Lanthanum indium co-doped strontium titanate conductor material and preparation method thereof

A conductor material, co-doping technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problem of not being able to improve the electronic conductivity and ionic conductivity of materials at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the lanthanum-indium co-doped strontium titanate conductor material described in the above technical solution, comprising the following steps:

[0038] (1) mixing tetrabutyl titanate, lanthanum oxide, and indium oxide with isopropanol and absolute ethanol to obtain an anhydrous mixed precursor solution of tetrabutyl titanate, lanthanum oxide, and indium oxide;

[0039] (2) Aging the anhydrous mixed precursor solution of tetrabutyl titanate, lanthanum oxide and indium oxide obtained in the step (1) with the strontium salt solution to obtain a strontium titanate sol co-doped with lanthanum and indium ;

[0040] (3) removing the solvent in the sol obtained in the step (2) to obtain a strontium titanate gel co-doped with lanthanum and indium;

[0041] (4) Calcining the lanthanum and indium co-doped strontium titanate gel obtained in the step (3) to obtain the lanthanum and indium co-doped strontium titanate conduct...

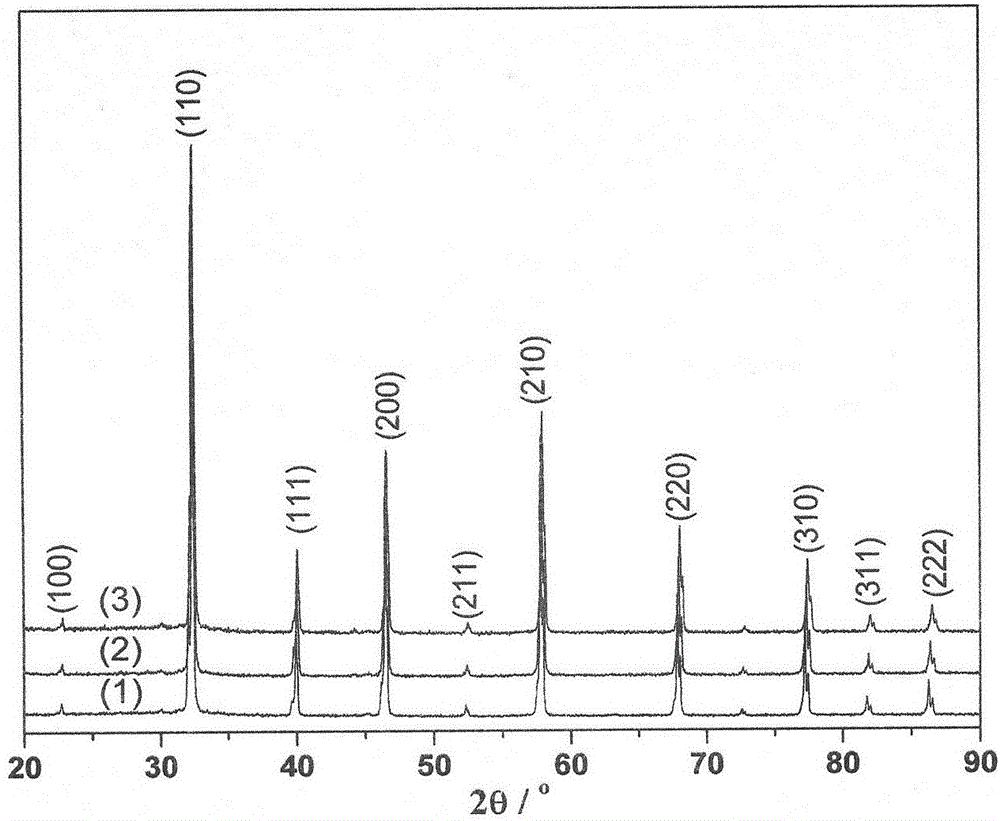

Embodiment 1

[0051] Lanthanum is doped at 30% and Indium is doped at 4%:

[0052] (1) First according to Sr 0.7 La 0.3 Ti 0.96 In 0.04 o 3 The stoichiometric ratio in (the molar ratio of strontium and lanthanum is 70:30; the molar ratio of titanium and indium is 96:4) Weigh 1.63g tetrabutyl titanate, 0.24g lanthanum oxide and 0.028g indium oxide and then mix tetratitanate Dissolve butyl ester in a mixed solvent of 30mL isopropanol and 10mL absolute ethanol, stir until uniform, put lanthanum oxide and indium oxide into the mixed solution of tetrabutyl titanate, and stir magnetically at 600r / min for 3h An anhydrous mixed precursor solution of tetrabutyl titanate, lanthanum oxide and indium oxide was obtained.

