Patents

Literature

48results about How to "Range of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

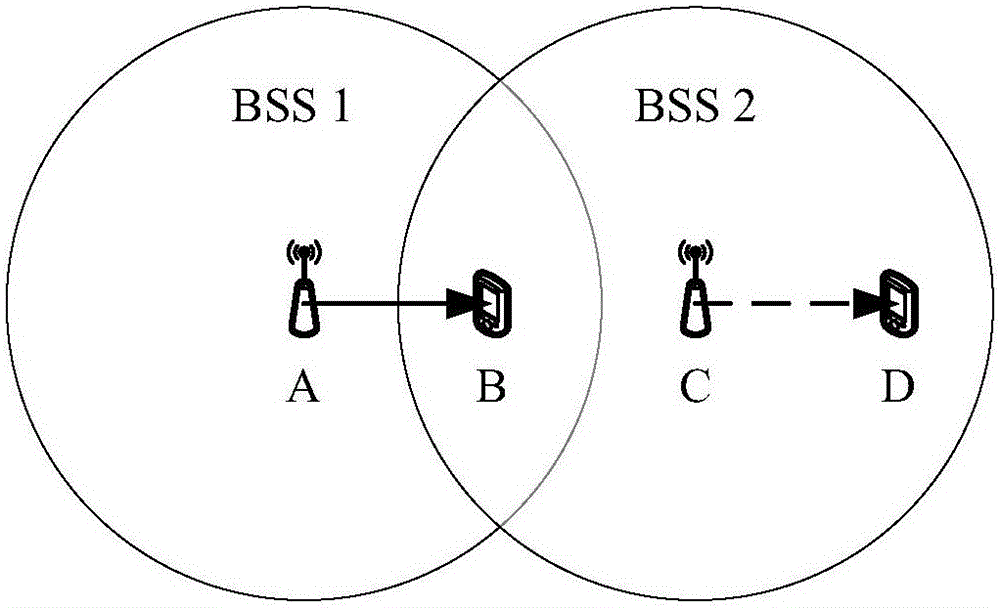

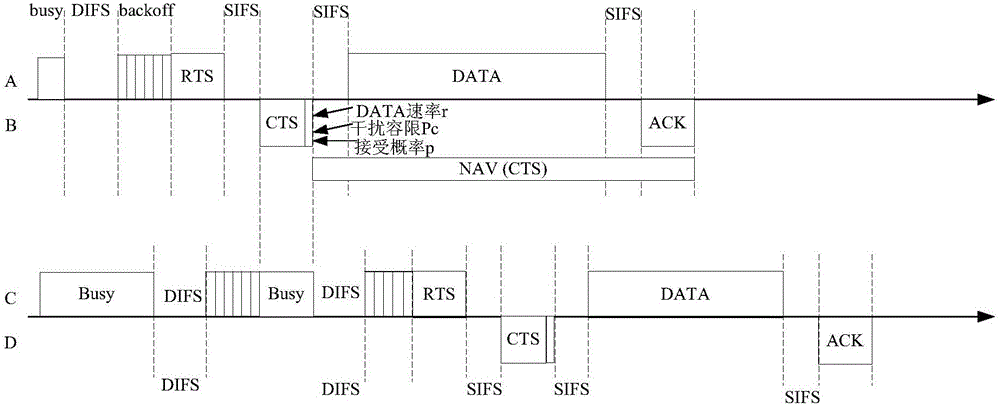

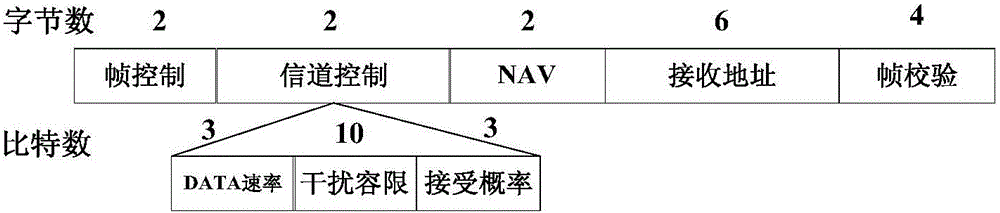

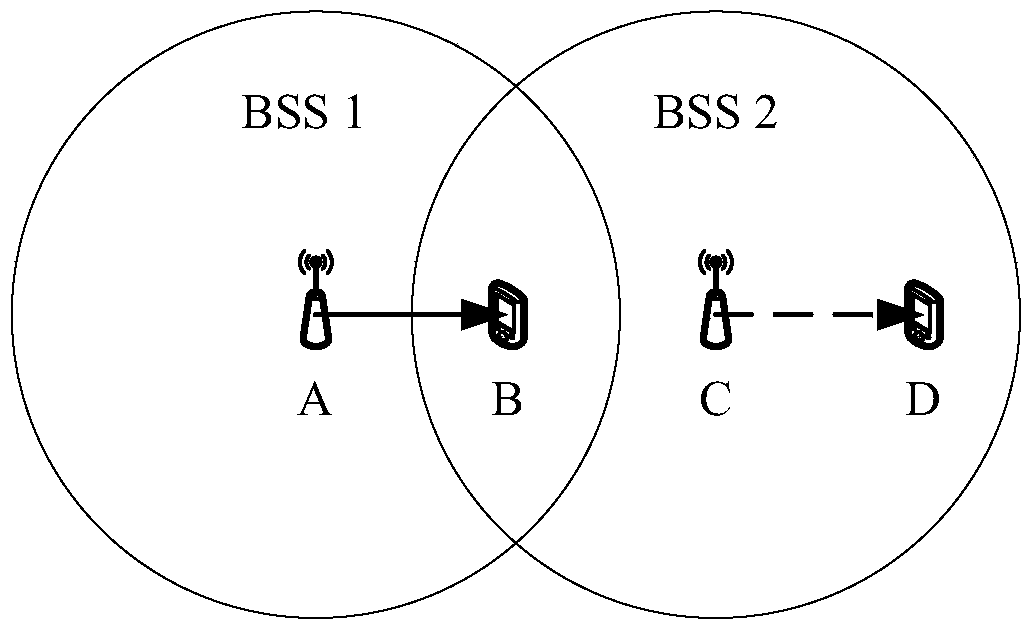

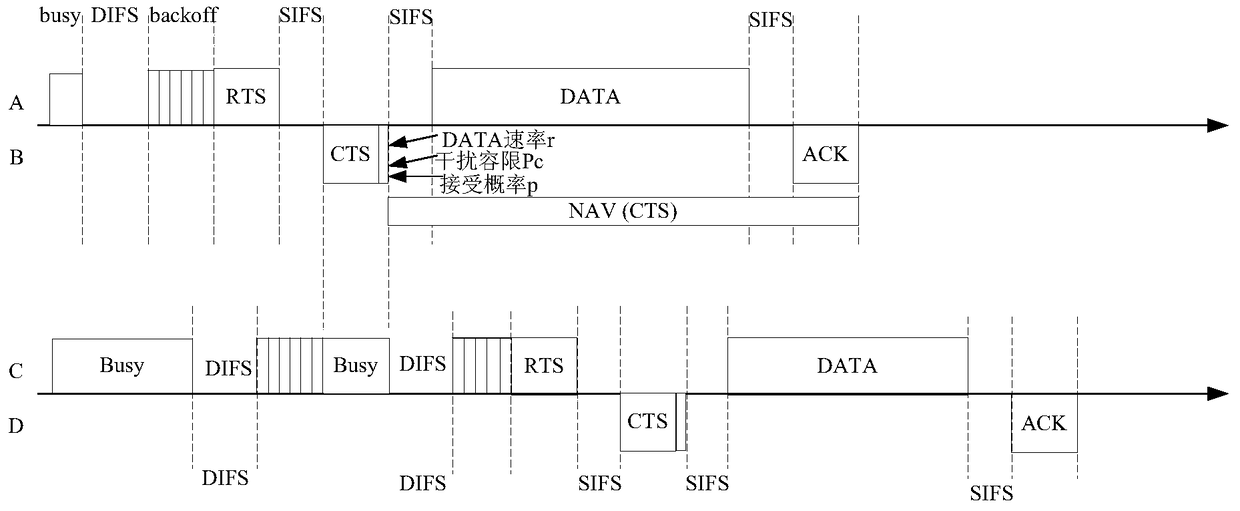

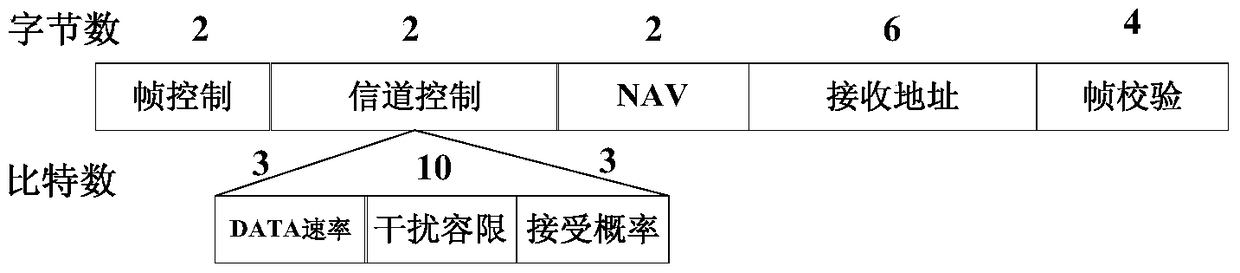

Carrier sensing method based on dynamic idle channel assessment threshold

InactiveCN105101453ARange of controlImprove space reuseWireless communicationCarrier signalNetwork allocation vector

The invention provides a carrier sensing method based on a dynamic idle channel assessment threshold. According to the method, the existing carrier sensing mechanism is improved, and a CCA (Clear Channel Assessment) threshold is adjusted and an effective range of an NAV (Network Allocation Vector) is controlled according to the channel condition, so that the concurrent transmission in a network is increased and the network throughput is improved. According to the method, the CCA threshold is dynamically computed and adjusted according to the receiving power, so that the spatial reuse of the network can be effectively improved, meanwhile, through carrying an interference margin and a probability of acceptance at a CTS (Clear To Send) group, the range of action of the NAV in the CTS group is effectively controlled, and the spatial reuse is further improved, so that the network throughput is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

