A kind of preparation method of quasi-single crystal high nickel multicomponent material

A kind of single crystal, high-nickel technology, applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve the problems of cycle performance and safety performance degradation, structural defects, battery capacity attenuation, etc., to improve cycle life and rate performance, Effects of improving ionic conductivity and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

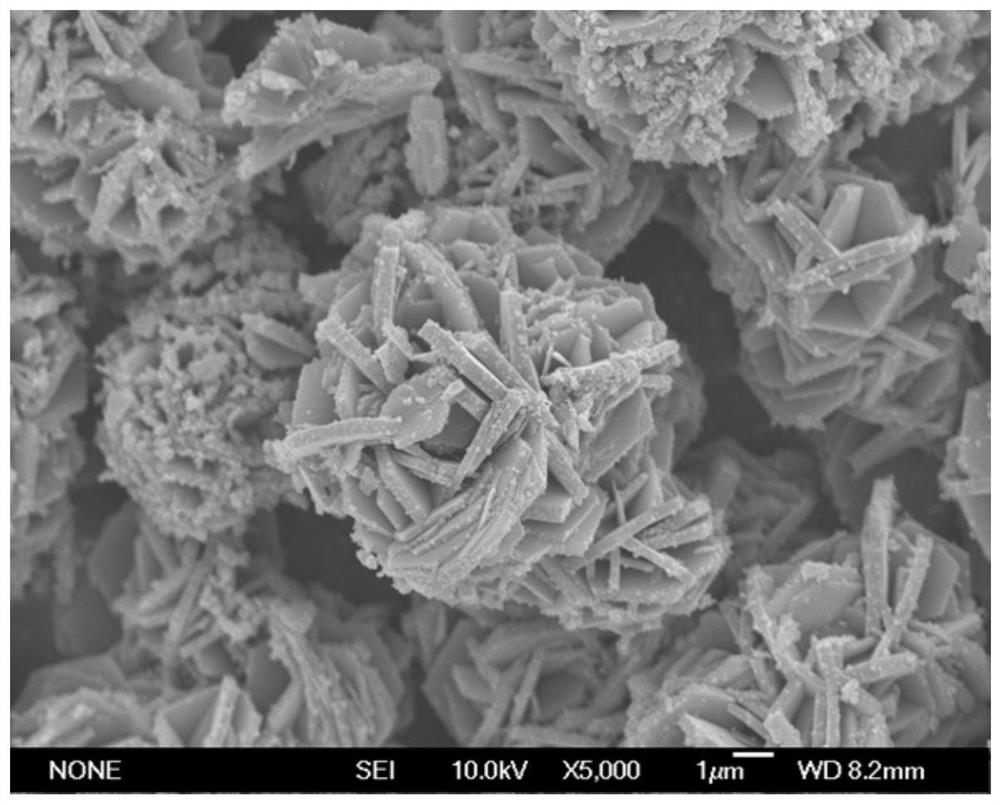

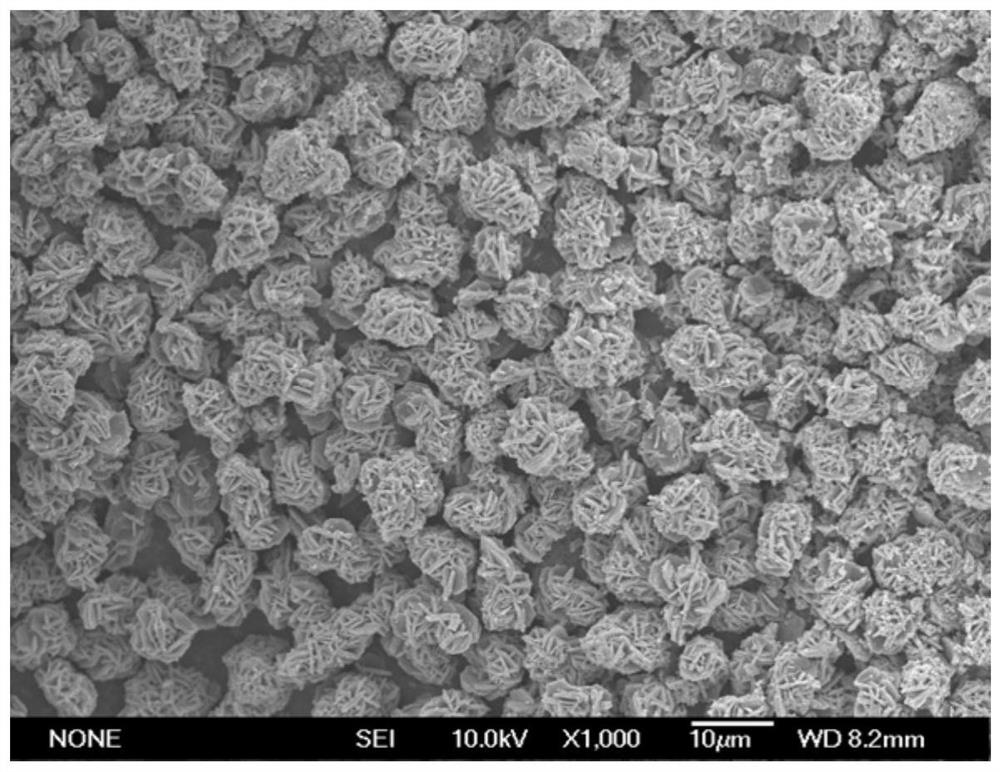

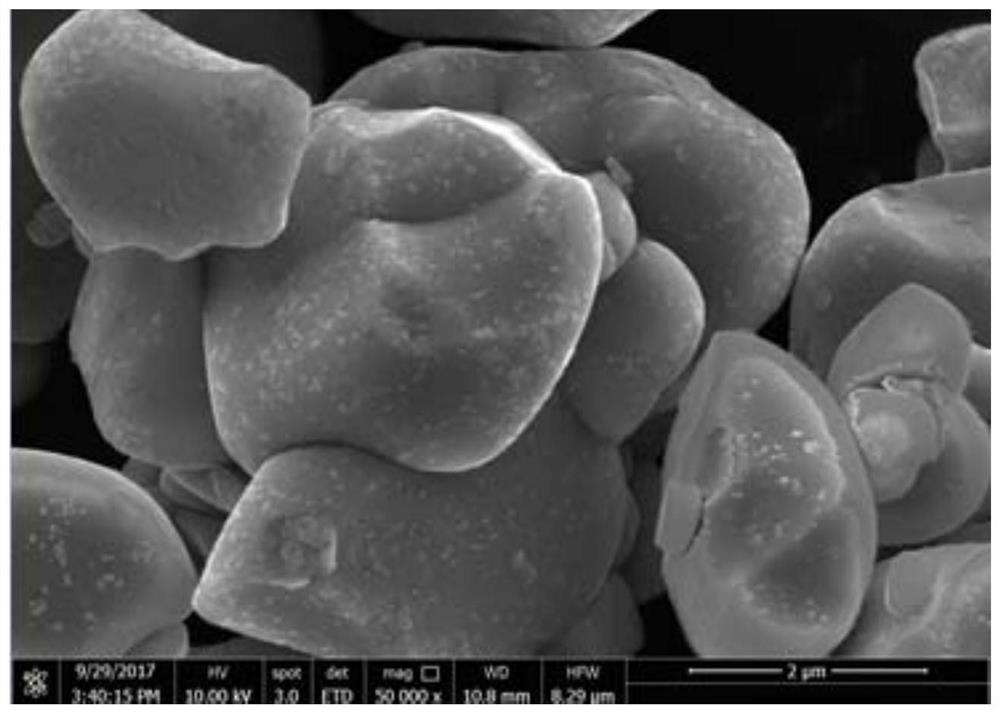

Image

Examples

Embodiment 1

[0039] A method for preparing a quasi-single-crystal high-nickel multi-element material, comprising the steps of:

[0040] (1) Preparation of single-crystal-like high-nickel cathode precursor:

[0041] a) Add 5L of bottom liquid and 5g of sodium citrate to the bottom liquid of the reactor under nitrogen protection atmosphere;

[0042] b) Configure 20L of nickel-cobalt-manganese ternary salt solution with a concentration of 2M, the molar ratio of nickel-cobalt-manganese is 8.2:1:0.8, and add the prepared nickel-cobalt-manganese tribasic salt into the reaction kettle at a speed of 600rpm at a constant speed of 1L / h. Stir the elemental salt solution with 35g of methylcellulose until completely dissolved, and at the same time control the pH value at 10.6±0.02 by adding a sodium hydroxide solution containing ammonia until the salt solution is completely injected;

[0043] c) Add 0.5M niobium nitrate and 0.5M ammonium bicarbonate solution at the same rate, and stop adding liquid wh...

Embodiment 2

[0049] A method for preparing a quasi-single-crystal high-nickel multi-element material, comprising the steps of:

[0050] (1) Preparation of single-crystal-like high-nickel cathode precursor:

[0051] a) Add 5L of bottom liquid and 5g of citric acid to the reaction kettle bottom liquid in nitrogen protection atmosphere;

[0052] b) Configure 20L of nickel-cobalt-manganese ternary salt solution with a concentration of 2M, the molar ratio of nickel-cobalt-manganese is 6:2:2, and add the prepared nickel-cobalt-manganese tribasic salt solution into the reactor at a speed of 1000rpm at a uniform speed of 1L / h. Stir the elemental salt solution and 30g of methylcellulose until completely dissolved, and at the same time, control the pH value at 10.95±0.02 by adding sodium hydroxide solution containing ammonia water until the salt solution is completely injected;

[0053] c) Add 0.5M zirconium nitrate and 0.5M ammonium bicarbonate solution at the same rate, and stop adding liquid whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com