Straight cylinder type metal cutting sheath

A metal cutting, straight-tube technology, applied in the fields of endoscopic cutting instruments, medical science, prostheses, etc., can solve the problem that the vena cava filter recovery hook cannot be captured by the wall, the vena cava filter adhesion cannot be minimally invasive peeling, and the vena cava It can improve the safety of surgery, reduce the risk of damage, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

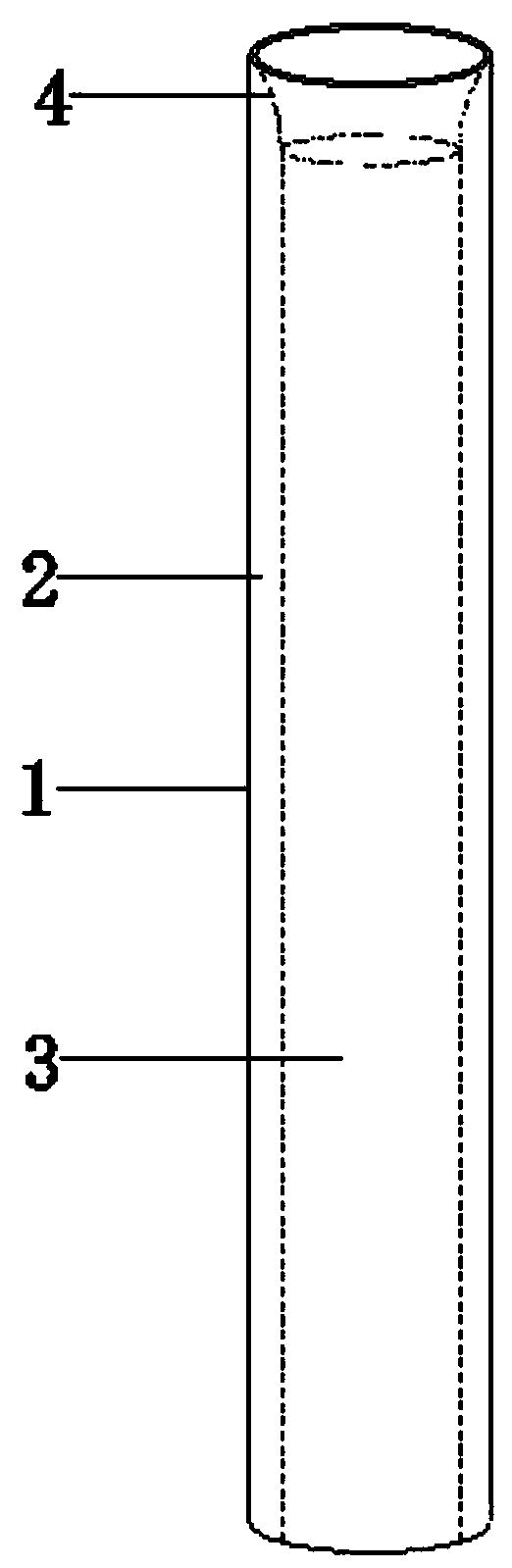

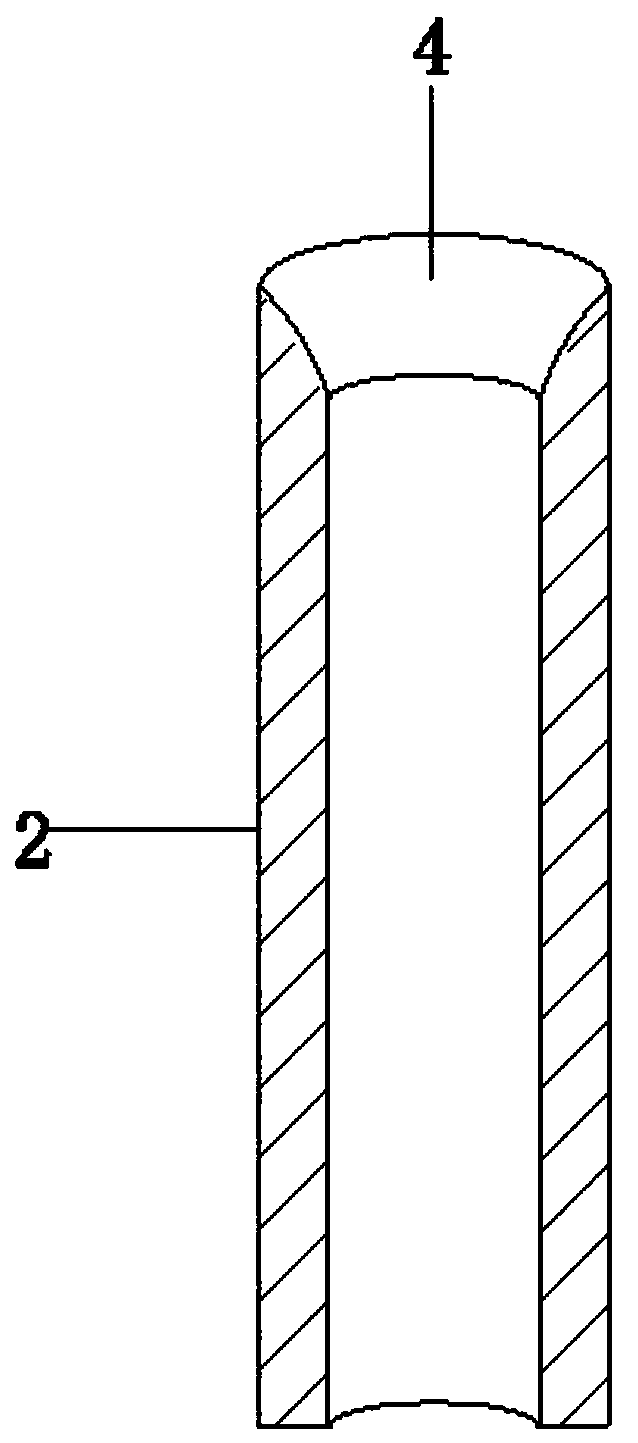

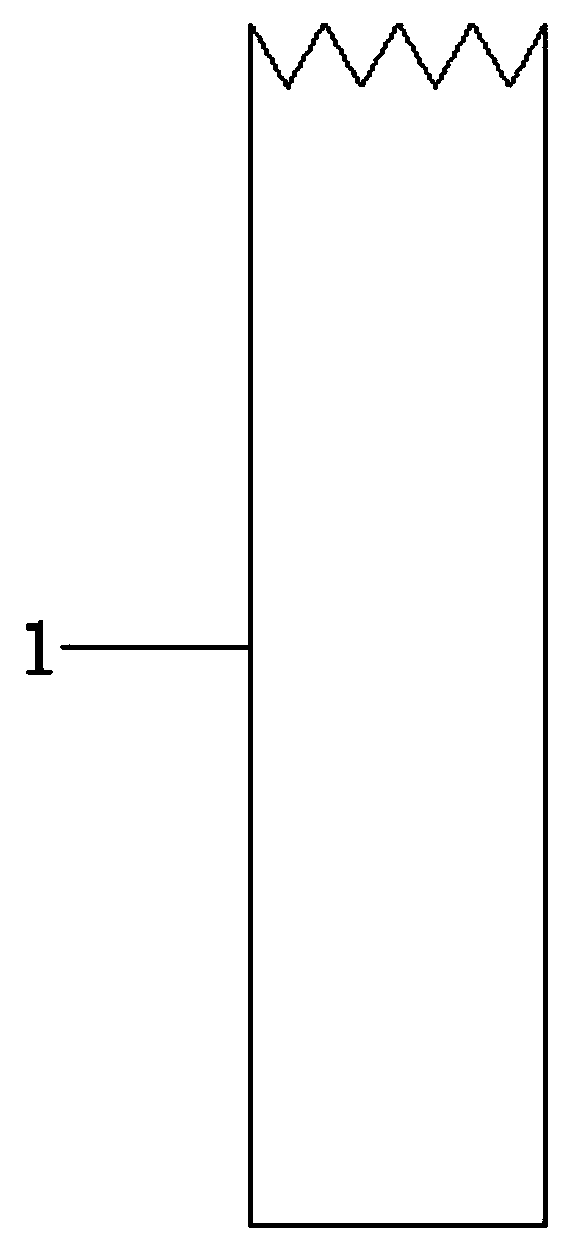

[0027] Embodiment 1, the straight metal cutting sheath body 1 uses medical 304 stainless steel material as the sheath for the recovery of the vena cava filter, and a serrated edge is made at the sheath mouth, which can ensure that the serrated edge is close to the outside of the metal rod of the vena cava filter, cutting The innermost part of the metal rod of the filter is adhered to the blood vessel wall, so that the wall of the vena cava is retracted in time while the adhesion tissue is cut off, further reducing the risk of damage to the wall of the vena cava and improving surgical safety.

Embodiment 2

[0028] Embodiment 2, the straight metal cutting sheath body 1 uses medical 316L stainless steel material as the recovery sheath for the vena cava filter, and makes a ring-shaped cutting edge at the sheath mouth, which can ensure that the cutting edge is close to the outside of the metal rod of the vena cava filter, cutting The innermost part of the metal rod of the filter is adhered to the blood vessel wall, so that the wall of the vena cava is retracted in time while the adhesion tissue is cut off, further reducing the risk of damage to the wall of the vena cava and improving surgical safety.

Embodiment 3

[0029] Example 3, the straight metal cutting sheath body 1 uses medical 316L stainless steel material as the sheath for the recovery of the vena cava filter, and a trapezoidal cutting edge is made at the sheath mouth, which can ensure that the cutting edge is close to the outside of the metal rod of the vena cava filter, cutting the filter The innermost part of the metal rod adhered to the vascular wall allows the vena cava wall to retract outward in time while cutting off the adhesive tissue, further reducing the risk of damage to the vena cava wall and improving surgical safety.

[0030] Processing method: use 316L stainless steel material, heat the 316L stainless steel material at a high temperature of 2000°C-2500°C for 30-35min, and use a beating machine to repeatedly beat the heated 316L stainless steel material to remove carbon, and put it into PAG after beating and removing carbon Refined polymer inorganic quenching liquid is used for quenching, repeated three times, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com