Lithium ion battery cathode slurry and preparation method thereof

A lithium-ion battery and positive electrode slurry technology, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as failure, battery swelling, and long time consumption, and achieve long service life, prolong service life, and improve rapid conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

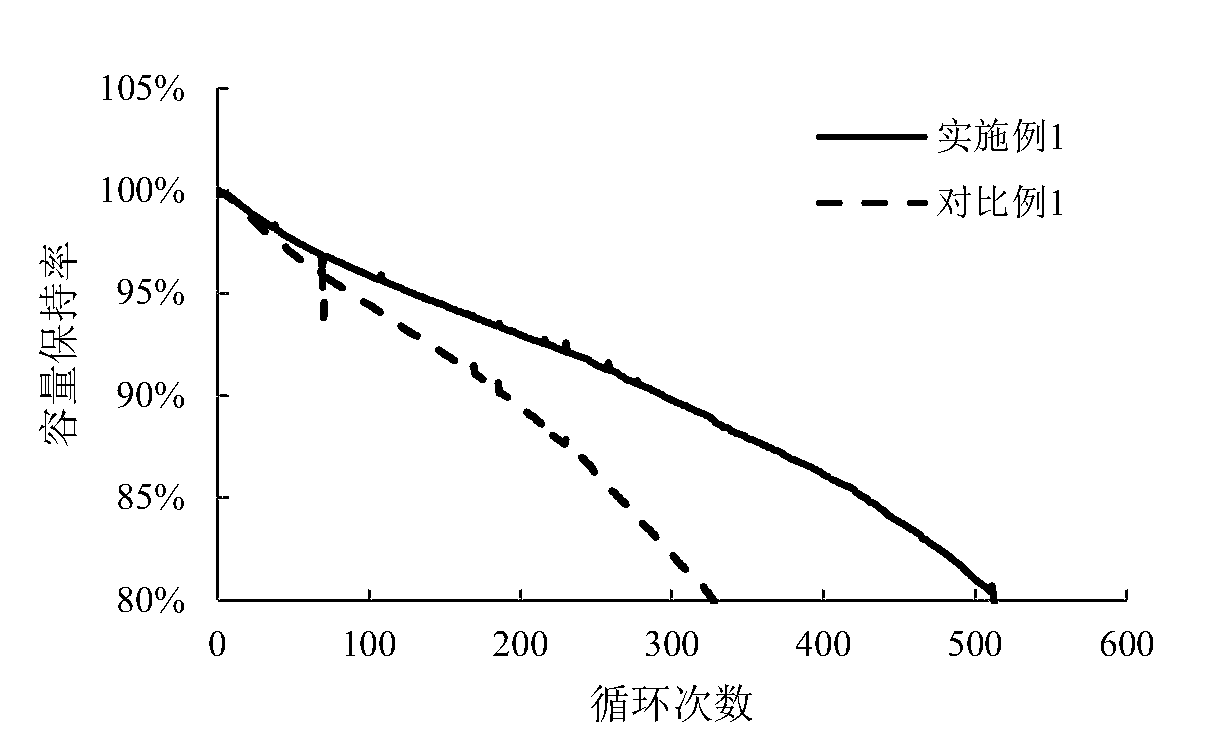

Embodiment 1

[0033] A preparation method of lithium-ion battery cathode slurry, specifically comprising the steps of:

[0034] First, according to the ratio in Table 1, add the active material, conductive agent, additive and binder into the double planetary mixing tank, stir for 30 minutes until the powder is fully mixed; add 12% N-methylpyrrolidone by weight of all solid components After that, turn on the revolution and stir for 60 minutes; add N-methylpyrrolidone of 16% by weight of all solid components, turn on the revolution and disperse and stir for 120 minutes, and test the viscosity of the slurry to be 4000-6000mpa s; vacuumize for 30 minutes and filter to obtain the positive electrode slurry material.

