Preparation method of modified lithium nickel manganese oxide cathode material

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the field of preparation of modified lithium nickel manganese oxide positive electrode materials, and can solve the problem of inability to form SEI film to isolate electrolyte and carbon materials, lower cycle performance of negative electrode materials, and difficulty in controlling environmental moisture, etc. problems, to achieve the effects of improving chemical stability, reducing contact, improving rate performance and cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

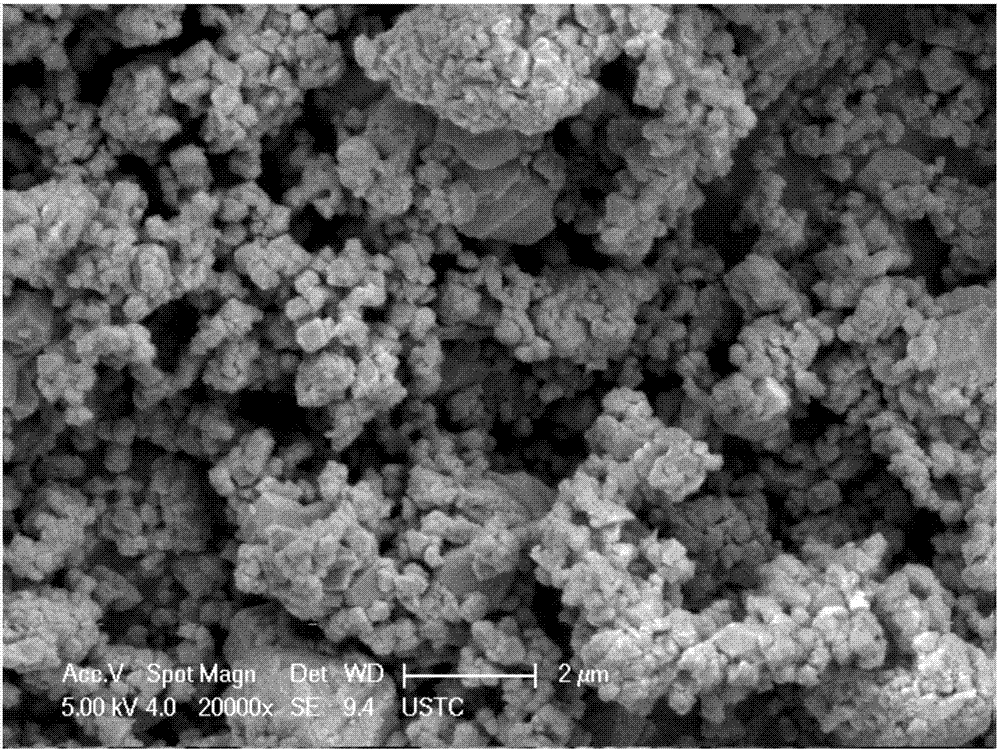

[0022] (1) Weigh out lithium carbonate, nickel acetate and manganese acetate according to the molar ratio of Li:Ni:Mn element 1.05:0.5:1.5, and then according to Ce 0.95 Fe 0.05 O 2 And LiNi 0.5 Mn 1.5 O 4 The theoretical synthesis mass ratio is 0.01:1, weighing Ce 0.95 Fe 0.05 O 2 , Will Ce 0.95 Fe 0.05 O 2 After mixing with lithium carbonate, nickel acetate, and manganese acetate, add deionized water for ball milling dispersion to obtain Ce 0.95 Fe 0.05 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The precursor of the material.

[0023] (2) The precursor of step (1) is vacuum dried and then calcined at a constant temperature of 700°C for 20 hours in an air atmosphere, and then naturally cooled to obtain Ce 0.95 Fe 0.05 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The modified lithium nickel manganate cathode material.

