Preparation method of lithium ion battery coating pole piece

A lithium-ion battery and coating technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of not being able to effectively prevent the contact between the electrolyte and the active material, hindering the deintercalation of lithium ions, and requiring high coating technology. Prevent contact, improve cycle life, reduce the effect of oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The following is a further elaboration on the preparation method of the coated pole piece of the lithium ion battery. The positive electrode active material of the lithium ion battery involved in the preparation method includes but is not limited to LiNi 0.5 mn 1.5 o 4 、LiCoPO 4 、LiNi x co y m z o 2 (where x+y+z=1), LiCoO 2 、LiMnPO 4 and LiMn 2 o 4 These kinds of high voltage cathode materials. Vitreous solid electrolytes are sensitive to moisture, and related operations must be done under anhydrous conditions.

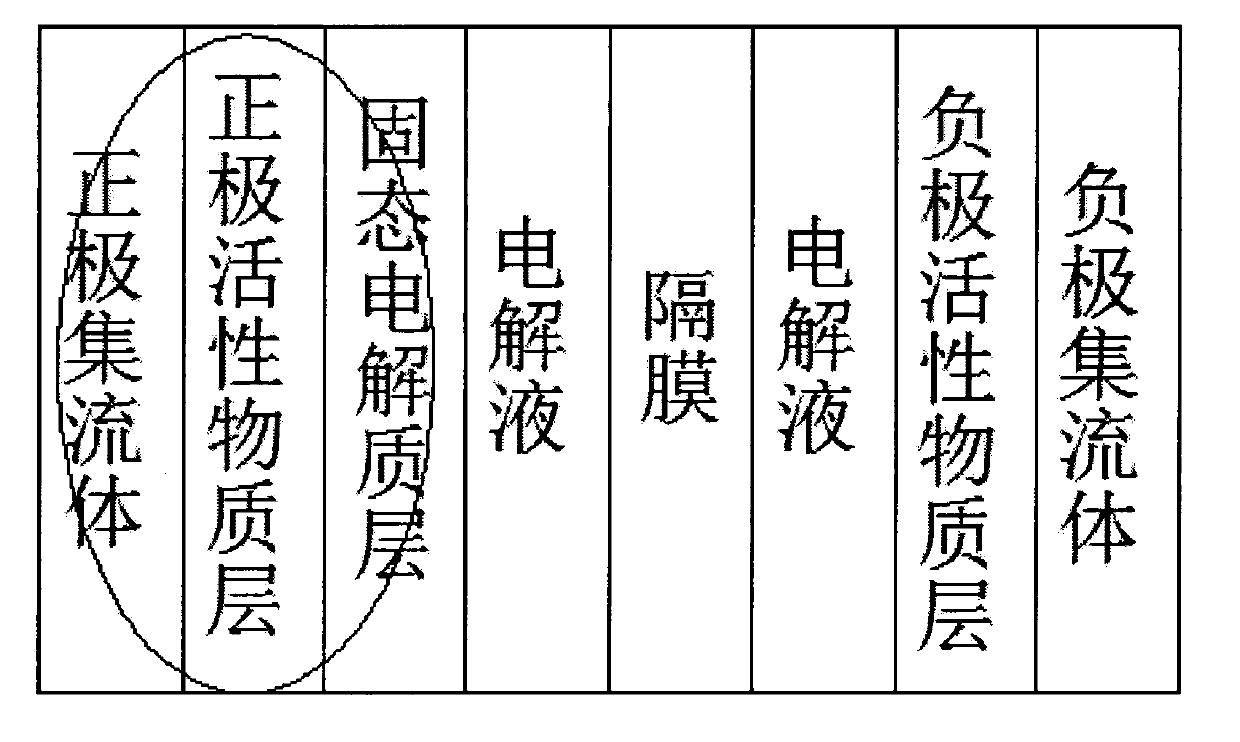

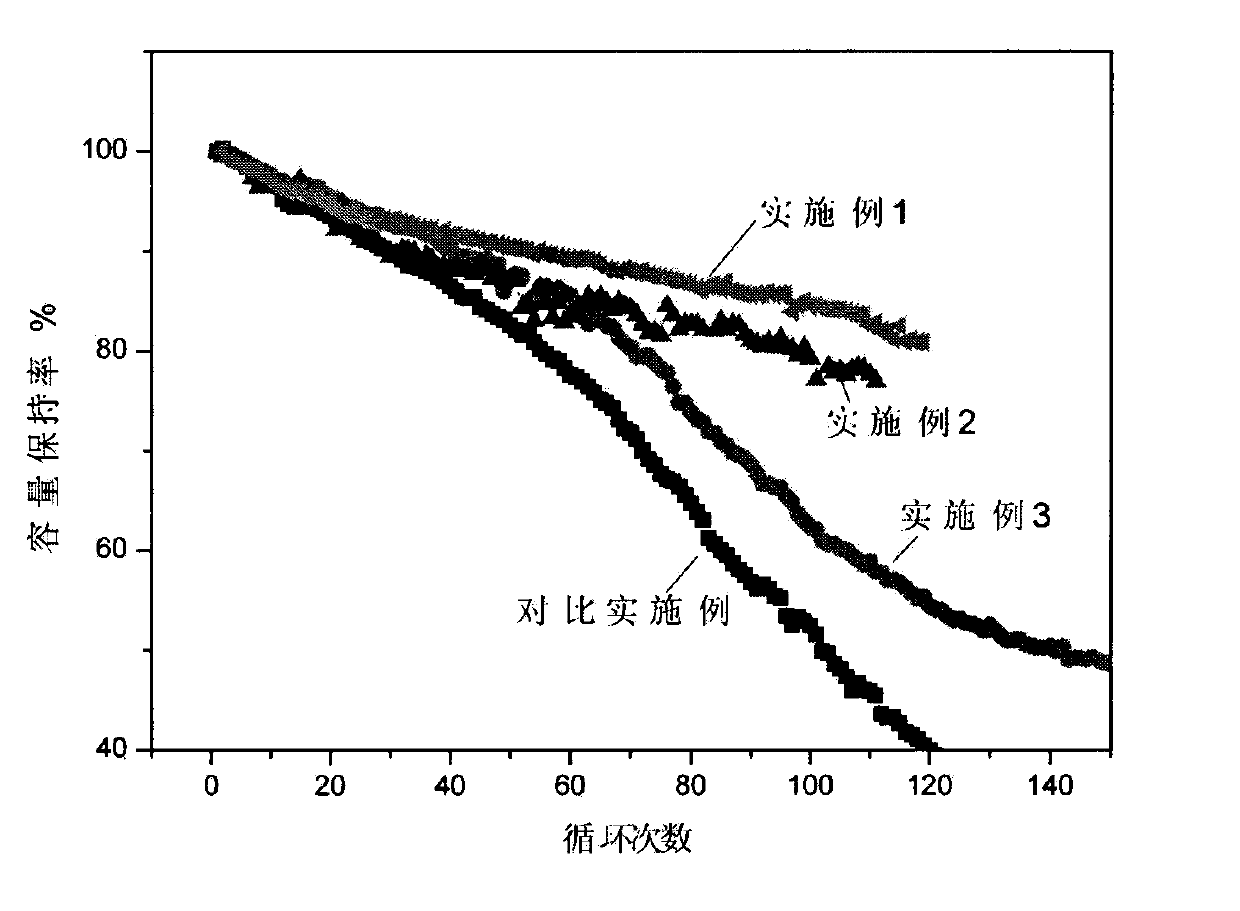

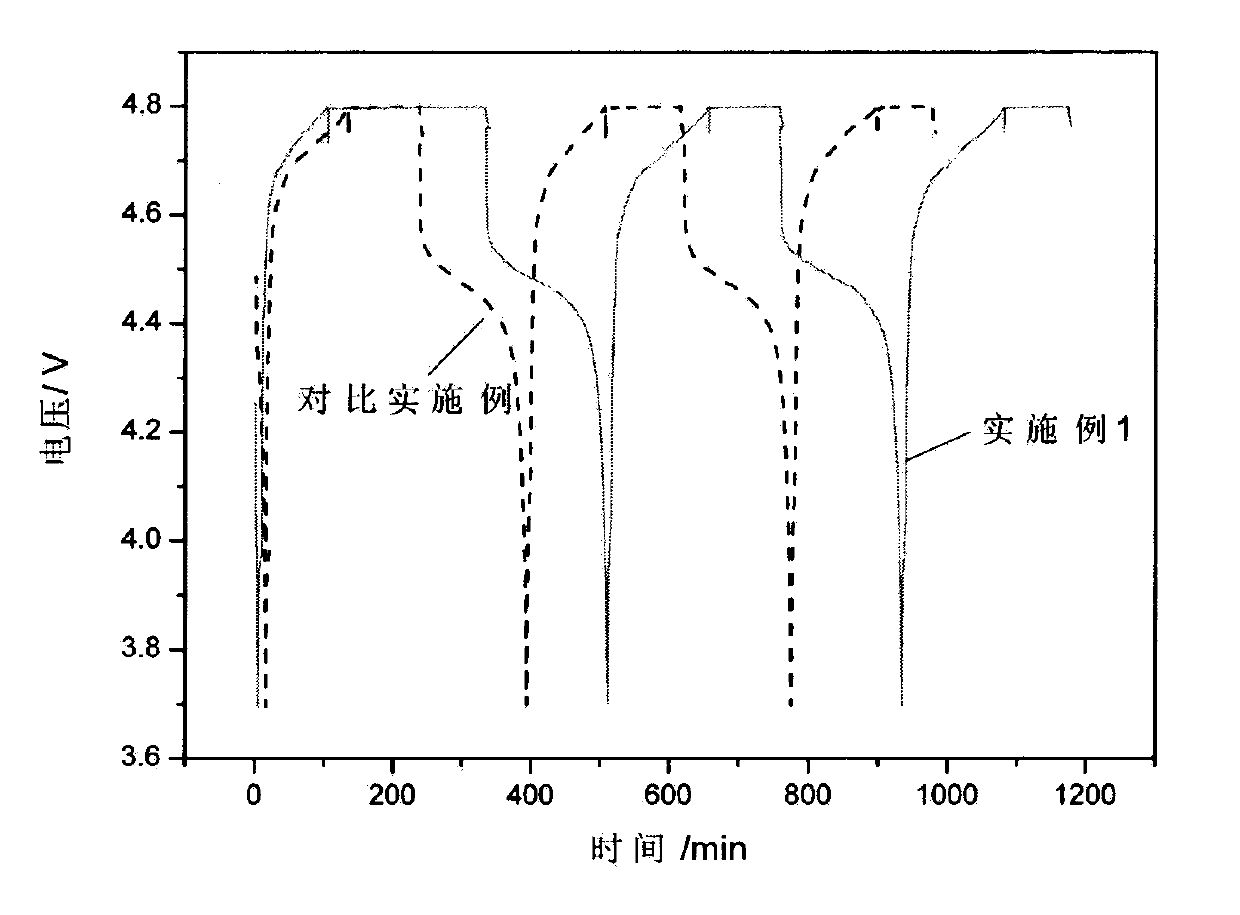