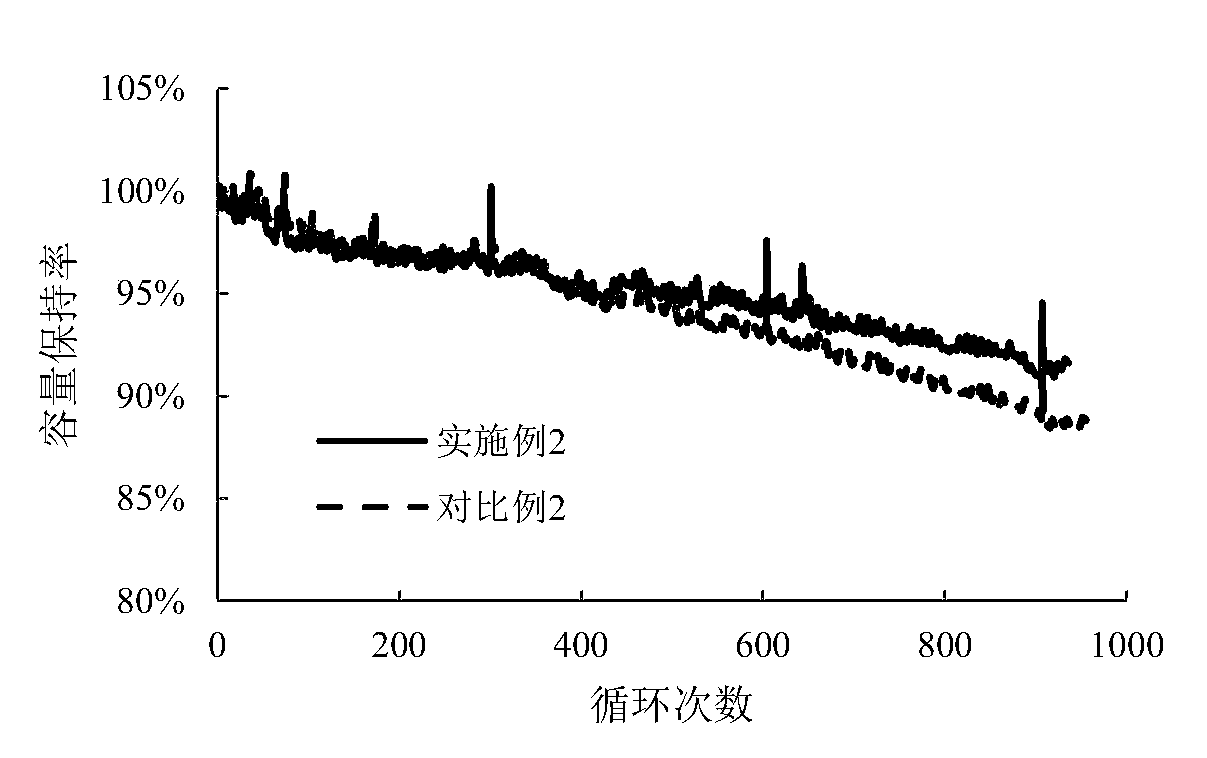

Embodiment 2

[0037] A preparation method of lithium-ion battery cathode slurry, specifically comprising the steps of:

[0038] First, according to the ratio in Table 1, add the active material, conductive agent, additive and binder into the double planetary mixing tank, stir for 30 minutes until the powder is fully mixed; add 16% N-methylpyrrolidone by weight of all solid components After that, turn on the revolution and stir for 60 minutes; add N-methylpyrrolidone of 16% by weight of all solid components, turn on the revolution and disperse and stir for 120 minutes, and test the viscosity of the slurry to be 4000-6000mpa s; vacuumize for 30 minutes and filter to obtain the positive electrode slurry material.

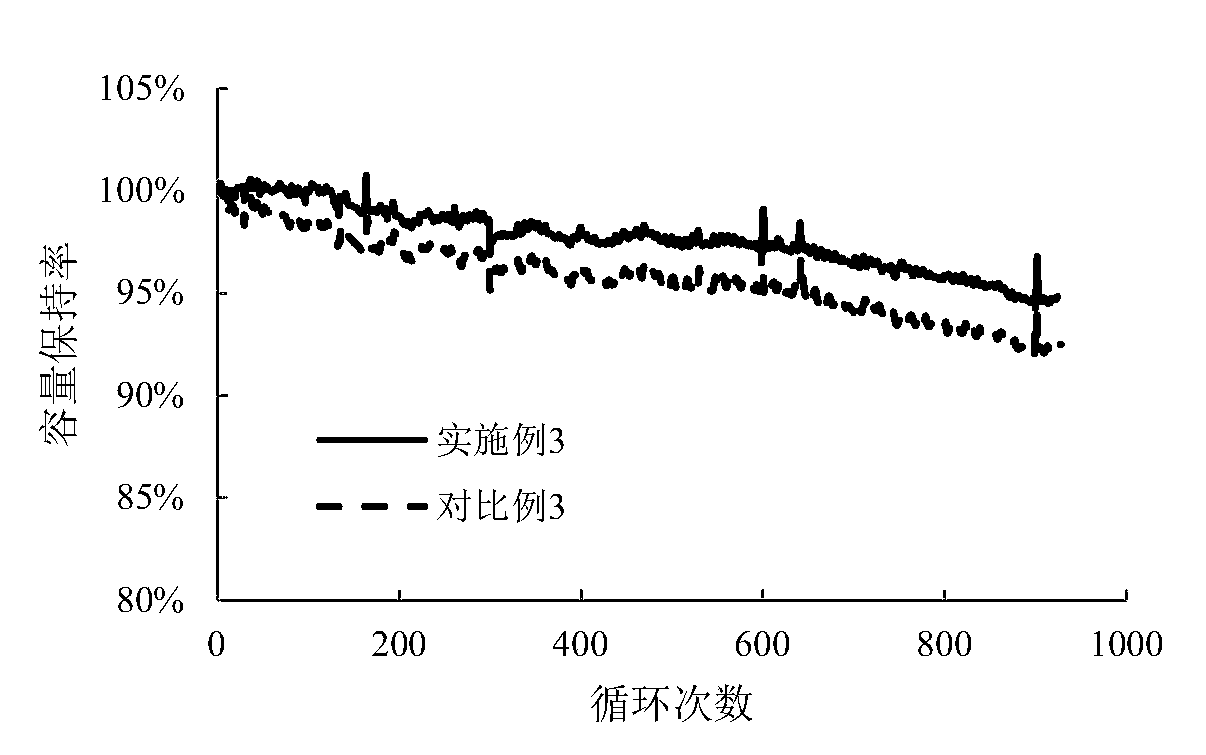

Embodiment 3

[0041] A preparation method of lithium-ion battery cathode slurry, specifically comprising the steps of:

[0042] First, according to the ratio in Table 1, add the active material, conductive agent, additive and binder into the double planetary mixing tank, stir for 30 minutes until the powder is fully mixed; add 50% N-methylpyrrolidone by weight of all solid components After that, turn on the revolution and stir for 60 minutes; add N-methylpyrrolidone with 32% weight of all solid components, turn on the revolution and disperse and stir for 120 minutes, and test the viscosity of the slurry to be 6000-8000mpa s; vacuumize for 30 minutes and filter to obtain the positive electrode slurry material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com