Flexible smart film material with photonic band gap structure and preparation method of flexible smart film material

A thin film material and energy band structure technology, which is applied in the field of flexible smart thin film materials and its preparation, can solve the problems of poor controllability of the driving direction of flexible thin films, single performance, uncontrollable response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

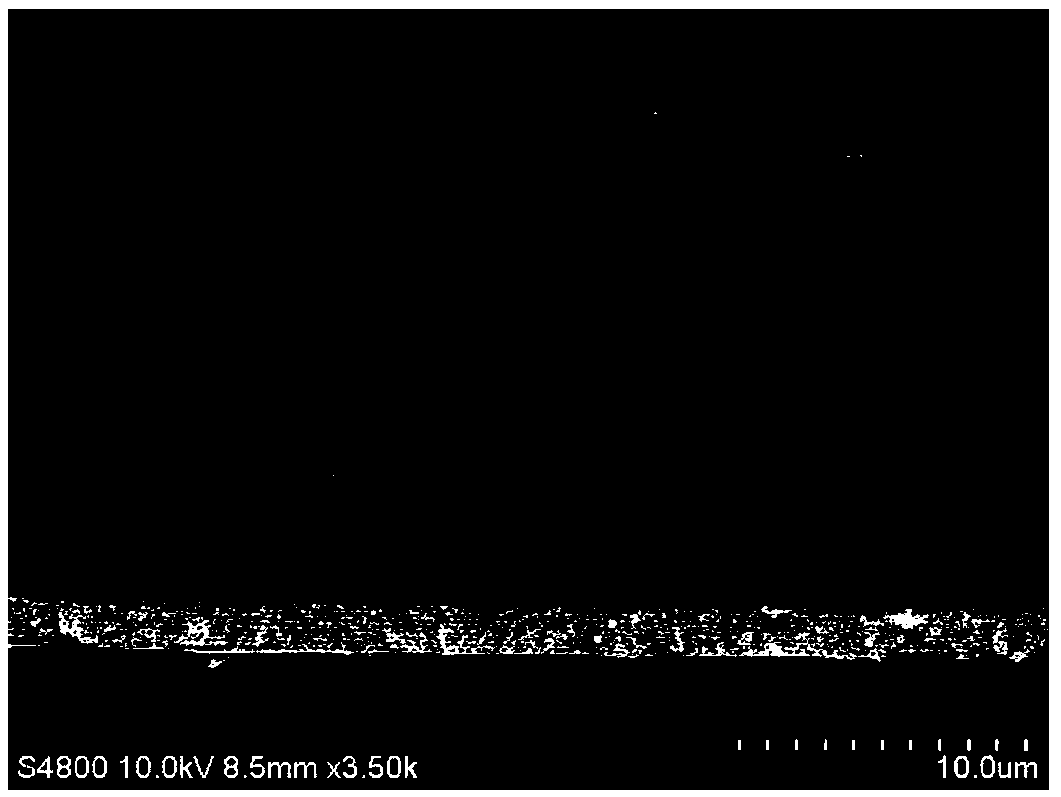

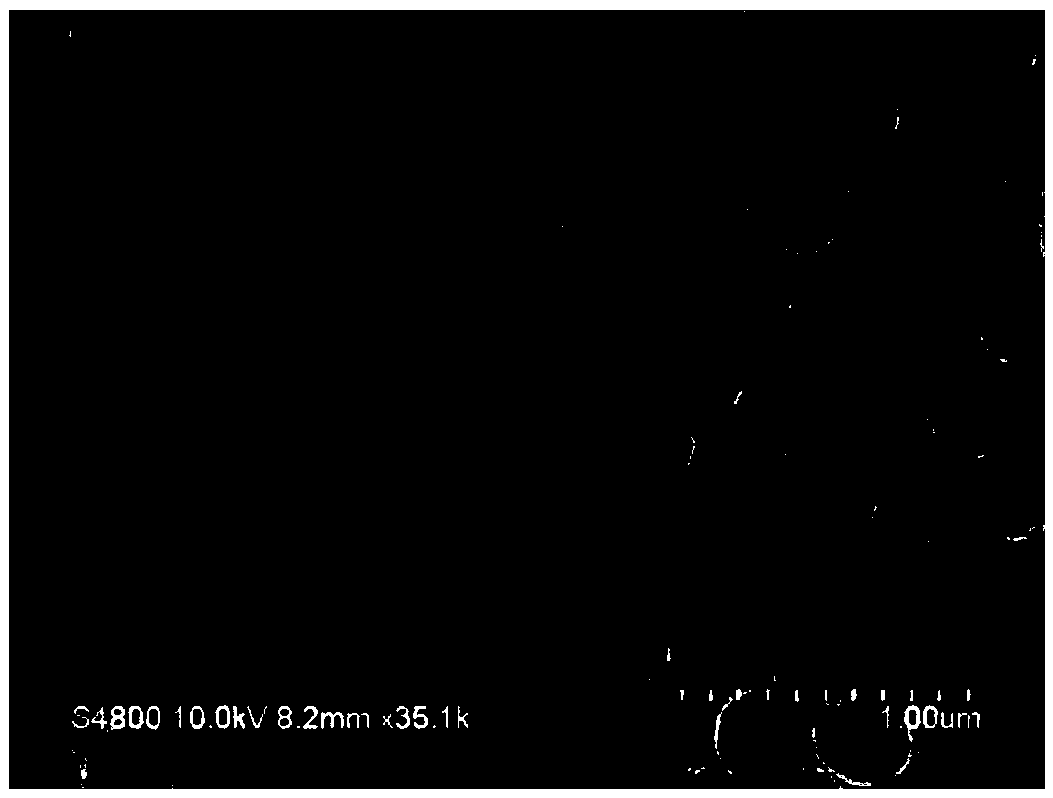

Image

Examples

Embodiment 1

[0036] A method for preparing a flexible smart film material with a photonic band structure, the preparation method specifically includes the following steps:

[0037](1) Photonic crystal template assembly: firstly, disperse monodisperse silicon dioxide particles with a particle size of 250nm in absolute ethanol, the concentration of the silicon dioxide particles is 0.001% by volume, and the cleaned glass The substrate is placed in the suspension, and when the glass substrate is placed, the glass substrate is controlled to form a certain angle with the bottom of the container holding the suspension, and the range of the angle is 30-80°, Then evaporate described absolute ethanol in the vacuum drying box, and the vacuum degree of the vacuum drying box is 0.3KMpa. After the absolute ethanol is complete, the silicon dioxide particles are regularly arranged on the glass substrate to obtain a photonic crystal template in which the silicon dioxide particles are periodically arranged;...

Embodiment 2

[0056] A method for preparing a flexible smart film material with a photonic band structure, the preparation method specifically includes the following steps:

[0057] (1) Photonic crystal template assembly: First, disperse monodisperse silicon dioxide particles with a particle size of 150 nm in absolute ethanol, the concentration of the silicon dioxide particles is 0.05% by volume, and the cleaned glass The substrate is placed in the suspension, and when the glass substrate is placed, the glass substrate is controlled to form a certain angle with the bottom of the container holding the suspension, and the range of the angle is 80°, and then vacuum Evaporate the absolute ethanol in a drying oven, and after the absolute alcohol is completely volatilized, the silicon dioxide particles are regularly arranged on the glass substrate to obtain a photonic crystal in which the silicon dioxide particles are periodically arranged template;

[0058] (2) Polymer-filled photonic crystal t...

Embodiment 3

[0064] A method for preparing a flexible smart film material with a photonic band structure, the preparation method specifically includes the following steps:

[0065] (1) Photonic crystal template assembly: first, disperse monodisperse silicon dioxide particles with a particle size of 350nm in absolute ethanol to form a suspension. The volume percentage concentration of the silicon dioxide particles is 0.08%. The cleaned glass substrate is placed in the suspension, and when the glass substrate is placed, the glass substrate is controlled to form a certain angle with the bottom of the container containing the suspension, and the range of the angle is 60°, and then evaporate the absolute ethanol in a vacuum drying oven. After the absolute alcohol is completely volatilized, the silicon dioxide particles are regularly arranged on the glass substrate, and the silicon dioxide particles are periodically arranged. Sexually aligned photonic crystal templates;

[0066] (2) Polymer-fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com