Long-acting PO film coating liquid and preparation method thereof

A coating liquid and long-acting technology, applied in chemical instruments and methods, coating, dissolution, etc., can solve the problem of insufficient bonding force between nanomaterials and polymer adhesives, decreased effect of dripping and defogging, and low production efficiency, etc. problems, to achieve the effect of facilitating the extraction of raw materials, solving friction damage, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention provides a technical solution: a long-acting PO film coating solution, which is composed of the following components in percentage: 48% of mixture A, 33% of mixture B, 1% of polyurethane emulsion and 18% of deionized water;

[0043] Said mixture A comprises 23% nano-alumina sol, 12% nano-zirconia sol, 6% surfactant, 5% acrylic resin nanoemulsion and 2% aqueous defoamer;

[0044] Said mixture B comprises 25% nano silica sol, 5% adhesion promoter and 3% fatty alcohol polyoxyethylene ether;

[0045] The pore volume of the nano-alumina sol is 0.4nm;

[0046] The pore volume of the nano-zirconia sol is 0.4nm;

[0047] The pore volume of the nano-silica sol is 0.4nm;

[0048] The surfactant is an acetylenic glycol-based surfactant.

[0049] A preparation method for a long-acting PO film coating solution, comprising the following steps:

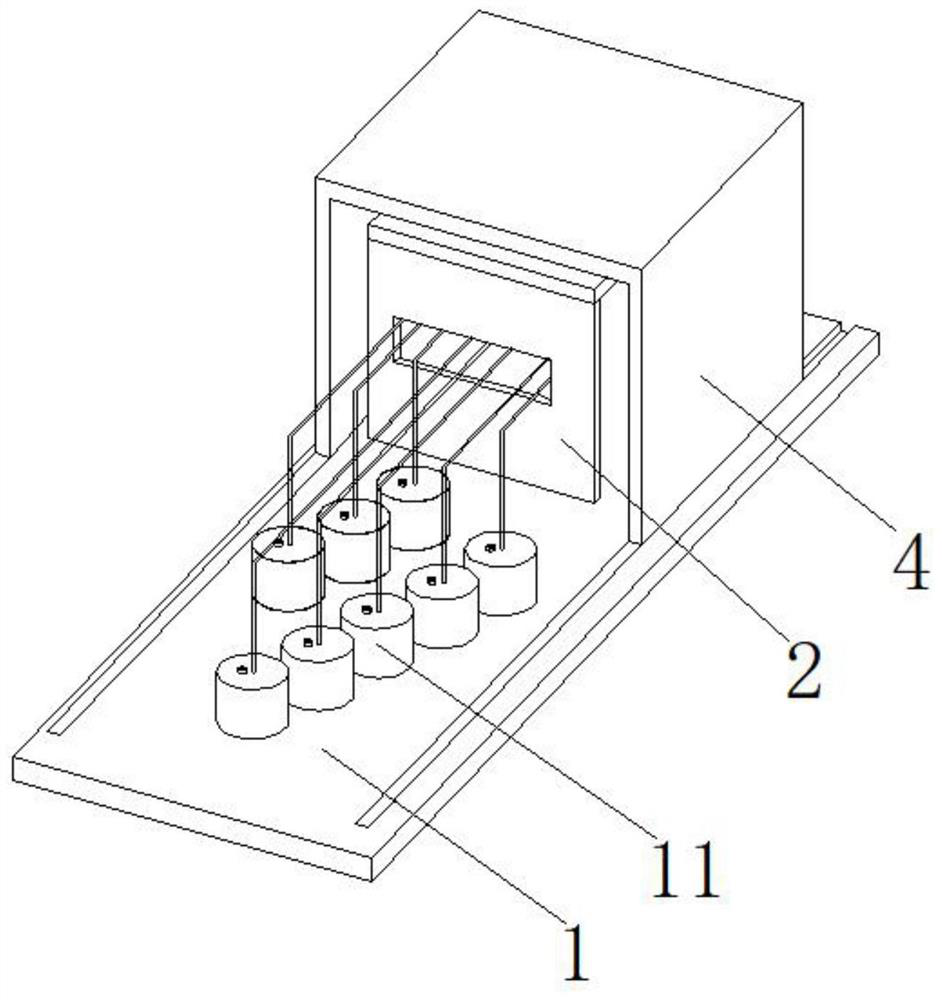

