Hydraulic back door opening device of side mounting car

A technology of opening device and rear door, applied in transportation and packaging, garbage receptacle, etc., can solve the problems of deformation of the rear door, causing accidents, and high strength of the rear door, so as to ensure the sealing and tightness, prolong the service life, and reduce the deformation. leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

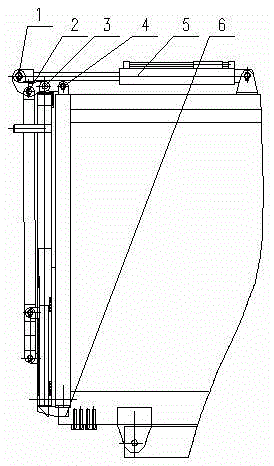

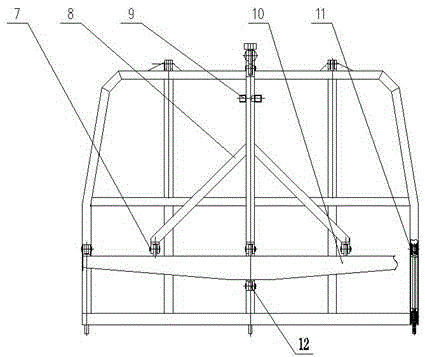

[0023] Further illustrate the present invention below in conjunction with accompanying drawing.

[0024] Such as figure 1 , figure 2 As shown, the side-mounted vehicle hydraulic rear door opening device is characterized in that it includes a rear door cylinder 5, a triangular connecting rod 8, and a crossbeam 10, and the hydraulic telescopic rod of the rear door cylinder 5 passes through the rotating shaft. Ⅰ1 is connected with the arc-shaped connecting plate, the arc-shaped connecting plate is connected through the hinge shaft 2 and the straight rod of the triangular connecting rod 8, the upper end of the straight rod of the triangular connecting rod 8 is provided with a retaining pipe 9, and the arc-shaped connecting plate passes through the rotating shaft II3 and the car The upper edge of the rear door is connected, and a rotating shaft III4 is symmetrically arranged between the upper edge of the rear door and the rear part of the carriage. The shaft seat of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com