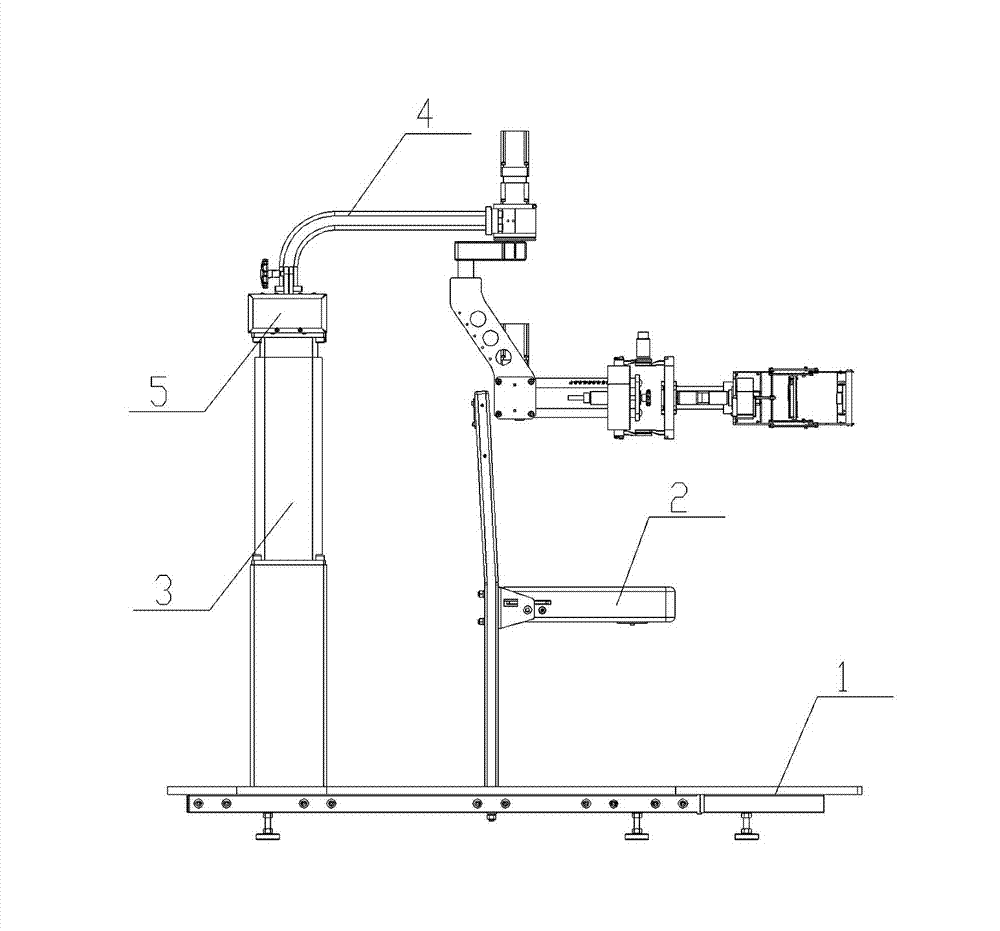

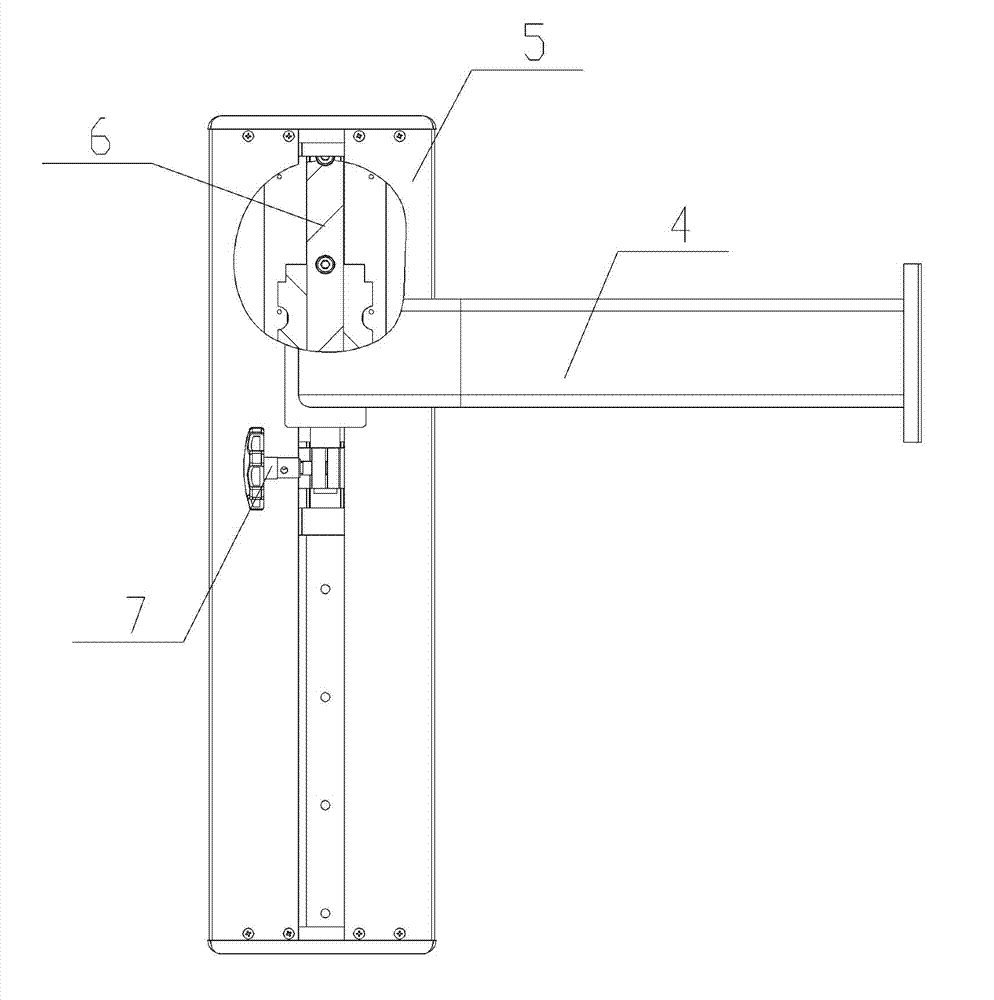

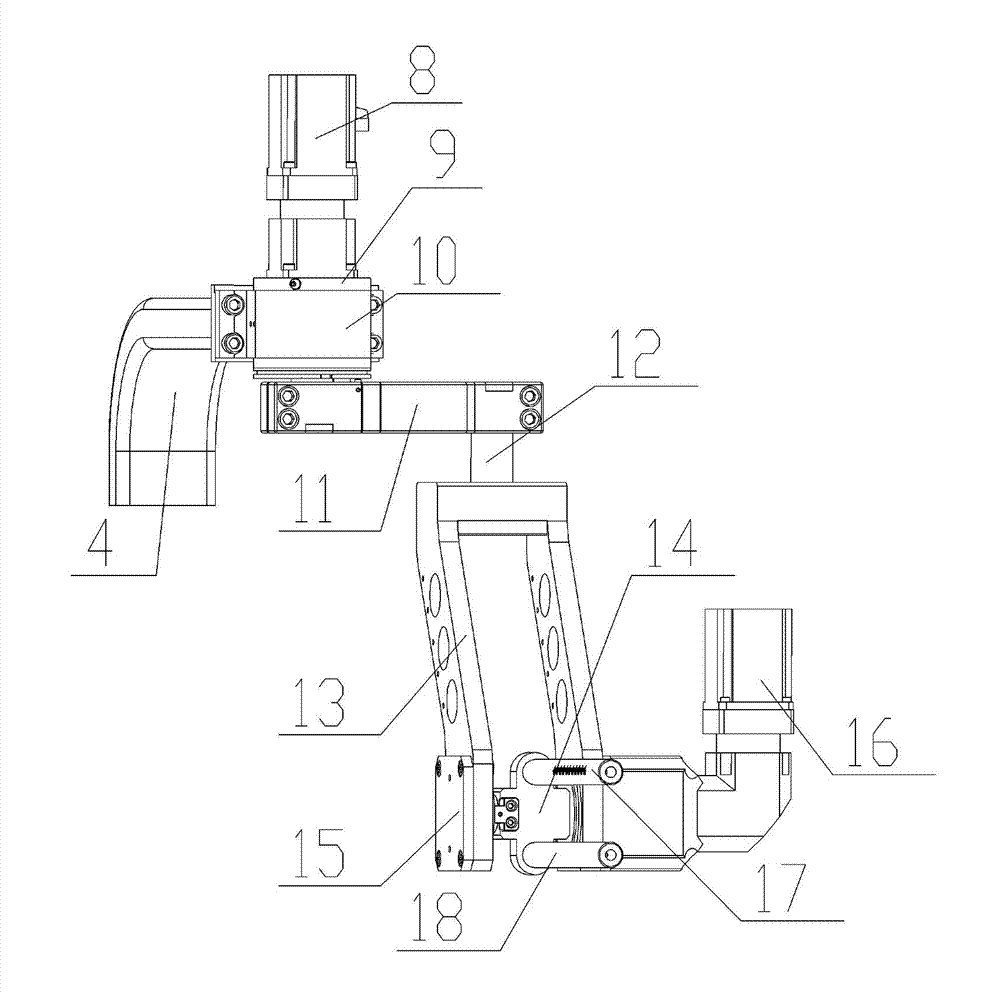

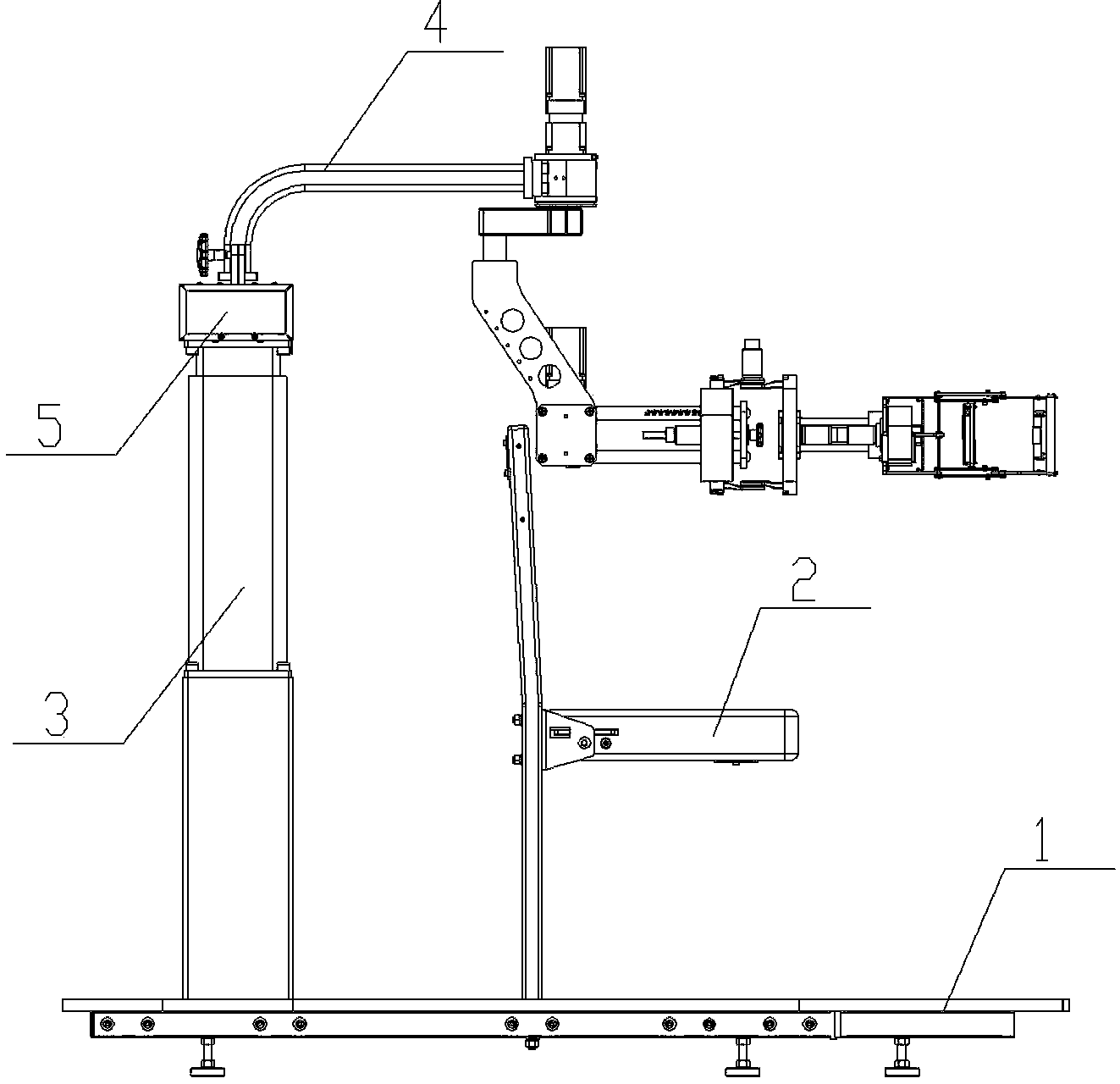

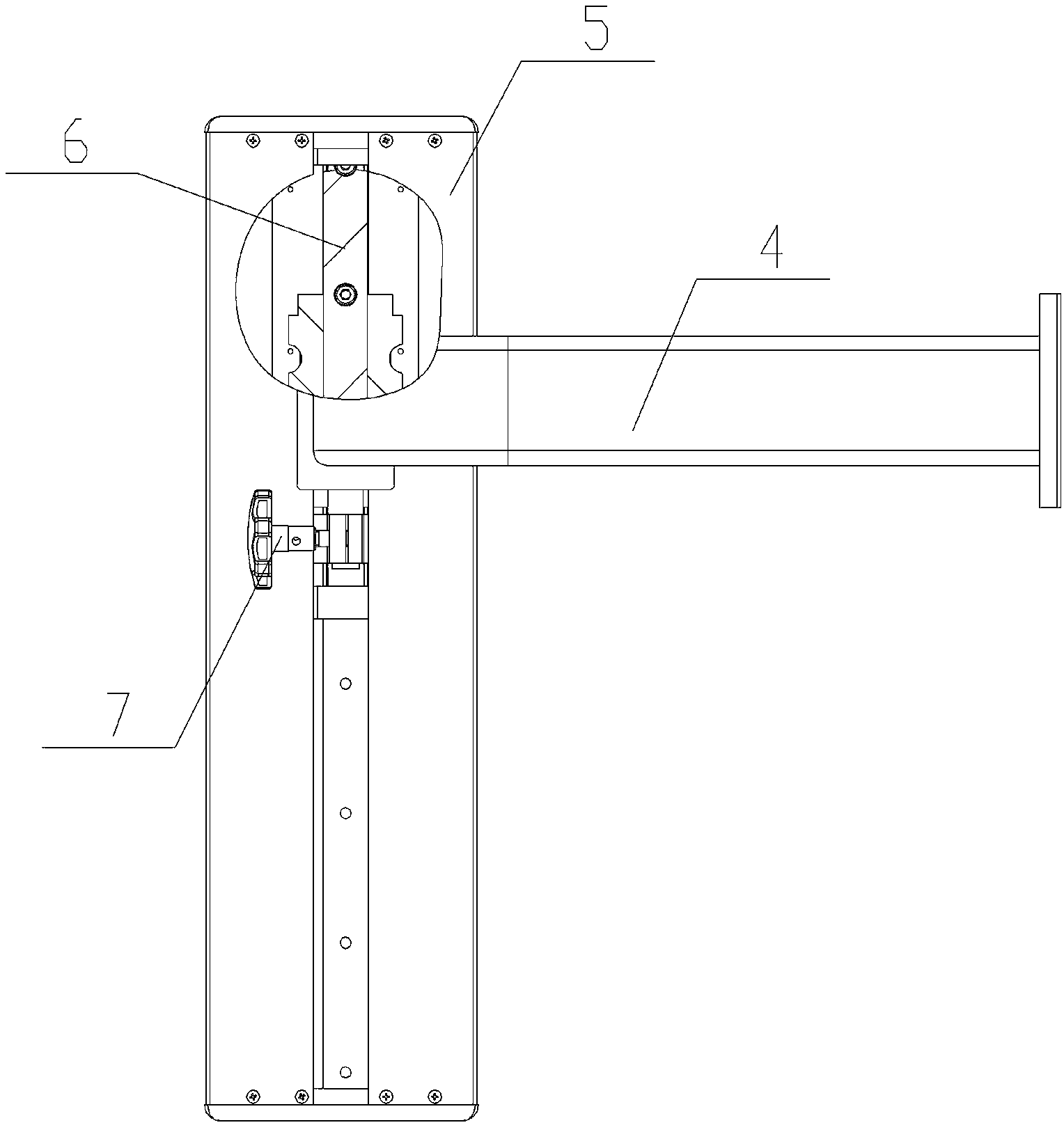

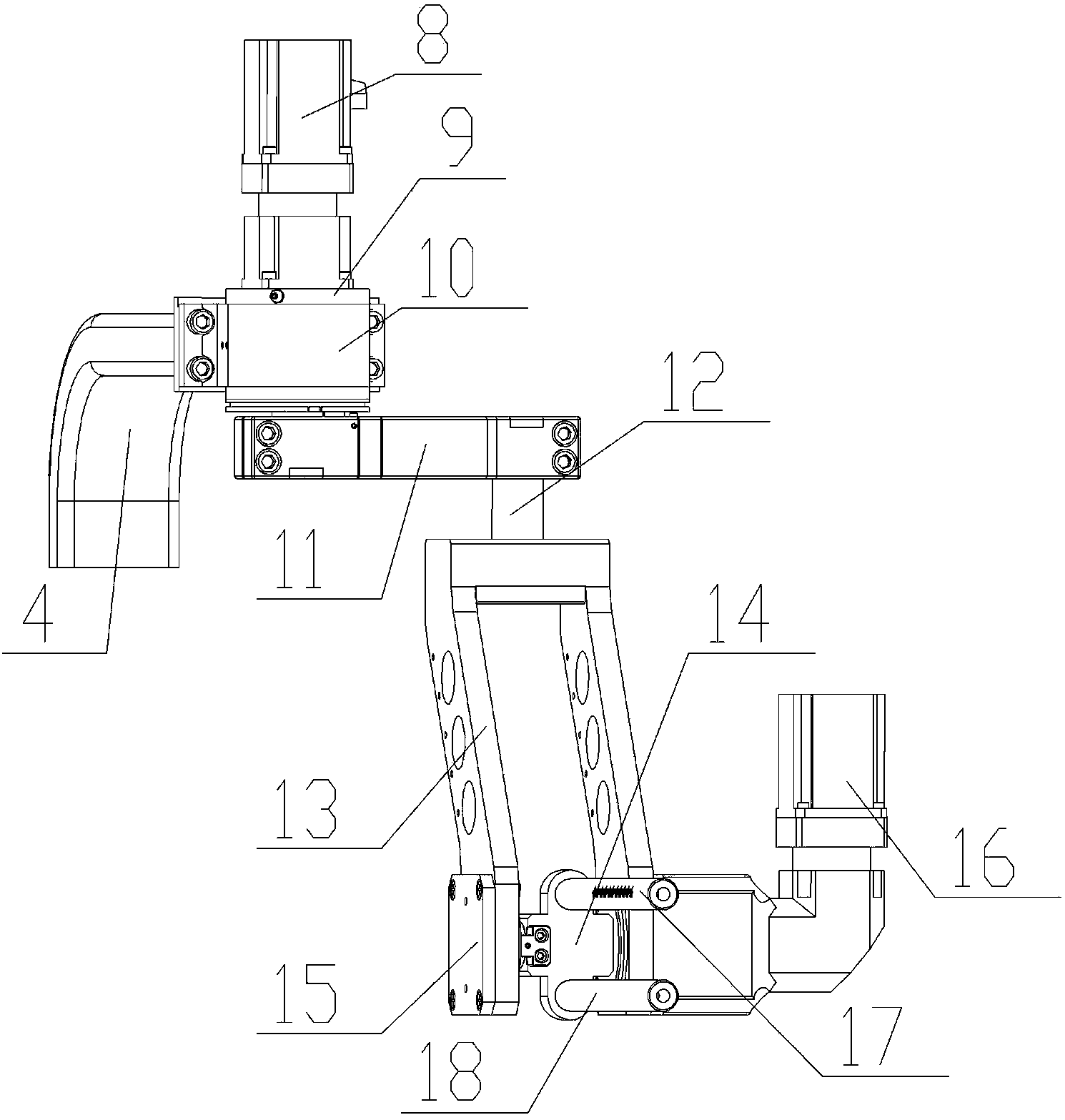

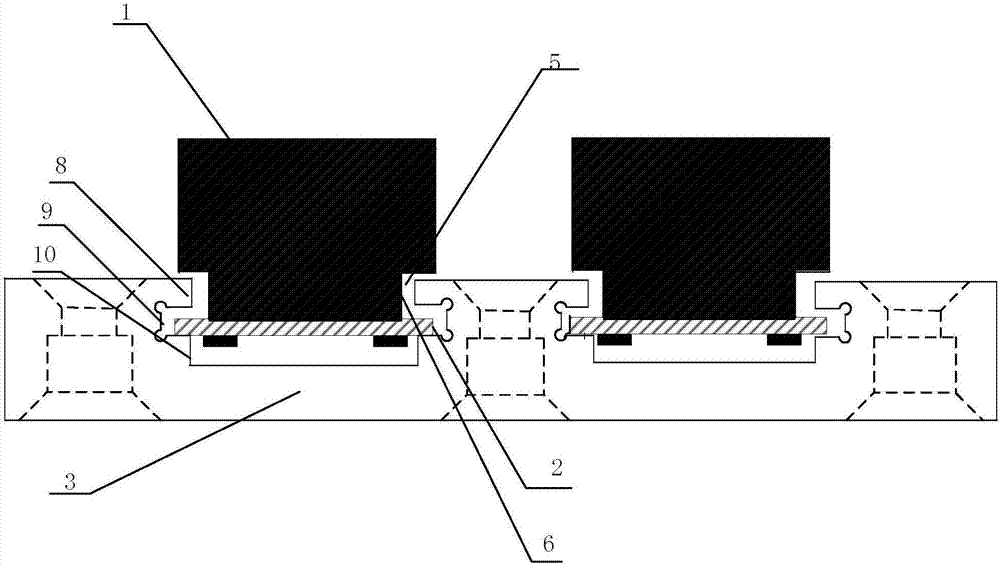

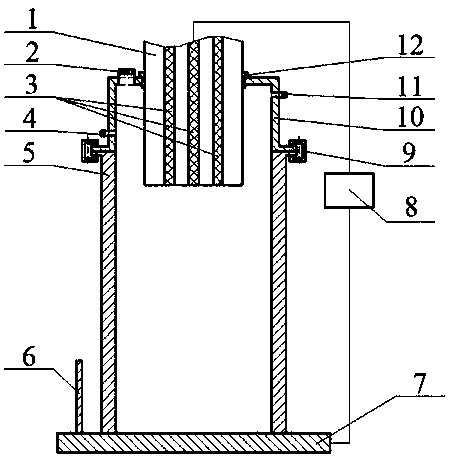

Upper-limb rehabilitation training robot

The invention relates to a medical rehabilitation training instrument. An upper-limb rehabilitation training robot solves the problems that existing equipment is complex in structure and hand joints cannot move comprehensively. The upper-limb rehabilitation training robot comprises a base (1), a support frame (3), a seat (2), a cantilever beam (4) and an upper limb training mechanism, wherein the upper limb training mechanism comprises a shoulder joint expanding and shrinking mechanism, an arm bending and stretching mechanism, a shoulder joint internal and external rotating mechanism connected and fixed with rotary rods (17 and 18), a front arm forward and backward rotating mechanism the same as the shoulder joint internal and external rotating mechanism, an elbow joint expanding mechanism fixedly connected with the shoulder joint internal and external rotating mechanism and the front arm forward and backward rotating mechanism through two pairs of rotating blocks (32 and 41), and a hand expanding mechanism fixedly connected with the shoulder joint internal and external rotating mechanism through slide bars (44 and 45). The upper-limb rehabilitation training robot is simple to operate and enables the joints to move comprehensively.

Owner:ANYANG SHENFANG REHAB ROBOTS CO LTD

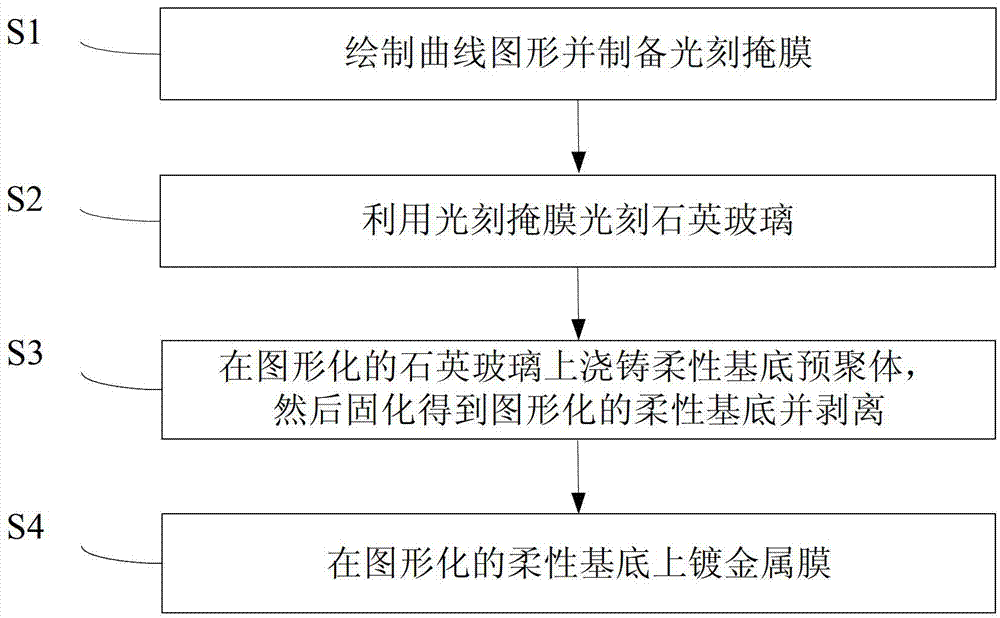

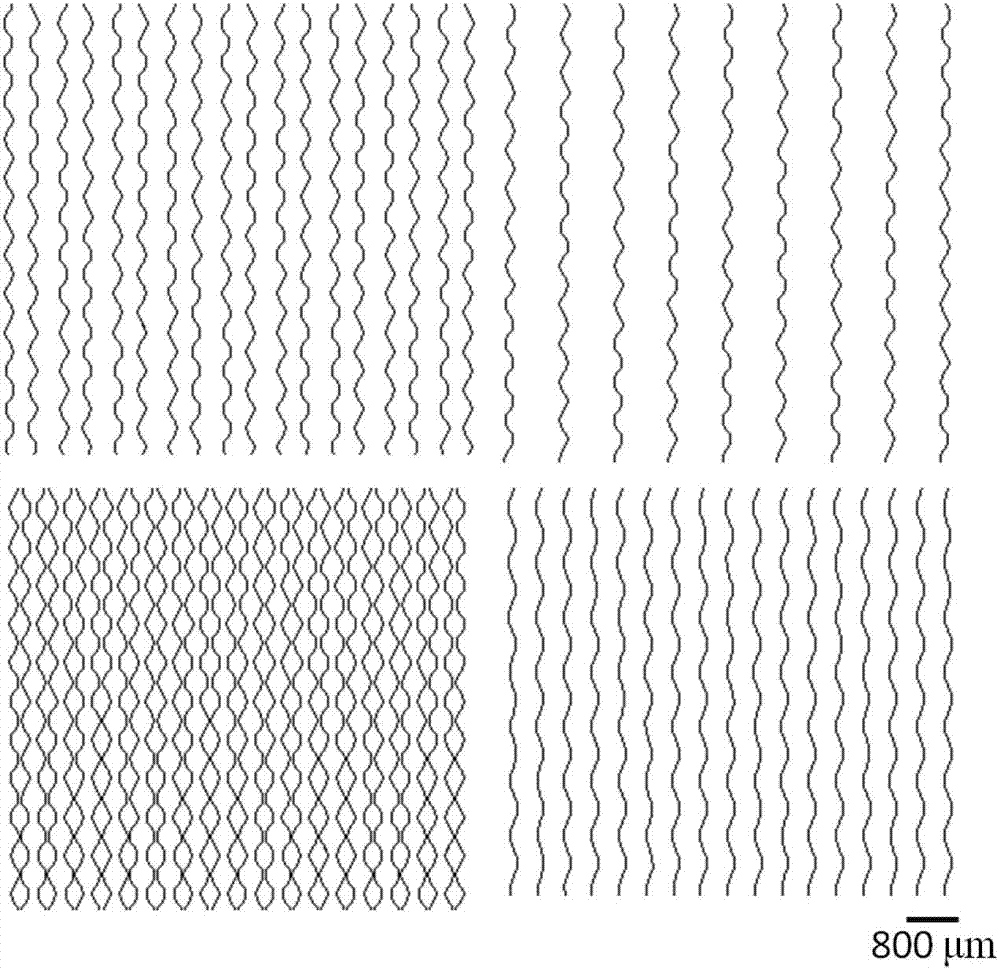

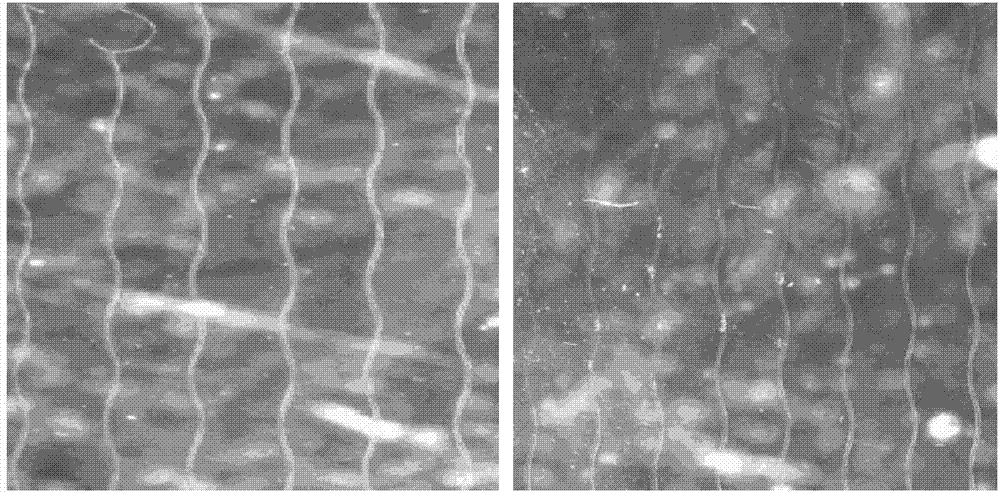

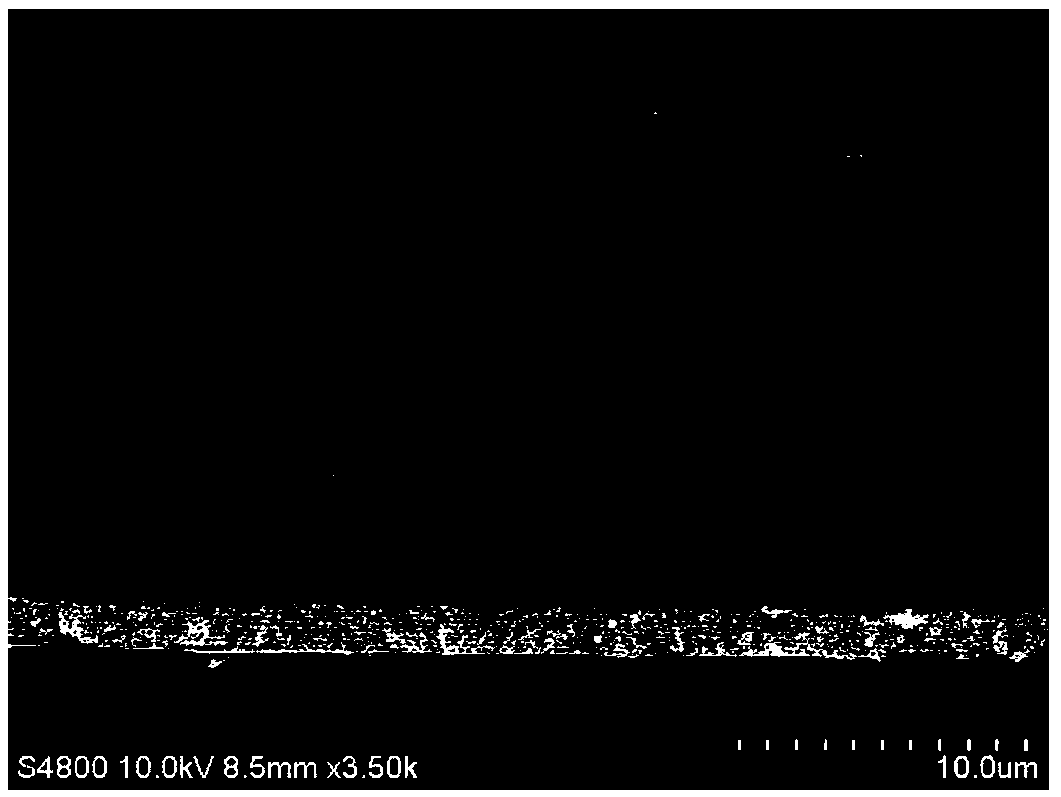

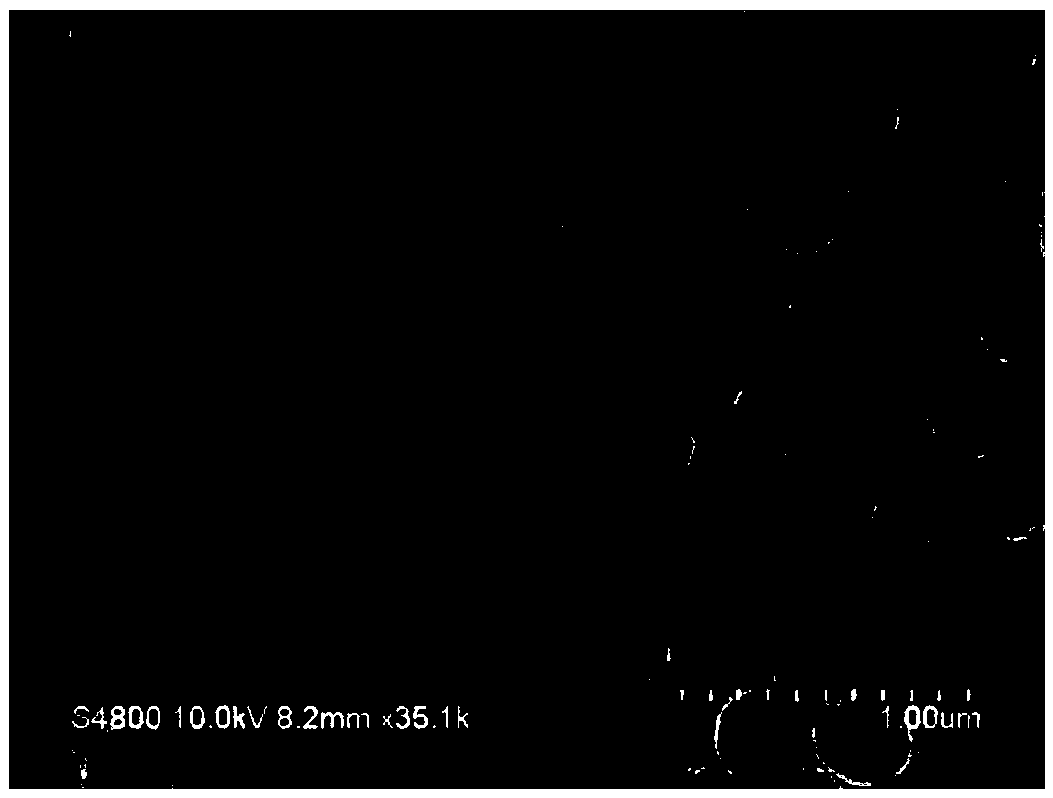

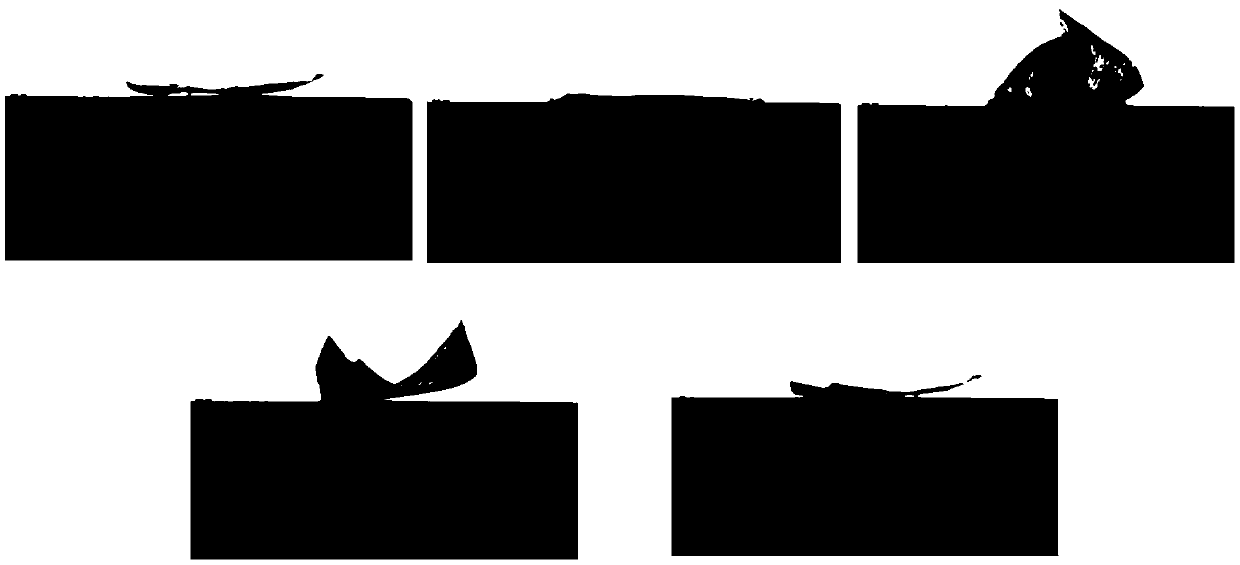

Forming method of flexible substrate film surface micro-structure

ActiveCN103204459AControl areaRange of controlDecorative surface effectsChemical vapor deposition coatingMicro structureStress distribution

The invention provides a forming method of a flexible substrate film surface micro-structure. The forming method includes plotting curve graphs and preparing a photolithography mask; carrying out silica glass photolithography by utilizing the photolithography mask; casting flexible substrate prepolymer on the graphical silica glass, and then solidifying to obtain and strip a graphical flexible substrate; and coating a metal film on the graphical flexible substrate. A curve structure is formed on the surface of a flexible substrate material, and then the film is coated on the substrate. Since temperature change produces thermal stress, the curve structure can be used for directing stress distribution inside the film; the curve structure with different curvatures, spaces and shapes can be designed to control regions and amplitudes of occurring of corrugation and buckling; and the forming method is simple to operate and easy to realize.

Owner:TSINGHUA UNIV

Flexible smart film material with photonic band gap structure and preparation method of flexible smart film material

ActiveCN105504318ARealize regulationBreak through the lack of a single performanceHigh concentrationPhotonic crystal

The invention discloses a flexible smart film material with a photonic band gap structure and a preparation method of the flexible smart film material. The preparation method comprises the steps as follows: firstly, spherical particles are taken as raw materials, and a photonic crystal template is obtained through assembly; then the photonic crystal template is filled with a low-concentration polymer solution and a high-concentration polymer solution of the same polymer sequentially and then subjected to solidification treatment, a solidified photonic crystal template filled with the polymer is obtained and soaked in a solution capable of dissolving the spherical particles, a film without the photonic crystal template is obtained, and the flexible smart film material is obtained after cleaning and drying. The prepared flexible smart film material combines characteristics of a photonic crystal and the polymer and has double characteristics of regulation of a light propagation path and chemical energy driving for the film, the defect of single performance of the traditional material is overcome, and the driving direction is controllable by changing a film cutting direction.