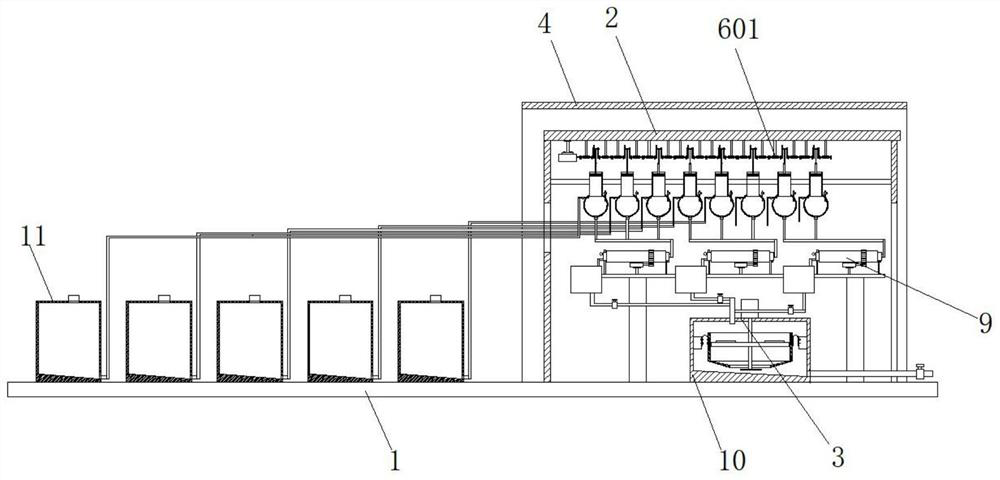

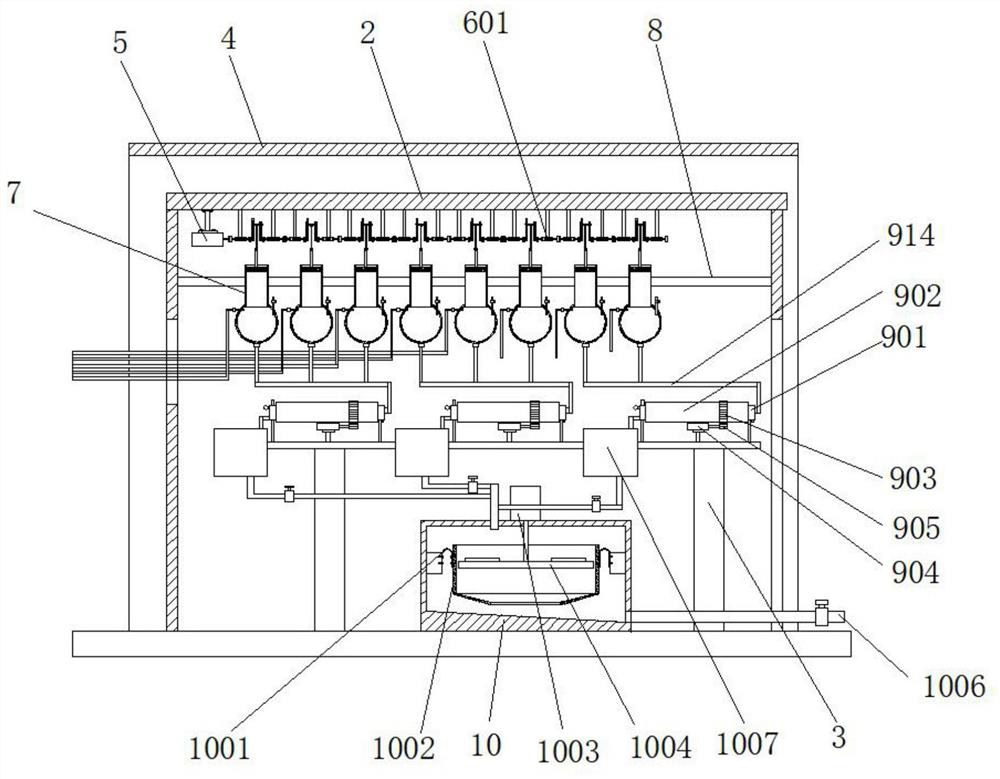

[0050] S1. Preparation of mixture A: Inhale a certain amount of nano-alumina sol, nano-zirconia sol, surfactant, ...

Embodiment 2

[0054] A long-acting PO film coating liquid, which is composed of the following components by percentage: 50% of mixture A, 31% of mixture B, 1% of polyurethane emulsion and 18% of deionized water;

[0055] Said mixture A comprises 28% nano-alumina sol, 12% nano-zirconia sol, 4% surfactant, 5% acrylic resin nanoemulsion and 1% aqueous defoamer;

[0056] Said mixture B comprises 24% nano silica sol, 4% adhesion promoter and 3% fatty alcohol polyoxyethylene ether;

[0057] The pore volume of the nano-alumina sol is 0.4nm;

[0058] The pore volume of the nano-zirconia sol is 0.4nm;

[0059] The pore volume of the nano-silica sol is 0.4nm;

[0060] The surfactant is an acetylenic glycol-based surfactant.

[0061] A kind of preparation method of long-acting PO film coating liquid, is characterized in that, comprises the following steps:

[0062] S1. Preparation of mixture A: Inhale a certain amount of nano-alumina sol, nano-zirconia sol, surfactant, acrylic resin nano-emulsion ...

Embodiment

[0077] Examples: Example 1 and Example 2, using the PO membrane coating solution prepared by the method provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com