Lithium-ion battery electrolyte for high-voltage ternary positive electrode material system

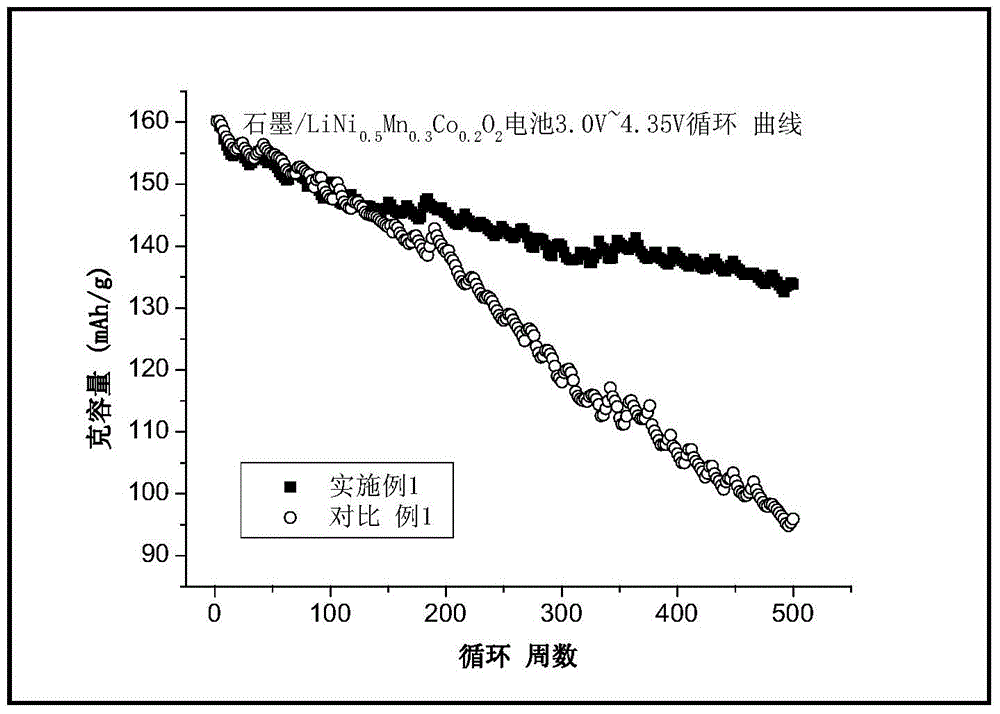

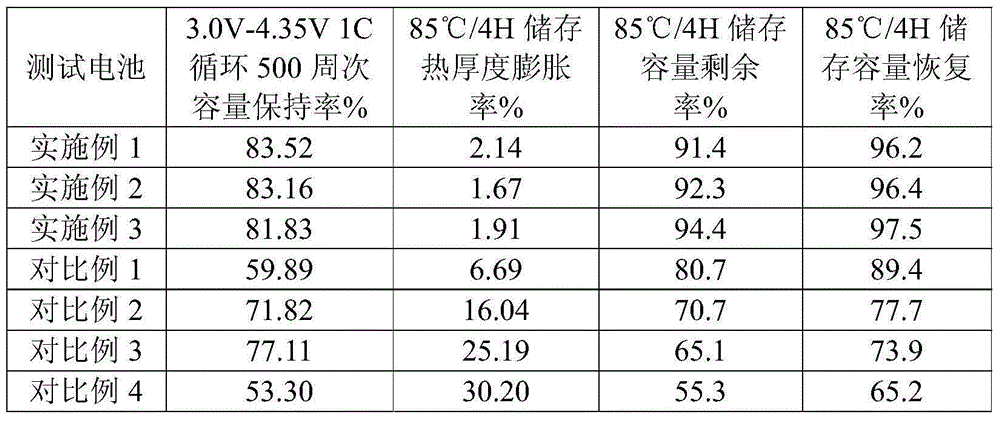

A lithium-ion battery and cathode material technology, applied in the field of high-voltage ternary cathode material system lithium-ion battery electrolyte, can solve the problems of large irreversible capacity for the first charge and discharge, inability to effectively suppress gas production, and battery reversible capacity loss. High capacity retention rate and capacity recovery rate, improved thermal stability, improved cycle performance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a glove box filled with argon, add methane disulfonic acid to the mixed non-aqueous solvent of ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and diethyl carbonate with a mass ratio of 25:5:15:55. Methyl ester, lithium bis(fluorosulfonyl)imide, succinic anhydride (additions accounted for 0.5%, 1.0%, 1.0% of the total mass of the electrolyte, respectively) and vinyl ethylene carbonate, succinonitrile and 1,2-di (2-cyanoethoxy)ethane (additional amounts accounted for 0.2%, 2.0% and 0.5% of the total electrolyte mass) additive; finally, slowly add 12.5% of the total electrolyte mass of lithium hexafluorophosphate to the mixed solution, and stir well Then the lithium ion battery electrolyte of Example 1 was obtained.

Embodiment 2

[0030] In a glove box filled with argon, add methylene methane disulfonate, bis(trimethyl)carbonate to a mixed non-aqueous solvent of ethylene carbonate, ethyl methyl carbonate, and diethyl carbonate with a mass ratio of 30:35:35. Lithium fluoromethanesulfonyl)imide, succinic anhydride (additions accounted for 2.0%, 0.5%, 0.5% of the total mass of the electrolyte), vinyl sulfate, 1,3-propane sultone and 1,3,6 -Hexanetrinitrile (additional amounts accounted for 0.5%, 1.0%, and 2.0% of the total electrolyte mass) additive; finally, slowly add lithium hexafluorophosphate accounted for 13.0% of the total electrolyte mass into the mixed solution, and stir well to obtain Example 2 Lithium-ion battery electrolyte.

Embodiment 3

[0032] In a glove box filled with argon, add methylene methane disulfonate and bis(fluorosulfonate) to the mixed non-aqueous solvent of ethylene carbonate, propylene carbonate, and diethyl carbonate with a mass ratio of 25:10:65. Lithium imide, methyl succinic anhydride (additions accounted for 0.5%, 2.0%, 1.0% of the total mass of the electrolyte, respectively) and vinylene carbonate, adiponitrile and 1,2-bis(2-cyanoethoxy Base) ethane (additional amounts accounted for 0.5%, 2.0%, and 0.5% of the total mass of the electrolyte) additive; finally, slowly add lithium hexafluorophosphate accounting for 12% of the total mass of the electrolyte into the mixed solution, and stir well to obtain the example 3 Lithium-ion battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com