Owner:UNIV OF SCI & TECH BEIJING

Special insulation barrier for drop-out fuse protector

Owner:STATE GRID CORP OF CHINA +1

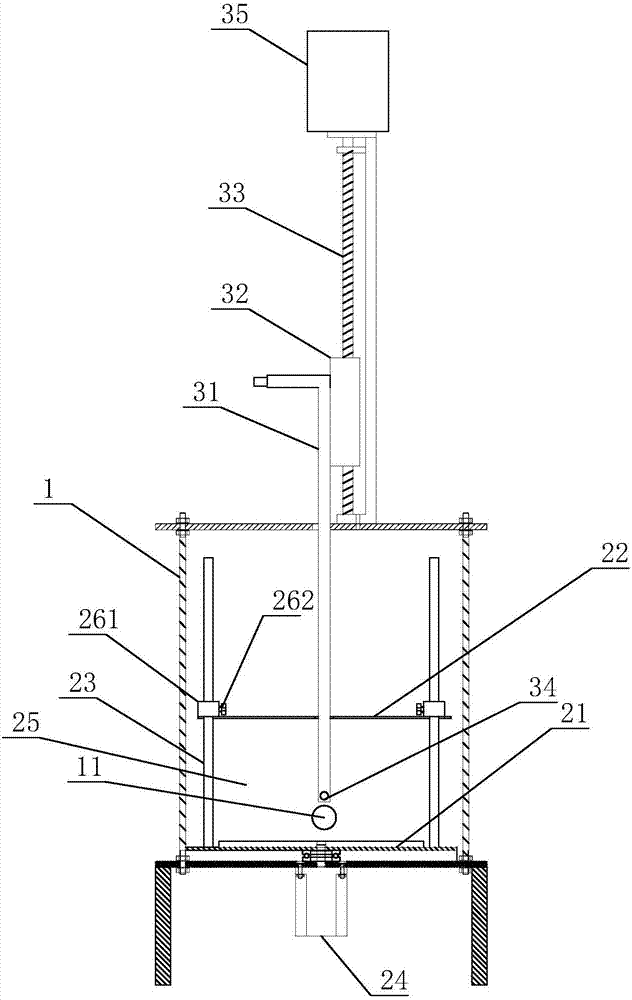

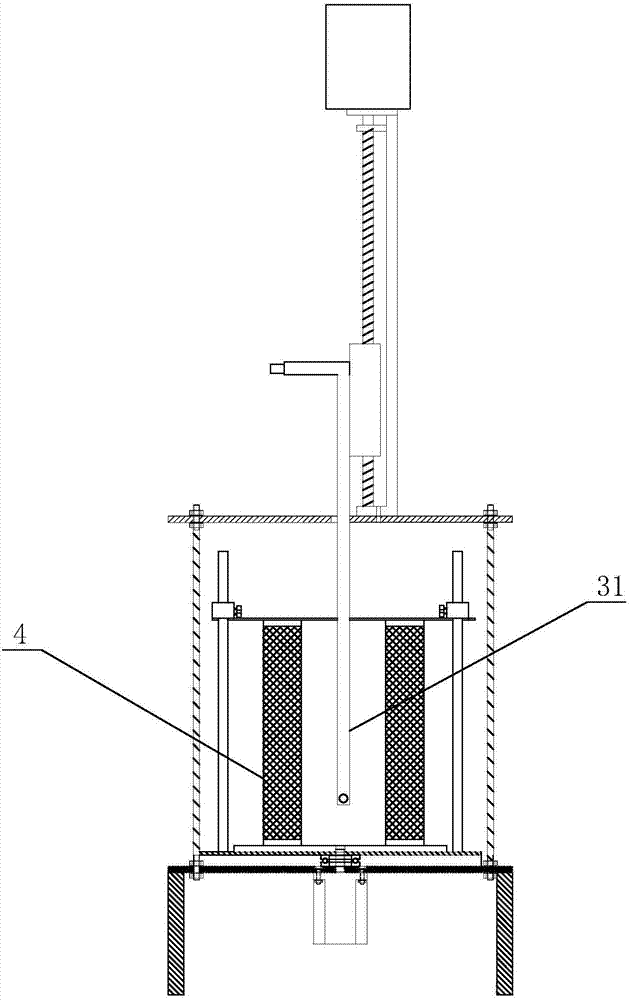

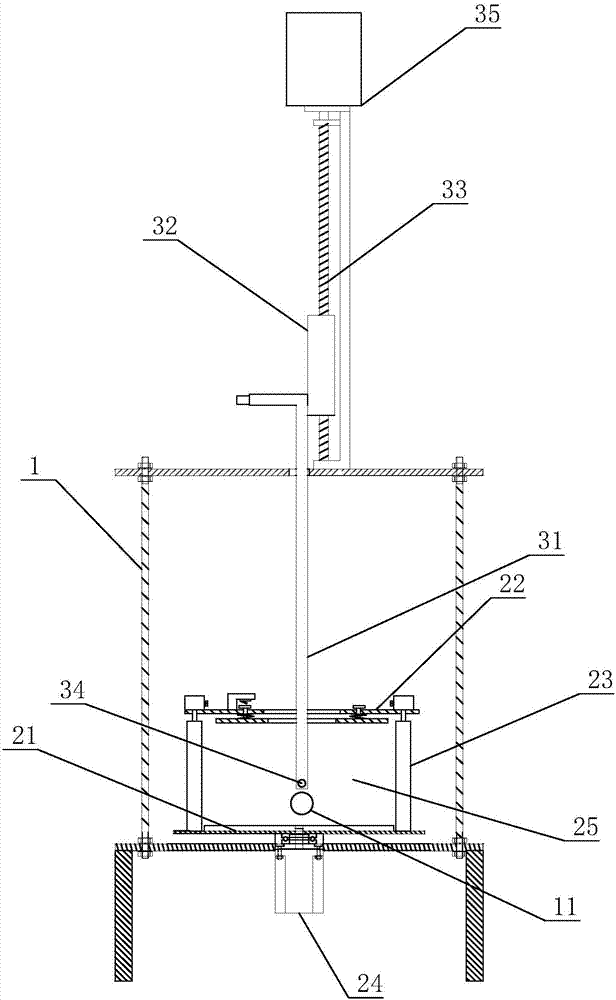

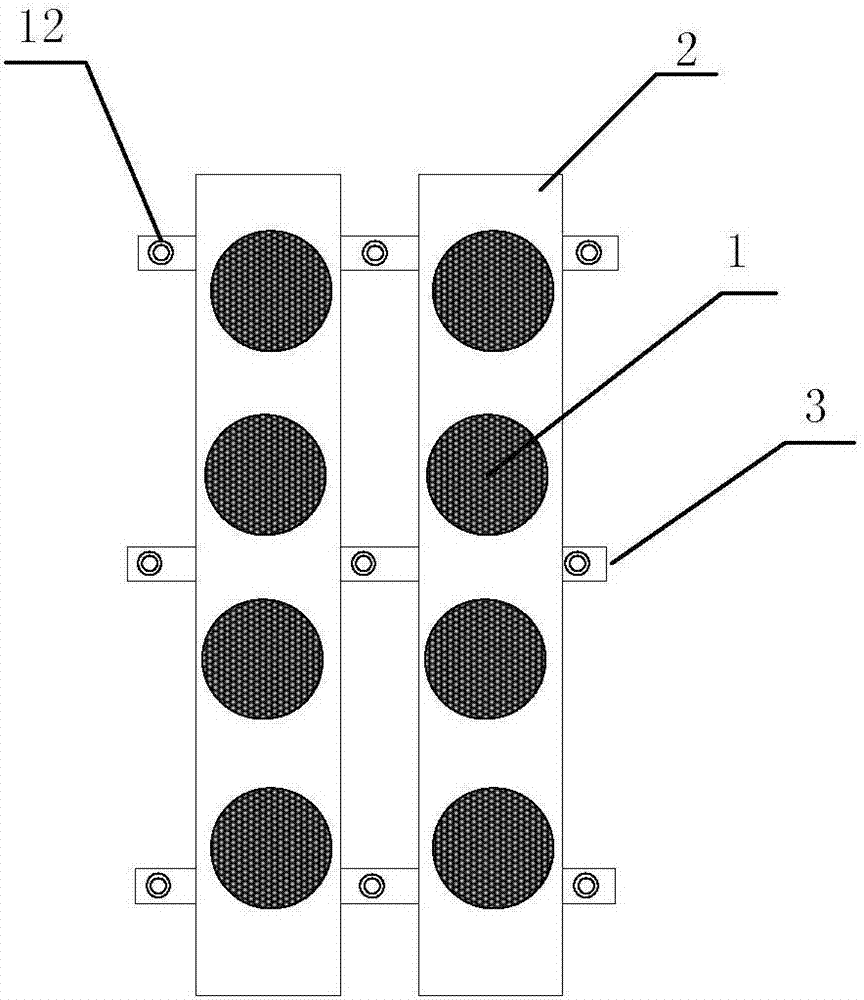

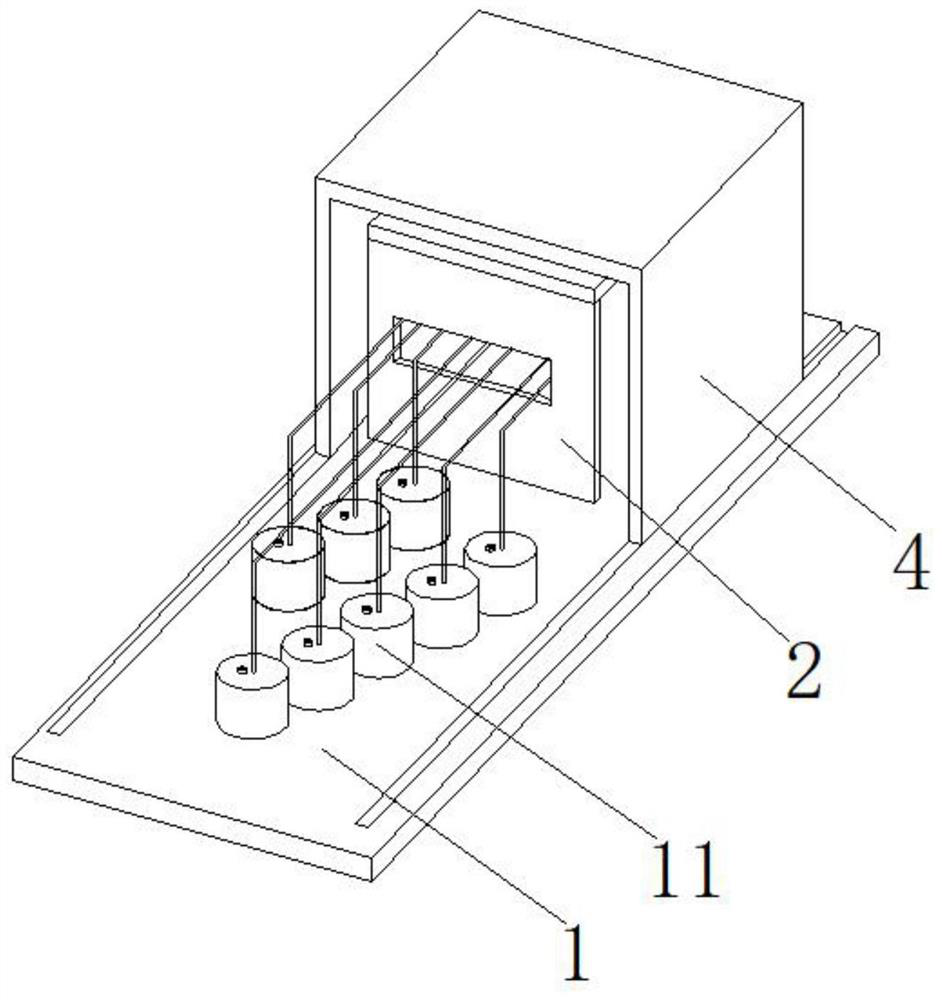

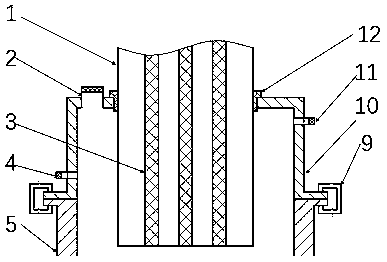

Air filter cleaning method and air filter cleaning machine

InactiveCN107413768ARange of controlAvoid interferenceDirt cleaningCleaning using gasesAir filterCleaning methods

The invention discloses an air filter cleaning method and an air filter cleaning machine adopting the air filter cleaning method. The air filter cleaning method comprises the following steps that (1) air filters are put in the air filter cleaning machine; (2) a top opening and a bottom opening of each air filter are sealed, the air filter cleaning machine is provided with air blowing holes jetting high-speed airflow outwards, and the air blowing holes stretch into inner cavities of the air filters and blow the high-speed airflow from the inner cavities of the air filters to the exterior of the air filters; (3) the heights of the air blowing holes are adjusted through the air filter cleaning machine, so that the high-speed airflow is blown to the inner walls, at different heights, of the air filters, the air filters are rotated through the air filter cleaning machine, and positions blown by the high-speed airflow can be adjusted in the circumferential directions of the air filters; and (4) the air filters are cleaned and taken out, and operation is finished. Human input is saved; airflow losses are small, and the cleaning effect is improved; and the air blowing cleaning positions can be constantly adjusted inside the air filters in the circumferential and axial directions, and thus comprehensive cleaning is realized, and the overall cleaning effect is further improved.

Owner:李晨晨

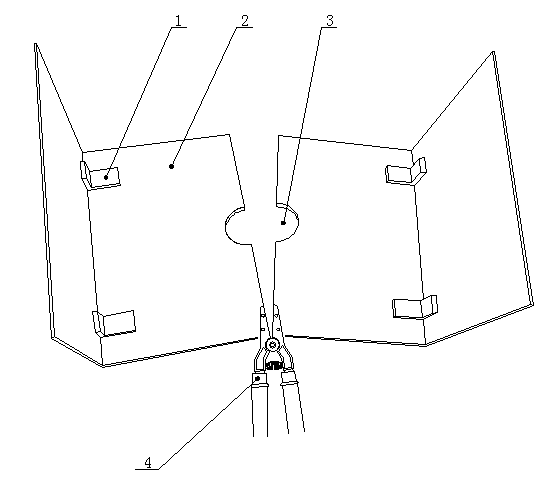

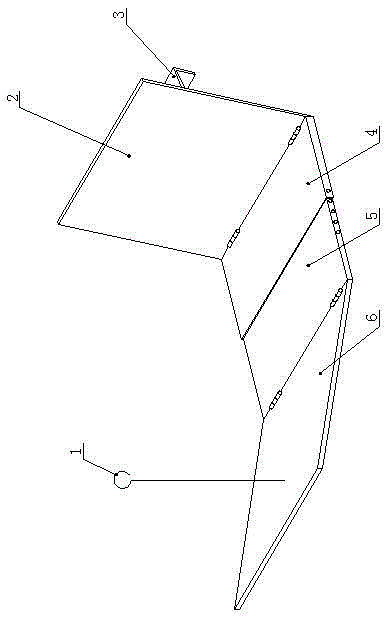

Special insulating barrier for changing pole-mounted circuit breaker

The invention relates to a special insulating barrier for changing a pole-mounted circuit breaker. The special insulating barrier comprises a first shielding plate and a second shielding plate, wherein a telescopic shielding plate is inserted into one end of the first shielding plate; the other end of the first shielding plate is movably connected with an electric pole side plate; an electric pole connector which is connected with an electric pole is arranged at the outer side of the electric pole side plate; the outer end of the telescopic shielding plate is movably connected with a second shielding plate; and the upper end of the second shielding plate is connected with a lead hook which is used for being articulated with a lead through an insulating rope. Due to implementation of the technical scheme, the special insulating barrier is simple in structure and can replace an insulating blanket; insulated shielding can be quickly finished; the labor intensity of hot-line operation personnel is also greatly reduced; and the movement range of the operation personnel on the pole can be relatively well controlled, so that the hot-line work safety is ensured.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO URUMQI ELECTRIC POWER SUPPLY CO +1

Subsurface engraving of three-dimensional sculpture

InactiveUS20030068468A1Range of controlOptimization of detailsBranding equipmentPicture framesLaser engravingHost material

A matrix is formed into a desired shape by pouring transparent liquid material into a mold. The material progresses from the liquid to the gelatinous state. Laser sculpting steps are performed when the material is still in a gelatinous condition to form small spots in the matrix. Because the material is non-solid gel when the laser beam applies its focused energy, there is no cracking or destruction. Intensity and duration of the laser pulse determine the size of the spots as does the timing in relation to the matrix material finally changing from gel to solid. Particular visual effects are produced at different degrees of solidity when sculpting. The liquid in the mold may be pressurized for removal of air bubbles after initial pouring of the matrix material and application of pressure after the laser sculpting controls the size of the spots in the finished product.

Owner:TREX ENTERPRISES CORP

Upper-limb rehabilitation training robot

The invention relates to a medical rehabilitation training instrument. An upper-limb rehabilitation training robot solves the problems that existing equipment is complex in structure and hand joints cannot move comprehensively. The upper-limb rehabilitation training robot comprises a base (1), a support frame (3), a seat (2), a cantilever beam (4) and an upper limb training mechanism, wherein the upper limb training mechanism comprises a shoulder joint expanding and shrinking mechanism, an arm bending and stretching mechanism, a shoulder joint internal and external rotating mechanism connected and fixed with rotary rods (17 and 18), a front arm forward and backward rotating mechanism the same as the shoulder joint internal and external rotating mechanism, an elbow joint expanding mechanism fixedly connected with the shoulder joint internal and external rotating mechanism and the front arm forward and backward rotating mechanism through two pairs of rotating blocks (32 and 41), and a hand expanding mechanism fixedly connected with the shoulder joint internal and external rotating mechanism through slide bars (44 and 45). The upper-limb rehabilitation training robot is simple to operate and enables the joints to move comprehensively.

Owner:ANYANG SHENFANG REHAB ROBOTS CO LTD

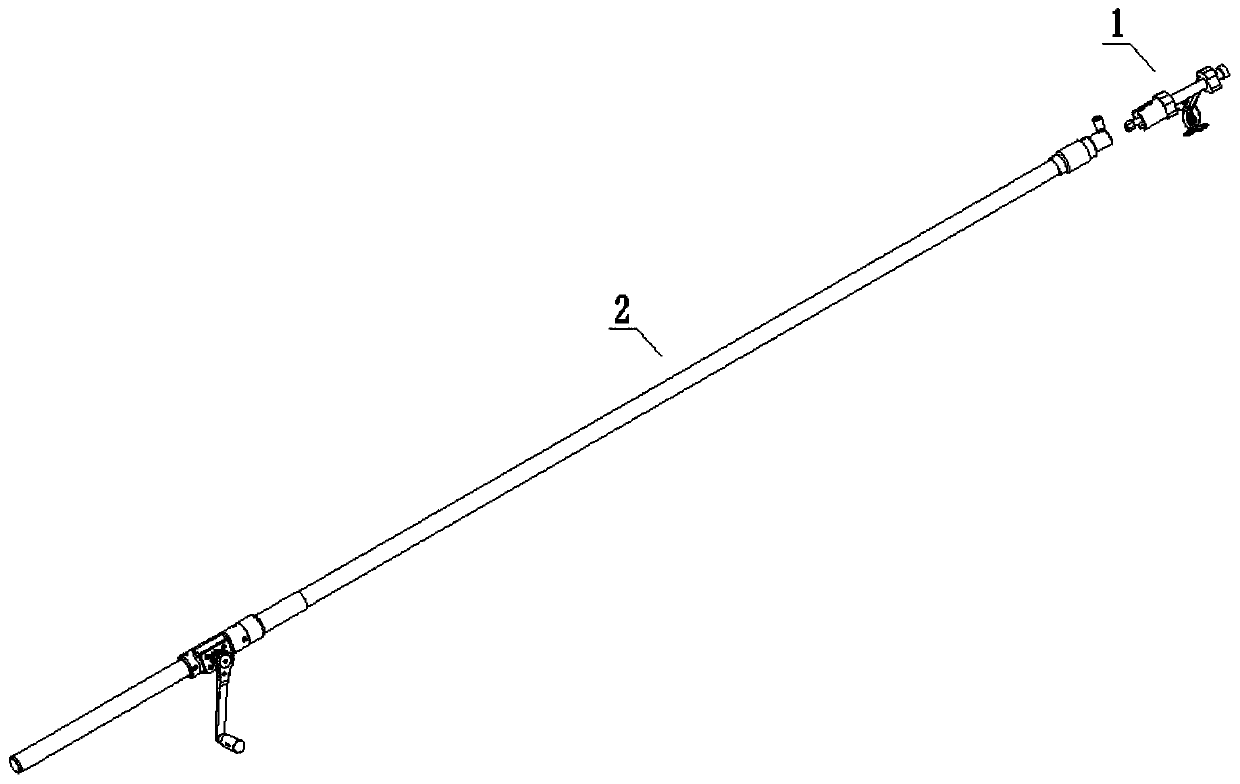

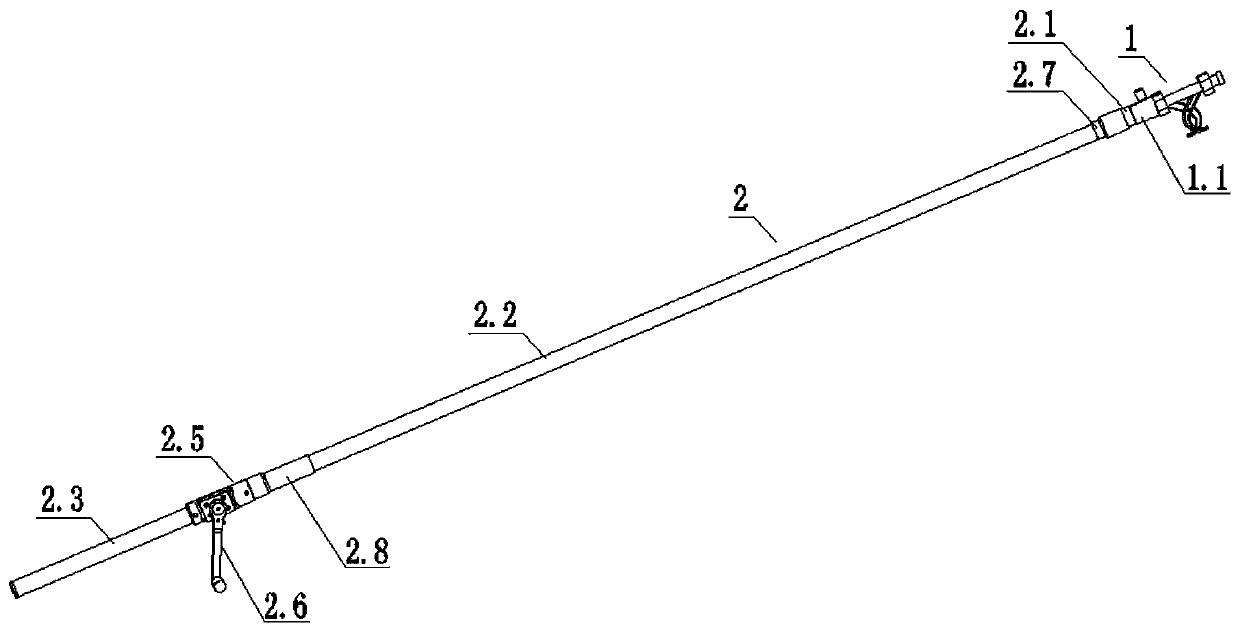

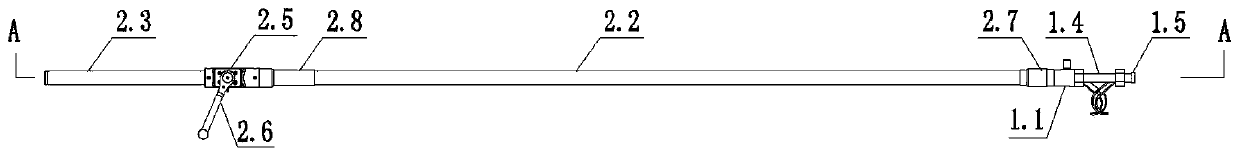

Insulating rod type wire clipper and using method thereof

ActiveCN110783850ARange of controlPrevent loosening and falling offApparatus for cutting/splicing cablesBolt cutterCrank

The invention discloses an insulating rod type wire clipper and a using method thereof. The wire clipper comprises a wire clipper fitting and an insulating torsion crank rod, wherein the wire clipperfitting comprises a quick plugging connector, an upper jaw transmission part, a lower jaw transmission part, a transmission bolt and an anti-drop nut, the insulating torsion crank rod comprises a quick plugging interface, a first fixed outer rod, a second fixed outer rod, a transmission inner rod, a crank connecting seat and a crank, the quick plugging interface is fixed at the top of the first fixed outer rod, the quick plugging interface is used for being in quick plugging fit with a quick plugging connector of the wire clipper fitting, the bottom of the first fixed outer rod is connected with the second fixed outer rod through the crank connecting seat, the transmission inner rod is assembled in the first fixed outer rod, an upper end is used for being in transmission connection with the quick plugging connector of the wire clipper fitting, a lower end is in transmission connection with the crank connecting seat, and the crank is plugged into one side of the crank connecting seat. The wire clipper is advantaged in that the wire clipper is simple in structure, convenient to operate, stable and reliable in transmission force, time-saving, labor-saving, low in working strength, reliable in connection, safe to use, high in working efficiency and the like.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

