Marking of an anodized layer of an aluminium object

An anodizing and marking technology, which is applied in the direction of copying/marking method, thin material processing, temperature recording method, etc., can solve the problem of preventing the coloring of the anodized layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

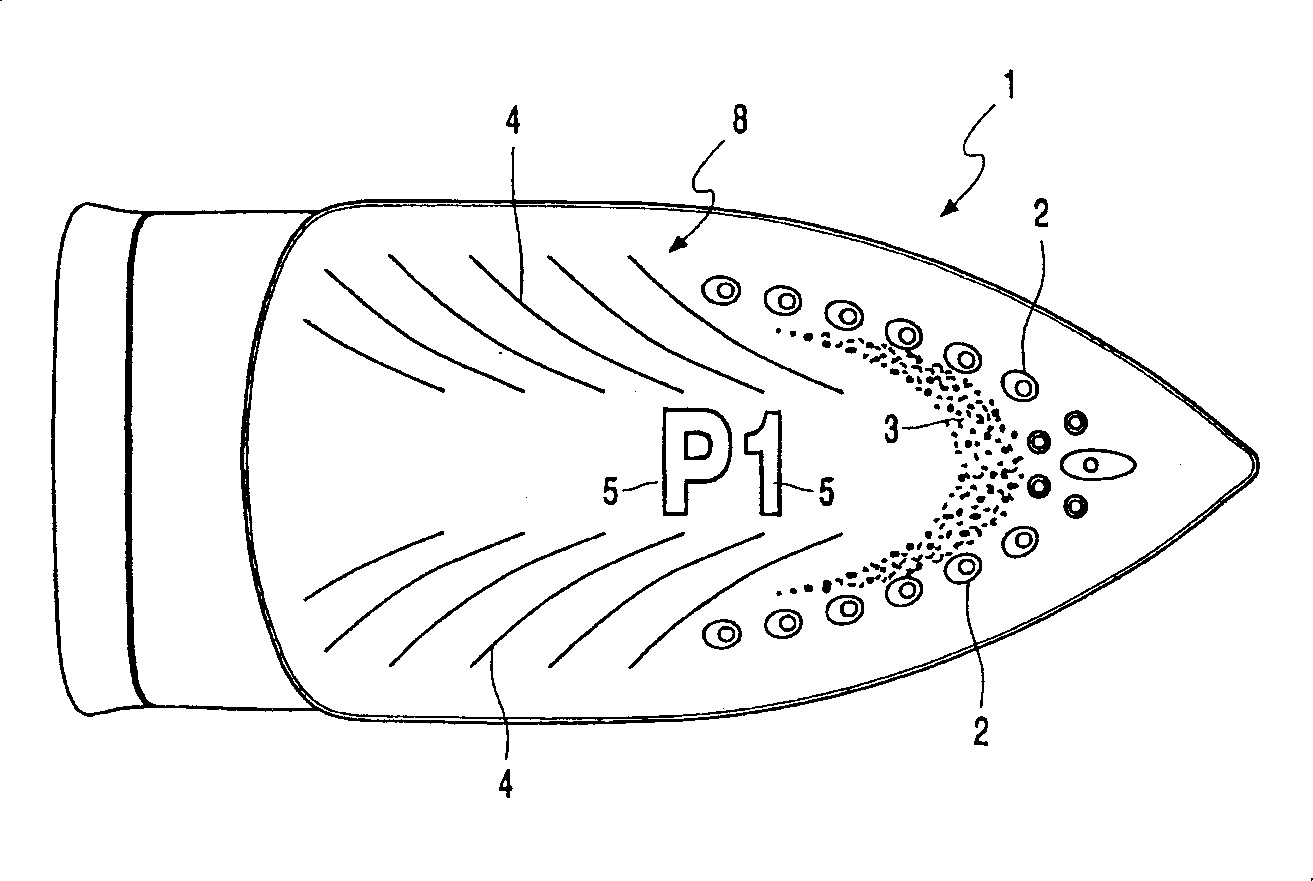

[0015] The part shown in the example figure is the bottom 1 of a steam iron with an outlet 2 for the passage of steam and markings such as: dots of the area 3, lines 4, and numeral-symbol characters 5 like typefaces .

