Special insulating barrier for changing pole-mounted circuit breaker

A technology of circuit breakers and insulating baffles on a column is applied in switchgear, electrical components and other directions, which can solve the problems of long time consumption, long insulation shielding time, complicated insulation measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] Specific implementation methods: the present application is not limited by the following examples, and the specific implementation manners can be determined according to the technical solutions of the application and actual conditions.

Embodiment

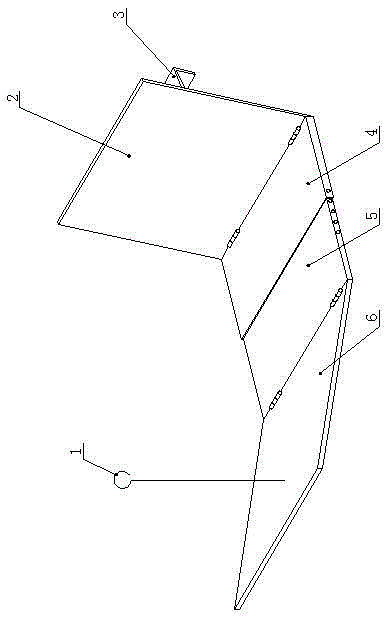

[0011] Example: such as figure 1 As shown, the special insulating baffle for replacing the pole-mounted circuit breaker includes a first shielding plate 4 and a second shielding plate 6. A telescopic shielding plate 5 is plugged into one end of the first shielding plate 4, and a pole side plate is flexibly connected to the other end. 2. A pole connector 3 connected to the pole is provided on the outside of the side plate 2 of the pole, and a second shielding plate 6 is flexibly connected to the outer end of the telescopic shielding plate 5, and the upper end of the second shielding plate 6 is connected by an insulating rope. With the wire hook 1 that hangs with wire.

[0012] The first shielding board 4 , the second shielding board 6 and the retractable shielding board 5 are all insulating parts. The wire hook 1 is an insulating part.

[0013] The pole connector 3 is an inverted L-shaped pendant, and an inverted U-shaped notch is formed between it and the pole side plate 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com