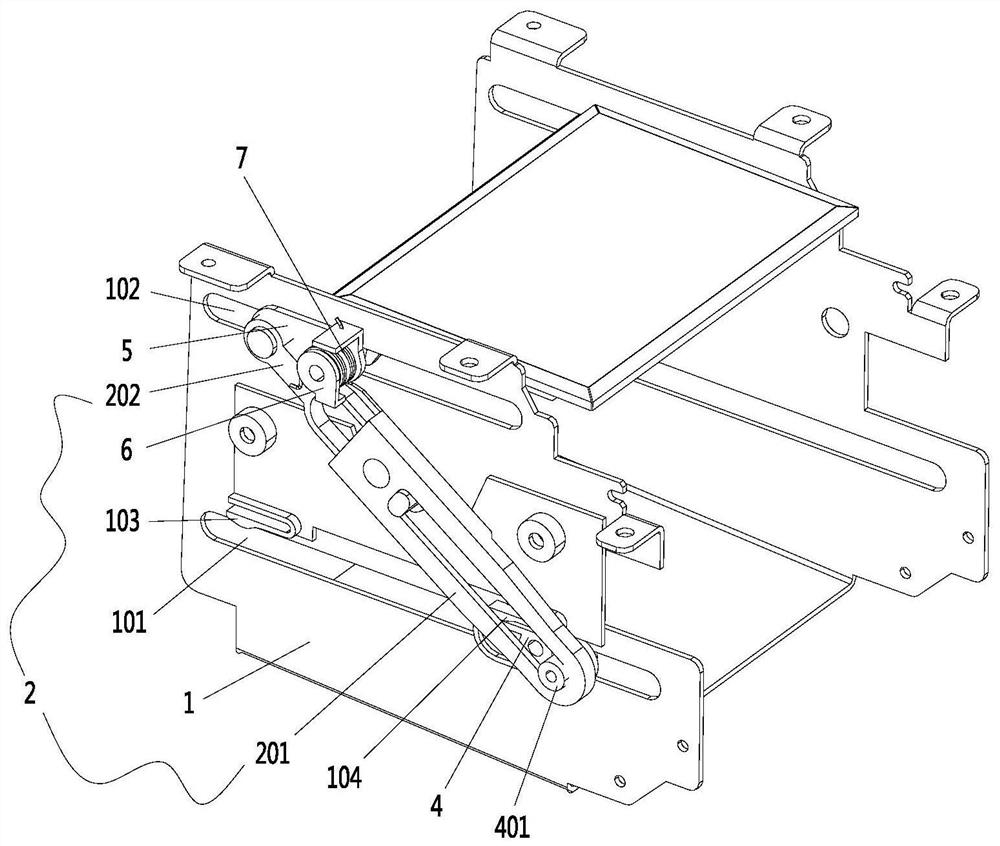

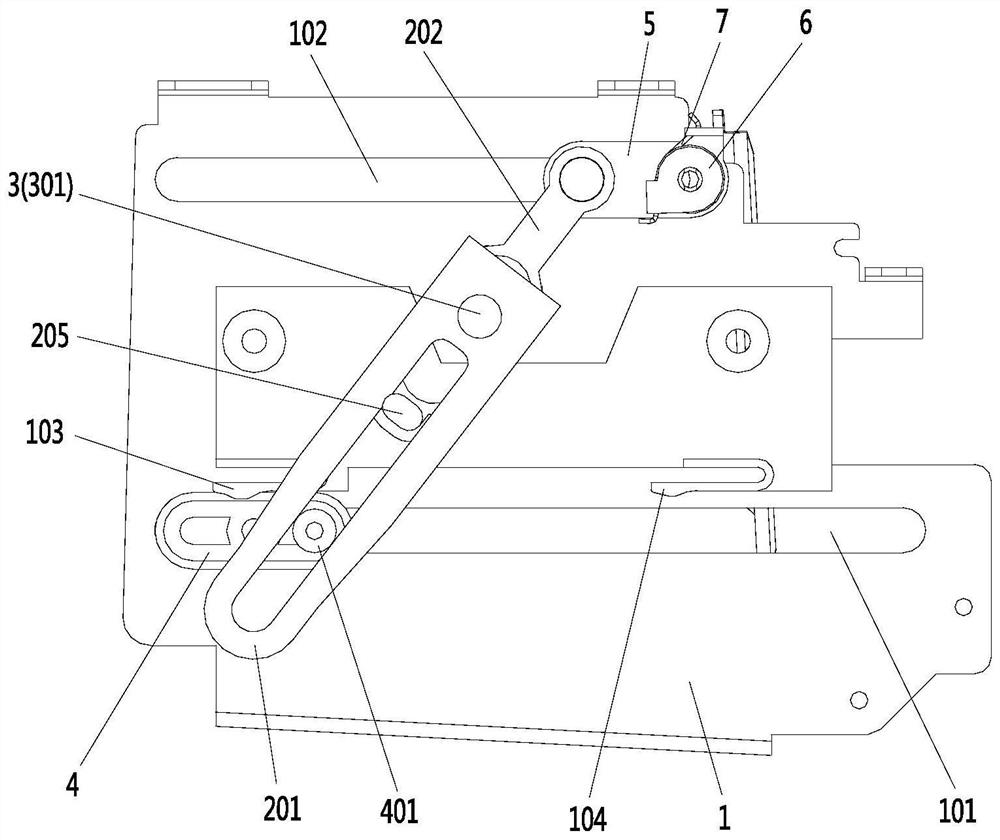

Hydraulic back door opening device of side mounting car

The invention discloses a hydraulic back door opening device of a side mounting car. The device comprises a back door oil cylinder, a triangular connecting rod and a cross beam; a hydraulic extension rod of the back door oil cylinder is connected with an arc connecting plate through a rotating shaft I; the arc connecting plate is connected with a straight rod of the triangular connecting rod through a hinge shaft; a stop pipe is arranged out of the upper end of a straight rod of the triangular connecting rod; the arc connecting plate is connected with the upper edge of a car back door through a rotating shaft II; rotating shafts III are symmetrically arranged on the upper edge of the car back door on two sides of the rotating shaft II; the triangular connecting rod is connected with the cross beam through a small concentric shaft; the two ends of the cross beam are connected with the car back door through lock pin parts I; and the bottom center position of the cross beam is connected with a center beam of the car back door through a locking pin part II. The device realizes automatic opening and locking of a back door of a self-loading / unloading garbage truck through controlling one oil cylinder; the opening angle of the back door is 130 degrees; and the device is simple in structure, convenient for installation and large in opening angle, reduces the manufacturing cost, and prolongs the service life of the back door.

Owner:QINGDAO ALLITE AUTO TECHNIC

Sound board component

PendingCN106921921AControl output frequencyRange of controlLoudspeakersTransducer circuitsEngineeringSounding board

The invention specifically relates to a sound board component. The sound board component comprises a buzzer, a buzzer PCB board and a bracket for installing the buzzer, wherein an installation slot is formed on the bracket, a left side wall structure and a right side wall structure of the installation slot are symmetric to each other, the structure at each of the side wall comprises a protruded mouth part, a PCB board fixing slot and a welding foot holding part from above down; the height and the width of the PCB board fixing slot are respectively greater than the thickness and the width of the edge of the buzzer PCB board; the buzzer PCB board can move left-right and down-up within a certain range in the installation slot, so that the vibration produced by the sounding of the each buzzer is overlapped when each buzzer produces the sound, the entire buzzer PCB board can produce a resonance effect, thereby producing a great sound attack effect by use of small electric quantity.

Owner:XIAN FUCHENG DEFENCE SCI & TECH CO LTD

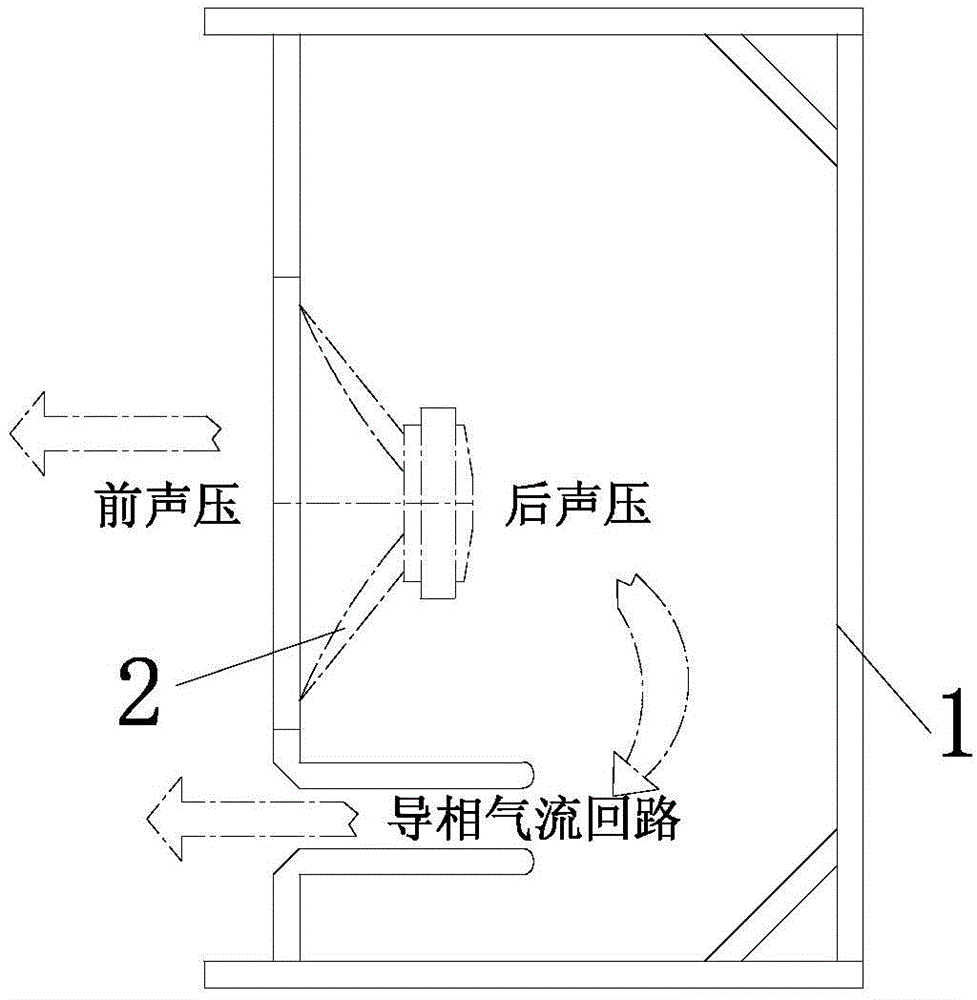

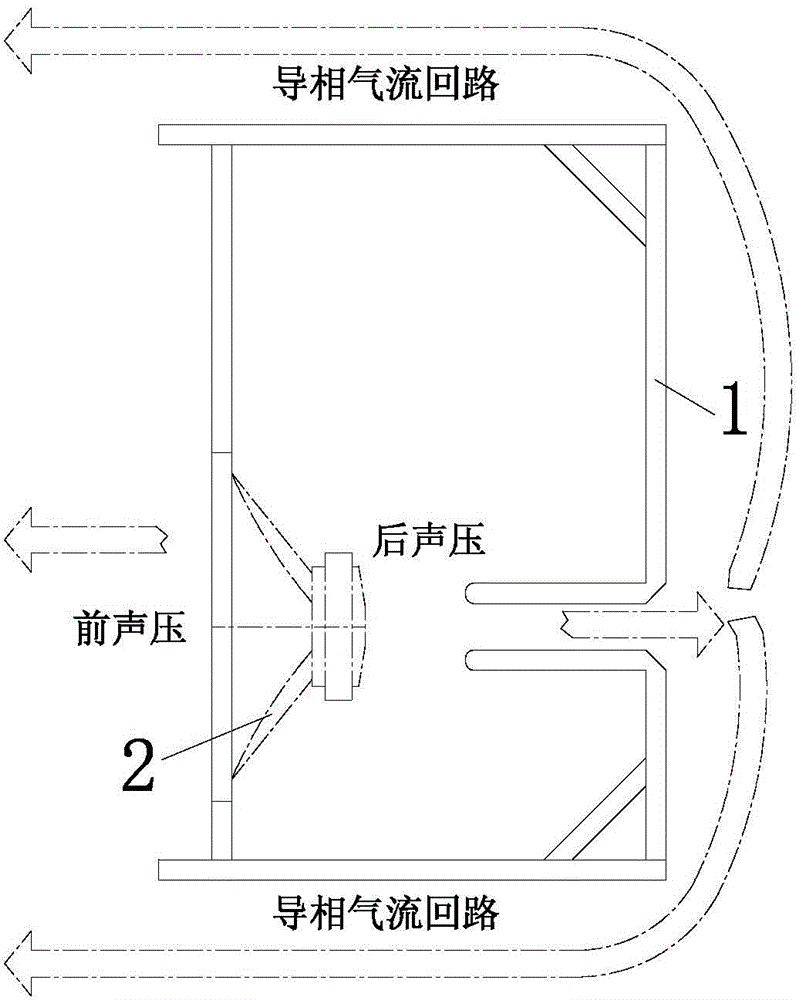

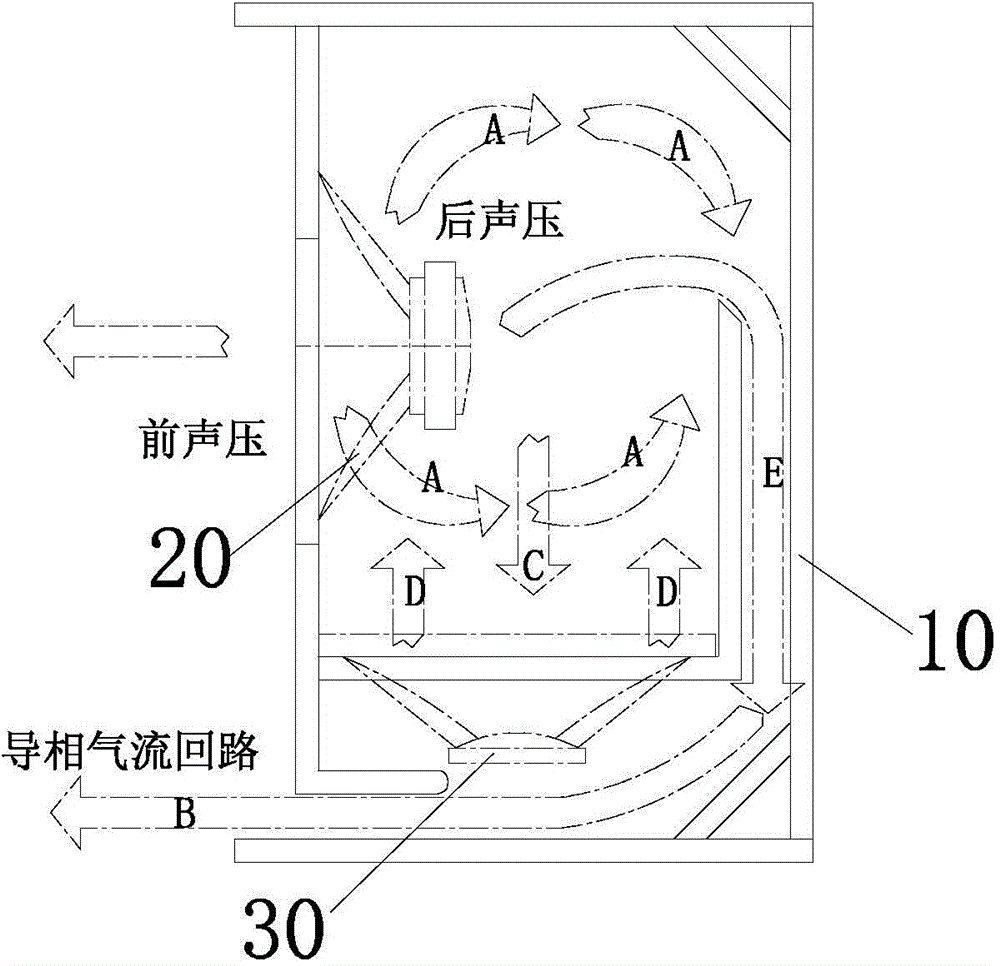

Low-frequency dynamic resonance enhancement loudspeaker box

ActiveCN104378712ARange of controlControl resonant frequencyFrequency/directions obtaining arrangementsResonanceEngineering

The invention relates to a low-frequency dynamic resonance enhancement loudspeaker box comprising a box body, a main loudspeaker and a resonator radiator. The main loudspeaker is mounted on the box body. The resonator radiator is mounted on a guide airflow loop in the box body and used for generating resonance with sound-wave airflow emitted from the main loudspeaker so as to control low-frequency dynamic and resonance frequency of the main loudspeaker. The technical defects of low-sound distortion caused during too low frequency, serious sound interference in high-medium sound frequency bands and the out-of-round loudspeaker paper cones in movement in over-high low-frequency amplitude, resulting in increase of damage rate of the loudspeaker and the like in the prior art can be overcome effectively, the loudspeaker box is low, deep, natural and extended in performance in the low sound region and is particularly suitable for being applied to K-rooms and Hi-rooms.

Owner:广州诺尊电子科技有限公司

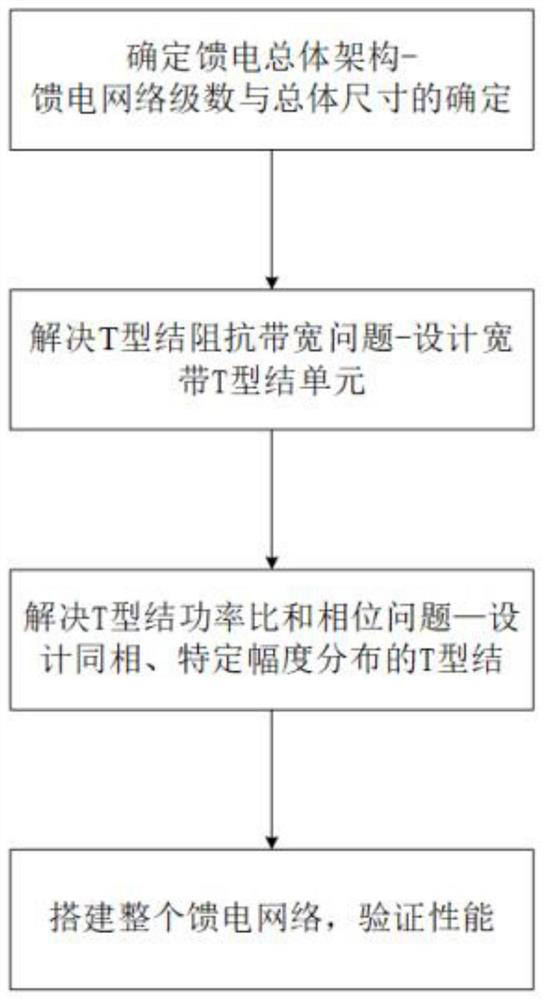

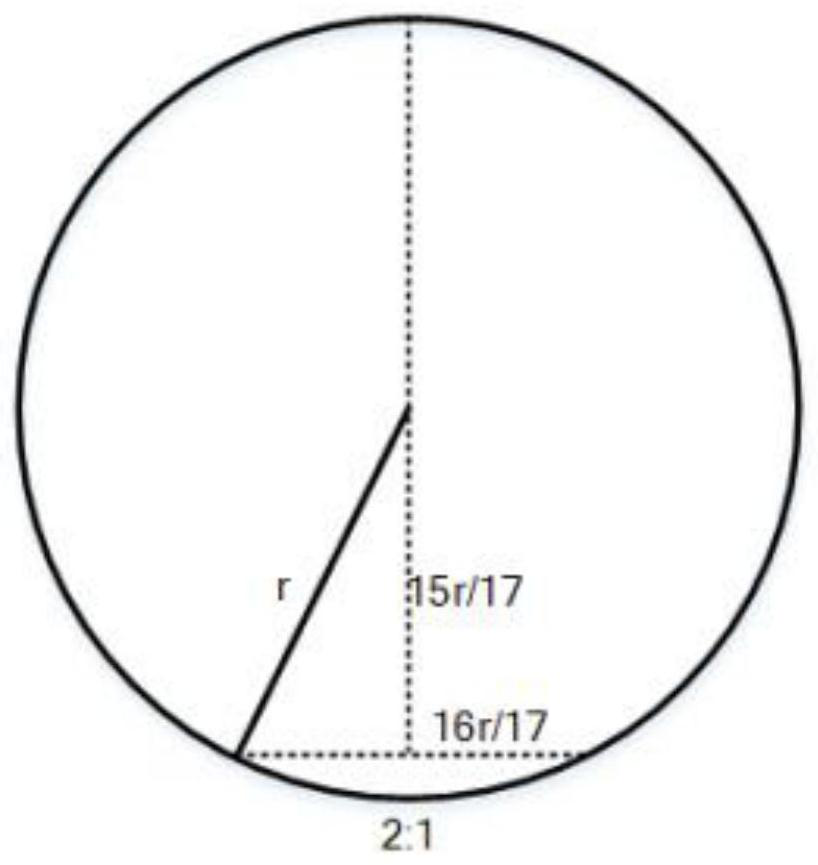

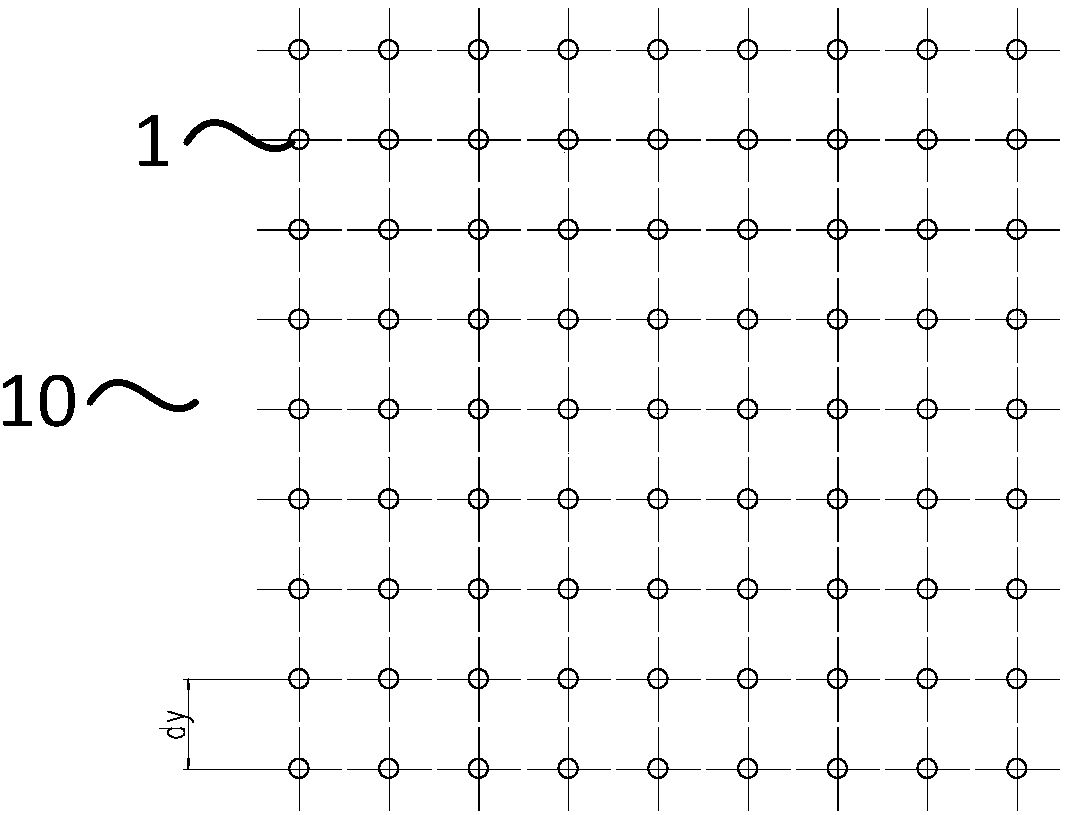

Design method of broadband miniaturized VICTS antenna feed network

PendingCN112035997AMiniaturizationRealize the same layer layoutParticular array feeding systemsDesign optimisation/simulationFull waveFull wave analysis

The invention discloses a design method of a broadband miniaturized VICTS antenna feed network, which comprises the following steps: determining the hierarchy of a power division network according tothe transverse size of a feed network, and determining the number of T-shaped junctions according to the hierarchy of the power division network and the longitudinal size of the feed network; analyzing a field mode propagated in the waveguide, calculating a main mode starting frequency and a main mode ending frequency, establishing a miniaturized T-junction model, and establishing a relationship between a T-junction structure parameter and a reflection coefficient; adopting a broadband technology to design a broadband and miniaturized T-junction, and adopting a full-wave analysis method to extract the relationship between the broadband T-junction and a reflection coefficient; The amplitude and the phase of the T-junction are adjusted, so that the T-junction meets the in-phase excitation output of specific power distribution; and designing a port conversion module and a transition matching and polarization adjusting module, and checking related indexes of the excitation source to reachset indexes. Effective compression of the longitudinal size of the feed network is achieved, in-phase output is achieved within the required frequency band range, meanwhile, the amplitude is accurately controlled, and therefore the gain and standing wave characteristics of the antenna are guaranteed.

