Method for fabricating nonmetallic slices by using laser

A laser processing, non-metallic technology, which is applied in the direction of machines for branding, crafts for producing decorative surface effects, decorative arts, etc. Clear and other problems, to achieve the effect of improving processing quality, reducing blur effects, and clear texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

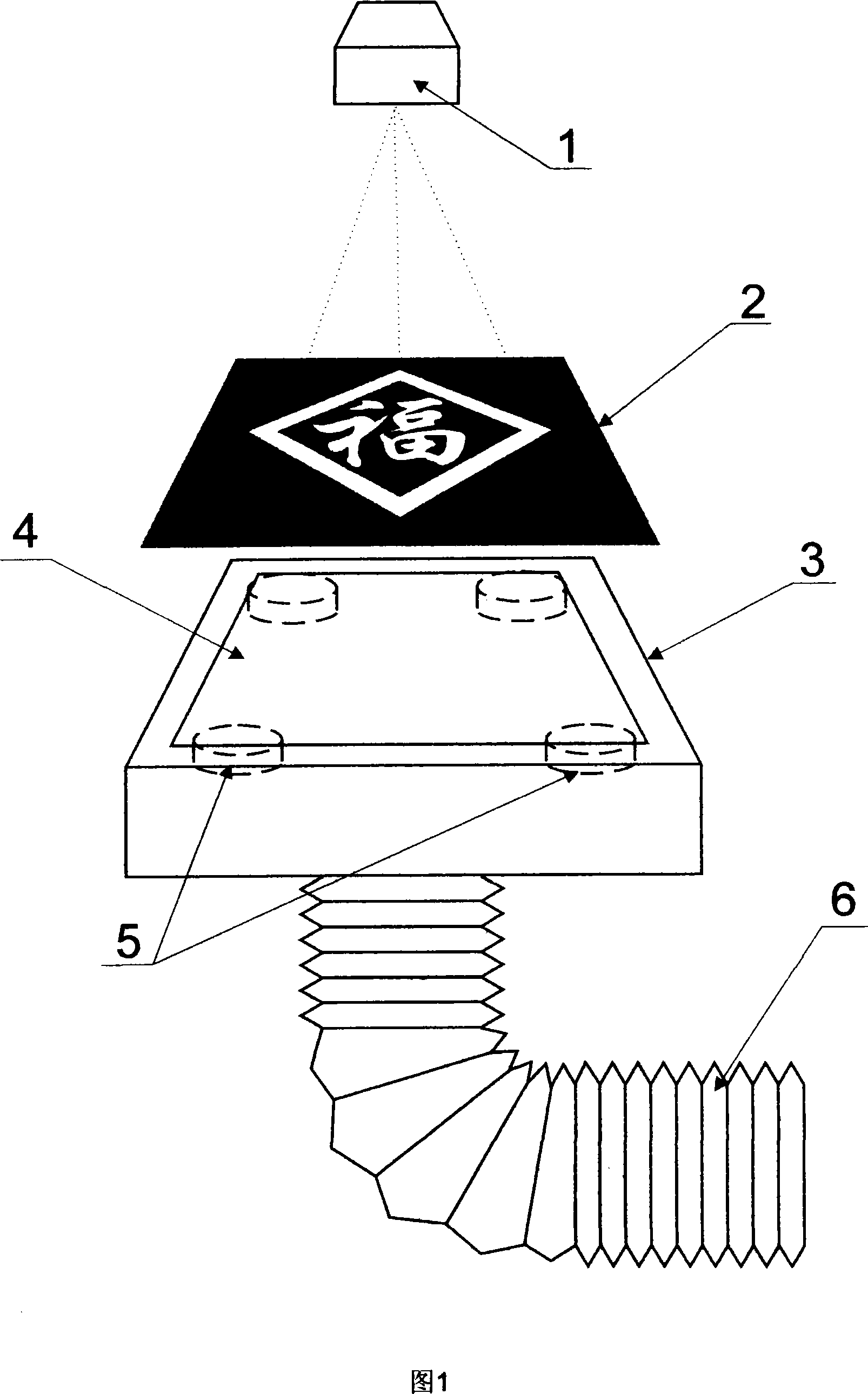

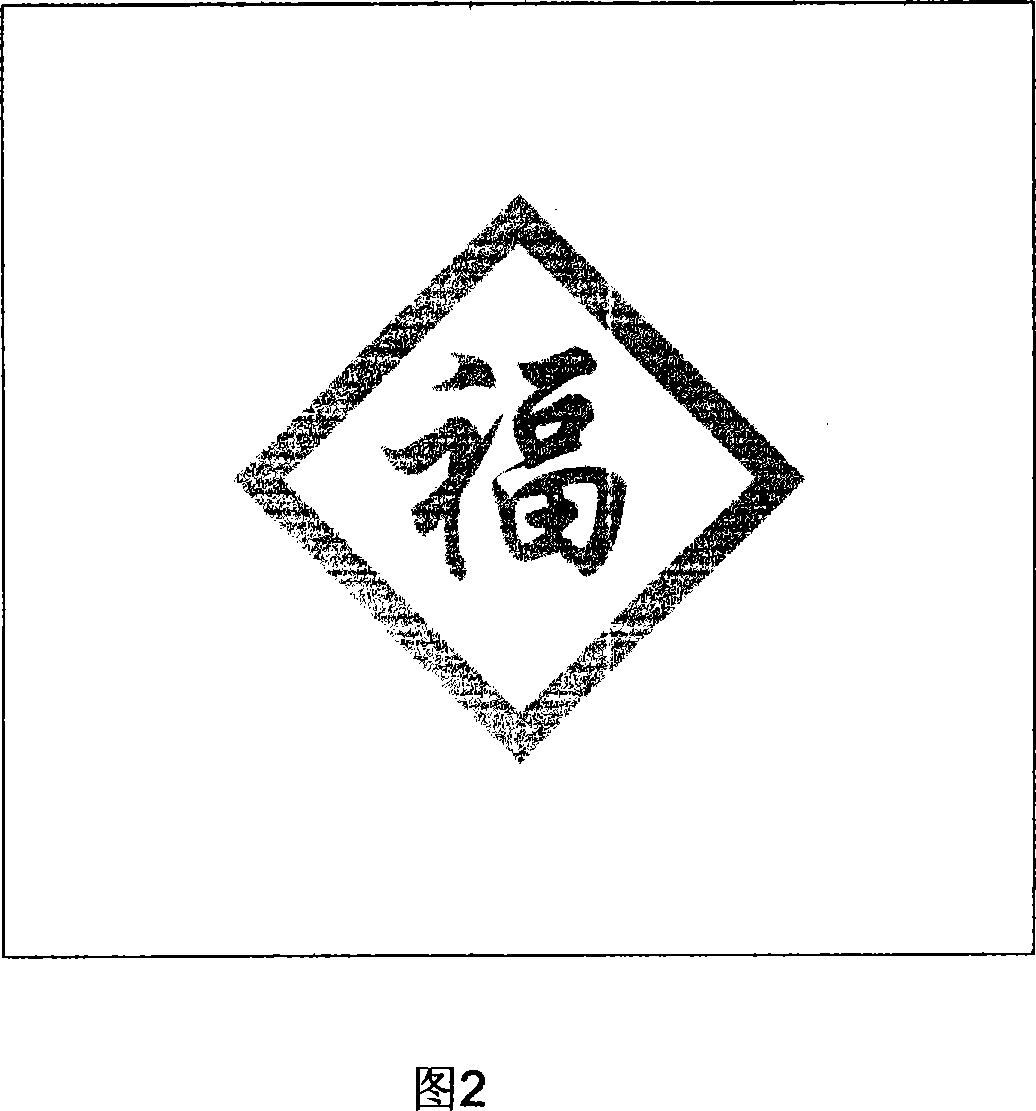

[0012] Referring to FIGS. 1-2 , the method of this embodiment includes the following equipment: a laser galvanometer marking device 1 , a metal template 2 , a workbench 3 , an electromagnet adsorption device 5 and a workpiece adsorption device 6 .

[0013] The main body is the laser galvanometer marking device 1. The galvanometer marking is a conventional and mature technology in laser applications, and can work stably for a long time. The description is omitted here. The metal template 2 is the core of the present invention. The iron template is made by etching or ablation patterns and textures according to the needs, and the places that need to be printed, marked and etched are hollowed out on the template. During processing, the template is set or placed on the workpiece 4---the veneer, and the laser emitted by the laser galvanometer marking device scans the entire area, and the laser carbonizes or burns the surface of the sheet at the hollowed out part of the metal template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com