Bamboo wood product pressing machine

A technology of pressing machines and products, applied in the direction of branding machines, decorative arts, embossed ornaments, etc., can solve the problems of low production efficiency, increase labor costs, reduce work efficiency, etc., achieve product quality assurance, reduce labor cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

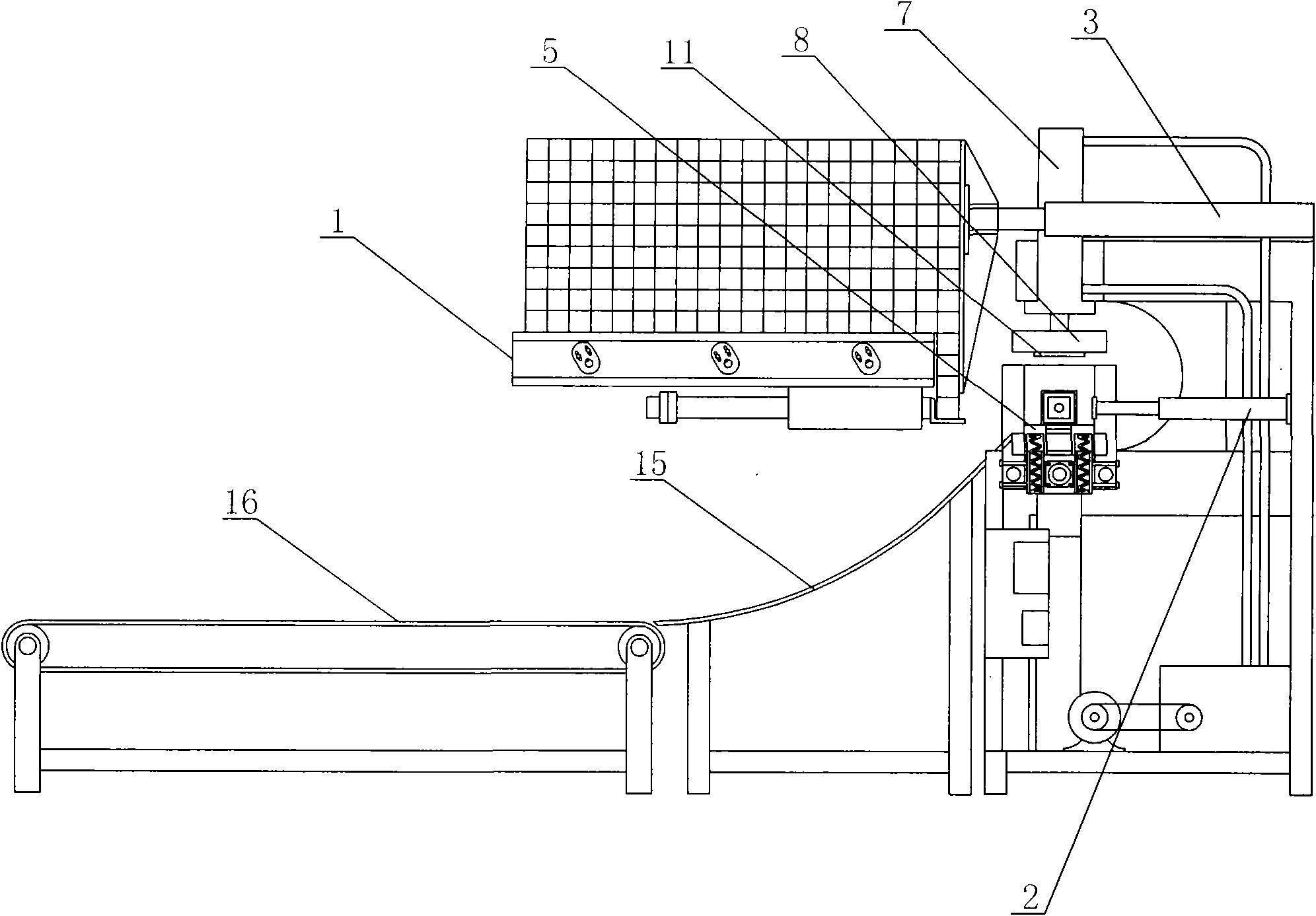

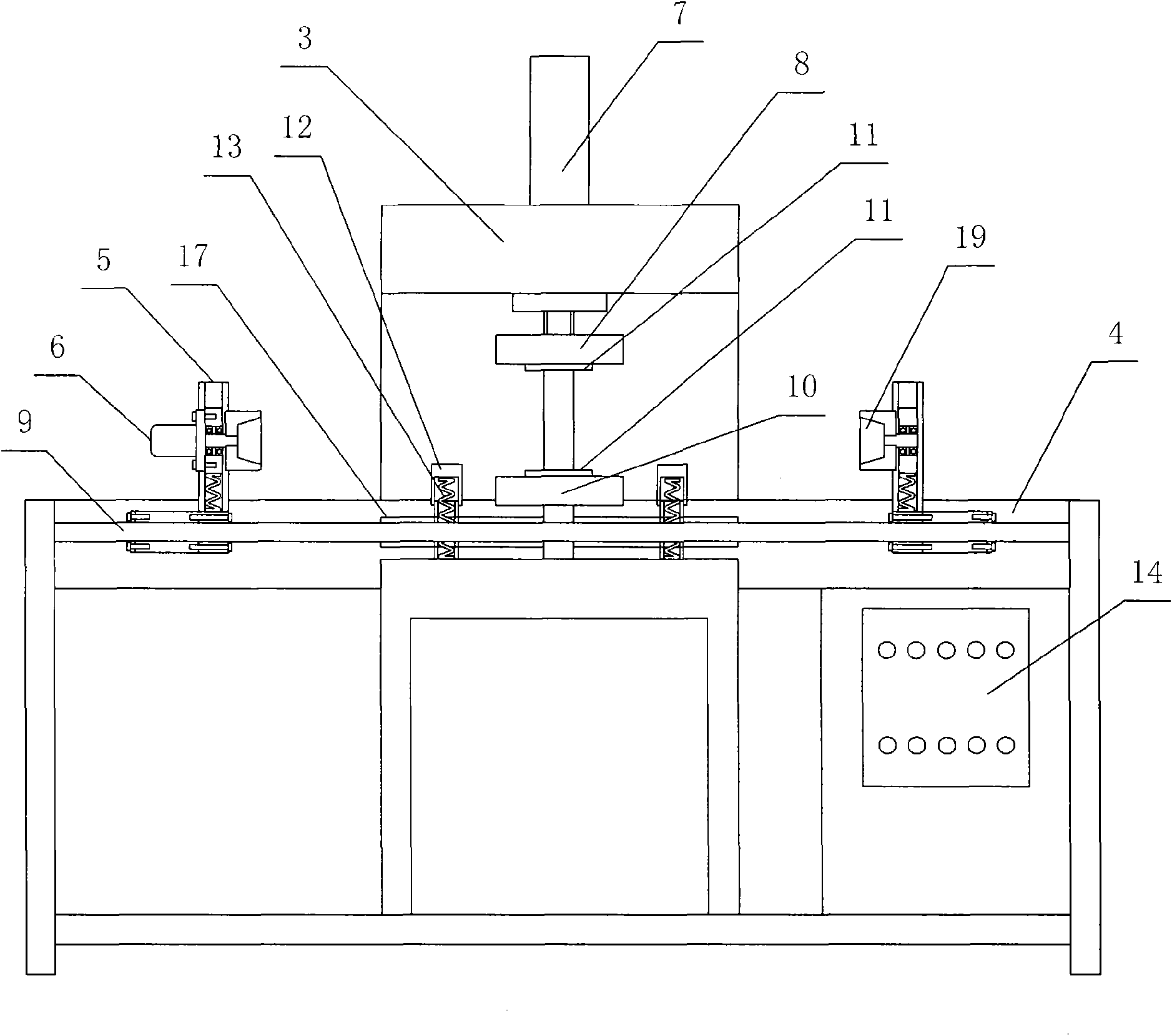

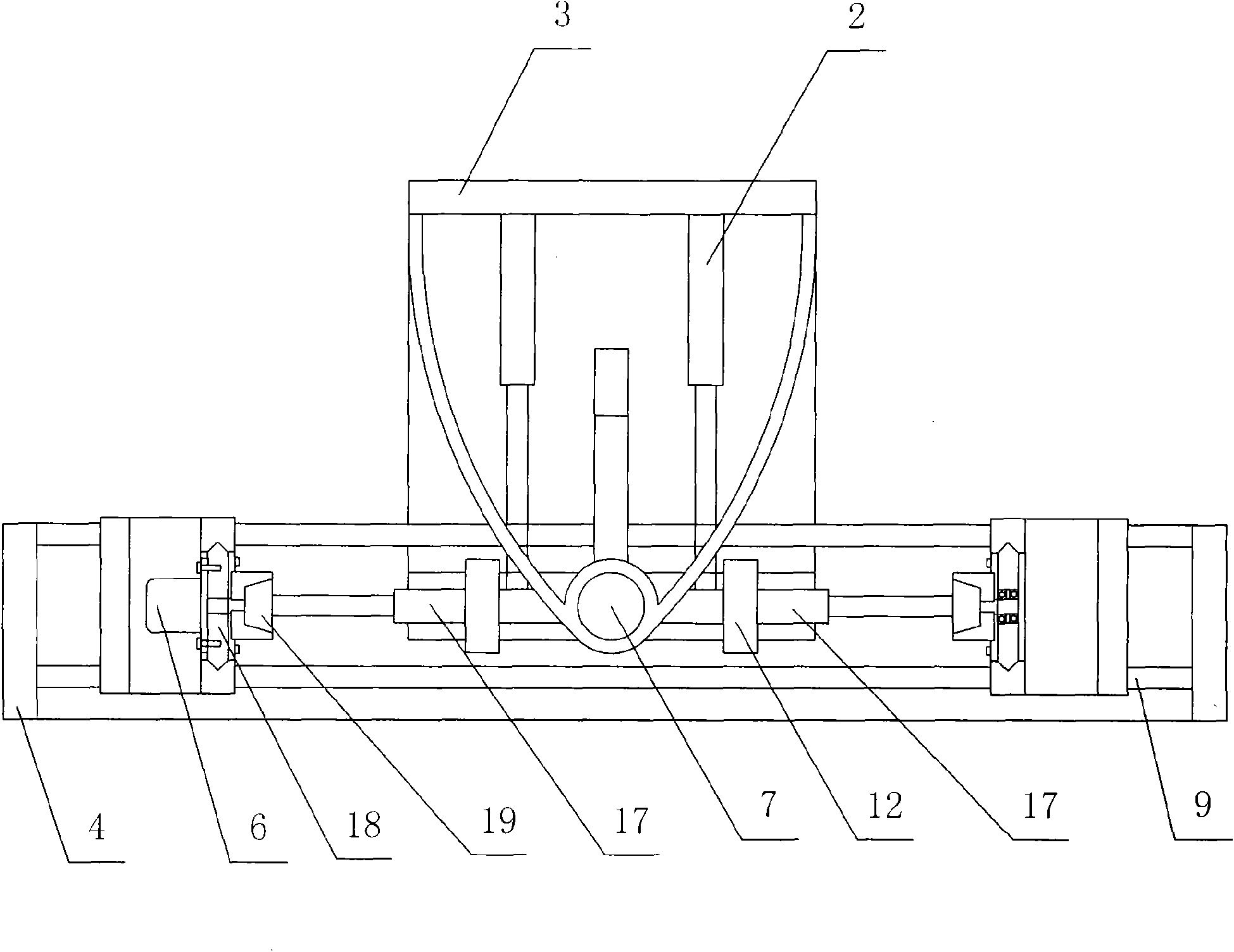

[0012] Implementation case: A pressing machine for bamboo and wood products, including a feeding device 1, a main frame 3, an auxiliary frame 4 and a lifting pressure device 7, the main frame 3 is connected to the auxiliary frame 4, and the main frame 3 is provided with a lift The pressure device 7 is provided with an electric heating device 8 that can move up and down with the lifting pressure device 7 on the lifting pressure device 7, and is provided with a fixed electric heating device 10 directly below the lifting pressure device 7 and on the main frame 3. Two electric heating devices There are molds 11 on both sides, elastic supporting devices 12 are arranged on both sides of the fixed electric heating device 10 on the main frame 3, springs 13 are arranged in the elastic supporting devices 12, and mobile locking devices 5 are arranged on the auxiliary frame 4. , the mobile locking device 5 is provided with a moving block 18, the mobile locking device 5 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com