Crystallization equipment special for remelting in-situ micro-alloying of high-speed steel electroslag and smelting method thereof

A technology of electroslag remelting and crystallization equipment, which is applied in the field of microalloying of high-speed steel, can solve problems such as uneven distribution along the radial direction and coarse carbide structure, and achieve carbide size reduction, fine structure, convenient and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

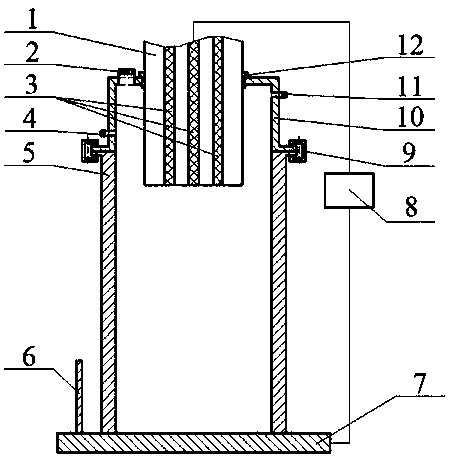

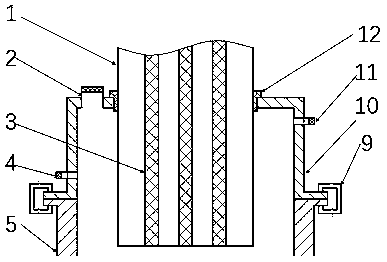

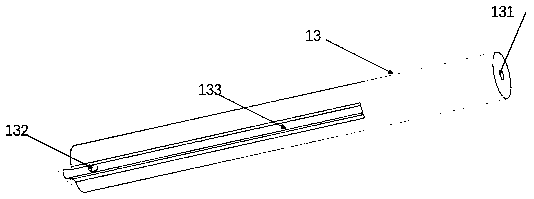

[0025] Such as Figure 1-Figure 4 As shown, the special crystallization equipment for in-situ microalloying of high-speed steel provided in this embodiment includes a bottom water tank 7, a transformer 8 and a crystallizer 5. The crystallizer 5 is located on the bottom water tank 7 and forms a crystallization pool together with the bottom water tank 7. An atmosphere cover 10 is arranged above the crystallization pool, and the atmosphere cover 10 is movably connected with the crystallizer 5 through buckles 9. The lower end of one side of the atmosphere cover 10 is provided with an air inlet 4, and the upper end of the side opposite to the air inlet 4 is provided with an air outlet 11. The top of the atmosphere cover 10 is provided with a slag filling port 2 near the edge, and the center of the atmosphere cover 10 is provided with a circular through hole, so that the electroslag remelted high-speed steel self-melting electrode steel ingot 1 can enter the crystallization pool thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com