Owner:重庆星轨科技有限公司

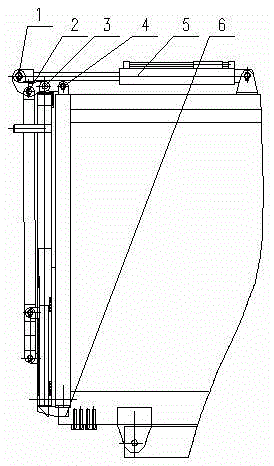

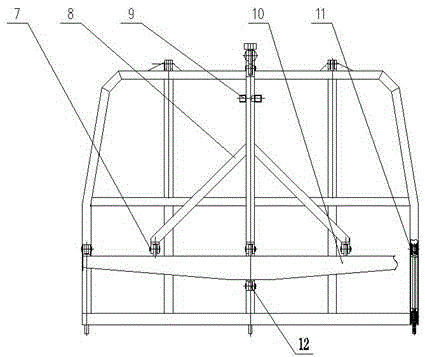

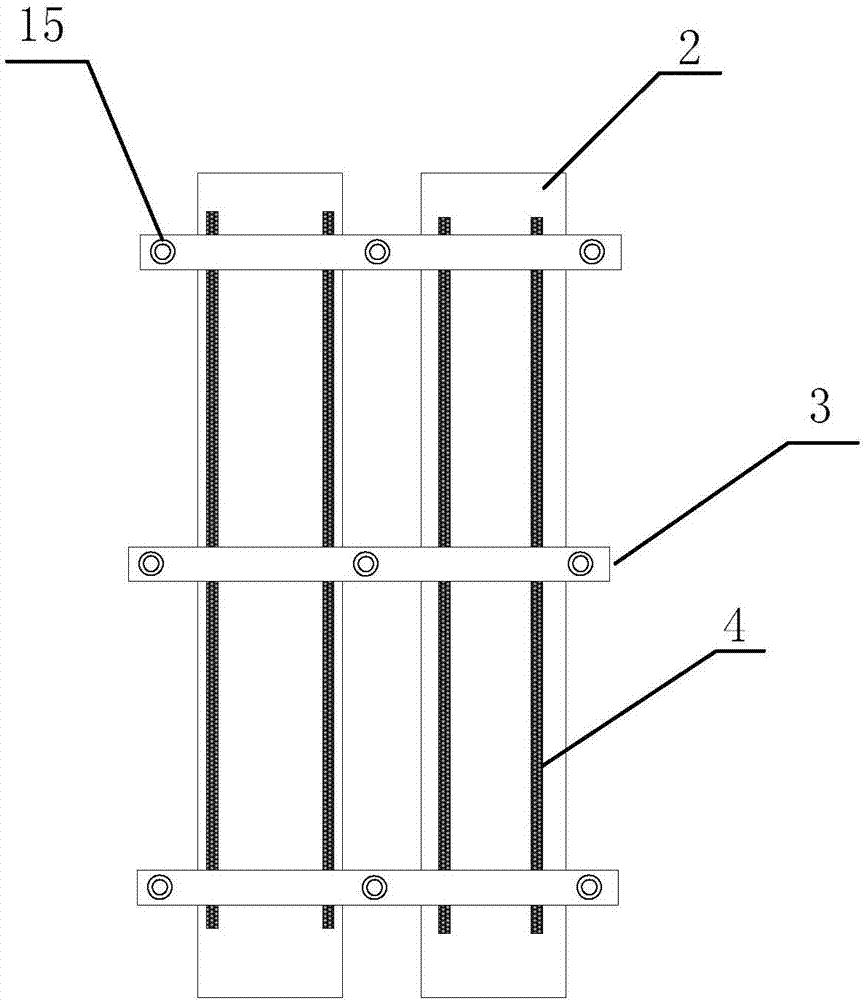

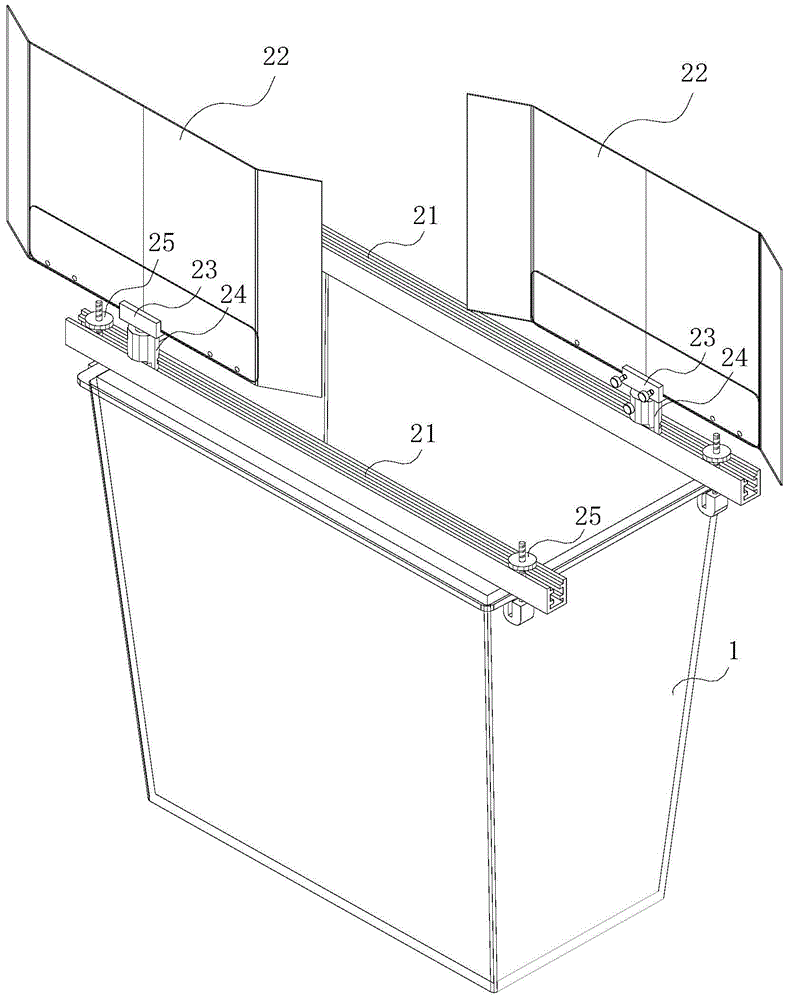

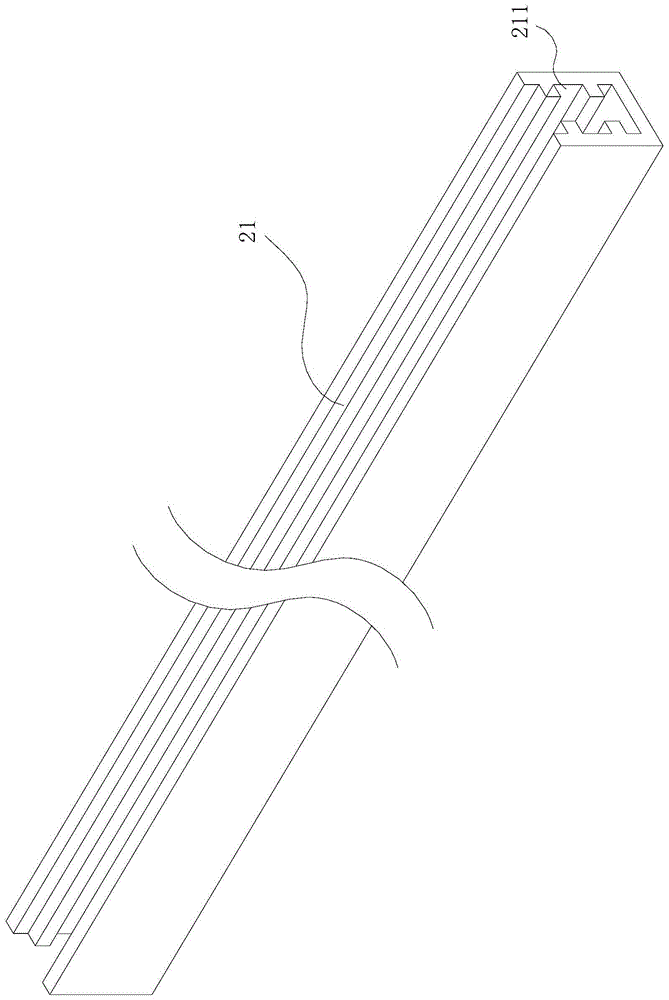

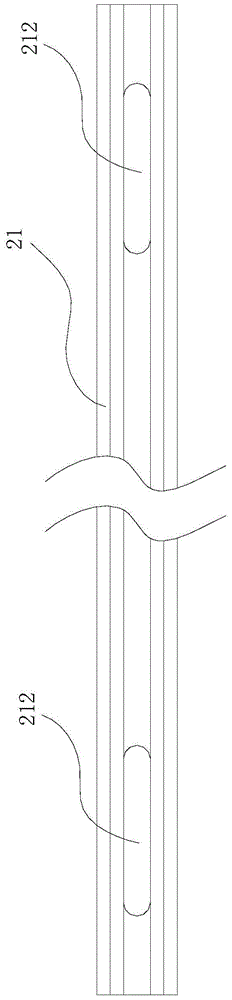

Isolation protective wall for bucket arm truck

ActiveCN104836162BSave energyRange of controlApparatus for overhead lines/cablesStructural engineeringBlock match

The invention discloses an isolation protective wall for bucket arm vehicles. The bucket arm vehicle includes insulating buckets, and the isolation protective wall includes two slide rails respectively fixed on one side of the insulating buckets, a plurality of insulating isolation baffles, The isolation baffle corresponds to the connected supporting connectors, sliders, and J-shaped bolts. There is a waist-shaped groove on both sides of each slide rail. The J-shaped bolts pass through the waist-shaped groove and are fixed on the upper edge of the insulating bucket. The two edges of the baffle are in the shape of a semicircle, and the lower edge of the main body is paired with a number of small holes. The upper part of the supporting connector is provided with a groove for clamping the insulating isolation baffle and fixed by fixing bolts to correspond to the insulating isolation baffle. The lower part is a nylon tube that matches and connects with the upper part of the slider. The side of the upper part of the slider has a small hole that is fixed and supported by the safety adjustment pin. The shape of the lower part is the same as that match the shape of the chute. The invention has the advantages of simple structure, convenient maintenance, effective protection, safety and reliability.

Owner:BENGBU POWER SUPPLY COMPANY STATE GRID ANHUI ELECTRIC POWER +1

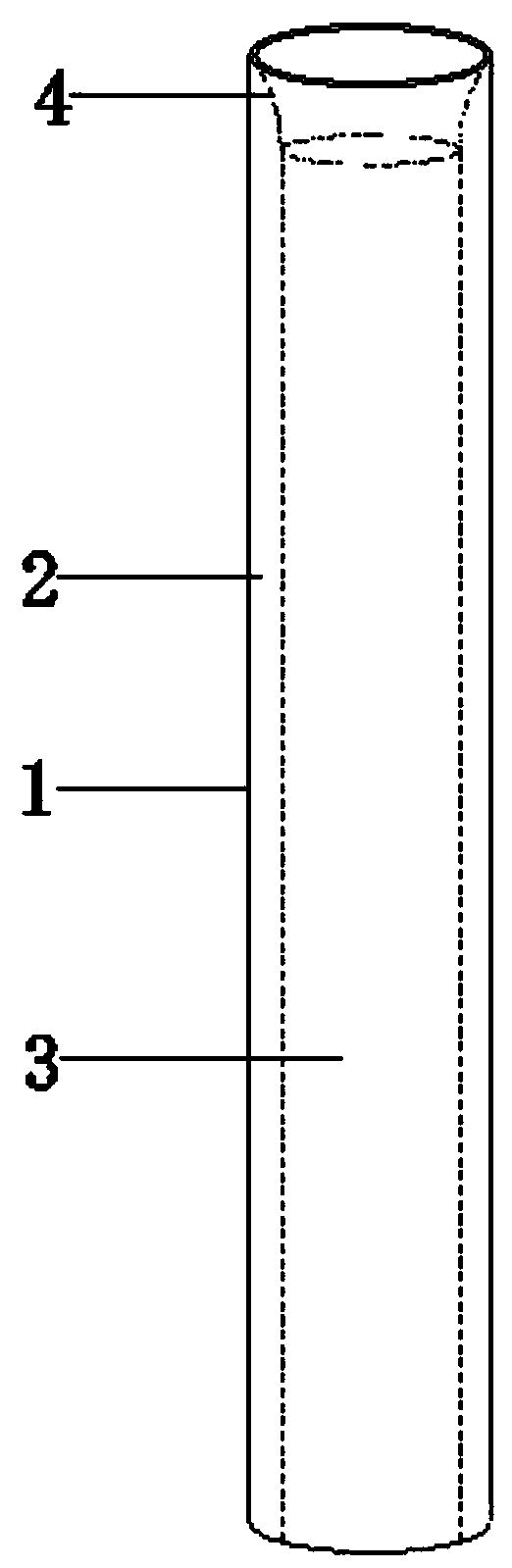

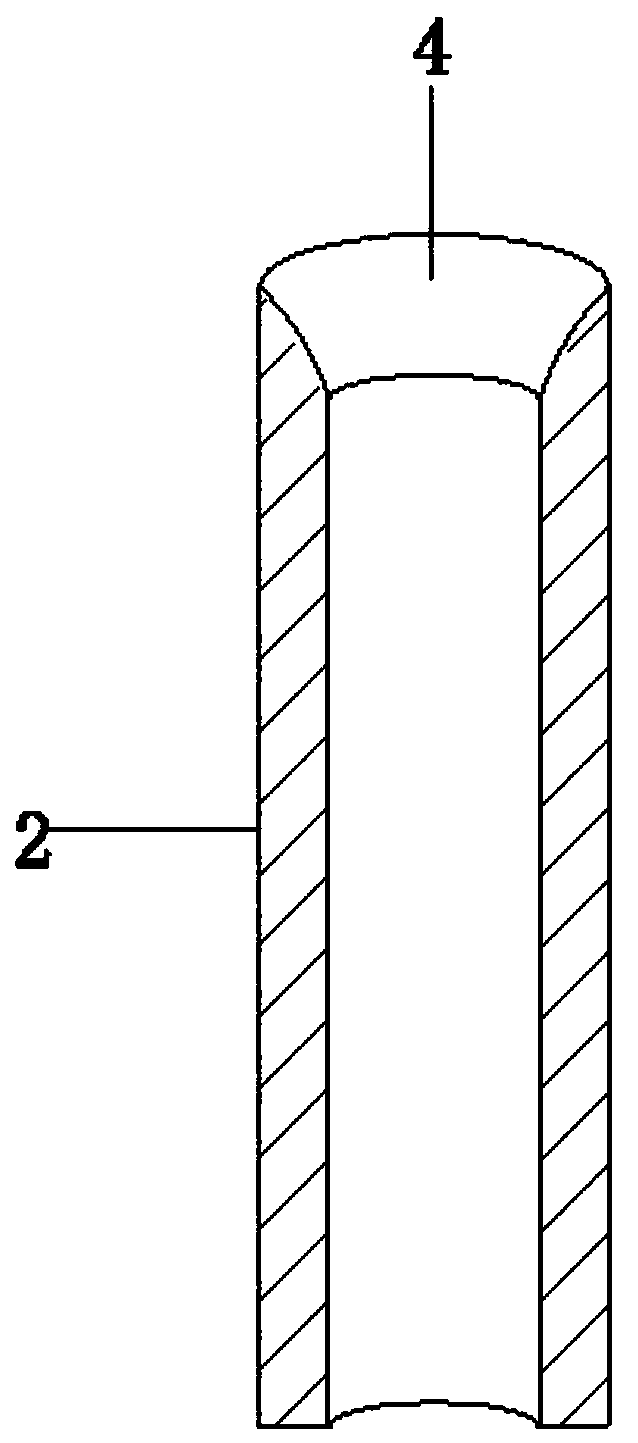

Straight cylinder type metal cutting sheath

InactiveCN109998733AReduce damageReduce risk of damageEndoscopic cutting instrumentsBlood vessel filtersOperation safetyVena cava filters

The invention discloses a straight cylinder type metal cutting sheath which comprises a straight cylinder type metal cutting sheath body. The straight cylinder type metal cutting sheath body is provided with a vena cava filter recovery pipe, a vena cava filter recovery pipe groove and an annular cutting edge. The annular cutting edge is arranged at a sheath opening of the straight cylinder type metal cutting sheath body so as to be closely attached to the outer side of a vena cava filter metal rod, so the damage to blood vessel walls is small and few blood vessel wall tissue components are cutoff when the vena cava filter metal rod is stripped off. The propelling speed and amplitude of the cutting sheath can be controlled, so the vena cava blood vessel walls draw back to the outer side intime when adhesion tissue is cut off, the damage risk of the vena cava blood vessel walls is further reduced, and the operation safety is improved. The put-on sheath wall of the straight cylinder type metal cutting sheath has a small thickness, the situation that a recovered sheath embedded section cannot advance when the cross sectional area of a compressed vena cava filter and cut tissue is larger than the area of an inner cavity of the recovery sheath can be reduced or avoided, and it is avoided that the vena cava filter cannot be recovered.

Owner:肖亮

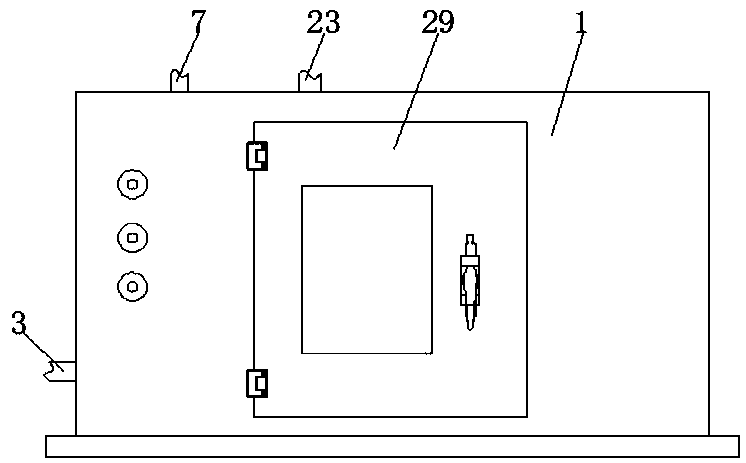

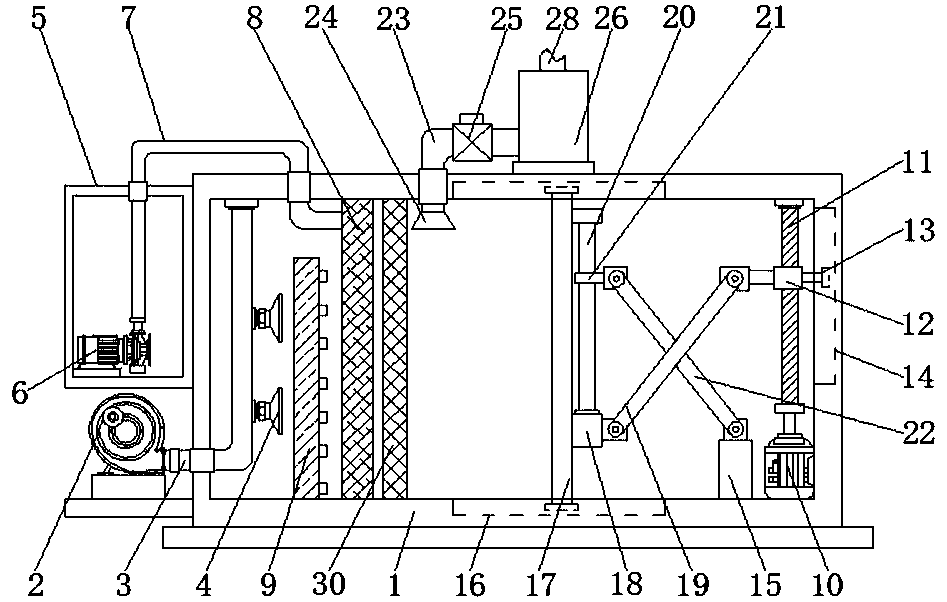

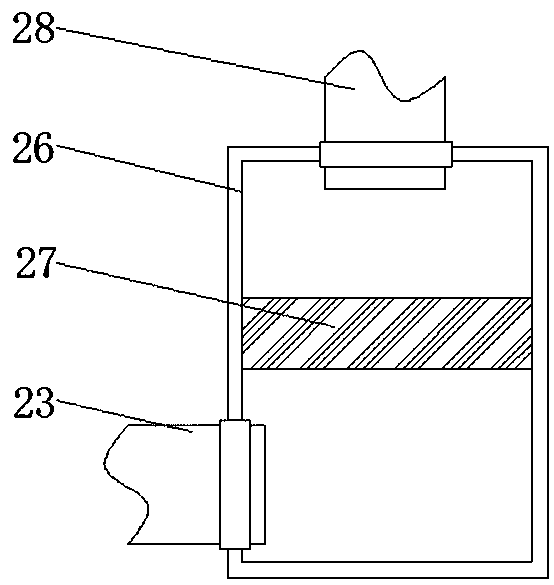

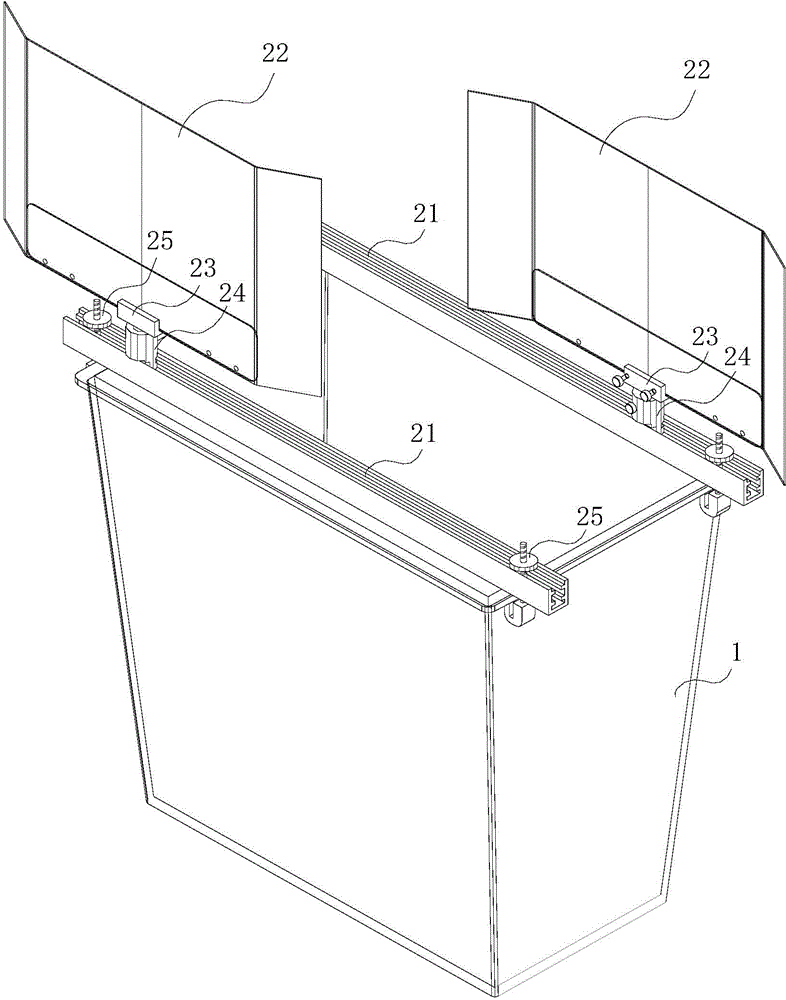

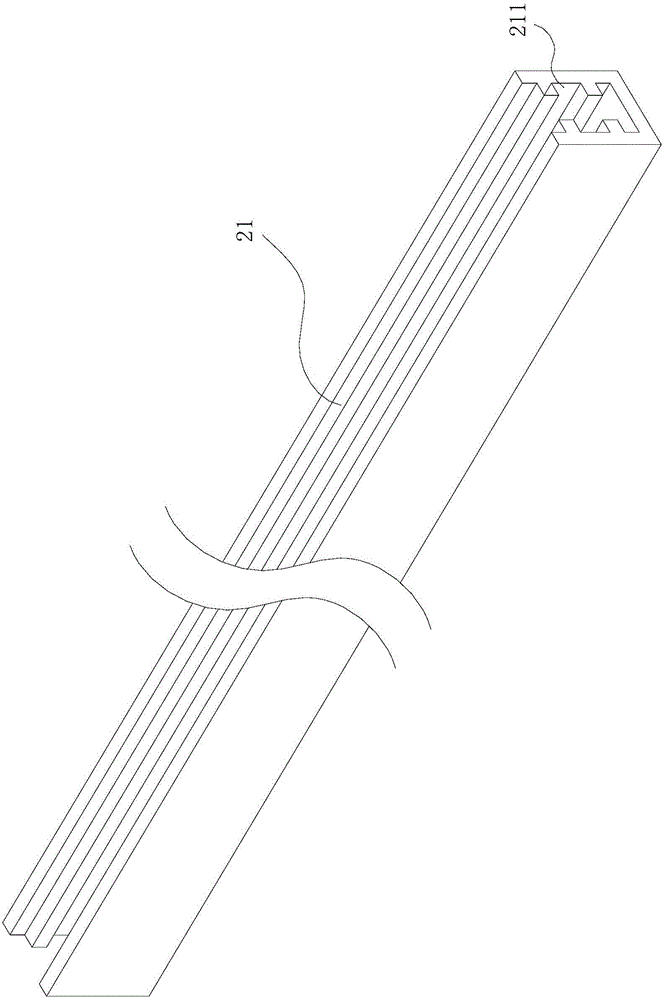

Animal suction type anesthesia device

InactiveCN108720965AReduce wasteReduce anesthesia costsVeterinary instrumentsInternal cavityEngineering

The invention discloses an animal suction type anesthesia device which comprises a box body. A hot air blower is fixedly connected to one side of the box body through a connecting plate; an air guiding pipe is communicated to an air outlet of the hot air blower; one end, far away from the hot air blower, of the air guiding pipe penetrates through the box body and extends to an inner cavity of thebox body. The animal suction type anesthesia device provided by the invention relates to the technical field of animal anesthesia; an anesthesia solution is atomized and diluted into the box body, sothat the waste of the anesthesia solution is greatly reduced, the anesthesia cost is reduced, the anesthesia solution in the box body is uniformly distributed, and a good anesthesia effect can be achieved on animals to be anesthetized; the volume of the box body can be conveniently adjusted, so that the activity range of the animals can be well controlled during anesthetization, and the device canbe suitable for anesthetizing the animals in different sizes so as to be wide in application range; the waste gas produced after anesthetization can be well filtered, so that the environment and thehealth of usage personnel are well protected.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Dedicated isolating and protecting wall for aerial lift truck

ActiveCN104836162ASave energyRange of controlApparatus for overhead lines/cablesAerial liftStructural engineering

The invention discloses a dedicated isolating and protecting wall for an aerial lift truck. The aerial lift truck comprises an insulation bucket. The isolating and protecting wall comprises two sliding rails, which are fixed at one side of the insulation bucket, a plurality of insulated isolation baffle plates, support connecting pieces, which are correspondingly connected with the insulated isolation baffle plates, sliding blocks, and J-shaped bolts. Kidney-shaped slots are respectively arranged at two sides of each sliding rail. The J-shaped bolts are fixed on the upper edge of the insulation bucket by traversing the kidney slots. Two sides of the insulated isolation baffle plates are semicircle-shaped. A plurality of small holes are arranged at the lower edge of a main body part of the insulated isolation baffle plates in pair. Grooves for clamping the insulated isolation baffle plates and the small holes corresponding to fixing bolts for fixing the insulated isolation baffle plates are arranged at the upper half parts of the support connecting pieces, and nylon tubes which are connected with the upper half parts of the sliding blocks are arranged at the lower half parts of the support connecting pieces. Small holes which use safety adjustment pins to fix the support connecting pieces are arranged at the side of the upper half parts of the sliding blocks, and the shape of the lower half part of each sliding block matches that of a sliding groove in one corresponding sliding rail. The dedicated isolating and protecting wall for the aerial lift truck is simple in structure, convenient to maintain, effective for protection, and safe and reliable.