[0053] (2) According to Sr 0.7 La 0.3 Ti 0.96 In 0.04 o 3 Stoichiometric ratio in (strontium, lanthanum molar ratio is 70:30) Weigh 0.75g strontium acetate, then dissolve strontium acetate in 3mL deionized water, stir until completely dissolved to form strontium salt solutio...

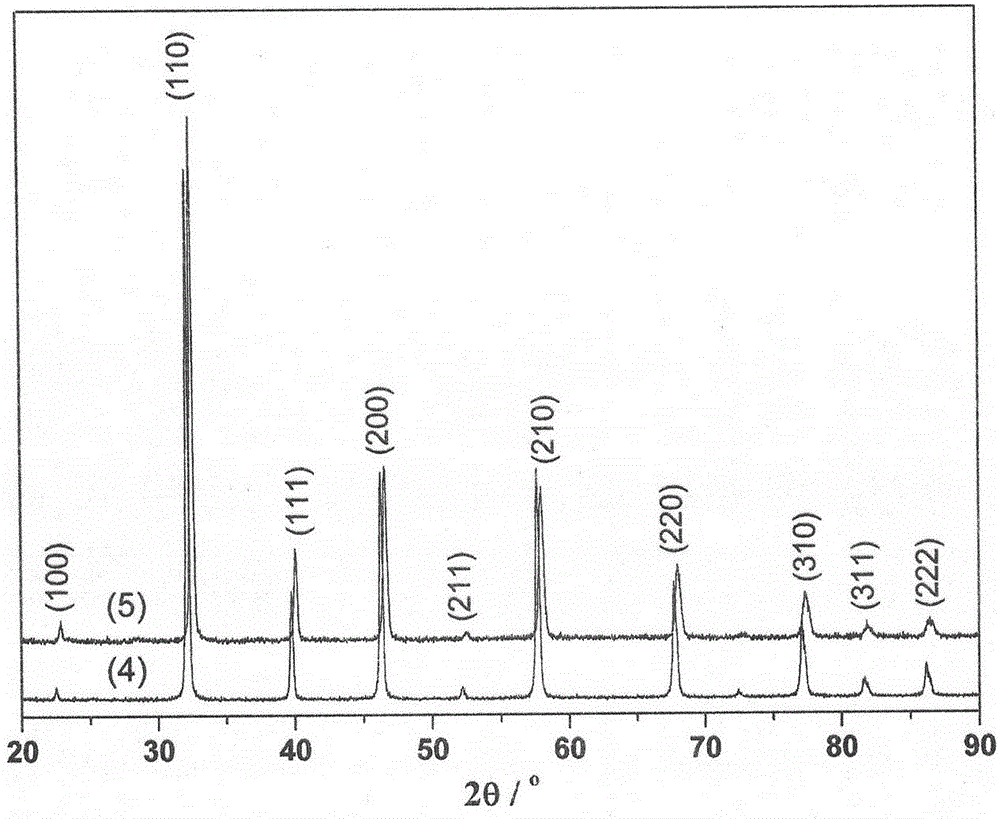

Embodiment 2

[0063] Lanthanum is doped at 30% and Indium is doped at 6%:

[0064] (1) First according to Sr 0.7 La 0.3 Ti 0.94 In 0.06 o 3 Stoichiometric ratio in Weigh 1.6g tetrabutyl titanate, 0.24g lanthanum oxide and 0.042g indium oxide; then dissolve tetrabutyl titanate in a mixed solvent of 40mL isopropanol and 10mL absolute ethanol, stir until uniform Finally, put lanthanum oxide and indium oxide into the mixed solution of tetrabutyl titanate, and stir magnetically at a rate of 600r / min for 3h to obtain an anhydrous mixed precursor solution of tetrabutyl titanate, lanthanum oxide and indium oxide.

[0065] (2) According to Sr 0.7 La 0.3 Ti 0.94 In 0.06 o 3 Stoichiometric ratio in Weigh 0.75g strontium acetate, then dissolve strontium acetate in 3mL deionized water, stir until completely dissolved to form strontium salt solution; mix the anhydrous mixed precursor solution of tetrabutyl titanate, lanthanum oxide and indium oxide Mixed with strontium acetate solution, and mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com