[0024] figure 1 It is a schematic cross-sectional view of the lithium-ion battery of Example 1-7 of the present invention, and the circled part is the coated positive pole piece of the present invention. It can be seen that the positive pole piece involved in the present invention mainly adds a layer of solid electrolyte layer on the surface of the positive active material, and effectively prevents the contact between the active material and the ele...

Embodiment 1

[0026] Take LiNi 0.5 mn 1.5 o 4 The positive electrode material is the research object, and the LiNi0.5 mn 1.5 o 4 , SP, PVDF and KS-6 were added to NMP in a certain order, mixed in vacuum for 5 hours, and then the slurry viscosity was adjusted to about 6000cps with NMP, and then the slurry was evenly coated on 20um aluminum foil on the coating machine and dried, according to Experimental process, the dry pole piece is rolled on a roller press to obtain a compacted density of 2.5g / cm 3 LiNi 0.5 mn 1.5 o 4 Positive pole piece, ready for use. Weigh a certain amount of PVA and dissolve it in acetone, stir it under vacuum for 2h to obtain a uniform solution, then mix 0.75 Li 2 S-0.25P 2 S 5 Add the solid electrolyte to the acetone solution of PVA, stir for 5 hours under vacuum cold water cooling, adjust the solid content to 70% with acetone, and the measured viscosity is 8000cps, and then apply the solid electrolyte slurry on the above-mentioned LiNi in a drying room 0....

Embodiment 2

[0028] Weigh a certain amount of PEO and dissolve it in acetone, stir it under vacuum for 5h to obtain a uniform solution, then mix Li 3 PO 4 -Li 2 S-SiS 2 Add the vitreous solid electrolyte into the acetone solution of PEO, stir for 7 hours under vacuum cold water cooling condition, adjust the solid content to 60% with acetone, and the measured viscosity is 10000cps, and then apply the solid electrolyte slurry in the drying room to the preparation in Example 1. Got LiNi 0.5 mn 1.5 o 4 The surface of the positive electrode sheet is dried in a vacuum oven at 70°C for 1h, and the coating thickness is 4um (the coating thickness drops to 3um after rolling), so as to obtain LiNi 0.5 mn 1.5 o 4 Positive Li 3 PO 4 -Li 2 S-SiS 2 Solid electrolyte coated electrode pole piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com