Owner:BENGBU POWER SUPPLY COMPANY STATE GRID ANHUI ELECTRIC POWER +1

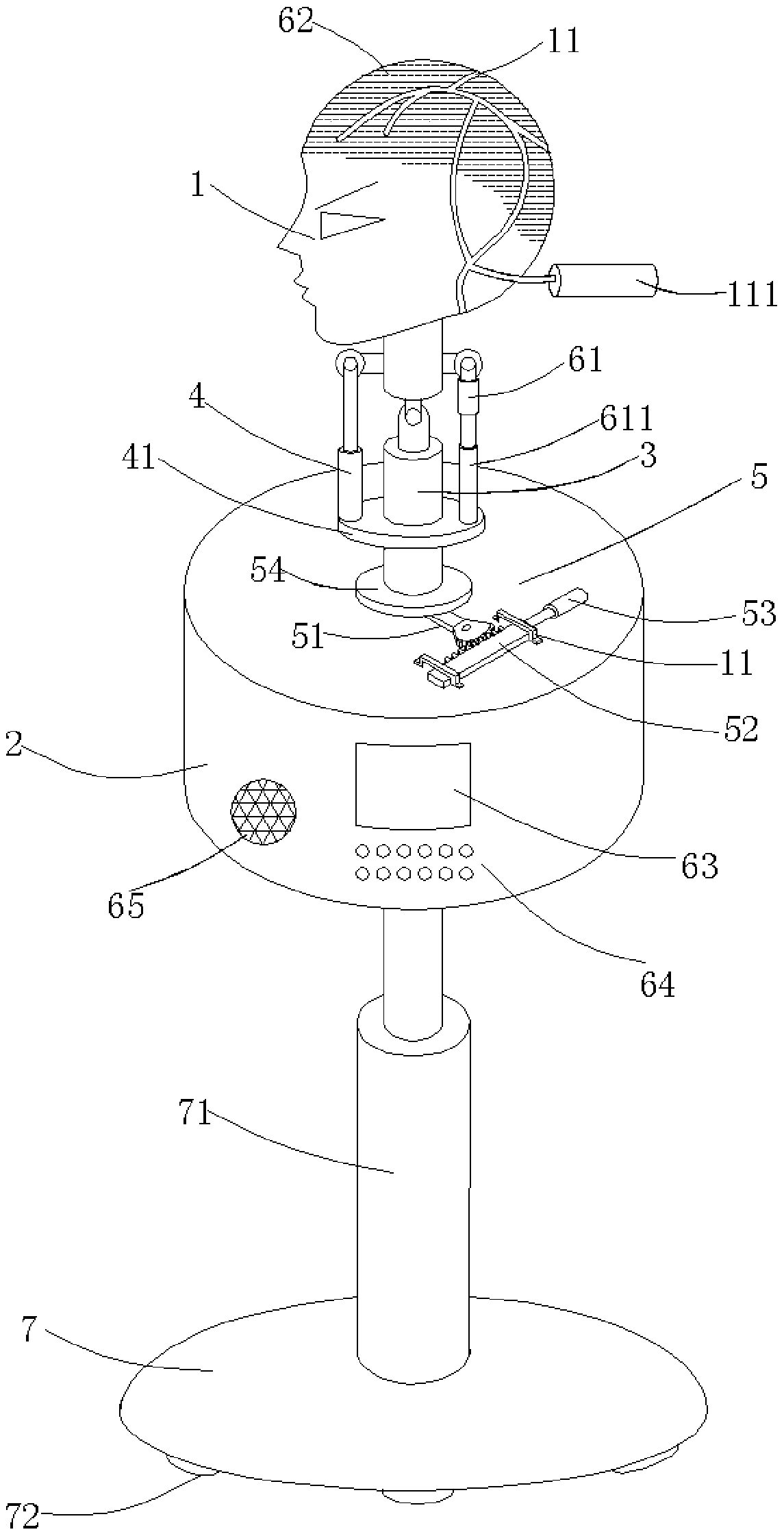

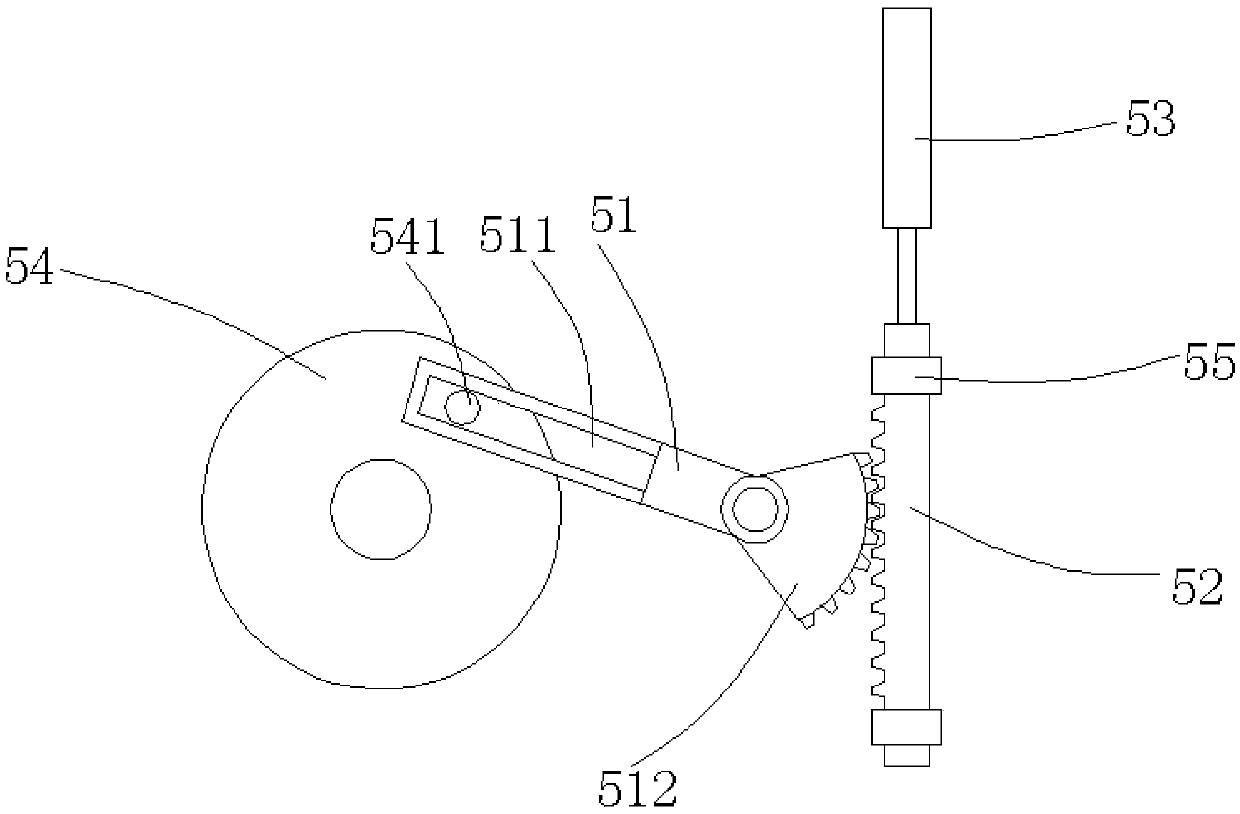

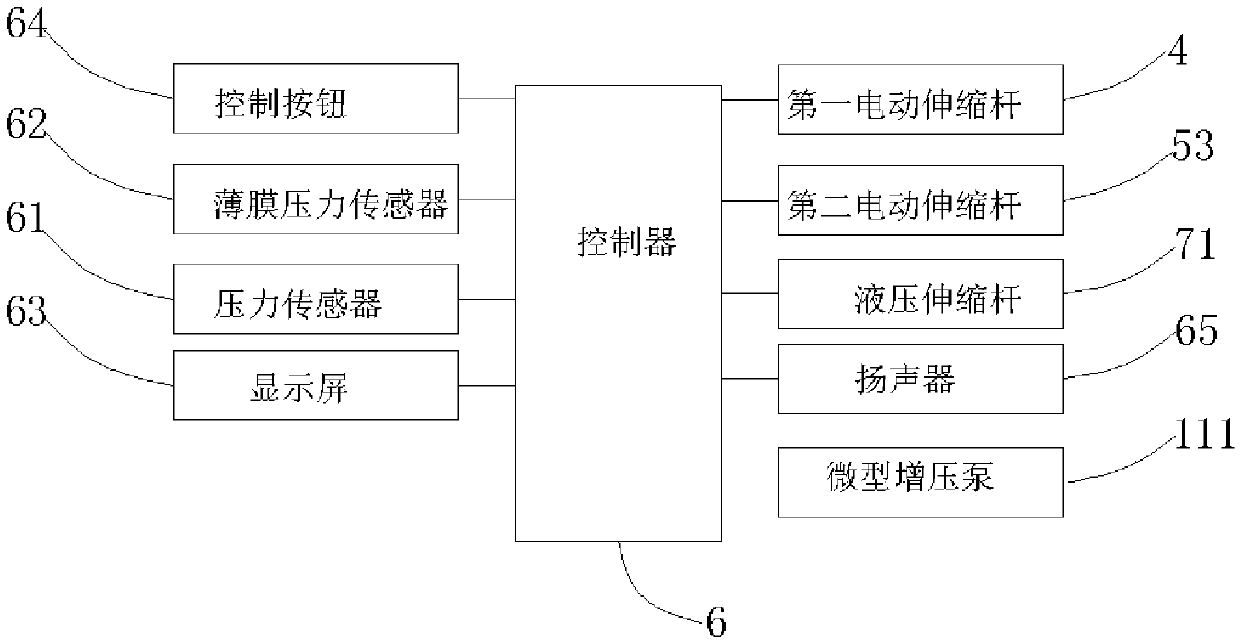

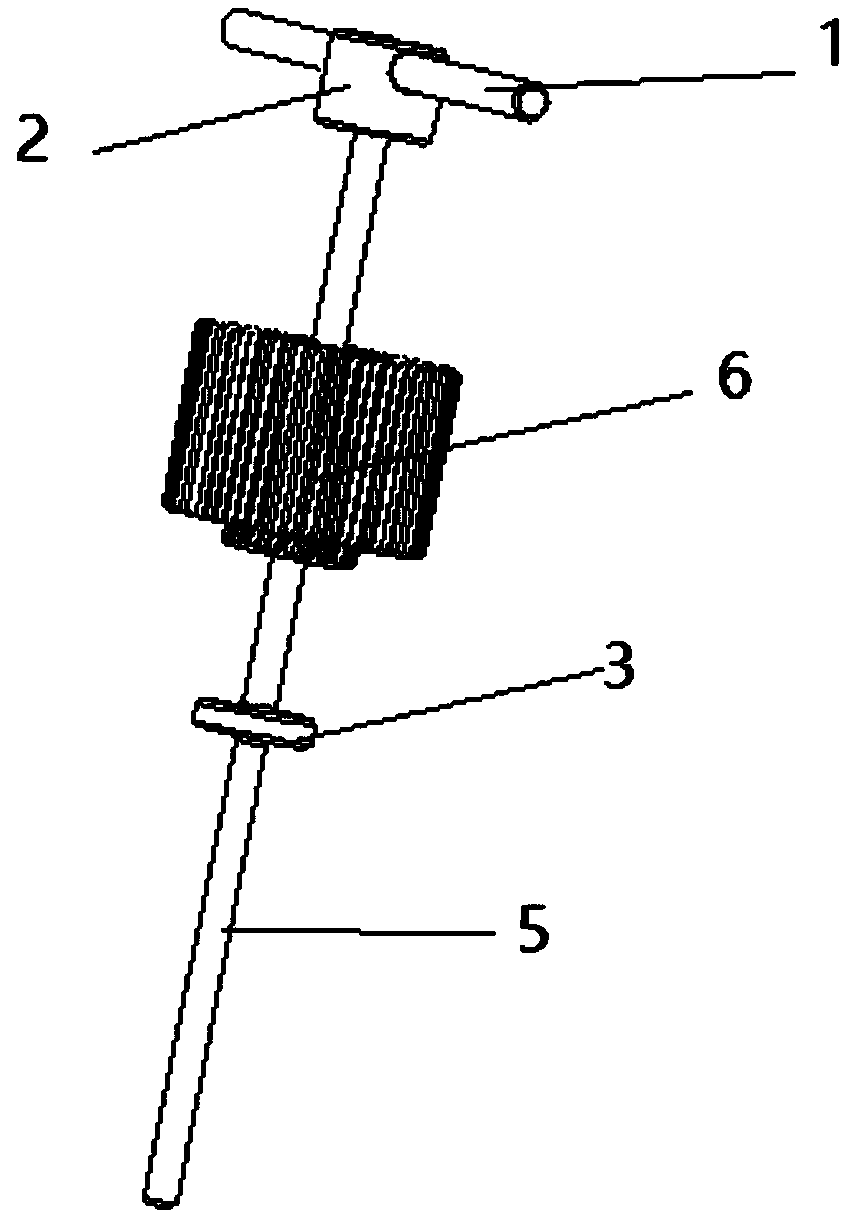

Child scalp vein model

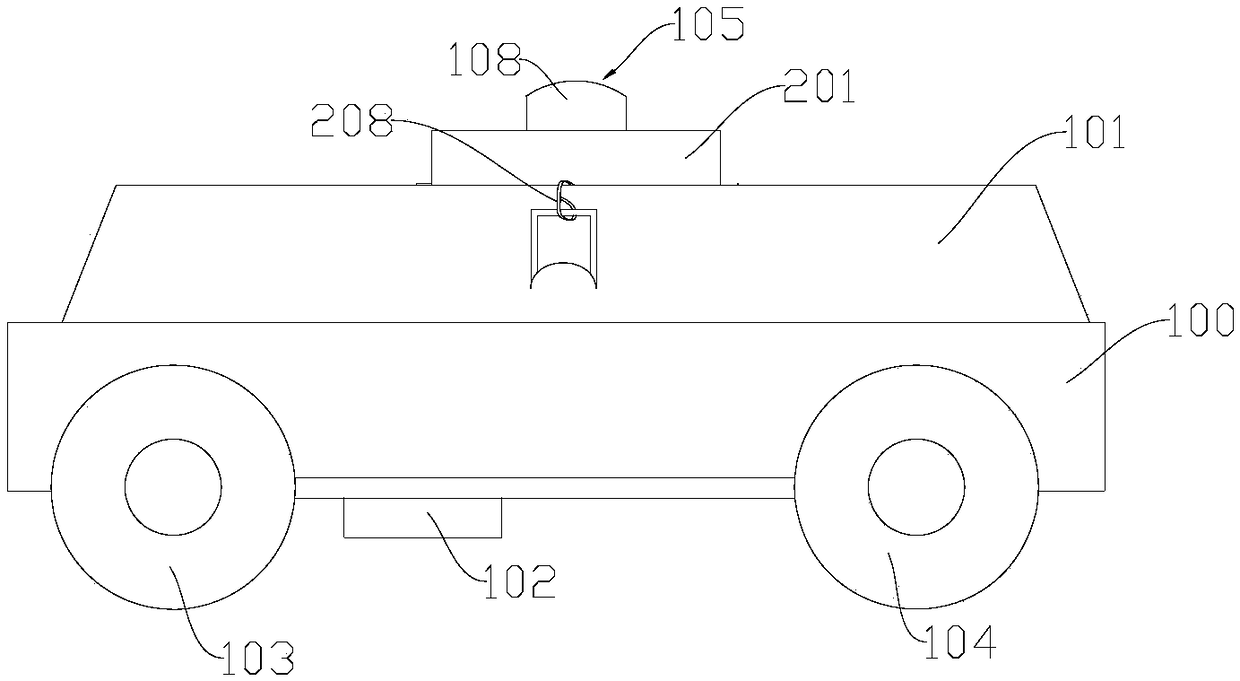

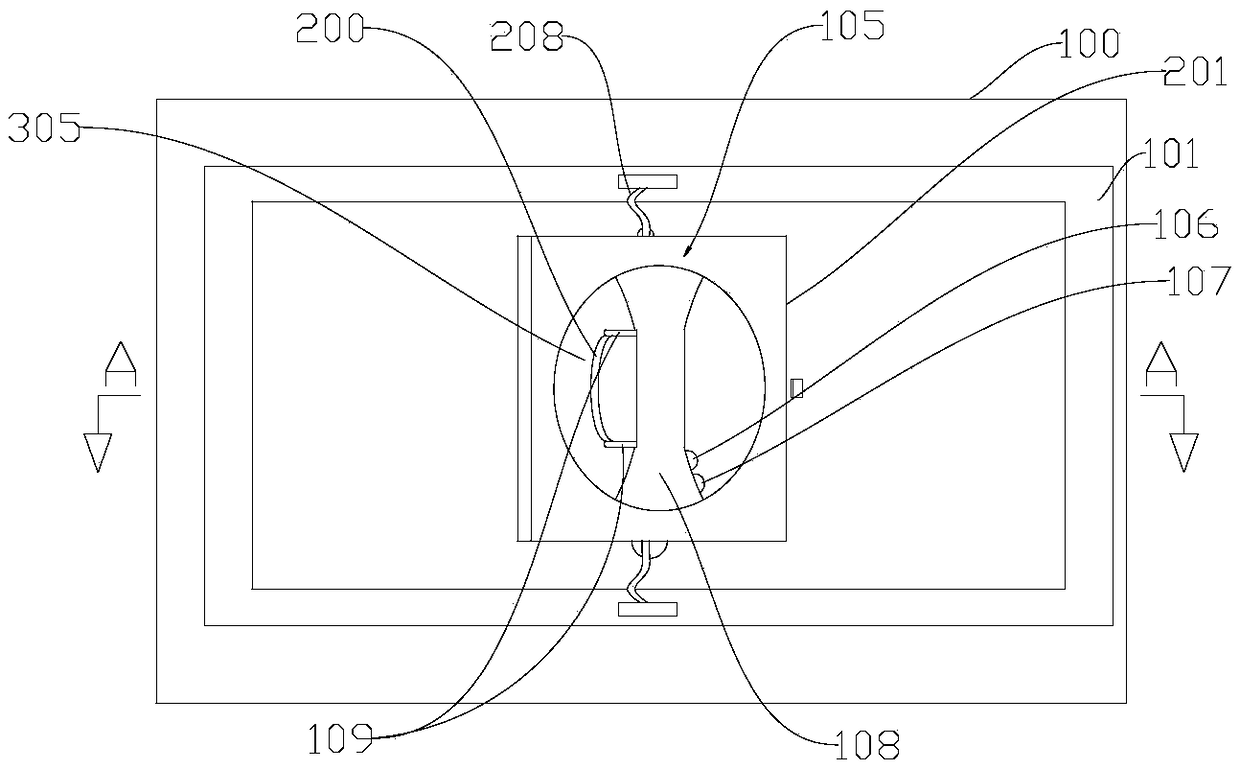

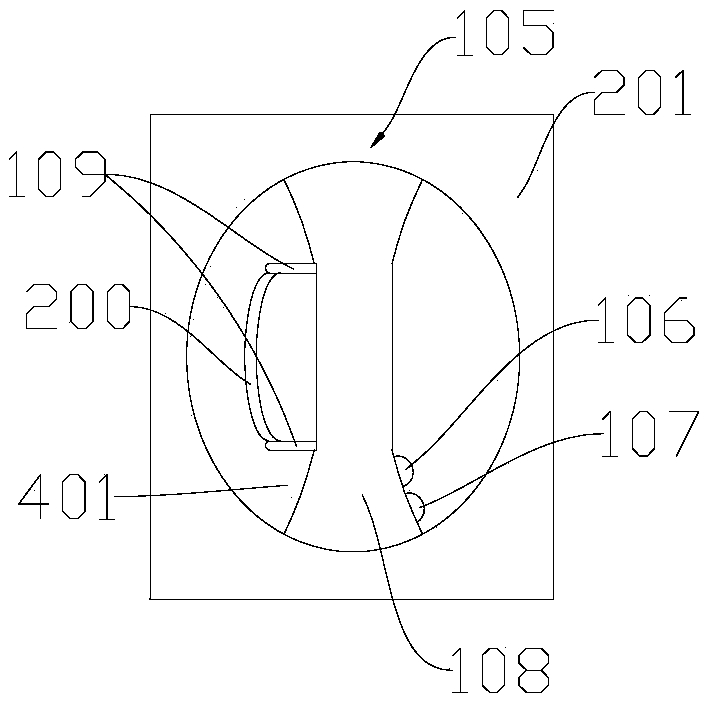

The invention relates to the technical field of medical teaching models, in particular to a child scalp vein model comprising a head model, a support base, a support rod, a pitch motion driving device, a shake motion driving device and a control device. The support rod has one end hinged to the head model and the other end rotatably connected to the support base. The head model is provided with avenous vascular network. The pitch motion driving device raises and lowers the head model. The shake motion driving device rotates the head model. The control device is configured to control the pitchmotion driving device and the shake motion driving device. The child scalp vein model of the invention can simulate the struggling movement of a child and effectively improve the technical level of scalp venepuncture for a medical worker.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

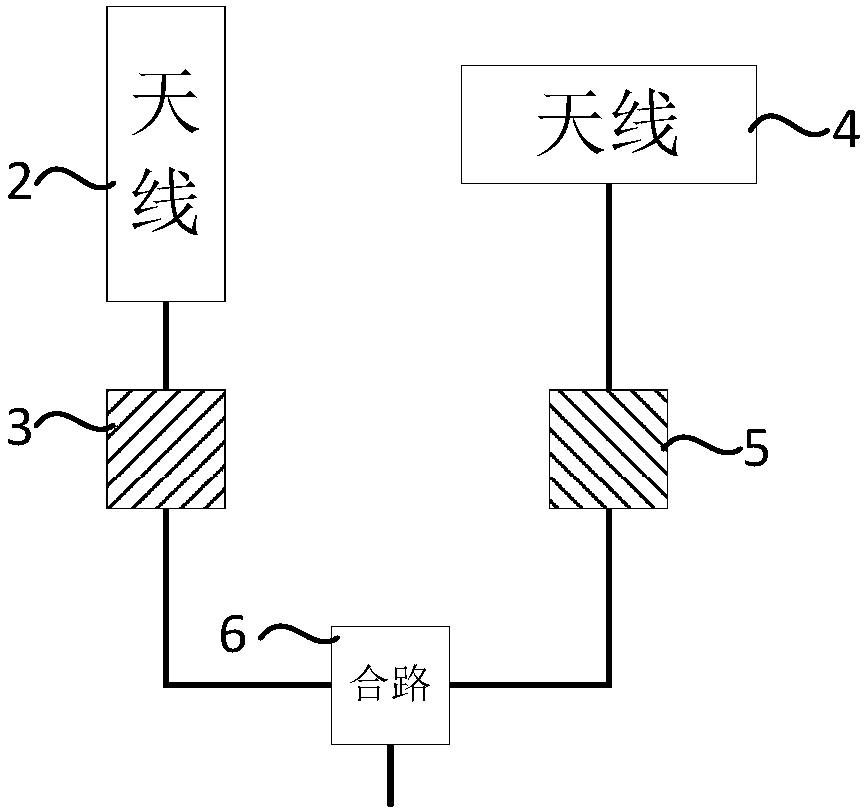

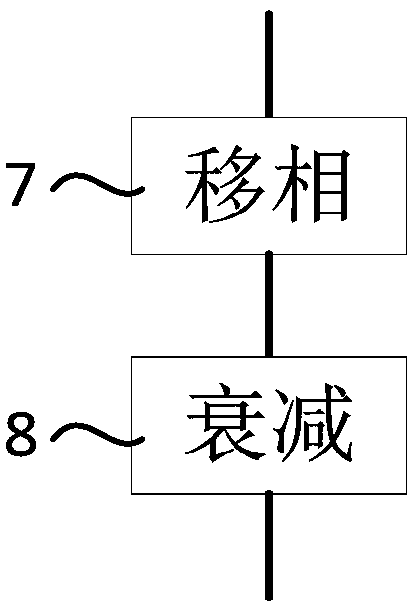

Variable polarization antenna and variable polarization antenna array

InactiveCN107785664AAchieve any polarizationControl phasePolarised antenna unit combinationsElectric fieldPhysics

The invention discloses a variable polarization antenna and a variable polarization antenna array. The variable polarization antenna particularly comprises a first antenna structure, a first variablepolarization control structure, a second antenna structure, a second variable polarization control structure and a combining structure, wherein the first antenna structure is connected with the firstvariable polarization control structure; the second antenna structure is connected with the second variable polarization control structure; the first variable polarization control structure and the second variable polarization control structure are connected with the combining structure; and electric fields of the first antenna structure and the second antenna structure are vertical. According tothe variable polarization antenna of the invention, through controlling the phase and the amplitude of the electric field of the antenna, random polarization of the antenna can be realized.