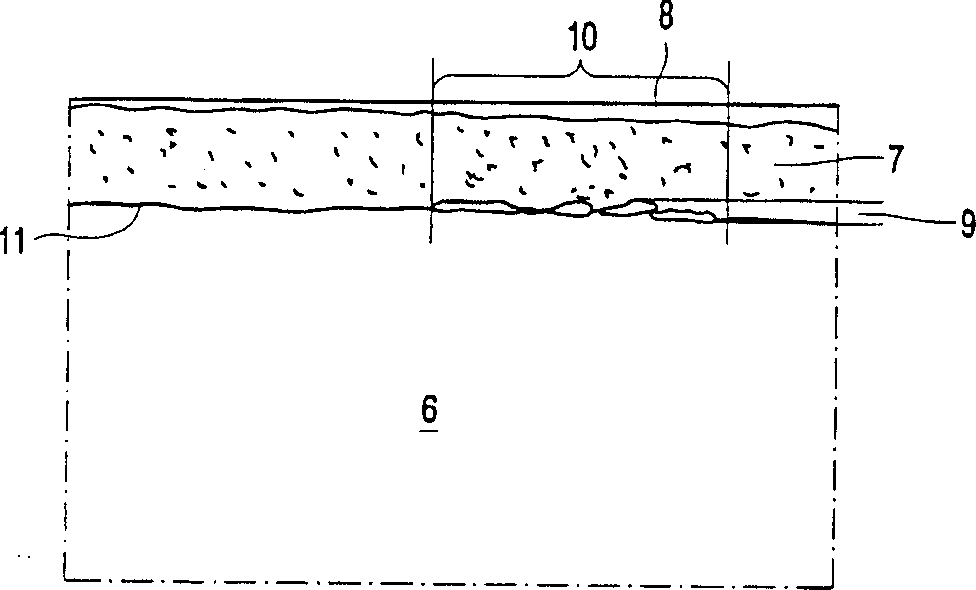

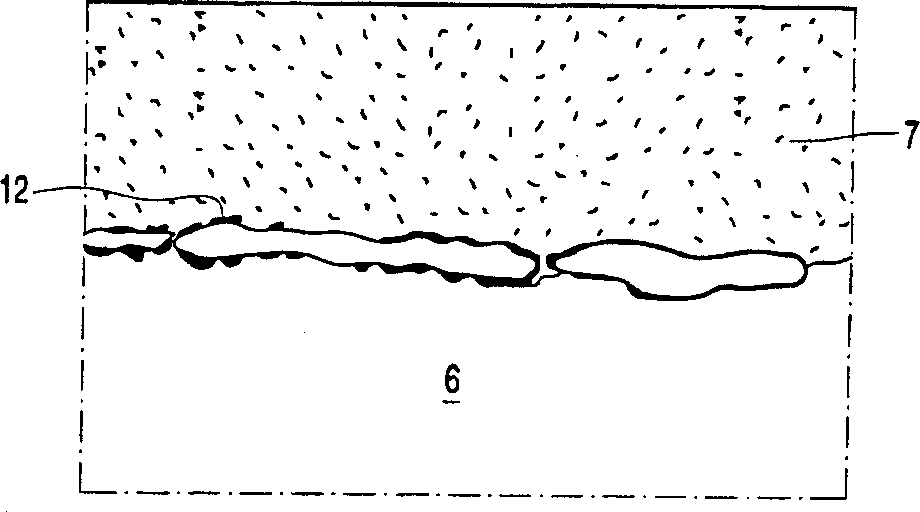

[0016] The bottom 1 is composed of a substantially plate-shaped substrate 6 made of aluminum alloy and an anodized outer layer 7 forming an ironing surface 8 of the bottom 1 . this is in Figure 2 to Figure 4 , which are micrographs at magnifications of 625X, 2500X and 10,000X, respectively.

[0017] The area of surface 8 forming indicia 3 to 5 can be visually distinguished by the human eye from other parts of surface 8 because it has visual properties that differ from corresponding visual properties of adjacent and other parts of surface 8 . The different visual properties of the regions of the surface 8 forming the markings 3 to 5 in this example are the chromaticity and gloss of these regions. These areas are gray-black to black in shade and somewhat le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com