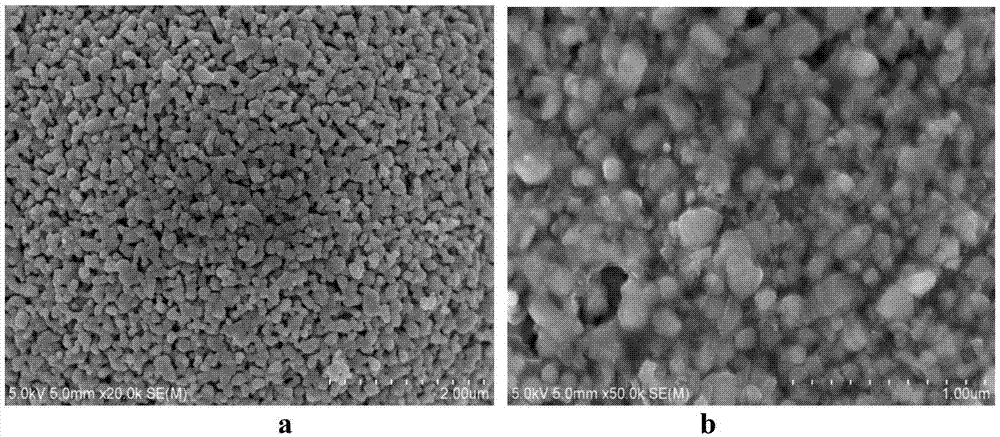

[0043] This embodiment provides a method for preparing a double-coated lithium-rich material whose surface is coated with metal oxide and carbon, which includes the following steps:

[0044] (1) Metal oxide coating (TiO 2 ) preparation:

[0045] 10g lithium-rich material Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 Soak in 30mL ethanol solution with 0.51g tetrabutyl titanate added dropwise, keep stirring in a water bath at 15°C for 6 hours, filter, wash three times, dry in a vacuum thermostat at 100°C for 4 hours, and then heat at 500°C Sinter for 2 hours to get TiO 2 Coating amount of 1wt% Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 composite material.

[0046] (2) Preparation of carbon coating:

[0047] Coated the above with TiO 2 Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 The material is immersed in 15 mL of an aqueous solution containing 0.33 g of sucrose, continuously stirred in a water bath at 80°C until the liquid evaporates to dryness, and then dried in a vacuum...

Embodiment 2

[0053] This embodiment provides a method for preparing a lithium-rich material whose surface is double-coated with metal oxide and carbon, which includes the following steps:

[0054] (1) Metal oxide coating (ZrO 2 ) preparation:

[0055] 10g lithium-rich material Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 Immerse in 25mL of isopropanol solution with 0.16g of zirconium isopropoxide, stir at 25°C for 6 hours under sealed conditions, then keep stirring at 60°C until the solution evaporates to dryness, and dry in a vacuum thermostat at 100°C for 6 hours , and then heated up to 500°C at a heating rate of 5°C / min for 2 hours to obtain ZrO 2 Coated Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 material, the coating amount is 0.5wt%.

[0056] (2) Preparation of carbon coating:

[0057] The above-mentioned coated ZrO 2 Li[Li 0.20 Ni 0.13 co 0.13 mn 0.54 ]O 2 The material is immersed in 20mL of an aqueous solution containing 0.165g of glucose, continuously stirred in a water ...

Embodiment 3

[0062] This embodiment provides a method for preparing a lithium-rich material whose surface is double-coated with metal fluoride and carbon, which includes the following steps:

[0063] (1) Metal fluoride coating (AlF 3 ) preparation:

[0064] 10g lithium-rich material Li[Li 0.23 Ni 0.10 co 0.10 mn 0.57 ]O 2 Immerse in 15mL of an aqueous solution containing 0.28g of aluminum nitrate, slowly add 10mL of an aqueous solution of 0.4g of ammonium fluoride dropwise under stirring conditions, and after the dropwise addition, keep stirring the mixed solution in a water bath at 50°C for 3 hours After that, filter, wash three times, dry in a vacuum oven at 100°C for 4 hours, and then sinter at 400°C for 2 hours to obtain 1wt% AlF 3 Coated Li[Li 0.23 Ni 0.10 co 0.10 mn 0.57 ]O 2 composite material.

[0065] (2) Preparation of carbon coating:

[0066] Coated the above AlF 3 Li[Li 0.23 Ni 0.10 co 0.10 mn 0.57 ]O 2 Materials, dipped into 20mL of aqueous solution containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com