Owner:INFORMATION SCI RES INST OF CETC +1

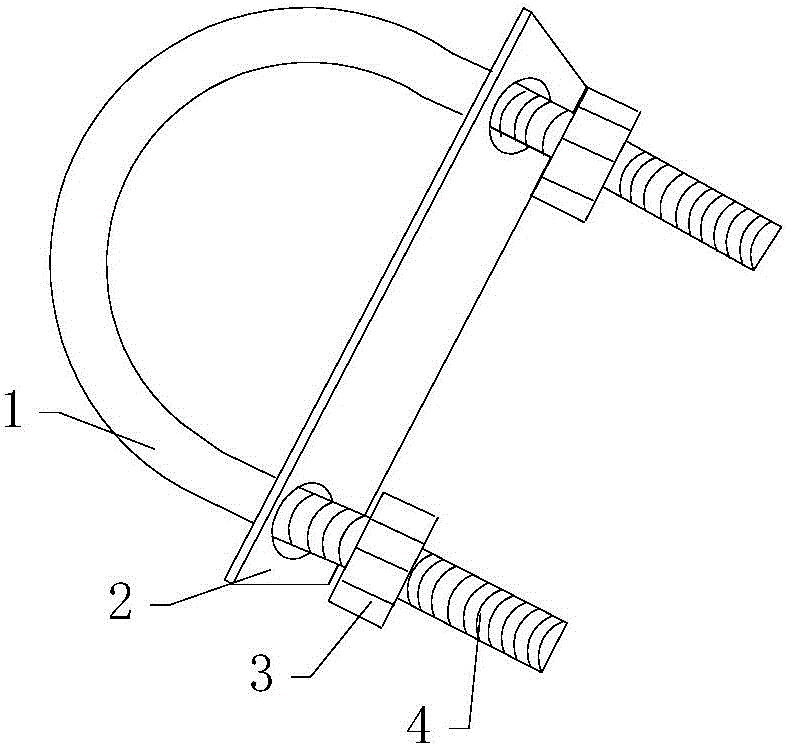

Oil extraction pipe fixing device

The invention provides an oil extraction pipe fixing device which comprises a U-shaped oil extraction pipe clamp, a limit baffle and fixing bolts, wherein the limit baffle is arranged at the tail ends of the extraction pipe clamp, the fixing bolts are used for limiting movement of the limit baffle, the U-shaped oil extraction pipe clamp comprises two arms and is cylindrical, threads are formed in the tail parts of the two arms of the U-shaped oil extraction pipe clamp, through holes are formed in the positions, at the distance of 2-5 cm from the edges, of the two sides of the limit baffle respectively, the limit baffle is mounted on the U-shaped clamp by the through holes, and the fixing bolts are arranged at the tail parts of the two arms of the U-shaped oil extraction pipe clamp and used for limiting movement of the limit baffle.According to the oil extraction pipe fixing device, the movement range of the oil extraction pipe is simply controlled by the aid of the created U-shaped clamp design, and fixing of a following pipe can be enhanced and the section size of a wall can be fixed by the aid of the design of the limit baffle, so that pipe fixing becomes simple and operation and disassembly are convenient.

Owner:TIANJIN LIFUTEKE IND & TRADE CO LTD

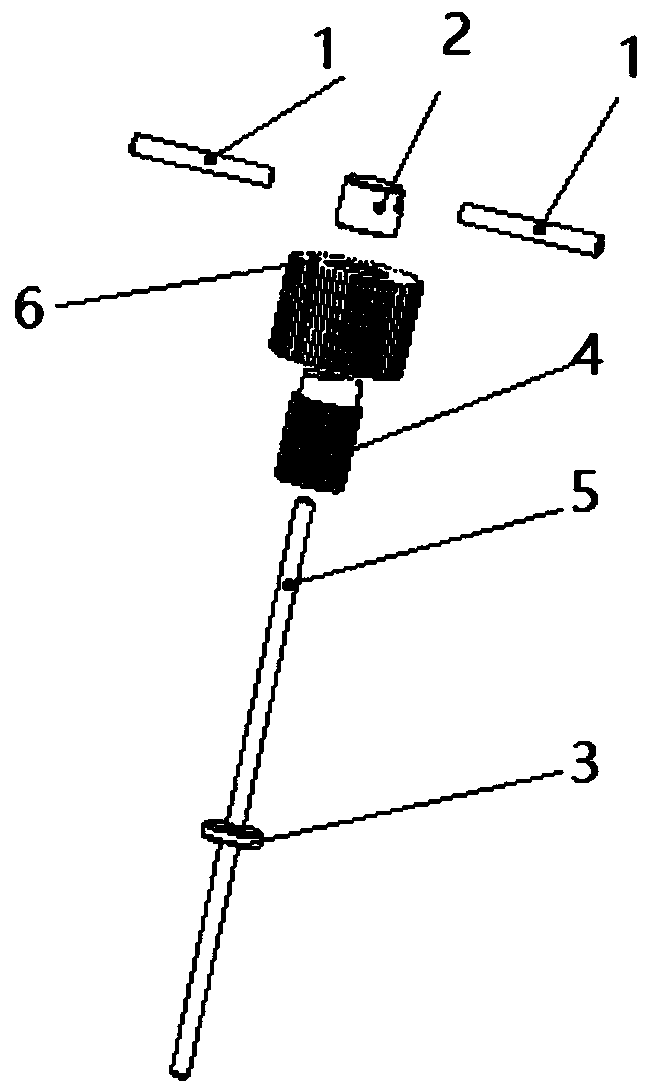

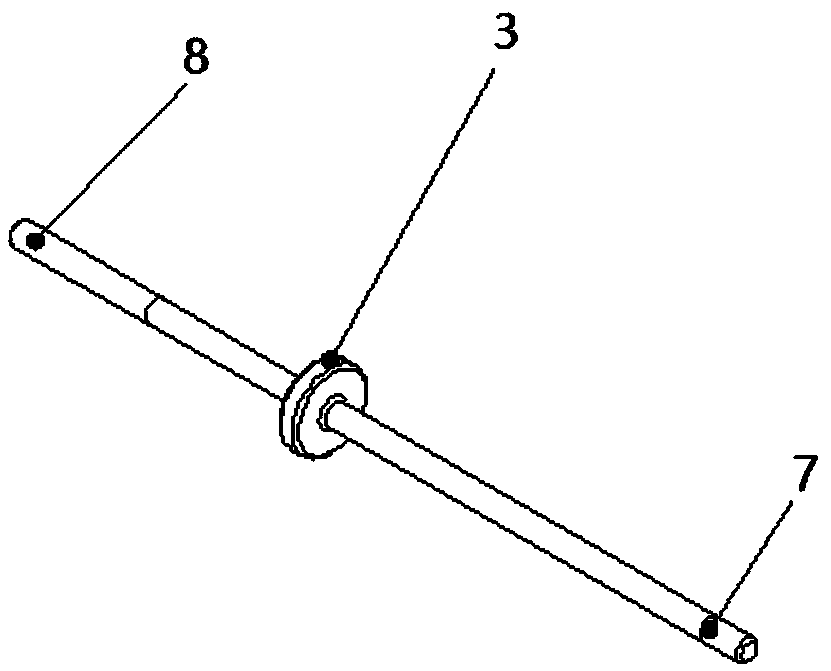

Structural pin assembling and disassembling tool

InactiveCN109015521ALower requirementRange of controlMetal-working hand toolsEngineeringFriction force

The invention discloses a structural pin assembling and disassembling tool, and relates to the technical field of positioning between satellite structures. The structural pin assembling and disassembling tool comprises two round rods, a handle force-bearing cylinder, a knocking hammer and a central rod, wherein the central rod is of a slender-rod-shaped structure vertically arranged. The outer wall of the central rod is sleeved with the knocking hammer, and the handle force-bearing cylinder is of a cylindrical structure. The handle force-bearing cylinder is coaxially and fixedly installed at the top end of the central rod, and the central rod penetrates through the knocking hammer in the axial direction and is fixedly connected with the handle force-bearing cylinder. The two round rods arehorizontally arranged in a straight line, and the two round rods are symmetrically and fixedly installed on the two sides of the handle force-bearing cylinder, an external pin is connected to the axial bottom end of the central rod in a butting mode. The structural pin assembling and disassembling tool is high in universality, safe and reliable in operation, convenient to implement and capable ofdismounting and mounting pins under the condition of larger friction force.

Owner:AEROSPACE DONGFANGHONG SATELLITE

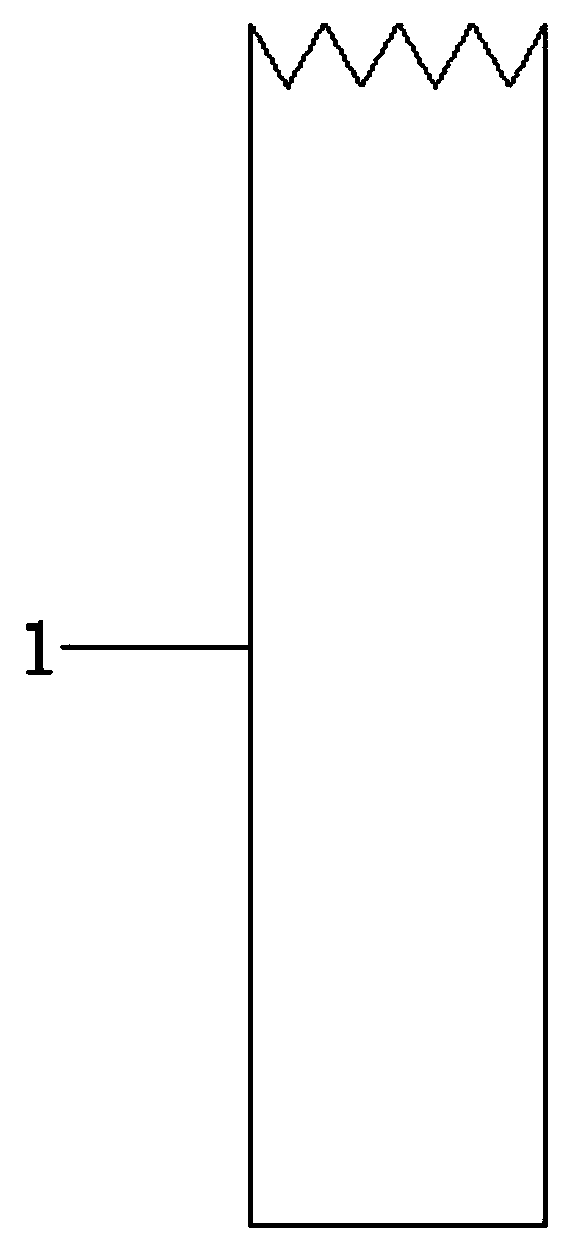

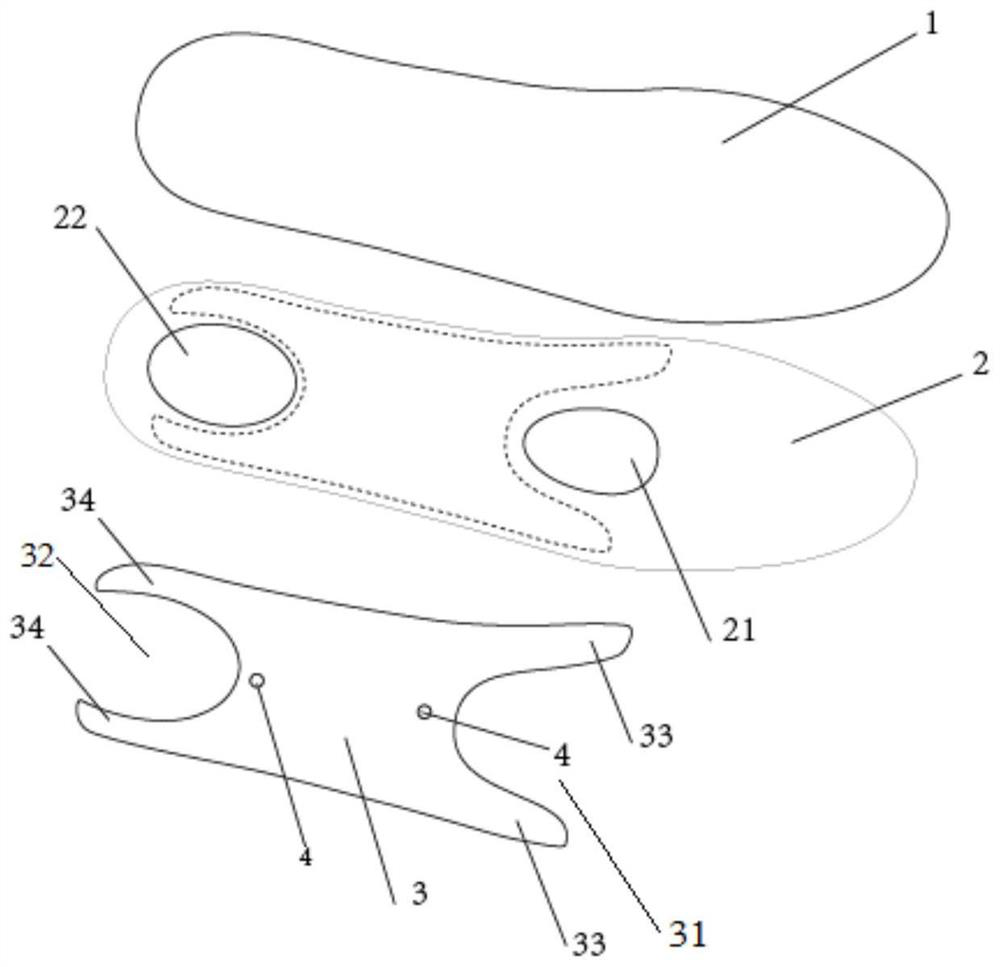

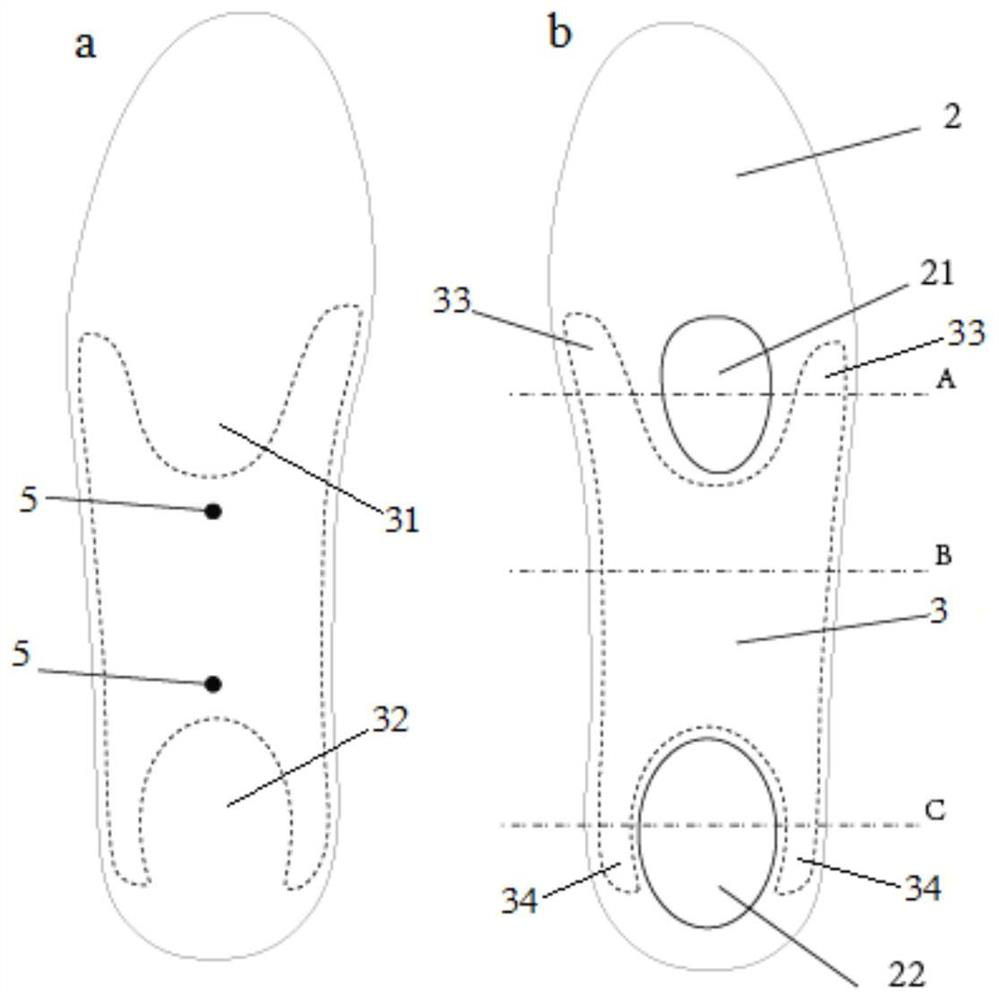

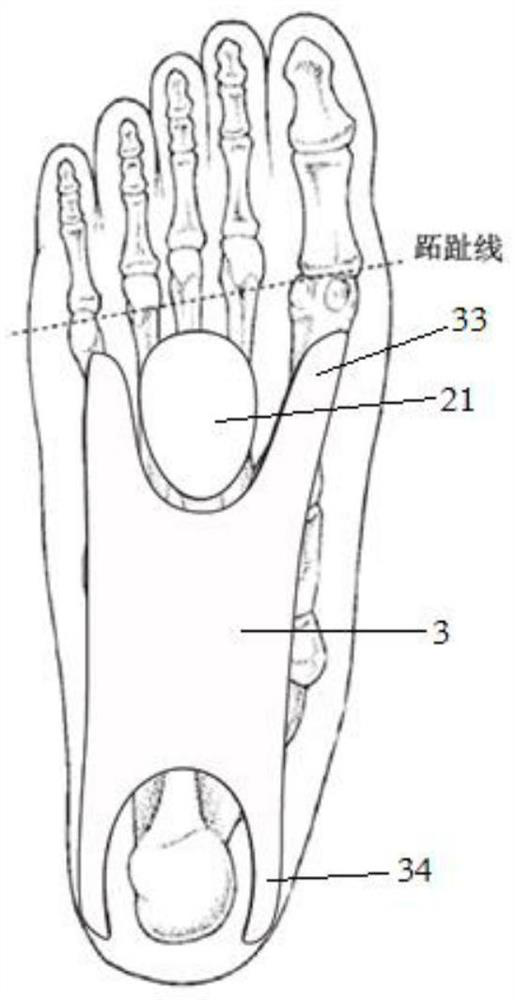

Foot arch supporting insole

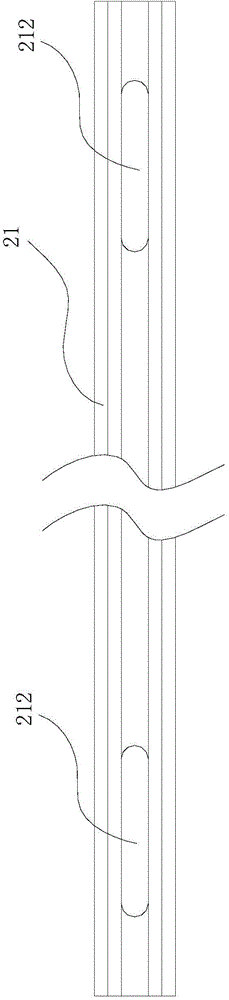

PendingCN114098221AIncrease stiffnessImprove pedal strengthInsolesBiological bodyPhysical medicine and rehabilitation

The invention provides a foot arch supporting insole. The foot arch supporting insole comprises a surface layer (1), a body (2) and an embedded supporting component (3). The surface layer (1) is arranged on the upper surface of the body (2), and the embedded supporting component (3) is arranged at the bottom of the body (2) in an embedded mode. The invention simulates the structural principle that a living body'meat 'wraps'bones', and provides a design method of an integrally formed insole by wrapping a hard support body with a flexible material. According to the supporting type insole designed in the scheme, the weight can be effectively dispersed to the inner side and the outer side of the front foot and the inner side and the outer side of the rear foot in the foot buffering stage, and stable and balanced supporting is formed.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Long-acting PO film coating liquid and preparation method thereof

PendingCN113527919AGood adhesionSolve friction damageMixer accessoriesCoatingsAcrylic resinActive agent

The invention discloses a long-acting PO film coating liquid and a preparation method thereof. The long-acting PO film coating liquid is prepared from the following components in percentage by weight: 45-50% of a mixture A, 28-33% of a mixture B, 0.6-1% of polyurethane emulsion and 16-18% of deionized water, the mixture A is prepared from 23 to 28 percent of nano aluminum oxide sol, 11 to 13 percent of nano zirconium oxide sol, 4 to 6 percent of surfactant, 5 to 7 percent of acrylic resin nano emulsion and 1 to 2 percent of water-based defoaming agent; and the mixture B is prepared from 23 to 28 percent of nano silicon dioxide sol, 4 to 5 percent of adhesion promoter and 2 to 3 percent of fatty alcohol-polyoxyethylene ether. The coating liquid is prepared from the nanometer sol with the large pore volume of 0.4 nm and the alkynediol surfactant through a raw material suction device, and the dripping persistence, the surface material scratching property and the film surface non-stickiness of the PO film coated with the coating liquid are remarkably improved.

