Board pyrograph manufacturing method and device

A production device and production method technology, applied in decorative arts, production tools, processes for producing decorative surface effects, etc., can solve problems such as low production efficiency, unstable production quality, and inability to meet personalized custom production, and achieve High-precision and high-quality heat transfer processing, the effect of improving surface quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

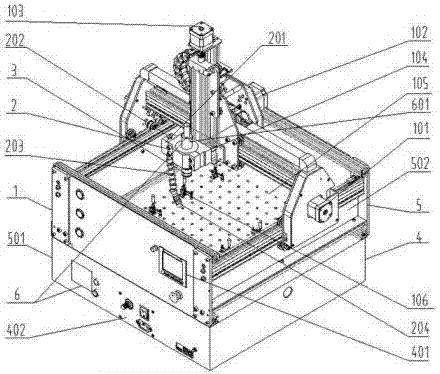

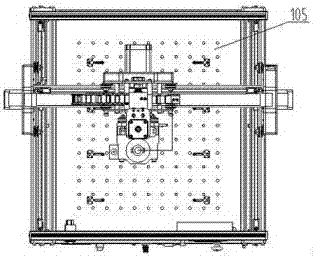

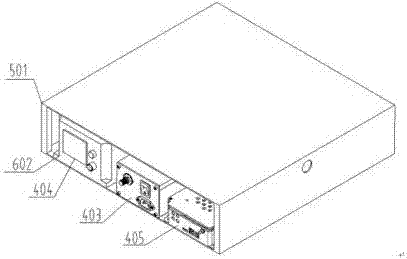

[0041] The present invention adopts a fully automatic hot stamping production method based on the combination of image processing technology, laser technology and numerical control technology. This method can convert the required hot stamping pattern into a digital image through image processing technology, and extract the grayscale image and Record the relationship between pixel size and position and gray value; according to the characteristics of continuous laser output, large heat, and adjustable light spot, the laser is used as a hot tool to burn heat transfer patterns; the application of numerical control technology can The heat transfer production process is subdivided into three axial movements of XYZ in the space, and combined with the gray value of the image and the process parameters (laser irradiation intensity, laser irradiation time, and laser irradiation distance) of the laser head pointing at the wooden board, the laser beam is completed on the wooden board. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com