Oil extraction pipe fixing device

A technology for fixing devices and oil production pipes, which is applied in the directions of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve the problems of unstable wall fixing and non-perpendicular orientation of pipe fittings, so as to facilitate operation and disassembly. , the effect of simple operation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

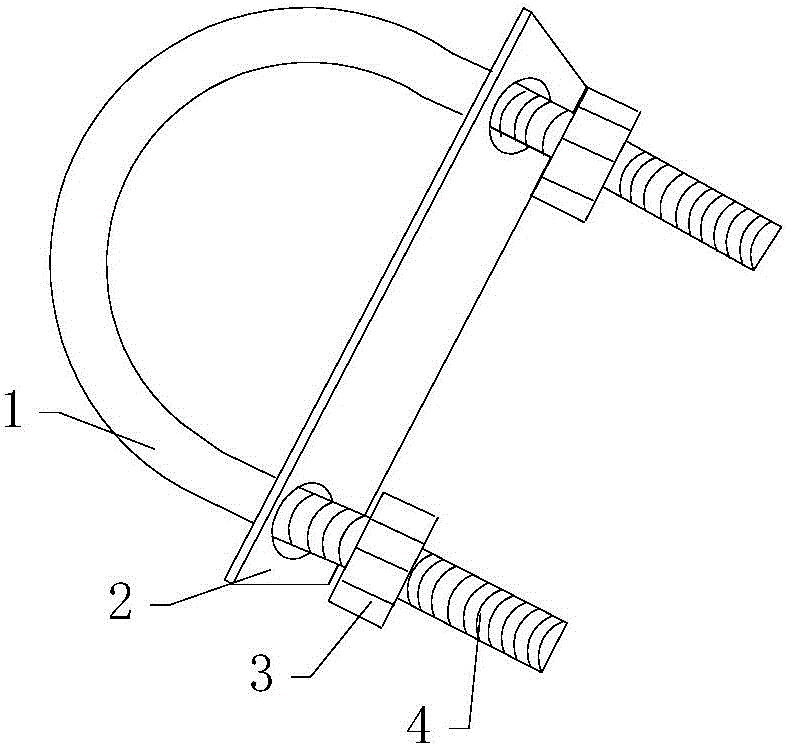

[0012] The oil production pipe fixing device includes a U-shaped oil production pipe clamp 1, a limit baffle 2 arranged at the tail end of the oil production pipe clamp 1 and a fixing bolt 3 for limiting the movement of the limit baffle 2. The U-shaped oil production pipe clamp 1 includes two arms, the U-shaped oil production pipe clamp 1 is cylindrical, and the tails of the two arms of the U-shaped oil production pipe clamp 1 are provided with threads. Both sides of the baffle plate 2 are respectively provided with through holes at a distance of 2 to 5 cm from the edge. The limit baffle plate 2 is installed on the U-shaped clamp through the through holes, and the fixing bolts 3 are arranged on the two arms of the U-shaped clamp. The tail is used to limit the displacement of the limit baffle 2.

[0013] The U-shaped oil production pipe clamp 1 is an elastic steel part.

[0014] The outer surface of the U-shaped oil production pipe clamp 1 is also provided with anti-slip threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com