Owner:杭州永盛塑料抗静电材料厂

Electric ab wheel and fitness equipment kit

InactiveCN106422184BRange of controlAvoiding Strain SituationsMovement coordination devicesCardiovascular exercising devicesMuscle strainsMuscle group

Owner:JIANGXI ELECTRIC VOCATIONAL & TECHN COLLEGE +1

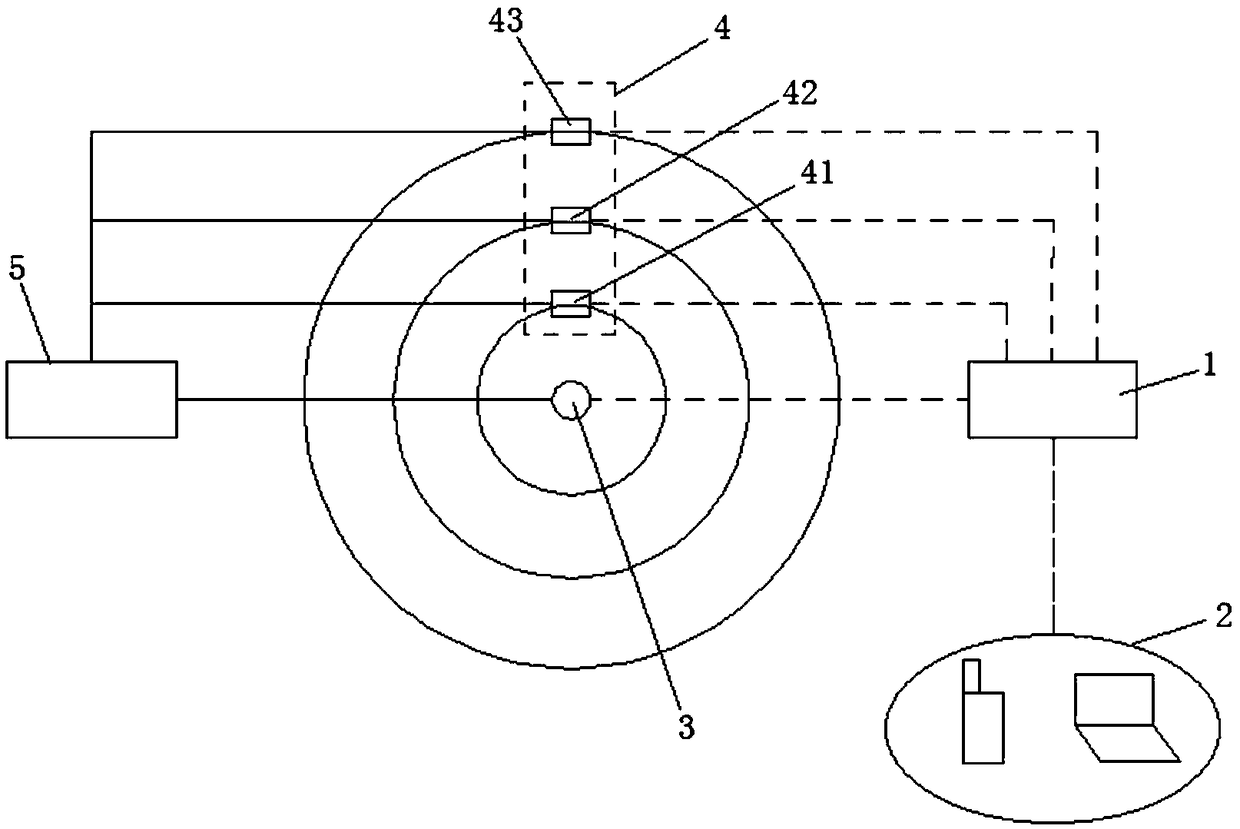

Intelligent remote safety chicken raising system and feeding method thereof

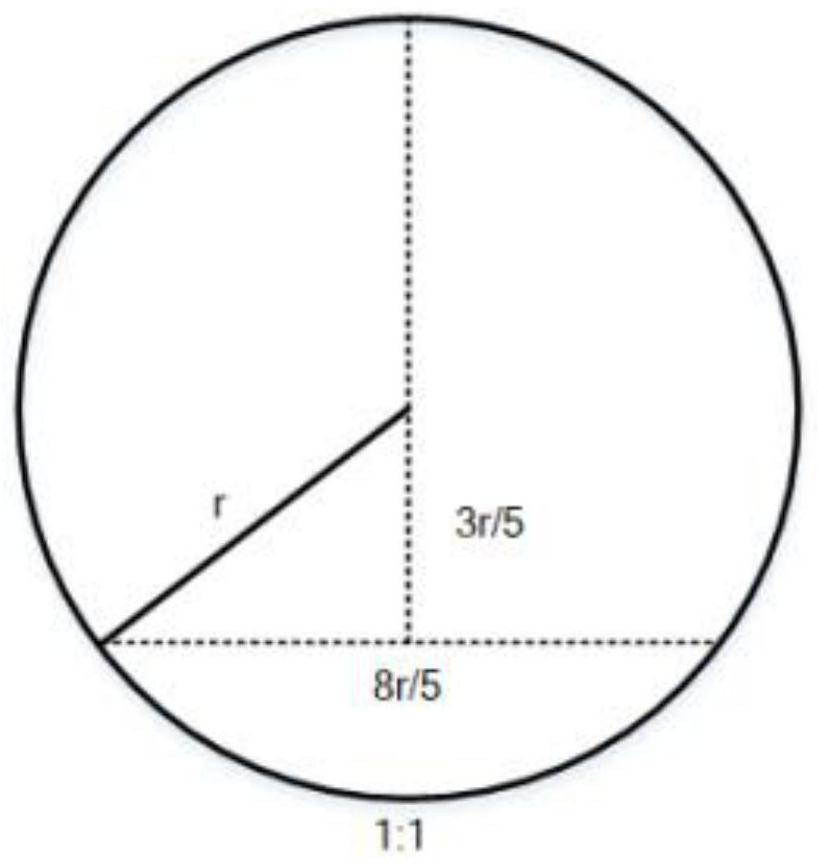

ActiveCN108967248ARealize the alarm functionRange of controlLivestock managementBird housingsWireless routerElectricity

The invention provides an intelligent remote safety chicken raising system and a feeding method thereof. A mobile terminal is in matched connection and communication with a wireless router, and the wireless router is in communication connection with an automatic feeder, an alarm device and a feeding device. The alarm device comprises a first infrared early-warning device, a second infrared early-warning device and a third infrared early-warning device in a core circular range, a middle circular range and an outer circular range of a feeding circular range in sequence. A solar device is in electrical connection with the first infrared early-warning device, the second infrared early-warning device, the third infrared early-warning device, the automatic feeder and the feeding device. The mobile terminal, the automatic feeder, the alarm device and the feeding device form the intelligent remote safety chicken raising system through a wireless network, a remote feeding method is implementedby adoption of the intelligent remote safety chicken raising system, automatic feeding according to types and weights of feeds can be realized, a chicken motion range can be controlled, and a feedingcircular range alarm function is achieved.

Owner:李东

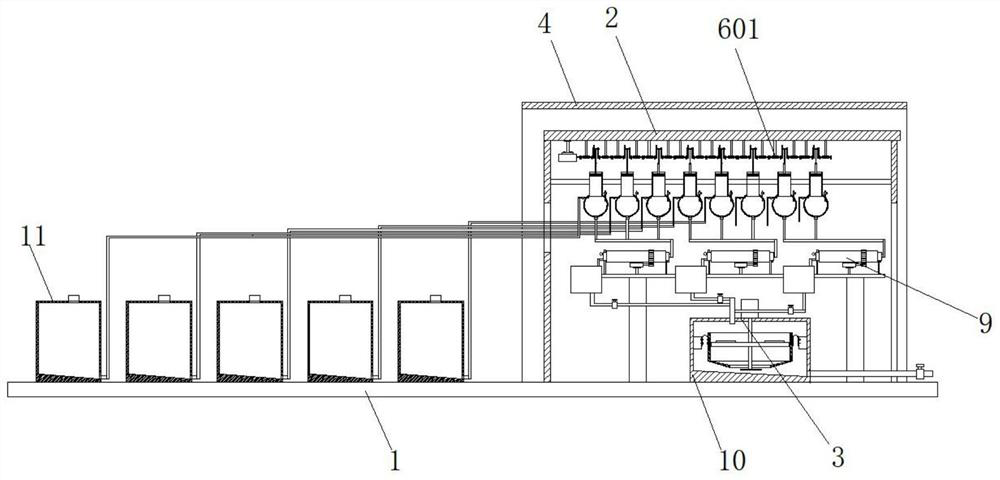

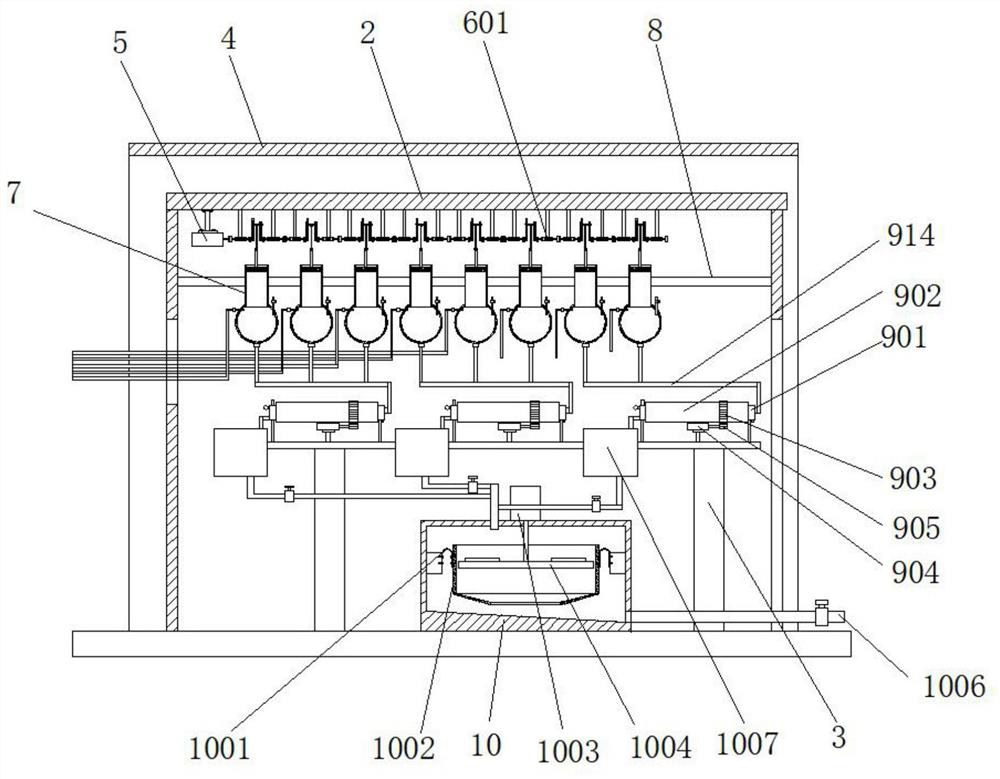

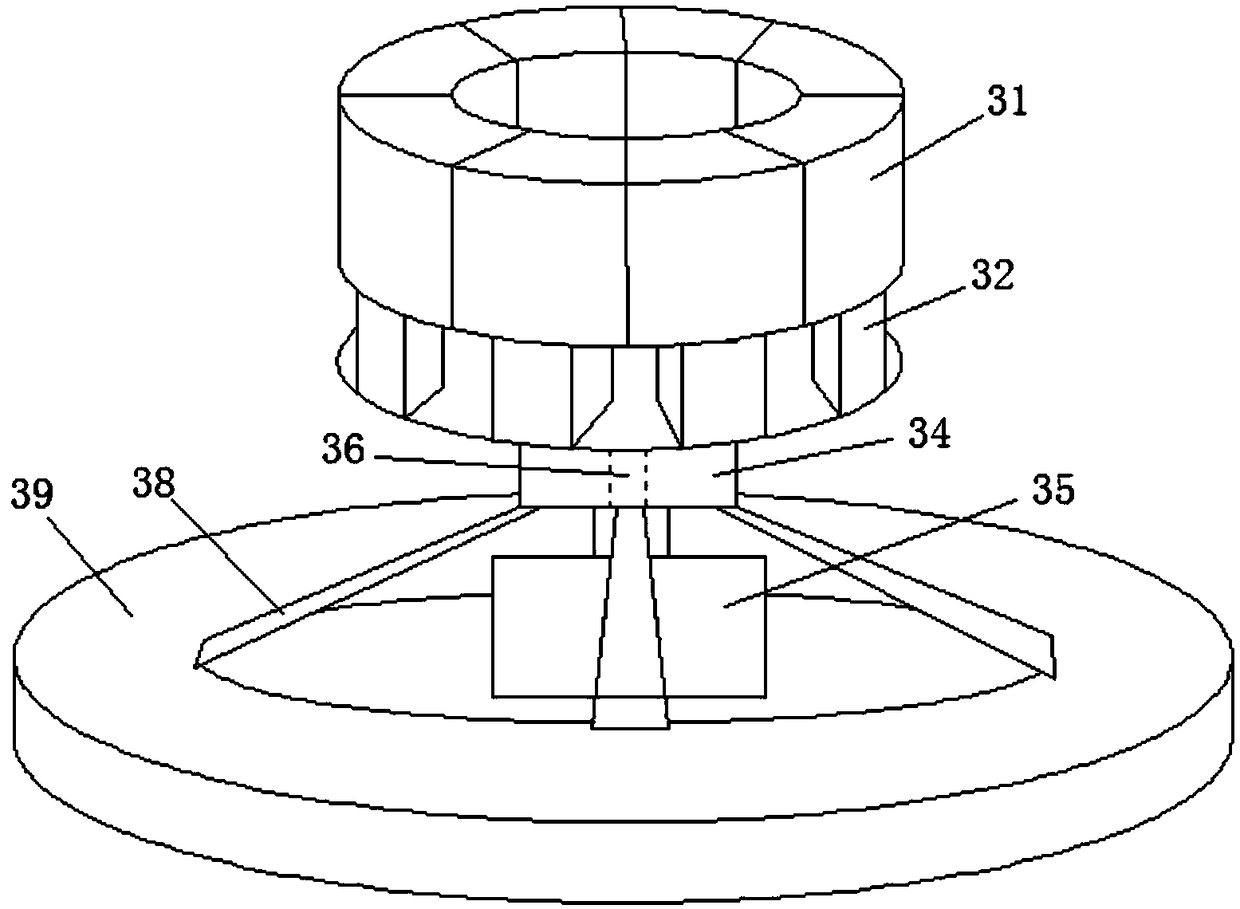

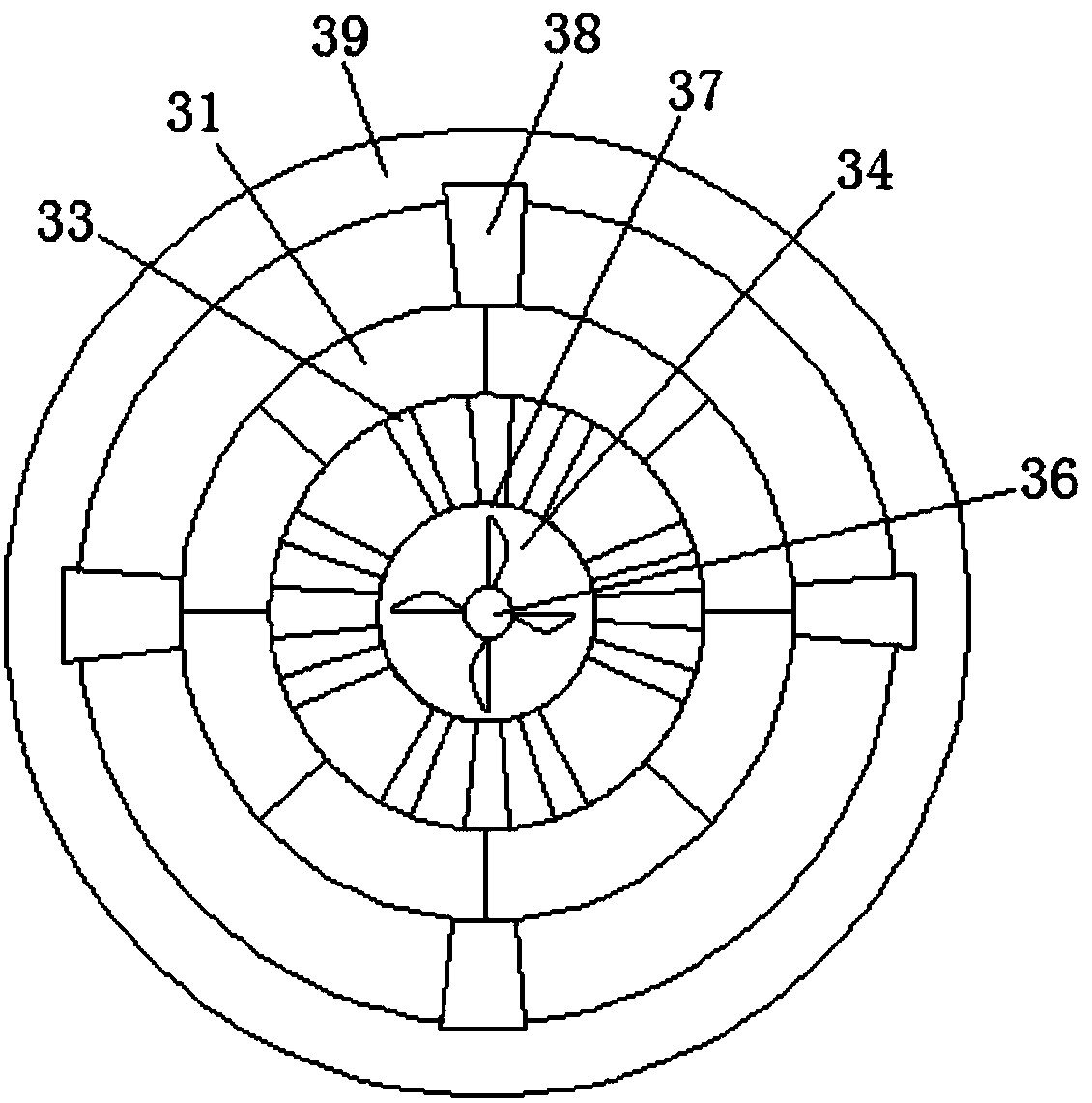

Crystallization equipment special for remelting in-situ micro-alloying of high-speed steel electroslag and smelting method thereof

The invention relates to the field of high-speed steel micro-alloying, in particular to crystallization equipment special for remelting in-situ micro-alloying of high-speed steel electroslag and a smelting method thereof. The crystallization equipment special for remelting in-situ micro-alloying of the high-speed steel electroslag comprises a bottom water tank, a transformer and crystallizers. A crystallizing pond is formed jointly by the crystallizers and the bottom water tank. An atmosphere cover is arranged on the crystallizing pond. Movable connection of the atmosphere cover and the crystallizers is achieved through connecting parts such as buckles and bolts. An air inlet is formed in the lower end of one side of the atmosphere cover, and an air outlet is formed in the upper end of theside, opposite to the air inlet, of the atmosphere cover. A slag-filling port is formed in the position, close to the edge, of the top of the atmosphere cover. A circular through hole is formed in the center of the atmosphere cover. One end of the transformer is connected with the bottom water tank, the other end of the transformer is connected with a self-fluxing electrode of the high-speed steel through a welded fake electrode, and a closed loop circuit is formed. By adopting the crystallization equipment for conducting of electroslag remelting, the yield is effectively improved for easy-to-burn microalloy elements; besides, elements added can participate in an organization evolution process as nucleation particles; texture of the high-speed steel is refined obviously; and the size of carbides is lowered conspicuously.

Owner:HEBEI UNIV OF TECH

A Carrier Sense Method Based on Dynamic Idle Channel Evaluation Threshold

InactiveCN105101453BRange of controlImprove space reuseWireless communicationClear to sendCarrier signal

The invention provides a carrier sensing method based on a dynamic idle channel assessment threshold. According to the method, the existing carrier sensing mechanism is improved, and a CCA (Clear Channel Assessment) threshold is adjusted and an effective range of an NAV (Network Allocation Vector) is controlled according to the channel condition, so that the concurrent transmission in a network is increased and the network throughput is improved. According to the method, the CCA threshold is dynamically computed and adjusted according to the receiving power, so that the spatial reuse of the network can be effectively improved, meanwhile, through carrying an interference margin and a probability of acceptance at a CTS (Clear To Send) group, the range of action of the NAV in the CTS group is effectively controlled, and the spatial reuse is further improved, so that the network throughput is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

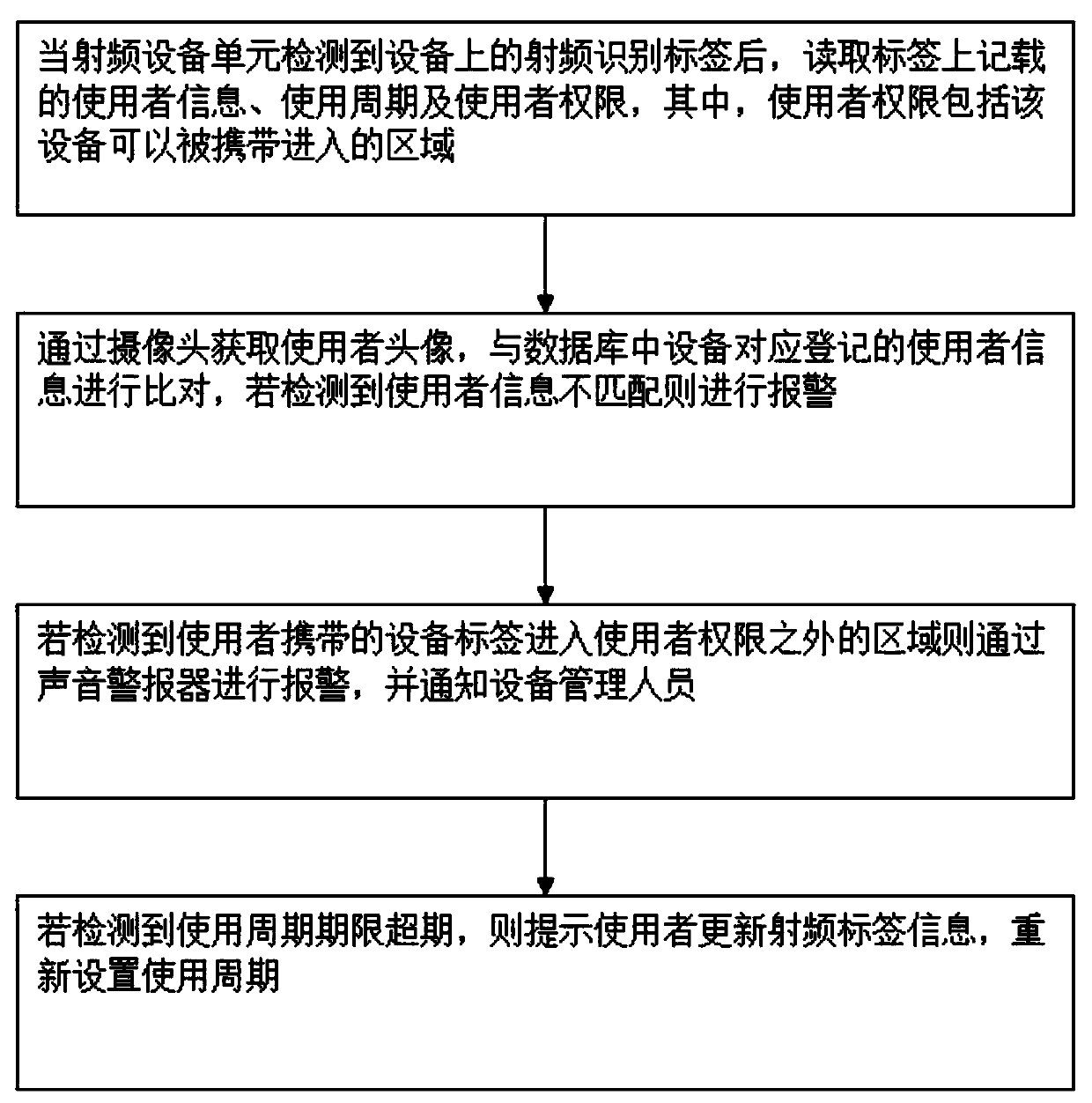

Equipment management platform and method based on radio frequency identification technology

InactiveCN111160577ARange of controlProhibited useCo-operative working arrangementsEmbedded systemRF module

The invention discloses an equipment management platform based on a radio frequency identification technology. The platform comprises a plurality of radio frequency identification units for reading and recording a radio frequency identification tag on the equipment, uploading read information to a server, and serving as a control center through an MCU; the MCU reads the equipment information on the label through an RF radio frequency module; the radio frequency identification units further comprise a UPS power supply unit, a sound alarm unit and a screen display unit. The UPS power supply unitsupplies power to the control center, the sound alarm unit and the screen display unit. Data reading and writing are carried out between the label and the radio frequency identification unit throughradio frequency signals. A manager logs in database data of the server through a browser, the radio frequency identification units are located at different positions, and when any radio frequency identification unit detects an equipment label, the position where equipment appears is recorded in the server.

Owner:AEROSPACE HI TECH HLDG GROUP

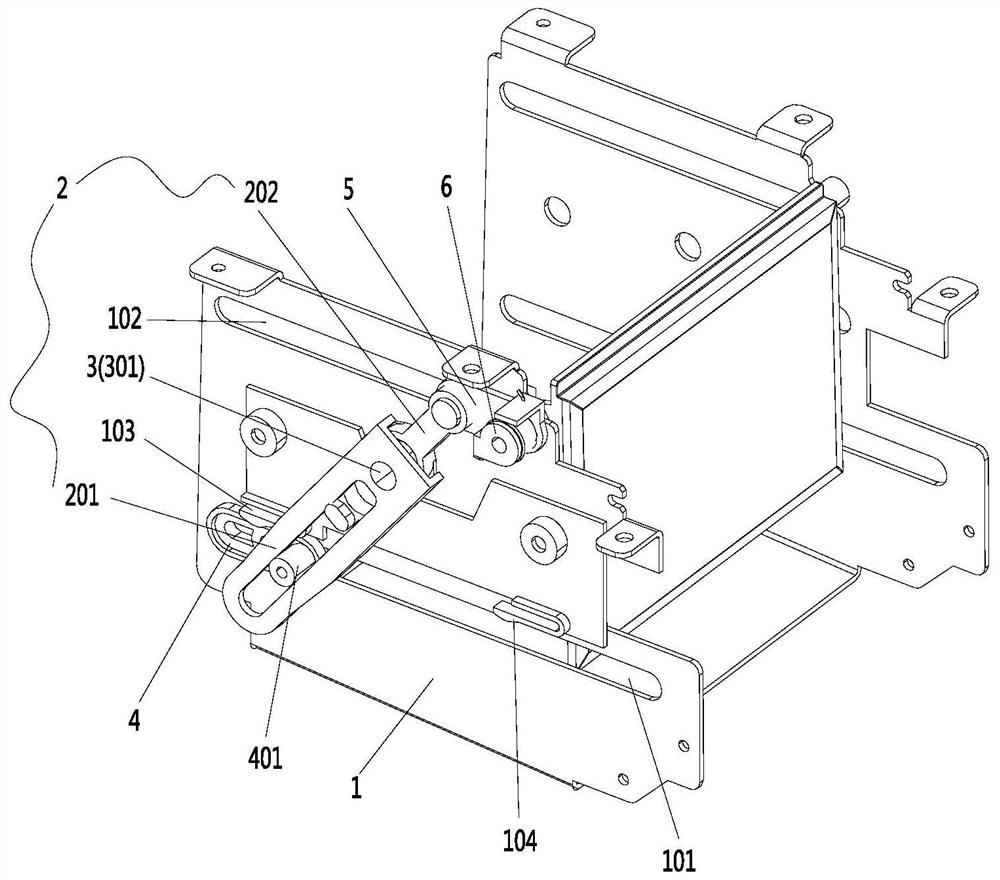

Transmission mechanism

The invention discloses a transmission mechanism. The transmission mechanism comprises a base, a connecting rod assembly capable of rotating around a rotating center, a driving unit connected with theconnecting rod assembly, and a first sliding block movably arranged on the connecting rod assembly and capable of sliding in a sliding groove of the base, wherein the driving unit drives the connecting rod assembly to rotate around the rotating center, and the sliding track of the first sliding block in the base sliding groove is defined by being matched with sliding of the first sliding block onthe connecting rod assembly. According to the transmission mechanism provided by the invention, the moving track of the transmission mechanism is set, the moving power of the first sliding block is transmitted to the second sliding block, and the second sliding block is provided with the mechanism capable of converting linear motion into rotary motion, so that the occupied space of the transmission mechanism is reduced while the transmission function is met; and the space utilization efficiency is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com