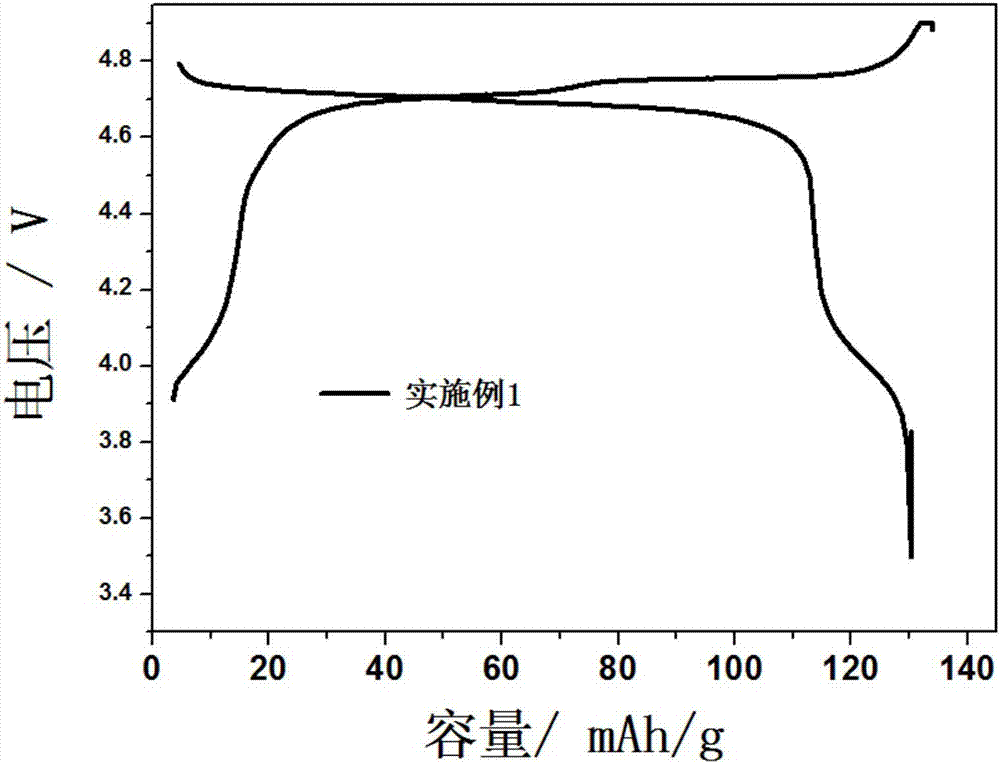

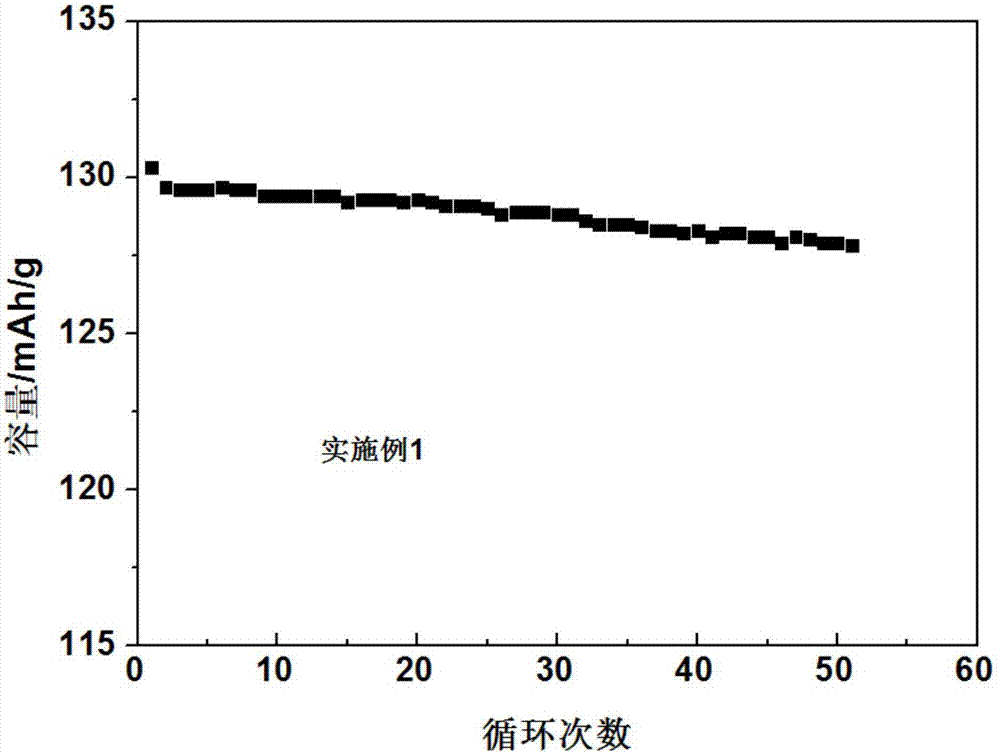

[0024] With reference to the drawings, Example 1 is used to illustrate the phase characterization and electrochemical performance of the modified lithium nickel manganate material prepared by ...

Embodiment 2

[0028] (1) Weigh lithium hydroxide, nickel sulfate and manganese sulfate according to the molar ratio of Li:Ni:Mn of lithium nickel manganate to 1.05:0.5:1.5, and then according to Ce 0.9 Fe 0.1 O 2 And LiNi 0.5 Mn 1.5 O 4 The theoretical synthesis mass ratio is 0.05:1, weighing Ce 0.9 Fe 0.1 O 2 , Will Ce 0.9 Fe 0.1 O 2 After mixing with lithium hydroxide, nickel sulfate and manganese sulfate, add absolute ethanol for ball milling dispersion to obtain Ce 0.9 Fe 0.1 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The precursor of the material.

[0029] (2) The precursor of step (1) is vacuum dried, then calcined at a constant temperature of 800°C for 15 hours in an air atmosphere, and then cooled naturally to obtain Ce 0.9 Fe 0.1 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The modified lithium nickel manganate cathode material.

[0030] The modified lithium nickel manganate cathode material synthesized in Example 2 has a capacity retention rate of 98.21% after 50 cycles of cycles.

Embodiment 3

[0032] (1) Weigh lithium acetate, nickel nitrate and manganese nitrate according to the molar ratio of Li:Ni:Mn of lithium nickel manganese oxide to 1.05:0.5:1.5, and then according to Ce 0.9 Fe 0.1 O 2 And LiNi 0.5 Mn 1.5 O 4 Theoretical synthesis mass ratio is 0.07:1 to weigh Ce 0.9 Fe 0.1 O 2 , Will Ce 0.9 Fe 0.1 O 2 After mixing with lithium acetate, nickel nitrate and manganese nitrate, add ethylene glycol for ball milling dispersion to obtain Ce 0.9 Fe 0.1 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The precursor of the material.

[0033] (2) The precursor of step (1) is vacuum dried and then calcined at a constant temperature of 900°C for 10 hours in an air atmosphere, and then naturally cooled to obtain Ce 0.9 Fe 0.1 O 2 Coated LiNi 0.5 Mn 1.5 O 4 The modified lithium nickel manganate cathode material.

[0034] The modified lithium nickel manganate cathode material synthesized in Example 3 has a capacity retention rate of 98.34% after 50 cycles of cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com