Copolymerized polyphenylene sulfide composite fiber manufacture method

A polyphenylene sulfide and composite fiber technology, which is applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of insufficient mechanical strength of fibers, unclear mechanical properties and strength, etc. The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

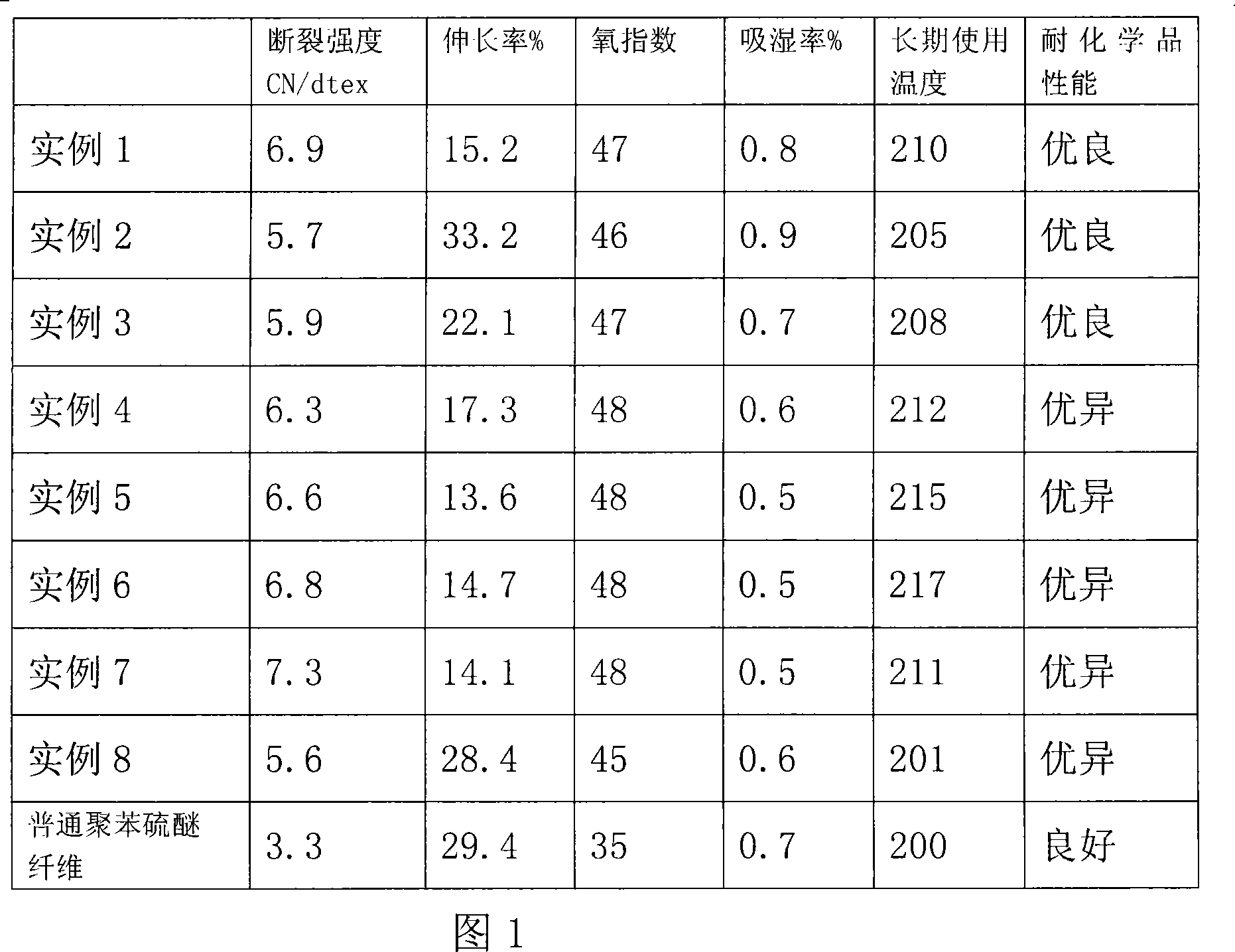

Examples

Embodiment 1

[0020] The process used is: fiber-grade copolymerized polyphenylene sulfide resin premixing treatment - vacuuming, twin-screw extruder melting - melt metering pump - forced filtration, spinneret assembly - filament cooling - winding and falling tube; adopt the following process conditions to produce as-spun silk.

[0021] 80kg of fiber-grade copolymerized polyphenylene sulfide resin with a weight-average molecular weight of 40,000 and a polydispersity coefficient of 1.98 with oligomers, cyclic compounds, reaction by-products, and reaction aids impurity content in the resin is no more than 0.1%, Add 5kg polyester resin (PET), 15kg polyether ether ketone (PEEK) resin 100kg, then 3.0kg (3.0%) heat stabilizer nonylphenol polyoxyethylene (4-10) ether phosphate diester and 0.5kg ( 0.5%) Antioxidant is GK-697 added to the fiber-grade copolymerized polyphenylene sulfide resin, stirred evenly by a high-speed mixer, and then extruded through an extruder to obtain composite resin slices,...

Embodiment 2

[0027] Add 5kg of polyester resin (PET), 15kg of polyphenylene sulfide sulfone (PPSS) resin 100kg to 80kg of fiber-grade copolymerized polyphenylene sulfide resin with a weight average molecular weight of 40,000 and its polydispersity coefficient of 1.92, and add 0.1kg (0.1% ) heat stabilizer nonylphenol polyoxyethylene (4-10) ether phosphate monoester and 2.5kg (2.5%) antioxidant GK-697 were added to the fiber-grade copolymerized polyphenylene sulfide resin. The draw ratio of the filaments is 6.8 times; the raw silk winding speed is 2300m / min, and the crystallization and solidification temperature range of the filaments is 510mm. All the other conditions are with embodiment 1.

Embodiment 3

[0029] Add 3kg of polyester resin (PET), 12kg of polyetheretherketone (PEEK) resin 100kg to 85kg of fiber-grade copolymerized polyphenylene sulfide resin with a weight average molecular weight of 50,000 and its polydispersity coefficient of 1.86, and then add 2.0kg (2.0% ) Heat stabilizer nonylphenol polystyrene ether phosphate diethanolamine salt and 1.3kg (1.3%) antioxidant GK-697 were added to the fiber-grade copolymerized polyphenylene sulfide resin, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com